Ukudalwa kweefom ze-bizarre ngoncedo lwamashiti agobileyo kunye aphukileyo ye-Plasterd: Guqula kubume bephepha le-plasterboard kunye nokufakelwa kwezakhiwo ezicekeceke.

Itemplate, apho unokukhupha khona iplani yemo enqwenelekayo, i-wizard nganye iqhuba ngendlela yayo kwi-STEPOOSTOOS (Plywood, i-chipwood, i-chipwood, eyomileyo.p.) Ngobukhulu be-8-16 mm. I-radius ye template incinci incinci kakhulu kunamancinci omhlaba owomileyo, kwaye i template sele isele injalo kwaye / okanye kufutshane nephepha le-plasterboard.

Ukugoba kwenziwa lula kakhulu. Ngaphambi kokuba le nto iyimfuneko ekufumaneni ukuba leliphi icala lomsebenzi xa kugoba kuya kunyanzelwa. Ke, kweli cala, kwiBillet yenza uthotho lwezinqe kwi-10 ukuya kwi-20 mm yokunyusa kunye nobunzulu becala lesithathu sephepha okanye ngaphezulu. Ungazisebenzisa nge-shill, kodwa iingcali zisebenzisa i-rollele ekhethekileyo. Okulandelayo, lo mphezulu umanzi ngamanzi ngeponji okanye ibrashi. Ukulungiswa kufuneka kwenziwe amaxesha aliqela ngaphambi kokugcwalisa i-Plaster core ngamanzi (kuyayeka ukuba ifakwe malunga neyure). Ukuze usebenze ngokulula kwaye akazange afumane elinye icala leshiti (kule meko, xa i-flexing yekhadibhodi inokwenzeka), elingenanto lifakwe ecaleni kwendlela yokhuni okanye i-gesiber. Emva koko i-WorpieCE ifakiwe ngononophelo kwi template ngokuhambelana necala layo ephepheni kwaye igobe kakhulu kuyo.

Kwisikhundla segonti, umsebenzi wokusebenza ulungisiwe kwaye ushiye ukomisa. Umzekelo, inokusongelwa malunga namatyeli aliqela kunye neribhoni enamathelayo kwaye isuse itemplate kwi template esetyenziselwa iphepha elilandelayo. Ixesha lokutyulwa komsebenzi ukusuka kwi-12 kuye ku-22.

Ukwenzela ukwenziwa kwezinto ze-curvilinear ngerediyo encinci ye-curvature, enye indlela isetyenziswa ukusuka kwi-100 ukuya kwi-20000mm. Eyona nto iphambili imi ngolu hlobo lulandelayo. Kwicala elingasemva (ubuso bongeza egumbini) lokulinganisa umsebenzi wokungasebenzi uthotho lwee-rooves ezifakelweyo, imigca ye-gorallel. Ubunzulu, ububanzi kunye nenyathelo le-grooves kuxhomekeke apho i-curvatus ye-curvature kufuneka ukuba ifumane. Inqanaba elincinci le-grooves kunokuba banzi kwaye banzulu (ukuya kwikhadibhodi kwicala elingaphezulu), ibhloko kakhulu kwaye igobe kakhulu kwaye igobe kakhulu. Ngendlela, ii-grooves zinokwenziwa zincinci kule ndawo ingenanto usebenzisa i-chisel. I-billlet ke icocekile ngokupheleleyo eluthulini kwaye ifakwe kwipateni elungiselelwe ngaphambili. Kwangelo xesha, ukugoba, kwaye ukugcina imilo entsha yee-grooves isetyenziswa. Eyona nto ilunge kakhulu koku ilungele indawo yokuhlala ". Emva kokomisa i-itoty, isiqwenga esinokufakwa endaweni.

Yenza umphezulu wenqanaba kunye nendawo eyaphukileyo enika amathuba ongezelelweyo okuqulunqwa kwezinto ezikwingaphakathi okanye ezifihlayo zoNxibelelwano lweProjekthi ye-Vistars ukuya kwikhadibhodi (kodwa ibhodi yekhadibhodi ayicingi !!!) Kwezo ndawo ziyimfuneko ukwenza ikhefu.

Iphepha elincinci le-radius plastermer iphepha

| Igqabi lamagqabi | I-radius igoba ngephepha le-MM | ||

|---|---|---|---|

| 6.5 | 9.5 | 12.5 | |

| Emanzi | I-3300. | 3500. | I-31000. |

| Yomile | I-31000. | 32000. | 32750. |

Ukufakwa kweCeiling kunye nezakhiwo eziJoliweyo

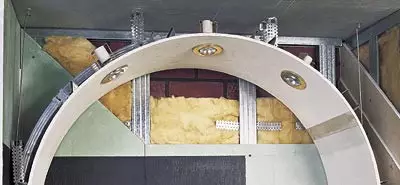

Ezona zinto ziphambili zala mafutha abizwa ngokuba ziiprofayili: Iindidi ze-ceiling ze-PP (i-60mm ububanzi kunye nobude be-27mm) kunye nohlobo lwe-radii ojikelezayo. Iinkalokazi zeeprofayili ezinjalo zingangeniswa ngaphakathi nangaphandle, ezikuvumela ukuba unike izinto zendawo yokusebenza kunye ne-cocave. Ukuba awuphumelelanga ukukhetha iiprofayili zenziwe zenziwe zenziwe zenziwe, emva koko iifom ezifanelekileyo zinokwenziwa ngokulula kuwe. Ukulungiselela le njongo, ukusikwa kwemisele ye-V-v-yenziwa kwiishelufu zeprofayile ngqo emva koko igobe umva. Isakhelo seeprofayili sibekwe esiphelweni de kuqhotyoshelwe iphepha elijikiweyo. Iiprofayili ezahlukileyo ezahlukileyo okanye iifreyimu ziqhotyoshelwe kwisilingi kunye nedowel okanye inqunyanyisiwe ekumiswe ngqo (iibakaki ezikhethekileyo), i-streds kwiprofayile kwiprofayili. Ukonyusa ubude bokumiswa okuqhelekileyo, ungafaka isicelo sovavanyo olukhethekileyo. Ukuhamba kweedosi kuxhomekeke kubume, indawo kunye nobunzima besakhiwo esimiselweyo, kodwa akufuneki sidlule kwi-80cm. Xa ufaka i-skeleton kakhulu, iphepha eligonjiweyo liqale ngokusesikweni kusetyenziswa i-T-Feped Suped Imement efakwe kwi-hlosi yokuhamba kunye nomgangatho. Emva koko ishiti liqhotyoshelwe kwiprofayile yeqhina esebenzisa isikrelemnqa, isuka embindini wephepha kwaye ngokuthe ngcembe iguqukela kwimiphetho. Izikrelemnqa kufuneka zibandakanywe kwindawo eyomileyo ukuya kumphezulu wephepha kwaye ungene kwiprofayili yensimbi ukuya kwi-10mm ye-10mm, kwi-4mm enzulu engama-20mm. Iintloko zezikrelem zisuswa yi-0.5-1 mm kwiphepha lomoya owomileyo, kwaye emva koko iqhutywa.

Iziqhulo zamaphepha e-plasterboard kufuneka zibekwiiprofayili zeProerdiatha okanye imivalo. Xa ingenakwenzeka, imitya yentsimbi ngobukhulu be-0.5-0.6 mm nobubanzi be-100 mm bubekwe kumalungu avela kwicala elingasemva kwamashiti. Emva koko, imithungo yenziwa ngokweetekhnoloji ezisemgangathweni, kwaye ukuba kukho imfuneko, emva koko i-shtving yomphezulu wonke.