Ukukhethwa kwamabhethri kunquma izinga lenduduzo endlini yonke inkathi yokushisa. Sizosho ukuthi yimiphi imikhiqizo engcono: kusuka ku-bimetal noma i-aluminium.

Ukuthola ukuthi iyiphi i-radiator yokushisa engcono, amamodeli we-aluminium noma ama-bimetallic kufanele akhethwe, kufanelekile ukuba ufile ukuze ujwayelane nama-plus kanye nohlobo ngalunye. Kungaleso sikhathi lapho isinqumo esifanele singathathwa khona.

Okudingayo ukwazi mayelana namabhethri e-aluminium

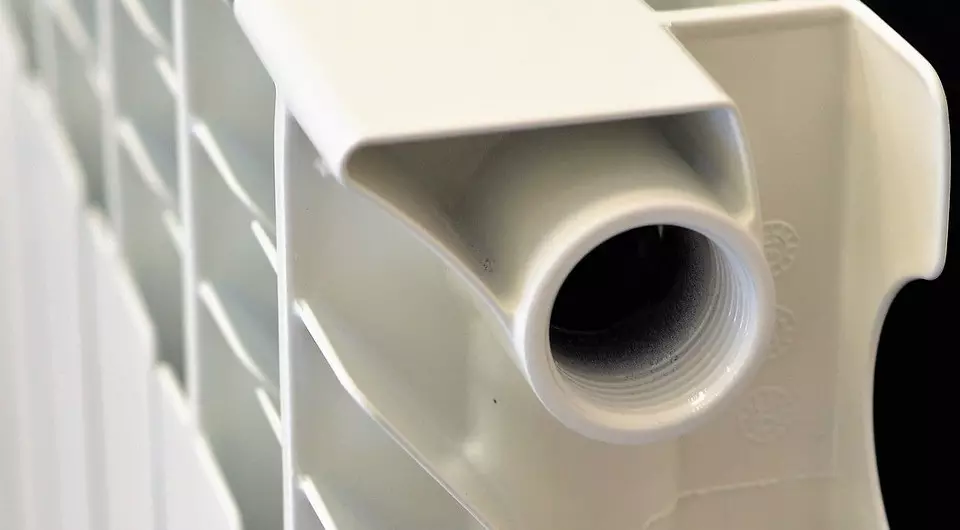

Ngokwenziwa kwamadivayisi anjalo, kusetshenziswa ubuchwepheshe obubili:

- Ukuphonsa. Ngakho-ke, umkhiqizo uthola iMonolithic. Ukungabikho kwazo zonke izinhlobo zamakhompiyutha noma umthungo kunikeza amandla akhethekile.

- Ukukhishwa. Ngokucindezela izikhala, izigaba zitholakala ngokulandelayo zihlanganiswe nebhethri. Ukuba khona kwezindawo zokuxhuma kubenza bazwele ngokwengeziwe ekucindezelweni kwengcindezi.

Ungavame ukuthola amadivaysi enziwe ngezindlela zokukhishwa, ngoba azibizi kakhulu ekukhiqizweni. Ngokusobala, ngokuya ngazo zonke izidingo zokusebenza, ama-radiator athembekile ngokulinganayo. IMonolithic kuphela engasebenza ngaphandle kokugcina, futhi amaqembu adinga ukuhlolwa okujwayelekile kokwehluleka kwezindawo zokuxhuma.

Kusuka ezinzuzo zama-aluminium amamodeli kufanele kuqashelwe:

- Ukudluliselwa okushisa okukhulu, ngenxa yegumbi lifudumala ngokoqobo imizuzu eyi-15 ukuya kwe-20. Lokhu kwenza ukuthi kwenzeke ukonga ukukhokha ukugeleza kokuphola.

- Isisindo esincane, ukuhlanganiswa, okusiza kakhulu ukufakwa.

- Ukuba khona kwe-thermoclap okuvumela ukuthi uguqule inani lamanzi kudivayisi. Lokhu kusindisa ekushiseni.

- Amamodeli ahlanganisiwe angagcwaliswa ngokuzimela ngezigaba ezintsha noma, kunalokho, akhiphe ngokungadingekile. Okwe-Cast, kungenzeka futhi, kepha kungcono uma kuzokwenza uchwepheshe.

Kwezinkinga ezibalulekile, kufanelekile ukubheka ukuzwela kwekhwalithi ye-coolant. Isibonelo, i-Alkali icekela phansi insimbi kuyo ibhubhise insimbi. Ama-radiator ahlanganisiwe asengozini enkulu. Phakathi kwezigaba kukhona ama-gaskets anganquma ngaphansi kwethonya lezinto ezithile. Ngakho-ke, ukwakheka okunolaka kohlobo lwe-antifreeze hlobo lwenjoloba olulonakalisayo ngokushesha okukhulu. Akunakwenzeka ukuzisebenzisa.

Ukungena kwamanzi okuvusa i-aluminium kuvusa ukusabela kwamakhemikhali okudlula nokwabiwa kwegesi ethile. Ngakho-ke, wonke amadivaysi kufanele afakwe nge-crane ye-maevsky. Ukudluliselwa kokushisa okukhulu kuhambisa iziphazamiso ezithile. Amabhethri akhulisa ngokushesha, ngakho-ke kudinga ukuhamba njalo kokuphola ukuze kugcinwe izinga lokushisa elinethezekile.

Konke mayelana namadivayisi we-bimetallic

Ukufinyelela okunye ukushiyeka kwamamodeli achazwe ngenhla futhi kugcinwe izinzuzo zawo, kuthuthukiswe imishini ehlanganisiwe. Igama lakhe libonisa ukuthi izinto ezimbili ezihlukile ezisetshenziselwa ukukhiqizwa kwazo. Le yi-aluminium nensimbi, emnyama noma engagculi. Emakethe ungathola amadivayisi anjalo ngezinhlobo ezimbili.

Owokuqala ubonakaliswa yiqiniso lokuthi ingxenye yalo yangaphakathi yenziwe ngensimbi, futhi yangaphandle - kusuka ku-aluminium. Emiklamweni yolunye uhlobo lwensimbi kuphela edlula umkhiqizo. Ukunquma ukuthi yimaphi ama-radiator angcono, i-aluminium noma i-bimetal, sizocubungula amadivaysi ohlobo lokuqala, ngoba yimikhiqizo ehlanganisiwe ehlanganisiwe.

Zenziwa ngaphansi kwengcindezi ephezulu ngokuxoshwa okuyinkimbinkimbi. Ngenxa yalokhu, kuvela umklamo onomgogodla wensimbi. Uma kwenziwa ngensimbi engenacala, impilo yenkonzo yedivayisi yanda cishe yesithathu. Ngakho-ke, ukuxhumeka kwekhwalithi ephezulu yezinto ezimbili kuqinisekiswa, okubangela ukudluliswa okusebenzayo kokushisa.

Izinzuzo zama-radiator kusuka ku-bimetal yilezi:

- Ukumelana nokukhulisa uketshezi lwengcindezi kunethiwekhi, ngenxa yokuba khona komgogodla oqinile.

- Ukudluliswa okuhle kokushisa futhi ngenxa yalokho, ukufudumeza okusheshayo. Lokhu kuchazwa ngokuba khona kwe-aluminium.

- Amandla okufudumeza amazinga okushisa aphakeme.

- Ukumelana nezinqubo zokugqwala, ikakhulukazi phambi komgogodla wensimbi engagqwali.

Okubi kubandakanya ukupholisa okusheshayo ngemuva kokumisa uketshezi olushisayo. Kwezinye izimo, ngekhwalithi enganele ye-Liquid CoolAnt, ukusabela kwayo nge-Metal Core kungenzeka. Idlula ngokukhishwa kwamagesi angalimaza imishini. Izindleko zalezo zinhlaka zinkulu impela. Lokhu kungabhekwa njengengozi yabo.

Yini engcono, i-aluminium noma i-bimetallic fashing radiator? Qhathanisa amapharamitha aphambili

Kuyacaca ukuthi izinhlobo ezimbili zifana kuphela. Qhathanisa izakhiwo zabo eziyisisekelo.Ukumelana nengcindezi ephakeme

Enye yezinto ezibaluleke kakhulu zebhethri. Umthwali wokushisa kunethiwekhi uhamba ngaphansi kwengcindezi, futhi ezinhlelweni ezahlukene inani lawo lingahlukahluka. Ngakho-ke, ngezindlu eziphansi kanye nezindlu ngazinye, kuncane. Okokugqama kwezitezi eziyi-16 noma ngaphezulu, ukubaluleka kukhulu kakhulu. Kungenxa yokuthi iqiniso lokuthi igumbi elivuthayo likhona, kunengcindezi enkulu kudingeka ukukhuphukela kukho.

Ngaphezu kokuphakama kwalolu hlelo, ithonya lokuphikiswa kwe-hydraulic lithintwa yinkomba, okungukuthi inani lokujika kwamapayipi, inani lama-cranes, njll. Kuyadingeka ukubheka futhi kungenzeka ama-hydrowards, okungukuthi, amaconsi abukhali ngaphakathi kohlelo oluphakama ngenxa yezizathu eziningi. Ngakho-ke, ukumelana nengcindezi ephakeme yebhethri kubaluleke kakhulu.

I-Aluminium isho izinsimbi ngamandla amancane. Kwenziwe ngamathuluzi we-IT, ikakhulukazi amamodeli eqembu, awakwazi ukudlulisa umehluko obalulekile. Zivame ukubhujiswa ngama-hydrowards. Abanconywa ukuthi basebenzise kumanethiwekhi aphezulu wokucindezela. Insimbi inamandla amakhulu. Njengoba kunikezwe amamodeli we-bimetallic, umnyombo wenziwe ngale ndaba, ayakwazi ukumelana ne-ATM angama-50.

Ukumelana nokugqwala

I-Aluminium, njengawo wonke ama-aleoys wensimbi, angamalungu ezinsimbi ezisebenzayo. Bangena kalula ekuphenduleni ngamanzi, okuthi, eqinisweni, okubhekwa njengokugqwala, ngoba izinsimbi zingama-onidized futhi zacekelwa phansi. Kodwa-ke, i-AL ikwenza ngenkani ukwedlula insimbi, ikakhulukazi amabala. Njengoba kunikezwe ukuthi ikhwalithi yendawo epholile ohlelweni lwezakhiwo zamafulethi iphansi ngokwesiko futhi kunokungcola kwamakhemikhali, izinqubo zishesha kakhulu.

Ngaphezu kwalokho, izinga lokushisa labo eliphakeme le-Liquid Liquid liyasheshisa. Abakhiqizi bakhava amadivaysi kusuka ngaphakathi ngesendlalelo esikhethekile sokuvikela, kepha akunikezi umphumela omkhulu. Ikhwalithi ephansi ephansi imvamisa iqukethe ukungcola okuxakayo okuvikela ukuvikelwa futhi kuyaphela. Ngakho-ke, ngokuchaza ukuthi iyiphi i-radiator yokushisa okufanele uyikhethe - i-bimetallic noma i-aluminium, kuyadingeka ukubheka ukuthi ukugqwala kutholakala kalula ekukhetheni kwesibili.

Ukumelana nokushisa okuphezulu

Izinga lokushisa elijwayelekile lokuphola aliphakeme kune-90 °, noma ngabe kubanda kakhulu ngaphandle. Kodwa-ke, kwezinye izimo, ngenxa yephutha lezisebenzi zase-boiler House, izinkinga nge-automation kanye nezinye izizathu eziningi, kungadlula leli nani. Lapho ushisa ngokweqile, ama-radiator ahluleka, okuyingozi kulabo abahlala endlini. I-Aluminium ayibekezelela amazinga okushisa angenhla + ngo-110 °, i-bimetal isebenza kakhulu ku-140 °.Izinga lokudlulisa ukushisa kwebhethri

Ijubane ledivayisi elinikeza ngalo ukushisa emoyeni lincike kokuqukethwe okukhiqizwa ngalo. Umnikazi werekhodi phakathi kwezinsimbi ezisele ekudluliseleni ukushisa kwe-aluminium. Ishisa ngokushesha kakhulu futhi ipholile. Imishini ehlanganisiwe eyenziwe ngezinto ezimbili inokudluliswa okuncane kokushisa. Lokhu kuchazwa ngokuba khona komgogodla wensimbi. Ibambezela ngandlela thile.

Kodwa-ke, izinga lokudlulisa ukushisa kwamadivayisi anjalo lise likhulu. Umehluko phakathi kwezingxenye ezimbili ezifanayo zamadivayisi ezinhlobo ezahlukahlukene cishe nge-10-20 w, okuthi ngezimo zangempela ngeke kuphawuleke. Kepha ngokusemthethweni ukudluliswa kokushisa kwamabhethri e-aluminium ngaphezulu.

Izici zeMontage

Ubunzima lapho ufaka amabhethri wezinhlobo zombili azenzeki. Ziyahluka ngesisindo esincane, ngakho-ke ukuzipholisa odongeni akunzima. Yonke imisebenzi ehlobene nokuxhumeka kwemikhiqizo kumele yenziwe ngokuqinile ngokuya ngemithetho ukuvikela ukubonakala kokuvuza. Okuwukuphela kobunzima obungabhekana nakho ukuthi kungenzeka ukuthi amadivaysi avela kumadivayisi avela ku-aluminium athambile ngokujikeleza okungalungile. Ukufaka, kuyadingeka ukugcina ukuqaphela okuthile.

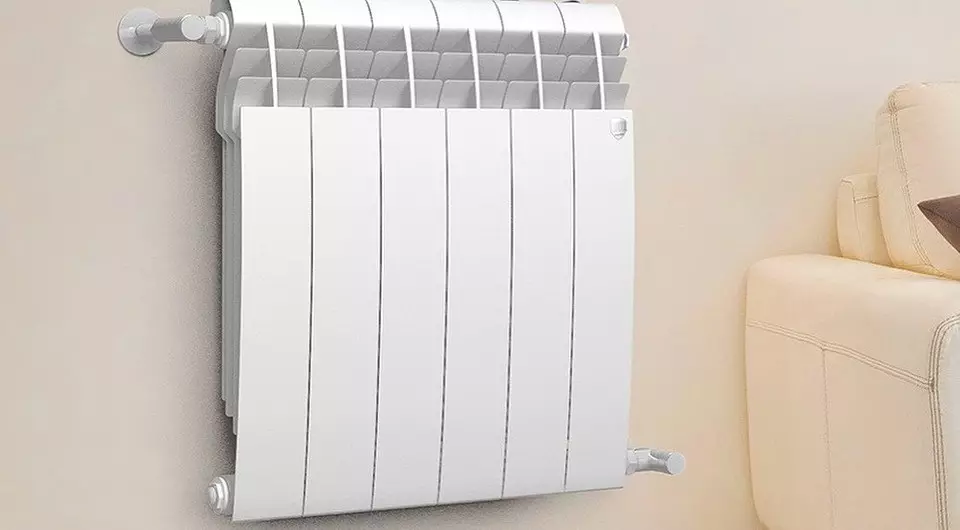

I-Aluminium Radiator noma i-Bimetallic: Yini ongayikhetha ekhaya

Kungabonakala sengathi umkhiqizo ohlanganisiwe uyindlela engcono kakhulu yedivayisi yokushisa. Kodwa-ke, lesi siphetho asikufanele ukwenza. Izezithazo zokusebenzisa amadivaysi ahlukahlukene kuya ngemibandela yokusebenza kwayo. Ngakho-ke, amabhethri e-aluminium afakazele amanethiwekhi aphansi okucindezela. Zonke lezi zindlela zonke ezakhiweni zangasese nezenhlaka. Inketho ephelele yamamodeli anjalo ifudunyezwa endaweni eyodwa, izindlu ezinamatende amathathu.

Okuhle kunakho konke, bazizwa "ezinhlelweni zohlobo oluvulekile. Inketho ehlanganisiwe ilungele amanethiwekhi aphezulu wokucindezela. Iyakwazi ukudlulisa ama-hydrowards abalulekile namazinga okushisa. Amamodeli anjalo alungele ukwanda okuphezulu, amabhilidi amakhulu aphezulu aphezulu anamakamelo amaningi, njll. Mhlawumbe inkinga yokukhetha ibingavele ingekho uma zombili izinhlobo zamadivayisi zazinezindleko ezifanayo.

Kodwa-ke, intengo ye-bimetal iphakeme kakhulu. Ngokuphindaphindeka kabusha, umehluko obalulekile uyatholakala efulethini noma endlini. Ngakho-ke, lapho ukhetha amabhethri, kunconyelwa kakhulu ukubheka imibandela yokusebenza kwawo futhi, ngokusekelwe kulokhu, yenza isinqumo. Ungazami ukonga ngekhwalithi. Amafayitela ashibhile ngeke asebenze okuncane kuphela, ngenxa yengozi eyandayo yengozi, baba nengozi empilweni yokuhlala endlini.