Ngexesha lokwakhiwa kwendlu yezitena okanye iibhlokhi, ukomeleza i-Cridetement kunye nomgangatho wezangaphandle uyathandwa. Sixelela malunga neentlobo zezakhiwo kunye nendlela yokwakha i-overlap ngaphandle kwempazamo.

Ukomeleza umgangatho wekhonkrithi kubalulekile ukuba kusetyenziswe isandi kwaye akufanelanga ukuba kungakhathalelwanga kwiidrasi ezithelekiswa nezamthi zeplanga. La elide kakhulu, ukumelana umthwalo ukusuka wamatye izahlulelo, izinyuko, ifenitshala omkhulu, nto leyo ibhexesha isisombululo kwemisebenzi ecwangcisiweyo. Kukho iintsilelo, okokuqala kubo bonke abanxulumene nesidingo sokutsala izixhobo ezinamandla kunye nenani elibalulekileyo labasebenzi, ngerente izixhobo ezizodwa kunye nezixhobo. Ukomeleza imigangatho yekhonkrithi kuhlala kufuna ulungelelwaniso olongezelelekileyo, ngamanye amaxesha ukubola kwaye phantse kuhlala kuyibiza ngokuba yimbeko ngakumbi kuyilo olusekwe kwimiqadi yomthi.

Ukuze ukuba overpay uze ungasindisi neziphumo ezibi umgangatho, kuqala kwiinto zonke, iingenelo neengozi nobuchwepheshe eyahlukeneyo ukwakhiwa seqela ezinjalo kufuneka kufunyanwe ngaphandle.

I-Slab yangaphambili

Ngolwakhiwo olusezantsi kwezindlu, ugqityiwe kwii-verlapps zisetyenziswa ikakhulu iintlobo ezintathu: i-PC (i-PC (enee-voids ezijikelezileyo), i-PB (i-PB (i-PB (iPl (PB (iProfayile yePhezulu). Iipleyiti zePC kunye ne-PB zikhutshwa ngobungqingqwa be-220 mm, ngelixa okwesibini zibonakaliswa yiJometri echanekileyo kunye nolona phawu lubalaseleyo lomphezulu (ziphantsi kwe-grating emdaka). Ipleyiti pho, ubukhulu be-160 mm, ithathelwa ingqalelo ukuba ilungele ukwakhiwa kwabucala, njengoko iindonga kunye nesiseko zilayishwa kancinci, zenza lula ukufunyanwa komda we-on of torlang kwaye ngaxeshanye, amandla (amandla) , kuphela engaphantsi kakhulu kwiintlobo zePC kunye neepleyiti ze-PB. Izityalo zinika iimveliso ezininzi ngobukhulu, nangona Iizilebhu zixhaphakileyo 100, 120, 150 cm ububanzi, ubude eyahlukileyo kuleyo 2.4 ukuya-9 m nge songezo cm 10 (kodwa oku akuthethi ukuba imali 9 m ingaba ivinjelwe ngaphandle kwenkxaso eyongezelelweyo).

Ububanzi beqonga lezentengiso leepleyiti ezindongeni zesitena kufuneka ubuncinci ube yi-100 mm. Xa ikhulisa, amalawa abekwe kwi-suble yesisombululo. Ukuba akukho candelo lefekthi kwi-faps, imingxunya kufuneka itywine kwiintloko zeepleyiti.

Ezindlwini iibhloko ukukhanya (alephuze amagwebu eziphathekayo, bonts istro, arbolite, yodongwe aneentunja) ukwenzela kwimbono umthwalo kwipleyiti umqokeleli ugcwalise monolithic w / b ibhanti 200 mm ububanzi ukuphakama 100-150 mm.

Kuba isixhobo, intshukumo kwi zinonxibelelwano monolithic okanye ingqokelela-monolithic ifakiwe yi formwork emphethweni nokwandisa isakhelo wezifundo

Izinto eziluncedo eziphambili idlulela ukusuka amacwecwe ezigqityiweyo - ngesantya esiphezulu ufakelo, kungenzeka lwemveliso yomsebenzi ebusika (kubushushu alithe gangqa -10 ° C) kwaye yaziwa kanye iimpawu amandla amacwecwe, iinkqubo imveliso leyo imithetho engqongqo kwaye ijongiwe ngononophelo.

Kwelinye icala, ubukhulu esiqingqiweyo se-Iizilebhu ngandlel nzima umsebenzi ke lowo wengcibi yokuluka, nemilo yazo yoxande kunyanzeleke ukuba ezinye zeenkolelo non-esezantsi izisombululo zokwakha (iindonga radius, erkers polygonal, njalo njalo). Iidrives ezinzima: Kuya kufuneka ubhenele ekunciphiseni kwedayimani yedayimani, intaba ye-rigels. Okokugqibela, kuya kufuneka urente i-crane kwaye ucele uncedo lwezinto ezinamava ukukhusela iimpazamo xa ubeka iipleyiti. Ipleyiti i-PNTO yokuhanjiswa iya kuxabisa malunga ne-1700 ruble. Kwi-1 m2, kunye neendleko zokufakwa kwabo-ukusuka kwii-ruble ezingama-3500. Ngasemva kwesitovu.

Uninzi lweepleyiti zefektri zine-grooves egrovu eyenza kube lula ukutywina

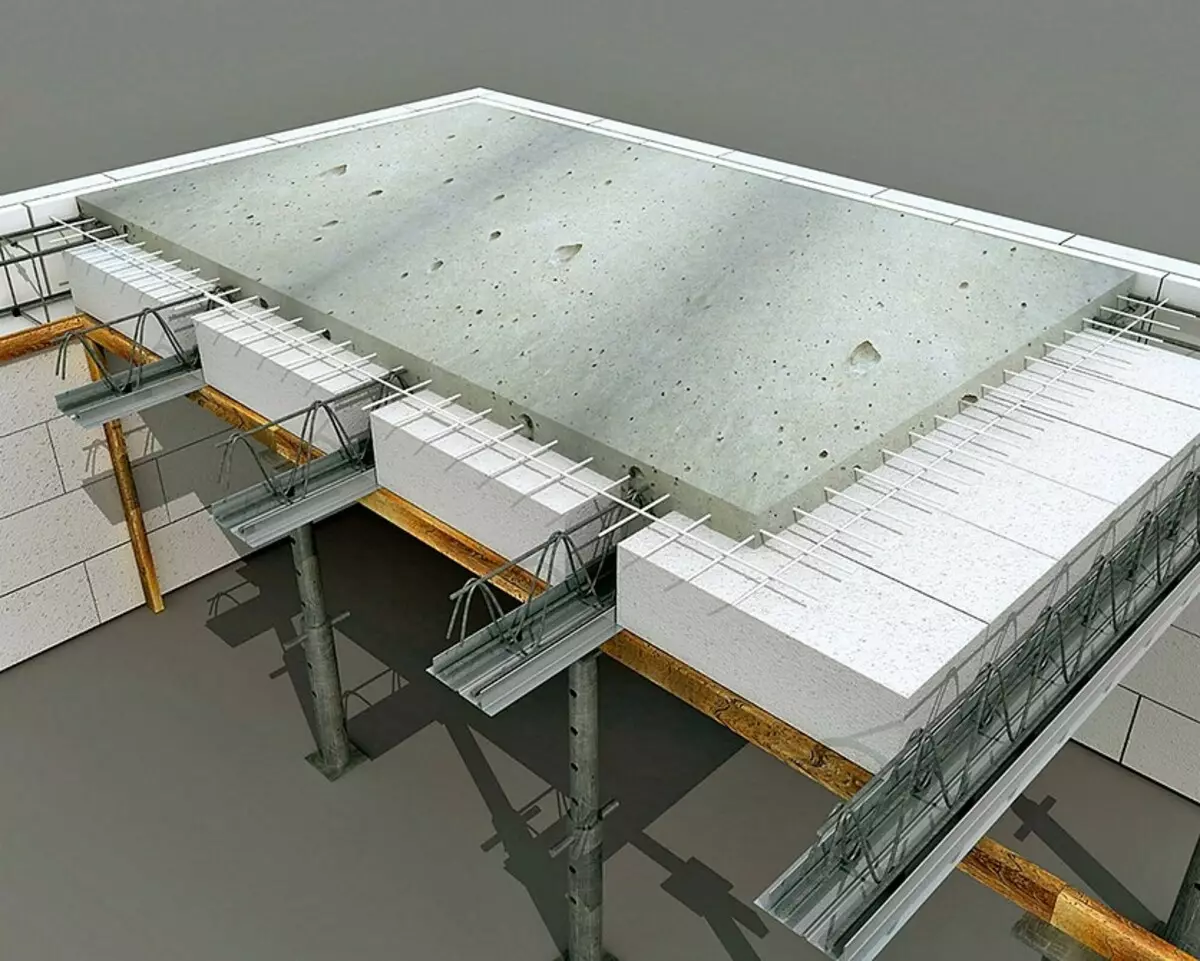

I-Monolithic Slab Dollap

Le uyilo luhlengahlengiswa ngokulula kwifom yesakhiwo kwaye inokwakhiwa ngaphandle kokusetyenziswa kwe-crane. Xa yobunzima, lidlula iqela, ngoko umoya yengxolo ngcono FUMANA kwaye uthintele ezivuzayo (leyo endlwini yelizwe kwenzeke kwakhona kwaye basongele akukho imiphumo ebuhlungu ngaphantsi kwi kwigumbi isixeko).

Xa eyila a slab monolithic, inkqubo yayo ilawulwa yi imigangatho - SP 52-101-2003, SP 52-117-2008 kunye SP 63.13330.2012. Kwinqanaba lokuqala, kuya kuba yimfuneko ukwakha umsebenzi ovela ePlywood, obhinqileyo okanye ezinye izihlangu ngenkxaso kwimimandla kunye neeracks. Umsebenzi ongafumanekiyo ovela kumgangatho oqeqeshiweyo uya kukhawulezisa ukwakhiwa, kodwa kwixesha elizayo uya kwenza ukuba kube nzima ukugqiba ukuqhelana.

Emva kokuhlanganisa umsebenzi we-Overlap lonke, inkqubo yenqanaba lesibini ukusuka ekuqiniseni i-Deameter ye-10 mm inomgangatho obaliweyo welding.

Iipleyiti ze-sundle ezivela kwikhonkrithi eziqinileyo zinqabile kakhulu. Iphepha lokubuyela umva liyinto ephantsi yokufuma

Inkqubo yokugada ikhonkrithi kufuneka yenziwe njengexesha elifutshane, ikrokra umxube wefektri nokuhanjiswa kwemoto. ukulungiselela oluzimeleyo ngekhonkrithi alwamkelekanga, kuba ngelo xesha ukuba ukuphepha ezininzi "iqhosha lokulayita" beentanda zakho, nto leyo eya kuba kakhulu kuncitshiswa inqaba slab. Ingafuneki kakhulu ukwakha i-monolithic ngaphezulu kwexesha lokubandayo, kuba kungenxa yokwanda kweendleko kwaye igqityiwe ukuncipha kwengqikelelo yesakhiwo. Kuba namhlanje, ixabiso lesixhobo se-1 M2 se-monolithic w / w ngaphezulu kwe-200 mm (ukusebenza kunye nezixhobo ngaphandle kwe-5 yamawaka ruble.

Amanqanaba aphambili okukhulisa iMonolithic ngaphezulu

Ngaphezulu kweZihlangu zomsebenzi zeFomu Ukusasaza amanzi aqengqelekayo kwaye wanyusa isakhelo sokuqiniswa, ukuqhawula intonga ngecingo. Ikhonkrithi yentengiso egcwalisiweyo. Umsebenzi wasuswa ngeentsuku ezingama-20 xa ikhonkrithi ifumene i-80% yamandla.

Iqokele i-monolithic egqumayo

Le teknoloji eyaziwayo kwinguqulelo entsha yokwakhiwa okuphantsi inyuswa inikezelwa namhlanje ukusuka kuMarko, turiang kunye ne-ytong. Eyona nto iphambili kukuba kuqala ukuchitheka kudlula imiqadi yethambo lemveliso. Phakathi kweebhulethi (ngenkxaso yamasheldu abo) abeka umgangatho oqinileyo kwiibhloko zemiphunga. Olu luyilo lusebenza njengomsebenzi ongcolileyo, ngaphezulu kwendlela ephakanyiswe kwi-mesh kwi-uqinise. Emva koko wagalela umxube wekhonkrithi kunye ne-filler elungileyo; Ubungqingqwa bomaleko ngaphezulu kweebhloko kufuneka zibe ngama-50-70 mm. Kucetyiswa ukuba usebenzise i-PROODTE Conqodity Priment Ikhonkrithi yeyabo, eyona nto iphambili kukuthintela "ukubanda" i-thungs xa kusenziwa imiqadi.Itekhnoloji ye-monolithic yenza ukuba ikwazi ukwenza ngaphandle kwezixhobo ezinamandla zokuphakamisa (ukuphakamisa imiqadi engaphezulu kwe-120 kg, ungayisebenzisa i-kg ye-kg, ungayisebenzisa i-Shield Fible) kunye nokonga ixesha kunye nemali kwi Ukulungelelanisa isixhobo esikhutshiweyo. Iindleko zemiqadi kunye neebhloko zimalunga ne-1,400 ruble. Kwi-1 M2, kwaye i-overlap egqityiweyo iya kuxabisa malunga nee-ruble ezingama-4500. nge-1 m2).

Amanqanaba aphambili eNdibano naseMonolithic Dreatlap

Okokuqala, iphakanyiswa ezindongeni kwaye ifakwe kwiProjekthi yeProjekti yokuqinisa izakhelo zemiqadi. Emva koko, babeka iibhloksi zekhonkrithi ekhanyayo, kwaye ngaphezulu kwabo - igridi yokuqiniswa. Imiqadi kufuneka ityhalelwe ngeeracks, kungenjalo banokungabinabo. Igalele umxube wekhonkrithi.

Ukufakwa kwe-Monolithic ngaphezulu kwe-overlaip kuya kuququzelela ubuchule bokusebenza nge-racks eguqukayo. Kuyinyani, iindleko zerente zayo ziphezulu kakhulu- ukusuka kwi-ruble ye-ruble eziyi-1600. ye-50 sq. m ngosuku

Uyomeleza njani imingxunya kunye neelogo

Iziqwenga zezitepsi, i-hatches, amanzi amdaka kunye nemibhobho yomoya, ii-chimneys kufuneka zinikezwe xa uyila kwaye wenze ngaphezulu ngexesha lokufakwa. Ngokwemigangatho yokwakha, imingxunya yobukhulu obubalulekileyo (ngamacala okanye ububanzi obuyi-300 mm okanye ngaphezulu) kwiiplate ze-monolithic kufuneka zisekwe kwicandelo le-roltings epheleleyo lezixhobo zokusebenza, ezifunekayo ngokubala ipleyiti njengeqinileyo.

Ngeeplate yokuxhela, kunqweneleka ukusebenzisa iipleyiti ezizodwa ezinemingxunya (i-Alas, ahlengahlengiswa kakubi kwizakhiwo eziphantsi) okanye ukubonelela ngeekholamu zenkxaso kunye / okanye zokulayisha imiqadi. Ngaphandle komeleza kwaye ukuqinisekiswa, ukubala kuvunyelwe ukwenza imingxunya ngaphakathi komgama ukusuka kumgama ukusuka kumgama ukusuka kumgama ukusuka kumgama ukusuka kumgama osuka kwenye iribbon rib kwenye (kwi-slabs engakwazi ukusika icandelo eliqinileyo).

Wenza njani i-butts ngaphandle kwe-rocks

Ukugula okudumileyo kwezakhiwo eziphakamileyo zepaneli eziphezulu-racks kwi-phaphailing kumalungu eepleyiti zengqokelela yeqokelelo, kwinkqubo yokusebenza kwayo. Le ngxaki ayisoloko inokwenzeka ukuba inqande ilungelo. Kodwa ungazama. Isitshixo sempumelelo siza kusebenza iipleyiti ezikumgangatho ophezulu onomthamo othambileyo, ukulayisha ngononophelo kwendawo enesiza kunye nokusasazwa komthwalo kumgangatho wesibini kwaye ufake imililo ejongene nayo.

Ngokuphatheni ukuhlangana kweepleyiti, kubalulekile ukusebenzisa izixhobo ezisemgangathweni eziphezulu kwaye ungashiyi ilifa elichaphazela kakubi ingxolo yengxolo yomoya. Ngokwesiqhelo, itywina le-tubimar lifakwe emazantsi omthungo (ngokomgaqo, i-polyurethane foam), kwaye ke i-Poliurethane Foam yeBandla-isisombululo sesanti sesamente ayiphantsi kwe-M250, iphekisiwe kwisiseko se-M250 Ingubo yangaphantsi yamanzi.

Ngaphezu kwe-25 mm yobubanzi benziwa kusetyenziswa itekhnoloji yokuphosa i-monolithic usebenzisa i-teraction esuswe okanye eyoyikisayo kunye nokuqiniswa okunyanzelekileyo.