Ukukhetha kweebhetri kugqiba inqanaba lokuthuthuzela kwindlu lonke ixesha lokufudumeza. Siza kuxela ukuba zeziphi iimveliso ezingcono: kwi-bimetal okanye i-aluminium.

Ukufumanisa ukuba yeyiphi i-radiator engcono, i-aluminium okanye iimodeli ze-Bimitallic kufuneka zikhethwe, kufanelekile ukuba zikhule ziqhelene nokudibanisa kunye nohlobo lohlobo ngalunye. Kuphela kuxa kuthathwa isigqibo ngokuchanekileyo.

Yintoni ekufuneka uyazi malunga neebhetri ze-aluminium

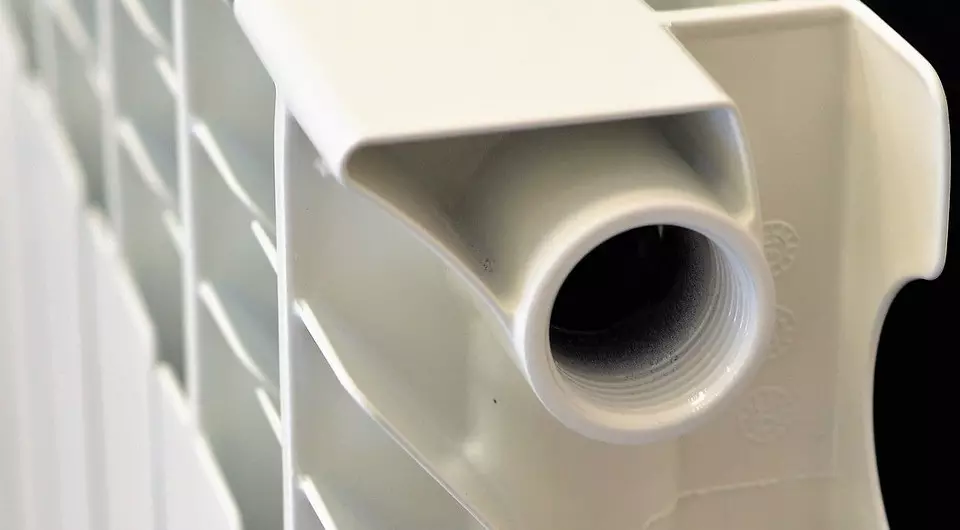

Ukuveliswa kwezi zixhobo, iitekhnoloji ezimbini zisetyenziswa:

- Ukuphosa. Ke, imveliso ifunyenwe i-monolikic. Ukungabikho kwazo zonke iintlobo zemichiza okanye imigibe inika amandla akhethekileyo.

- Ukuphuma. Ngokucinezela izikhala, amacandelo afunyanwa kamva adityaniswe kwibhetri. Ubukho beendawo zokunxibelelana zibenza baveze uxinzelelo olukhulu kuxinzelelo oluphakamileyo.

Uninzi luhlala lufumana izixhobo ezenziwe ngeendlela zokupheliswa, kuba zixabisa kakhulu kwimveliso. Ithiyori, ngokuxhomekeke kuzo zonke iimfuno zomsebenzi, i-radiators ithembekile ngokulinganayo. Kuphela yi-monolithic kuphela enokusebenza ngaphandle kolondolozo, kwaye amaqela afuna ukuhlolwa rhoqo kokusilela kweendawo zokudibanisa.

Ukusuka kwiingenelo zeemodeli ze-aluminium kufuneka kuqatshelwe:

- Ukudluliselwa kobushushu obukhulu, enkosi kweli gumbi liyafudumeza ngokoqobo imizuzu eli-15 ukuya kwengama-20. Oku kwenza ukuba kwenzeke ukuba igcine kwintlawulo yokuhamba kwe-uthotho.

- Ubunzima obuncinci, ukungcola, okungqina kakhulu ukufakelwa.

- Ubukho be-thermoclap ekuvumela ukuba uhlengahlengise inani lolwelo kwisixhobo. Oku kusindisa ekufudumeleni.

- Iimodeli zangaphambili zinokugqityeza ngamacandelo amatsha okanye, ngokuchaseneyo, susa ngokungeyomfuneko. Ukuphosa, kunokwenzeka, kodwa kungcono ukuba kuya kwenza ingcali.

Iimbaleki ezibalulekileyo, kufanelekile ukuba uqaphele ubuntununtunu kumgangatho wokuphola. Umzekelo, i-alkali itshabalalisa isinyithi kuyo sitshabalalisa isinyithi. I-radiator ye-radiators ekhethiweyo ingaba sengozini ngokukhethekileyo. Phakathi kwamacandelo kukho irhasi enokugqiba phantsi kwempembelelo yezinye zezinto ezithile. Ke, ukwakhiwa okukreqileyo kohlobo lwe-antiformeze yohlobo lwerabha ngokukhawuleza. Akunakwenzeka ukuba uzisebenzise.

Amanzi angena i-aluminium ikhuthaza impendulo yekhemikhali edlulisela ulwabiwo lwegesi. Ke ngoko, zonke izixhobo kufuneka zixhotywe nge-crane ye-maevsky. Udrevesi omkhulu wobushushu uhambisa izinto ezithile eziphazamisayo. Iibhetri zikhawuleza zibanda kakhulu, ngoko kufuna ukuhamba okuphumelelayo kwi-coollant ukugcina ubushushu obukhululekileyo.

Zonke malunga nezixhobo zeBimitallic

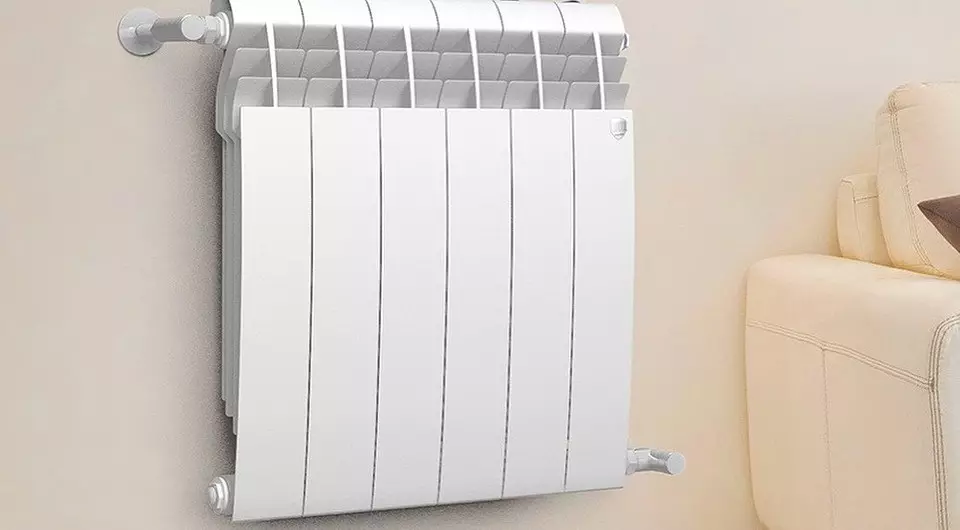

Ukufikelela kwinqanaba leemodeli ezichazwe apha ngasentla kwaye lulondoloze izibonelelo zabo, izixhobo ezidityanisiweyo zenziwe. Igama lakhe libonisa ukuba izinto ezimbini ezahlukeneyo ezisetyenziselwa ukwenza. Le yi-aluminium kunye nentsimbi, emnyama okanye ingonakali. Kwimarike unokufumana ezi zixhobo kwiindidi ezimbini.

Eyokuqala iphawulwa yinto yokuba inxenye yangaphakathi yenziwe ngokupheleleyo ngentsimbi, kwaye yangaphandle-evela kwi-aluminium. Kumzobo wolunye uhlobo lwensimbi kuphela edlula kwimveliso. Ukugqiba kweliphi i-radiators engcono, ialuminiyam okanye i-bimatal, siza kuqwalasela izixhobo zohlobo lokuqala, kuba ziyimveliso edityanisiweyo edityanisiweyo.

Zenziwa phantsi koxinzelelo olukhulu ngokulahla okunzima. Ngenxa yoko, kuguquka uyilo kunye nesiseko sensimbi. Ukuba yenziwa ngentsimbi engenasimo, ubomi benkonzo yesixhobo buyanda malunga nesithathu. Ngenxa yoko, uqhagamshelo olusemgangathweni oluphezulu lwezinto ezimbini luqinisekisiwe, olubangela ukuhanjiswa kobushushu obusebenzayo.

Izibonelelo zee-radiator kwi-bimatal zezi:

- Ukuxhathisa kolwandiso lolwandiso kwinethiwekhi, ngenxa yobukho besixhobo esiqinileyo.

- Ukuhanjiswa kobushushu obuhle kwaye ngenxa yoko, ukufudumeza ngokukhawuleza. Oku kuchazwa lubukho be-aluminium.

- Amandla okufudumeza kumaqondo obushushu aphakamileyo.

- Ukuxhathisa kwiinkqubo zokulwa, ngakumbi phambi kwesiseko sentsimbi engenasitayile.

Izinto ezingalunganga zibandakanya ukuphola ngokukhawuleza emva kokumisa ulwelo olushushu. Ngamanye amaxesha, kunye nomgangatho ongonelanga wesipholo esiphuhlileyo, impendulo yayo enesiseko sesinyithi kunokwenzeka. Idlula ngokukhutshwa kweegesi ezinokonakalisa izixhobo. Ixabiso lezinto ezinjalo likhulu kakhulu. Oku kunokujongwa njengeyona nto yabo engahambelaniyo.

Yintoni ebhetele, ialuminium okanye i-bimiators head? Thelekisa iiparamitha eziphambili

Kucacile ukuba iintlobo ezimbini ziyafana kuphela. Thelekisa iipropathi zabo ezisisiseko.Ukuchasana noxinzelelo oluphakamileyo

Enye yezona mpawu zibalulekileyo kwibhetri. Umkhweli otshisayo kwinethiwekhi uhamba phantsi koxinzelelo, kwaye kwiinkqubo ezahlukeneyo ixabiso lingahluka kakhulu. Ke, ngenxa yokuphakama okuphantsi kunye nezindlu ezizezodwa, zincinci. Ukuqaqambisa imigangatho eli-16 okanye ngaphezulu, ukubaluleka kukhulu kakhulu. Kungenxa yento yokuba igumbi eliphakamileyo elishushu libekwe, kufuneka uxinzelelo olukhulu lokuphakama.

Ukongeza kokuphakama kwelungiselelo, impembelelo yokungaxhathisi i-hydraulic ichatshazelwe sisikhombisi, oko kukuthi, inani lemibhobho, inani leekhreyithi, njl. Kuyimfuneko ukuba uthathele ingqalelo kwaye inokwenzeka i-hydrowards, oko kukuthi, ukrwada ngaphakathi kwinkqubo ephakamayo ngenxa yezizathu ezininzi. Ke ngoko, ukuxhathisa uxinzelelo oluphakamileyo lwebhetri kubaluleke kakhulu.

I-Aluminium ibhekisa kwiintsimbi ezinamandla amancinci. Yenziwe ngeempahla, ngakumbi iimodeli zeqela, azikwazi ukudlulisela umahluko obalulekileyo. Zihlala zitshatyalaliswa zii-hydrobord. Azange bacetyiswe ukuba basebenzise kwiinethiwekhi zoxinzelelo oluphezulu. Intsimbi yomelele kakhulu. Ngenxa yokuba iimodeli ze-Bimitallic, isiseko senziwe kwezi sixhobo, bayakwazi ukumelana ne-ATM 50.

Ukunganyangeki

I-Aluminiyam, njengazo zonke iintsimbi zentsimbi, zezezinyithi ezisebenzayo. Bangena ngokulula ngamanzi, nto leyo, enyanisweni, ithathwa njengezisu, kuba izinyithi ziyachaphazeleka kwaye zitshatyalalisiwe. Nangona kunjalo, ngaba i-al iyenza ngenkuthalo ngakumbi kunentsimbi, ngakumbi ayinakumbi. Inikezwe ukuba umgangatho we-complatent quaund kwinkqubo yezakhiwo zegumbi ngokwesiko iphantsi kwaye kukho ukungcola okusebenzayo ngemichiza, iinkqubo zikhawuleza kakhulu.

Nangaphezulu, ubushushu babo obuphakamileyo bendawo engamanzi bukhawulezisa. Abavelisi bagubungela izixhobo ngaphakathi kunye nongqingo olukhethekileyo olukhethekileyo, kodwa alunikeli mpembelelo enkulu. Umgangatho ophantsi opholileyo uhlala enezinto ezingcolileyo ezixhaphakileyo ukuba ukhuselwe kukhuselo kwaye kuya kuba kungekho lula. Yiyo loo nto, ngokuchaza ukuba yeyiphi na iradiiator ukuba inyule - i-Bimitallic okanye i-Aluminiyam, iyimfuneko ukuba ithathele ingqalelo ukuba i-comrosion ichaphazeleka kakhulu kukhetho lwesibini.

Ukuxhathisa ubushushu obuphezulu

Iqondo lobungakanani eliqhelekileyo le-Colalnti lingaphezulu kwe-90 °, nokuba kubanda kakhulu ngaphandle. Nangona kunjalo, kwezinye iimeko, ngenxa yempazamo yabasebenzi bezindlu ze-boiler, iingxaki ezinokuzenzekelayo kunye nezinye izizathu, zinokudlula eli xabiso. Xa ihambahamba ephatheni, i-radiators iyasilela, iyingozi kwabo bahlala endlwini. I-Aluminium ayizimeli ngaphezulu kobushushu ngaphezulu + 110 °, i-bimatal isebenza nge-140 °.Inqanaba lokuTshintshela kobushushu bebhetri

Isantya apho ifowuni inika ubushushu emoyeni kuxhomekeke kwinto eyenziwa yiyo. Umnini werekhodi phakathi kweentsimbi ezisele kwi-Alumnum Heat Speed. Iyabetha ngokukhawuleza kwaye ipholile. Isixhobo esidityanisiweyo esenziwe ngezinto ezimbini zinokutshintshelwa okuncinci kobushushu. Oku kuchazwa bubukho besixhobo sensimbi. Iyacothisa inyawo.

Nangona kunjalo, inqanaba lokudlulisela ubushushu kwezi zixhobo zisekhulu. Umahluko phakathi kwamacandelo amabini afanayo eentlobo ezahlukeneyo zeentlobo ezahlukeneyo malunga ne-10-20 W, ezo kwiimeko zokwenyani aziyi kukhankanywa. Kodwa ugqithiso lobushushu obusezantsi kweebhetri ze-aluminium ngaphezulu.

Iimpawu zeMontge

Ubunzima xa ufaka iibhetri zazo zombini ezi ntlobo zihlala zenzekile. Bahluke kubunzima obutyibilikayo, ke bachitha eludongeni akukho nzima. Yonke imisebenzi enxulumene nonxibelelwano lweemveliso kufuneka zenziwe ngokungqongqo ngokwemigaqo yokuthintela ukubonakala kwezinto zokuvuza. Ukuphela kobuso obuvela apho unokujamelana khona kukwenziwa kwengcaciso yezixhobo kwi-aluminium ethanjisiweyo enesandla esingachanekanga. Ukufaka kuzo, kuyafuneka ukugcina isilumkiso esithile.

I-Aluminium radiator okanye i-bimitallic: Yintoni onokuyikhetha ekhaya

Isenokubonakala ngathi imveliso edityanisiweyo yeyona ndlela ilungileyo yesixhobo sokufudumeza. Nangona kunjalo, esi sigqibo asikufanelekile ukwenza. Ukwenzeka kokusebenzisa izixhobo ezahlukeneyo kuxhomekeke kwiimeko zomsebenzi wabo. Ke, iibhetri ze-aluminium zizifezekise iinethiwekhi zoxinzelelo olusezantsi. Zonke ezi ziinkqubo kwizakhiwo zabucala nezukisiweyo. Inketho efanelekileyo yemodeli enjalo ishushu kwisithuba esinye, esiphezulu seediliya ezintathu.

Eyona nto ibaluleke kakhulu, "baziva" kwiinkqubo ezivulekileyo. Inketho edibeneyo ilungile kwiinethiwekhi eziphezulu zoxinzelelo. Iyakwazi ukudlulisela i-hydrober ebalulekileyo kunye nobushushu. Iimodeli ezinjalo zilungele ukunyuka okuphezulu, izakhiwo ezinkulu eziphezulu ezinamagumbi amaninzi, njl. Mhlawumbi ingxaki yokhetho iya kubakho ukuba zombini iindidi zezixhobo zazineendleko ezifanayo.

Nangona kunjalo, ixabiso le-bimatal liphezulu kakhulu. Ukuphindaphinda, umahluko ubalulekileyo ufunyenwe kwindlu okanye indlu. Ke ngoko, xa ukhetha iibhetri, kuyacetyiswa kakhulu ukuba uthathele ingqalelo iimeko zomsebenzi wabo kwaye, ngokusekwe koku, yenza isigqibo. Sukuzama ukugcina umgangatho. Ixabiso eliphantsi aliyi kusebenza kancinci, ngenxa yomngcipheko osindileyo wengozi, ziyingozi kwimpilo yezempilo yokuhlala endlwini.