Peb qhia kom xaiv cov ntaub ntawv kub-insulating, txiav txim siab qhov tsim nyog tuab thiab lub zog thiab muab nws tso rau lub hauv paus.

Qhov kev xav tau rau lub rwb thaiv tsev sab nraud ntawm cov qauv hauv tsev tshwm sim hauv cov rooj plaub sib txawv. Piv txwv li, thaum nws yog npaj los npaj kev npaj ntawm qab daus, hauv qab daus lossis tiv thaiv lub hauv paus ntawm cov hmoov frosty. Tom qab tag nrho, feem ntau ntawm cov av hauv txoj kab nruab nrab ntawm peb lub teb chaws yog av nplaum thiab loam. Lawv cov zaub mov feem ntau ua qhov ua rau muaj kev deormation thiab hauv paus ntawm lub hauv paus. Txheej txheej ntawm insulating cov khoom yuav ua kom tiav lossis qib cov kev tsis zoo no. Ib qho ntxiv, nws yuav ua kev tiv thaiv ntawm lub hauv paus ntawm kev puas tsuaj thaum lub qab qab ntawm cov av.

Kev Xaiv Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob

Feem ntau cov feem ntau, cov phiaj ntawm extruded polystyrene (xps), uas muaj cov khoom faib tawm unfomibuted kaw cov hlwb yog siv los tswj cov dej hauv av ntawm lub tsev. Cov khoom siv muaj lub thermal tsawg thermal - 0.028-0.032 w / (m • C), tsis muaj qhov tsawg kawg nkaus dej coefficient yog 0.2% nyob rau hauv volume) thiab, vim li ntawd, muaj lub siab fristance. Nws yog cov rackically racks, tsis raug rau rotting, ruaj khov nyob rau hauv lub nra.

Cov kev pabcuam lub neej ntawm cov phiaj ntawm extruded polystyrene hauv av yog tsawg kawg yog 50 xyoo. Nyob rau hauv peb lub lag luam, hom cua sov no yog muab los ntawm penopeles, Tekhnonikol, Ursa.

Extruded nthuav dav polystyrene (XPS) thev naus laus zis

Lub thickness thiab lub zog ntawm thermal rwb thaiv tsev

Qhov zoo tshaj ntawm cov thermal rwb thaiv tsev txheej rau lub hauv paus yog txiav txim siab raws li cov qauv piav qhia hauv cov tsev ". Hauv cheeb tsam uas muaj huab cua sib txawv, qhov ntsuas ntawm lub rwb thaiv tsev yuav txawv. Nyob rau hauv txoj kab nruab nrab ntawm Lavxias ntawm phab ntsa ntawm lub hauv paus txuas XPS daim phiaj nrog ib tug tuab ntawm tsawg kawg 50 hli. Tab sis cov ces kaum uas yog cog ua ntej ntawm txhua qhov, cov kws tshaj lij pom zoo kom cais cov khoom ntawm ntau dua cov tuab (60-100 hli).

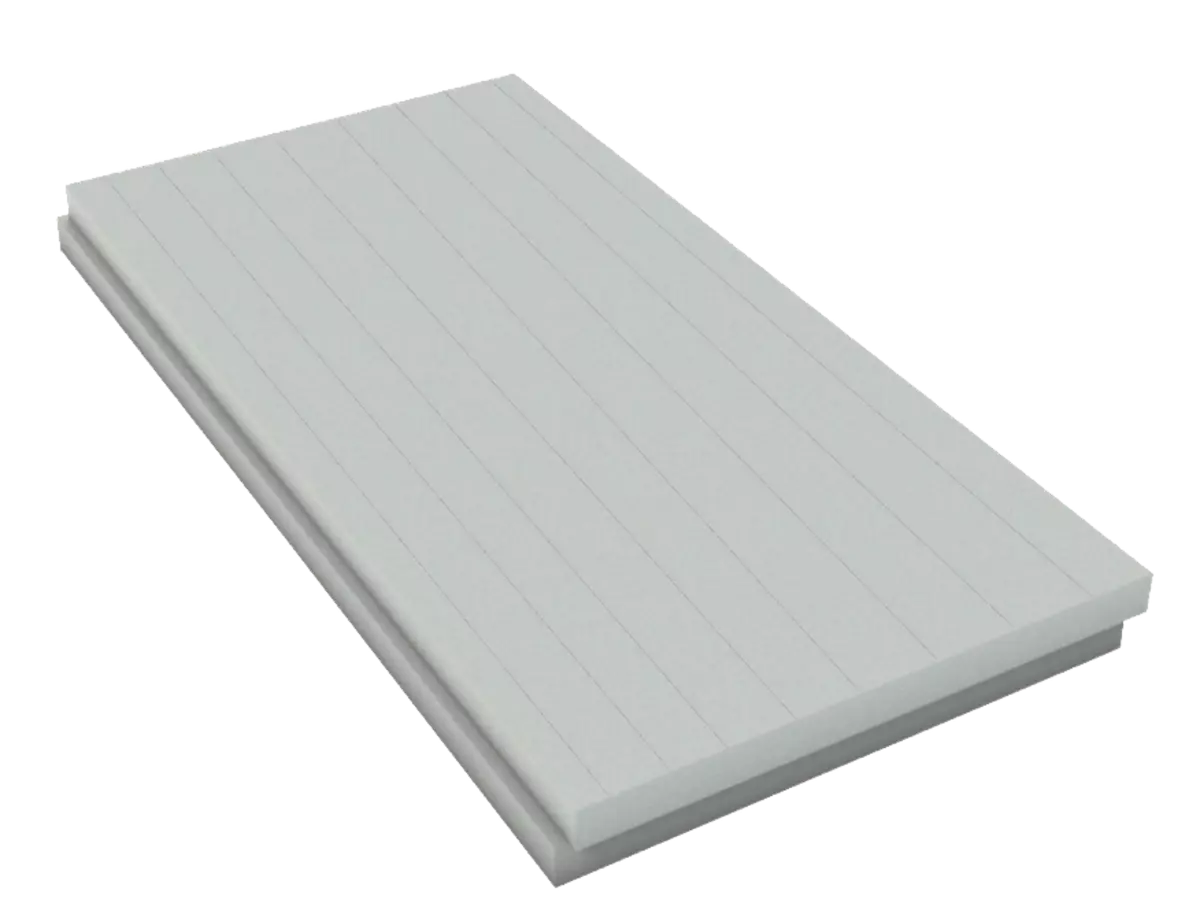

Extruded nthuav dav polystyrene (XPS) Ursa

Yog tias tsuas yog ntsug phab ntsa yuav tsum tau roulated, tom qab ntawd yuav tsum tau muaj zog dua los ntawm cov khoom insulating. Tom qab tag nrho, tsuas yog thauj khoom los ntawm cov av ntawm backfill yog siv tau rau nws. Yog li ntawd, muaj peev txheej compression txaus lub zog ua rau parameter: 150-250 kpa. Cov chaw thau khoom XPS Laid nteg ntaug hauv qab Foundation lossis hauv qab "ib tug" ntawm lub hauv paus, raws li kev yuav tsum tau ua rau lawv cov yam ntxwv muaj zog. Hauv qhov no, thermal rwb thaiv tsev cov phaj yog xaiv, lub compressive lub zog ntawm uas yog 250-400 kPa.

Ntawm qhov xaus ntawm cov phiaj ntawm extruded nthuav dav polystyrene muaj l-puab ntim khoom. Ua tsaug rau nws, cov pob qij txha ntawm cov neeg nyob sib ze ua lub tsev fuabtais, uas zam kev tsim cov choj uas txias. Cov pob qij txha ntawm cov ntoo saum ntoo khaub lig yog ntshaw kom lazinate nrog cov kua nplaum nrog cov kua nplaum lossis zoo.

Fastening cais mus rau lub hauv paus

Cov phiaj ntawm extruded polystyrene ua npuas ncauj yog tsau rau ntawm lub hauv paus ntawm lub hauv paus lossis phab ntsa ntawm txheej lossis inlet waterproofing. Rau fastening cov phiaj siv cov nplaum tshwj xeeb los yog zoo, uas tsis suav nrog cov kuab tshuaj organic (tsau, roj av, thiab lwm yam). Txwv tsis pub, cov kua nplaum yuav rhuav tshem cov polystyrene ua npuas ncauj.

Ntxiv nrog rau cov nplaum sib xyaw, cov kws tshaj lij pom zoo kom siv cov neeg kho tshuab nyiaj txiag lub ntsej muag, uas yog disc dowels. Cov khoom qis dua ntawm cov khoom lag luam insulating tso siab rau ntawm sandy-gravel txhaws. Tab sis nws yog qhov zoo dua ntawm kev sau theem ntawm lub hauv paus kom muab rau qhov no qhov kev tawm tsam me me.