Isitezi sokufudumeza sefilimu ekhangelayo yindlela enhle yokushisa igumbi. Sithi sikusho ngendlela efanele ngaphansi kwe-laminate.

Izici zohlelo lokushisa

Ukubekwa okunekhono kwefilimu phansi efudumele ngaphansi kwama-lineminate kucabanga ukuthi kuzoqedwa nawo wonke ama-nuances wokuhlanganisa ama-design amabili. Emsebenzini wayo, imishini yokushisa isebenzisa amagagasi e-IR. Ngaphakathi kwamaphaneli amancanyana ahlukahlukene, ama-radiator akhipha amagagasi obuhla be-infrared avaliwe. Ziya phezulu lapho izinto ezinkulu zibambezelekile. Kulokhu, phansi. Iqongelela ukushisa ngokwayo, kancane kancane ikunikeze umoya.

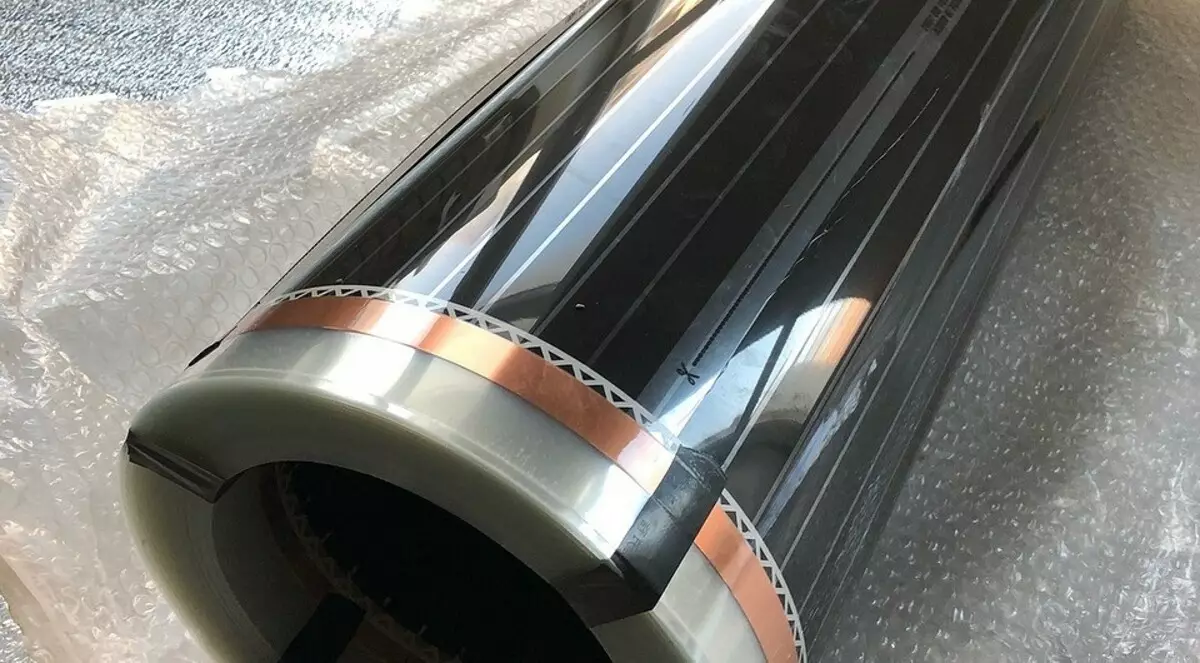

Imisebe ikhiqiza ama-carbox evitters aqoqwe emabhendi ambalwa. Ezinhlelweni ezinamandla ngokwengeziwe, i-canvas iqinile. Kunoma ikuphi, ngamandla wayo kukhona amathayi ahamba nge-bimetal, abhekele ukudluliselwa kukagesi ku-heater. Amandla anamandla ayahluka kusuka ku-120 kuya ku-230 W. Osayizi abahlukahlukene nobukhulu bendwangu.

Isibonisi sokugcina asidluli ku-2 mm, okuvumela ukuthi ufake okuqukethwe ngaphandle kwezinkinga ngaphansi kwanoma iyiphi imali ekhonjiwe. Ububanzi befilimu elijwayelekile bungaba yi-100, 80, 60 no-50 cm. Ukusebenziseka kalula, ilineni lihlukaniswe izingxenye, phakathi kwalo lingasikwa. Ubude obuphakathi kwengxenye enjalo bungama-20 cm. Ngakho-ke, uma kunesidingo, ungabeka indawo yokushisa yanoma iluphi uhlobo, noma ukwakheka okuyinkimbinkimbi kakhulu.

Phansi ifilimu ngaphansi kwe-lime: okufanele ucabangele lapho ukhetha ukunamathela

Ama-lamella ajwayelekile awakwazi ukufakwa kuma-heater. Kunezizathu eziningana zalokhu:

- Amaphaneli anokuphakelayo okuphansi okushisayo, okuzovimbela ukufudumala kwegumbi.

- Ngaphansi kwethonya lokushisa okuphezulu, iJiyomethri yamapuleti ingahluka, ngenxa yalokho, ingaphezulu lingagwinywa.

- Lapho kufudunyezwa, ukuhlanganiswa okufakelwa kungadedelwa izinto ezinobuthi.

Konke lokhu kunezizathu ezimbi kakhulu zokushiya ukusetshenziswa kwazo. Kodwa-ke, kunamamodeli akhethekile wezinto ezibonakalayo ezihloselwe ukubeka e-heater. Kubo, ukumaka okukhethekile kwenzelwe, okusetshenziselwa ukufakwa. Elinye iphuzu elibalulekile: ukuba khona okuphoqelekile kokhiye eLamella. Kufanele zibekwe kuphela kubuchwepheshe obuntantayo phansi, okungukuthi, ngaphandle kokuxhumana ngesisekelo. I-Laminate Laminate ayinakwenzeka.

Imithetho yokubekwa kwe-canvas yokushisa

Ukushisa kwalolu hlobo kungaba yikho konke okusemqoka futhi kuyakukhetha. Esimweni sokuqala, kuyadingeka ukubeka ifilimu nge-70% yendawo, okwesibili konke kuncike kwinombolo nomthamo wemithombo esemqoka yokushisa. Kodwa-ke, kunoma yikuphi ukwakheka, izincomo ezibalulekile kufanele zibhekwe.

- Esitezi esiphansi kwefilimu akuvunyelwe ekubekeni izinto zokushisa ezifakayo. Njengefenisha enkulu ngaphandle kwemilenze, amakhaphethi aminyene, njll. Uhlelo ezingosini ezinjalo zenze ngokweqile futhi lungahluleka.

- Izinto ezisindayo, ezifana nemishini yasendlini enjalo nefenisha, akufanele zime ngaphezulu kwe-IR Cannon. AmaLamel ngaphansi kwawo angahlupheka, okuzoholela ekucindezelweni ngokweqile e-heater. Ezimweni ezinjalo, kuphuka ngokushesha.

- Uma ukufudumeza okuhlanganisiwe kucatshangwa, akunakwenzeka ukuvumela ukuguquguquka kwama-liquating ukusetshenziselwa imithombo emibili yokushisa ngasikhathi sinye.

- Kufanele kukhunjulwe ukuthi i-zone yokushisa kwezinto zefilimu iphumele imingcele yayo engokomzimba. Ngalesi sizathu, akunconywa ukuthi kubekwe eduze kwezindonga, ifenisha enkulu, njll. I-Indent kumele ibe cishe ngo-3-10 cm. Kuya ngamandla kwemishini.

Kubeka kahle indwangu efudumele ebangeni elingu-0.5-0.6 m kusuka odongeni ngalunye. Lokhu kuzovumela esikhathini esizayo ukuba senze kabusha ifenisha, uma kunesidingo.

Ifilimu elifudumele yefilimu efudumele ngaphansi kwe-limisate: ubuchwepheshe obunekhono lokubeka

Uhlelo lokushisa luyiphayi eliyinqaba le-puff, okubalulekile ukubeka kahle. Cabanga ngesinyathelo ngesinyathelo ukuthi ungakwenza kanjani.Isinyathelo 1. Sidweba isisekelo

Kufanele kube owomile, ubushelelezi futhi uqine. I-Laminate ingabekwa kuphela kwisisekelo esihambisanayo. Ngakho-ke, uma umehluko wokuphakama udlula amamitha ayi-2 kwimitha ye-traffithphone, kuzodingeka wenze umsebenzi owengeziwe. Ukuvumelanisa i-concrete screed, uthele kahle ingxube yayo ebekiwe bese ulinda ukomisa ngokuphelele. Indawo yokhuni ilula ukuvumelanisa i-plywood.

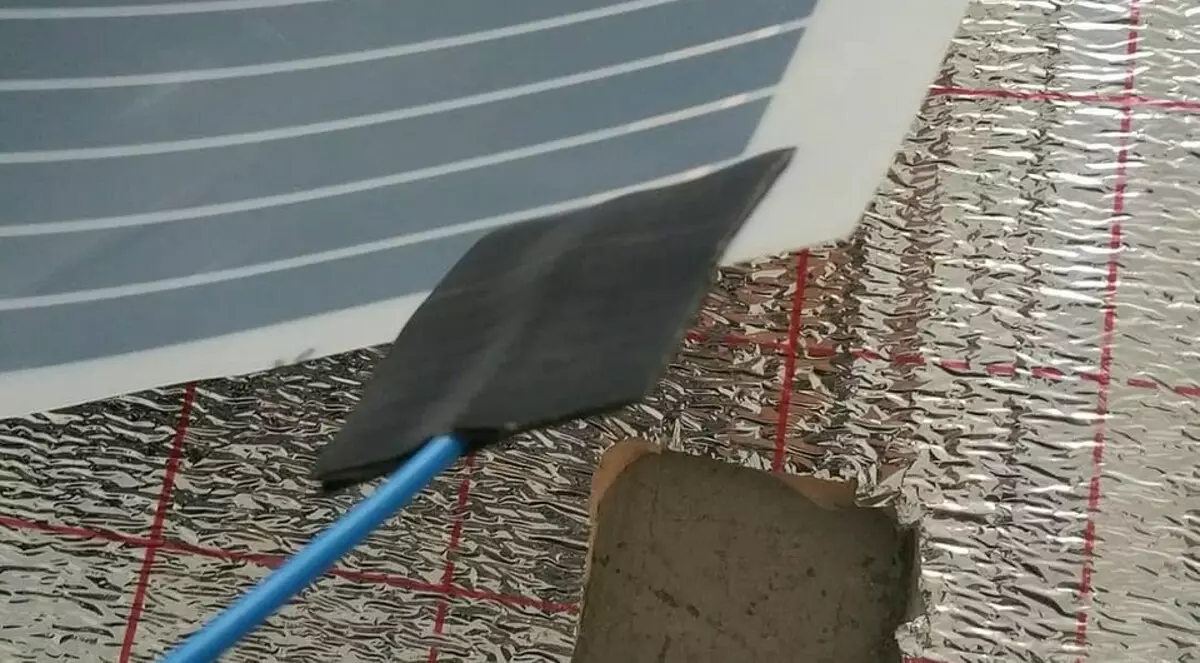

Isinyathelo 2. Beka ukufaka okushisayo

Ngokusebenza okujwayelekile kohlelo, kuyadingeka ukuhlomisa isendlalelo sokudlulisa ukushisa. I-Aluminium Foil ejwayelekile ayifaneleki ezimweni ezinjalo. Lokhu kuchazwa iqiniso lokuthi i-heater isebenza ngogesi, ngakho-ke, i-substrate akufanele yenziwe. Ngaphandle kwalokho, izingozi zingenzeka. I-insulator ikhethwe i-polyethylene noma ishubhu elinongqimba olukhanyayo olusetshenzisiwe kulo.

Ngaphambi kokubeka impahla, sihlanza ngokucophelela isisekelo kusuka kudoti nothuli. Ukusetshenziswa kwesicoci se-vacuum kumele. Phezu kobuso obumsulwa be-insulator. Sivala yonke indawo yegumbi, noma ngabe ifilimu ye-IR ngeke ibekwe yonke indawo. Amaphaneli afakwe omunye komunye ngesimo esincanyana odongeni. Ukuze ugweme izaba ze-insulator, zilungise ngetheyipu noma zikulungise ngqo kusisekelo se-stapler.

Isinyathelo 3: Vula ifilimu

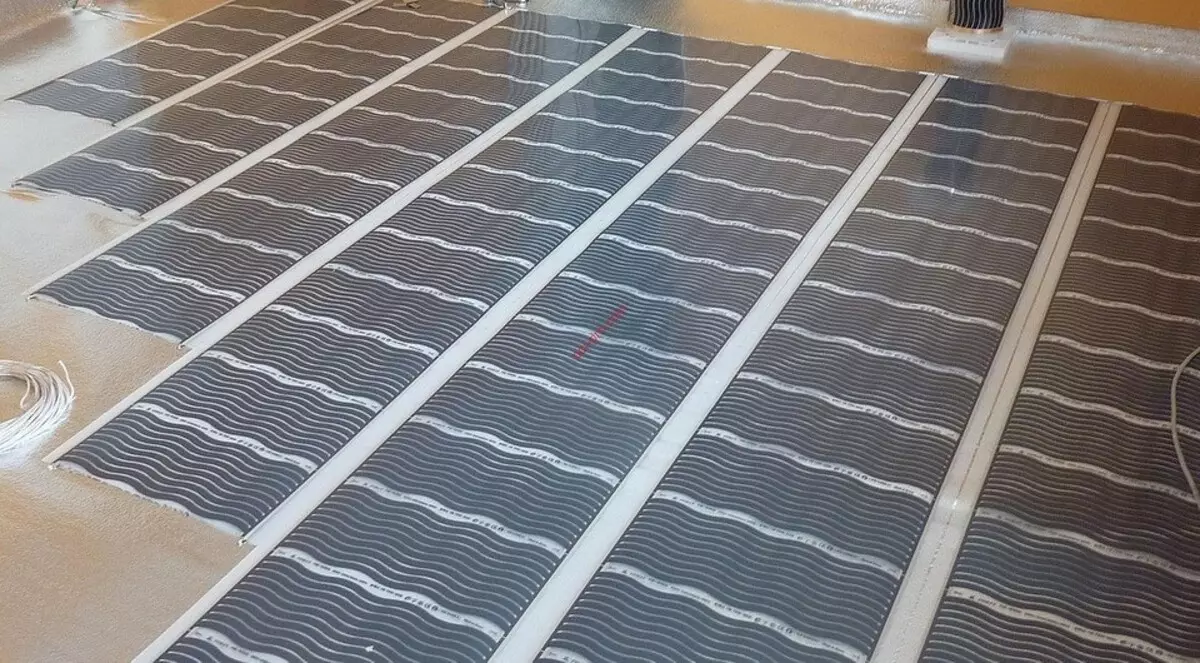

Ukugoqa imivimbo, izithobe kanye nezinhlangothi ezinde kakhulu zegumbi. Ngakho-ke, kuzokwazi ukunciphisa inani lokuxhumana okuxhumana. Uma kunesidingo, unqume i-canvas, kepha kuphela kumasayithi akhethekile aphawulwe ngelebula. Enqubweni yokubeka, ubuke ubuqotho bezinto abuphukile. I-canvas kufanele igcinwe ukuze ukunamathela kuphume.

I-Copper tower tires lapho ukubeka phansi kufanele kulale uhlangothi olucwebezelayo. Lokhu kuyadingeka ukuze uxhumane ngokuxhumeka. Amaphaneli ahlelelwe ngokwesisekelo usebenzisa itheyipu.

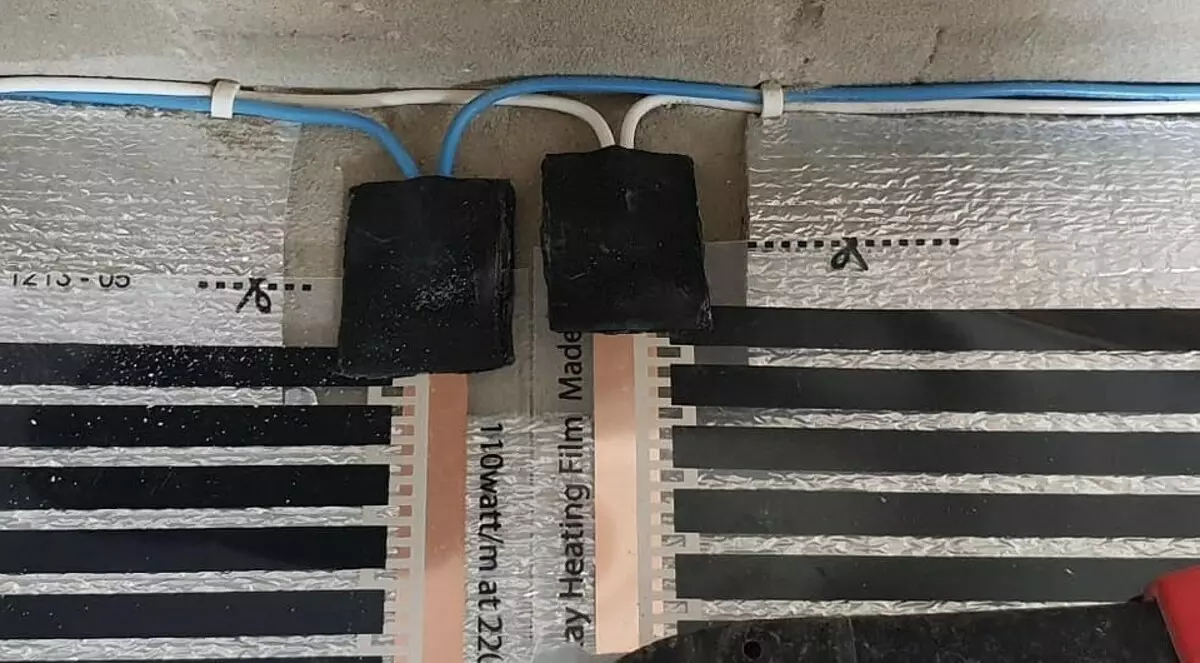

Ngemuva kokuthi wonke ama-heater abolile, sinquma ukuthi yimaphi amathayi azoxhunywa kwikhebula. Zonke iziza ezinamachashazi zihlukaniswa ngokushesha ekushintsheni. Ukuze wenze lokhu, vala nge-Bitumen Ribbon, okufanele ifakwe kwikhithi yemishini.

Isinyathelo 4: Beka inzwa eshisayo

Ngokusebenza okulungile kohlelo, into ibekwa endaweni ebandayo kakhulu yegumbi. Ngaphezu kwalokho, kumele kube phakathi kobubanzi be-strip, ukuze ibanga kusuka emaphethelweni alo liyafana. Awukwazi ukubeka inzwa eduze nodonga. Phakathi kwazo kufanele kube okungenani ama-500 mm. Elinye iphuzu elibalulekile. Uma ikhebula elijwayelekile ledivayisi alanele ukulibeka endaweni ekhethiwe, kufanele uthathe enye. Kuvinjelwe ukukhulisa ucingo.

Sika engxenyeni engezansi i-groove ngaphansi komzimba we-sensor kanye nesiteshi sokwenza ikhebula yalo. Sibeka into endaweni ukuze ifakwe ku-carbon heater. Lungisa idivaysi nge-Bitumen Ribbon, welula ikhebula kulo liye ku-thermostat. Ukuwohloka kwamafilimu nokulungisa okuphansi.

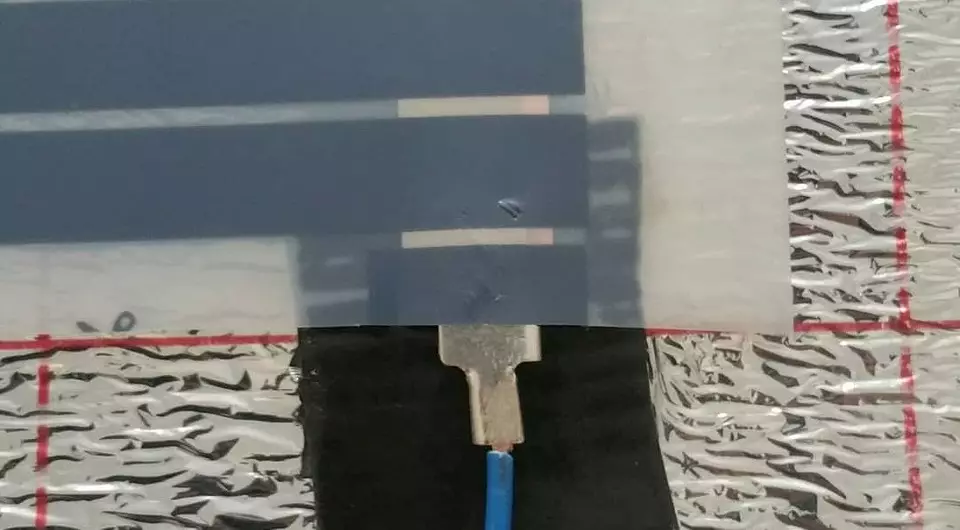

Isinyathelo 5. Faka ama-terminals

Ezindaweni lapho imishini yokulahla iyoxhunywa khona ecaleni, udinga ukubeka iziqeshana ezikhethekile-izikhungo. Imvamisa baneziqeshana. Kulokhu, i-petal ephezulu yento ifakwa ekutholeni kwe-PIN ye-PIN yefilimu, futhi kwembulwa ngaphansi ngaphansi kwawo. Ngemuva kwalokho sithatha ama-pliers futhi siqine, kepha ngobunono thrimp i-terminal, sinikeze ukuxhumana kwakhe okuthembekile ngethayi lethusi. Kwesinye isikhathi kunezinye izinhlobo zezinhlanganisela, imithetho yabo yomhlangano idinga ukubukwa kwimiyalo yemishini.

Isinyathelo 6. Xhuma ikhebula

Selula ucingo ngokulubeka eduze kweziza zokuxhumeka. Imvamisa izintambo ziboniswa ohlangothini olulodwa lwesistimu: kulula kakhulu ukuzixhuma kuma-heater. Yize kungenzeka futhi ukuhoxisa i-zero ne-sanation yocingo ezinhlangothini eziphambene zegumbi. Kulokhu, udinga ukuxhuma ngokucophelela ukuxhumana ukuze ungakhethi ibhasi elilodwa lokuhambisa ukuze ushintshe womabili oxhumana nabo.

Iziphetho zezintambo ezibekiwe zihlanzwa ngokufakwa kwe-1 cm bese zifaka kwi-terminal yokuxhumana. Crush the Piliers Emiphumela Emiveni. Sifakwe ngokuphephile ngetheyipu yebitume. Sinamathela imichilo ngaphezulu nangaphansi kokuxhumana, ngobumnene crimp. Ngenxa yalokhu, kufanele kutholakale i-cappule engavunyelwe manzi, ukuvikela ukuxhumana kusuka ekungeneni kwamanzi.

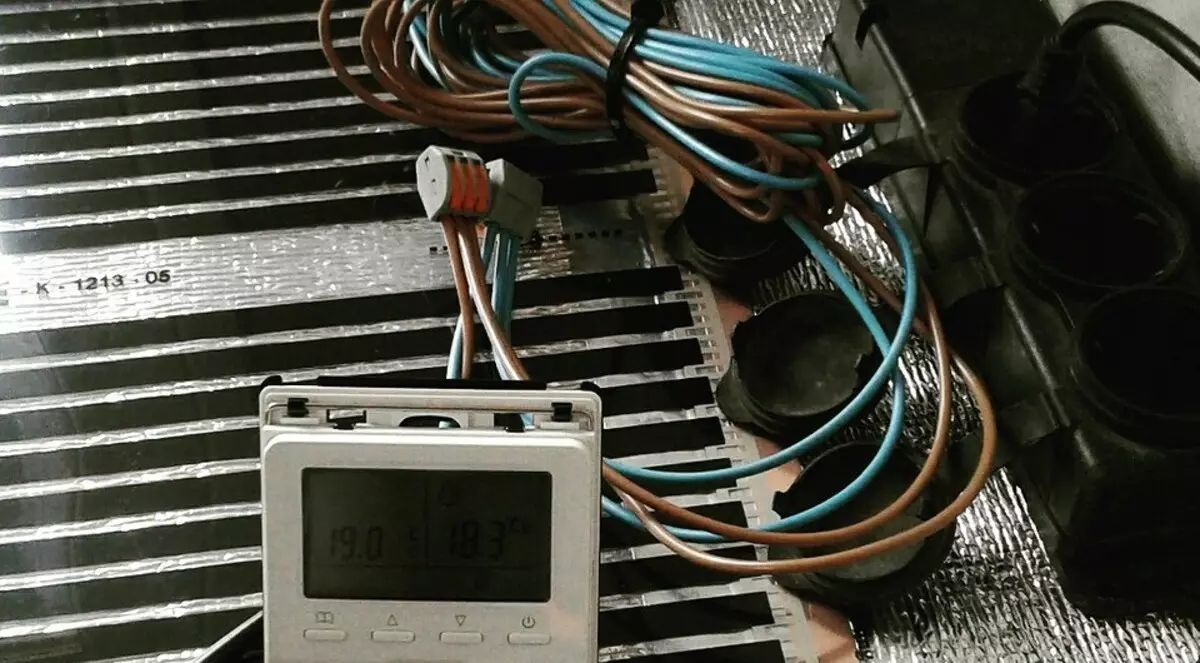

Isinyathelo 7. Xhuma i-thermostat

Ukushisa Floor Bearing Technology kuthatha ukuthi zonke izintambo kufanele zihlangane ngasikhathi sinye. Lapho zilungele i-thermostat. Kungasebenza izigaba eziningana zohlelo ngasikhathi sinye, kulokhu kubaluleke kakhulu ukukhethela kahle izesekeli ukuxhuma. Kufanele kube kuphela ama-terminal ama-terminal node, ukusonta okwenziwe ekhaya akuvunyelwe.

Iyunithi yokulawula i-thermostat ifakwe izixhumi ezikhethekile lapho izintambo zinamathiselwe khona. Ukuvimbela amaphutha, ama-pictographs akhombisa ukushintshana komhlaba, umthwalo kanye nokunikeza izigaba ze-voltage. Ngemuva kokuxhumeka, ikhebula ngalinye libekwe esiteshini esikhethekile bese lilungisa i-thermostat ibe yindawo.

Isinyathelo 8. Icala lesistimu yesivivinyo

Sihlola ubuqotho kanye nokunemba kwazo zonke izinhlaka ezenziwe futhi zenze ukwethulwa kwesitezi sokushisa. Uma konke kwenziwa ngendlela efanele, kufanele kusebenze ngokujwayelekile. Lapho ukhomba noma yiziphi izinkinga, kuyadingeka ukulungisa konke ukushiyeka nokusebenzisa kabusha imishini. Ukuze kucacelwe, sinikezela ukufakwa kwevidiyo phansi kwefilimu okufudumele ngaphansi kwe-laminate.Isinyathelo 9. Sibeka ukuhlanganiswa

Ama-Heater awakubekezeleli umphumela wamanzi, ngakho-ke kuyadingeka ukubeka isolatho yewebhu. Kuzoba ngokwanele lokho kuzoba yifilimu epulasitiki eminyanjeni engama-200, ezovikela umswakama futhi ngeke kubambezele imisebe ye-IR. Izinto ezibonakalayo ezinqunywe kumabhendi obude obufunayo bese ubeka ngesakhiwo sokushisa ngesinamathiselo esincane. Qiniseka ukuthi ubanikeza iScotch.

Manje usungaqala ukukhwela i-coating. Ungayibeka kanjani imodeli ye-lamiate ekhethiwe, udinga ukubheka iphakheji. Umenzi unikeza izincomo zokuthola umphumela ongcono. Lapho usebenza, kufanele kubhekwe okuthile ukuze ngengozi ungayeki i-heater yefilimu.

Ukubuyekezwa kwethoni efudumele yefilimu ngaphansi kwe-laminate kuhle. I-coating, yize iqiniso lokuthi i-insulator enhle yokushisa, ngokukhethwa kahle kwezinto zokwakha kanye nokufakwa okunekhono kuqongelela imisebe ye-IR bese kushisa ngokushesha igumbi. Futhi ukubukeka kwakhe okukhangayo nokuthungwa okumnandi kwenza isitezi sokushisa singasebenzi kuphela, kodwa futhi sihle.