Noma yikuphi ukufuya ngokushesha noma kamuva kufinyelela ekugqokeni okubucayi, khona-ke kufanele kuguqulwe. Kepha ukubeka impahla entsha esemdala, isisekelo esidala asifaneleki, ngoba ngasikhathi sinye singavuki, i-creak futhi kungekudala kuzofanela siqale ukulungiswa futhi. Ungasibuyisela kanjani phansi isisekelo?

Amakamelo okusalungiswa akhonza ukugqagqana, abhekele ukufakwa okuzwakalayo kwesikhala esilandelayo, futhi umsebenzi wokufudumeza wokushisa naye wenziwa ezitezi zokuqala nasezakhiweni zokushisa kwabathengi.

Photo: Knauf.

Lapho ulungisa "Abasekeli", cishe kufanele babuyise noma bakha kabusha phansi okusalungiswa. Uma uqala ukubheka, lo msebenzi ulula, ngoba akukho ukuntuleka kwezinto ezisetshenziswayo emakethe, futhi amafemu amaningi anikela ngezixazululo ezenziwe ngomumo, ezinjengezibopho zeqembu. Kodwa-ke, kwesinye isikhathi kuyinkinga ukwenza isinqumo, ngoba udinga ukubheka isimo sokugqagqana, imithwalo yokusebenza, ukuphakama kophahla, izimfanelo zabakhi, uhlobo lwezinto ezihlanganayo nezinye izinto. Futhi ngaphandle kwalokho, ngaphambi kokuqala umsebenzi, kuyadingeka ukuthola imvume kwiziphathimandla zokuhlola izindlu ukuze zishintshe ukwakhiwa phansi. Futhi indlu endala, kunzima kakhulu ukulungisa ukulungisa.

Photo: "I-Parquet Hall"

Izindlu ezindala kakhulu zinebhodi enkulu, isihlangu noma i-parquet exegayo

Photo: I-Legion-Media

Lapho ukulungiswa, ukugqokwa phansi kususwa kanye nomxhaso, khweza phansi okusha okusalungiswa futhi kubekwe, ngokwesibonelo, ibhodi esebenzayo ye-Laminate noma i-Parquet Board

Photo: I-Legion-Media

Ama-Lags ahlala isikhathi eside kunesikhungu se-cent-sand Screed, kepha isisekelo sokhuni singaphansi kokuqina, kuphakanyiswe ngokushesha futhi kulula ukulungiswa

Amaphutha ajwayelekile lapho elungisa phansi

- Ukuzama ukugqagqana ngezinto zokwengeza ezilinganayo (Plywood 4 mm ubukhulu, i-fiberboard, amakhadibhodi, njll.). Ubusuku bonke bazokwazi ukufihla isikhashana nje.

- Intaba yeLag engathembekile iye esisekelweni, ukusetshenziswa kwemigqa evumelana nezinto eziphilayo ezifuywayo.

- Ukusetshenziswa okungafanele kwezinto ezingenamanzi, njengokubekwa ngaphezulu kwe-lag nokufakwa kwefilimu ye-polyethylene ephazamisa ukuhwamuka komswakama ovela eStrata yesakhiwo.

- Ukuthululelwa i-WET Screed endlini enohlotshiswe kabi noma ngaphandle kwe-hydraulic infation substrate.

- Ukubeka izimbobo zangaphandle kuthayi lesihlabathi esingenamthungo. Uma ukulungiswa kufanele kuqedwe ngesikhathi esifushane, kufanele kukhethwe amazinga okushesha - Vetonit 6000 (Veber.vetonit), ukuveza-ukuqeda (ivsil), njll.

Ku- "stalinky"

Ezakhiweni zezindlu zawo-1930s. Ukugqama kungukugqama kokhuni ikakhulukazi (kusuka kubha ye-150 × 200 mm noma ngaphezulu). Ama-Barks ahlelwe i-Draft Boardwalk (ukusuka ohlangothini lwegumbi elingezansi, kufakwa ngodaka e-duranka), i-runneoid ibekelwe phansi futhi imbozwe esihlabathini noma esigangeni. Emishameni, ama-lags avumelanayo, okuthi, i-NASSIL kusuka emabhodini anobukhulu obungu-40 mm, esebenza isisekelo se-parquet. Eminyakeni yezempi yasempini, imishayo ekhonkolo eqinisiwe yesigaba esimisiwe se-T isetshenziswe kaningi, kanti amapuleti kakhonkolo akhanyayo angena amapuleti kusuka emthambekeni nasemuva.

Lapho isitezi esisha sitholakala endlini nge-Beam Snderlaps, kuyadingeka ukwenza ukuhlolwa kokuqala. Lo msebenzi unelungelo lokwenza izinhlangano zokwakha ezinelayisense lokugcina amagugu amasiko kanye / noma nesitifiketi sokwamukelwa kwe-SRO. Ekupheleni kokuhlolwa, udinga ukwenza isiphetho lapho ukubalwa kwekhono lokuthwala lokugcwala kuzokwethulwa (noma ukungasebenzi kokukwenza)), iziphetho, futhi kubonise nezindlela zokwakha kabusha. Kumazinga amaningi amakhulu, ngaphezu kwalokho kulayishwa imishayo akuvunyelwe; Ngaphezu kwalokho, izinqubo zokwakha ezihlobene nokusetshenziswa komlilo ovulekile, ukudlidliza okunamandla nokuthambisa okugcwele kakhulu kuyadingeka. Isibonelo, cabanga ngesinye sezixazululo ezisebenzayo.

Ukuguqula izitezi, susa isihlabathi, i-slag nezendlalelo ze-gasket. Bese usakazekela ngaphesheya kwezinto ezingavunyelwanga izindwangu ukuze uphenduke ugongolo ngalunye kusuka ezinhlangothini ezintathu. Kunengqondo ukusebenzisa imikhiqizo eqinile futhi eqinile esekelwe ku-cholester yengilazi kanye ne-bitumen eguquliwe ("i-bredrostelist tpp", "i-hpdrosteclozole tpp", "i-glass Walker TPP", i-polyvinyl chloride (ngokwesibonelo, i-SPOPLAN WP, i-LogicRoast) . Izibalo zamabhendi zihlehliswa yi-mastic noma (ye-PVC) ukuze zithambeke ngomoya oshisayo. Ama-Bark abekwe ngoboya obunamaminerali, anjenge-batts akhanyayo, "ama-acoustic batts" (rockiwool) noma "i-isose" ("isanta-goben" ("Saint-Goben") shube kusuka ku-80 mm. Izinto ezizwakalayo zokushisa kufanele zimbozwe ngesendlalelo sokufaka ngaphansi kwamanzi okuvumelekile, okungcono ukusebenzisa ulwelwesi lokuphaphama, ngokwesibonelo, iTyvek (DuPont), "Optima" ("Technikol"), njll.

Ama-lags amasha angenziwa ngemigoqo eyomile yase-antiseptic ngesigaba esingu-50 × 70 mm nokuningi; Imikhiqizo ye-Aluminium izobiza i-oda lobukhulu obubizayo (kusuka kuma-ruble angama-260 nge-1 p. M. M), kepha kuzovumela ukukhulisa ubulukhuni bedizayini - phansi kuzoba khona kancane kusuka emithanjeni nasekudlidliza lapho uhamba. Ama-lags afakwa esigabeni esingadluli kuma-500 mm, avumelanisa kahle ngokuvundlile - ama-wedges epulasitiki aphilayo alungele le nhloso.

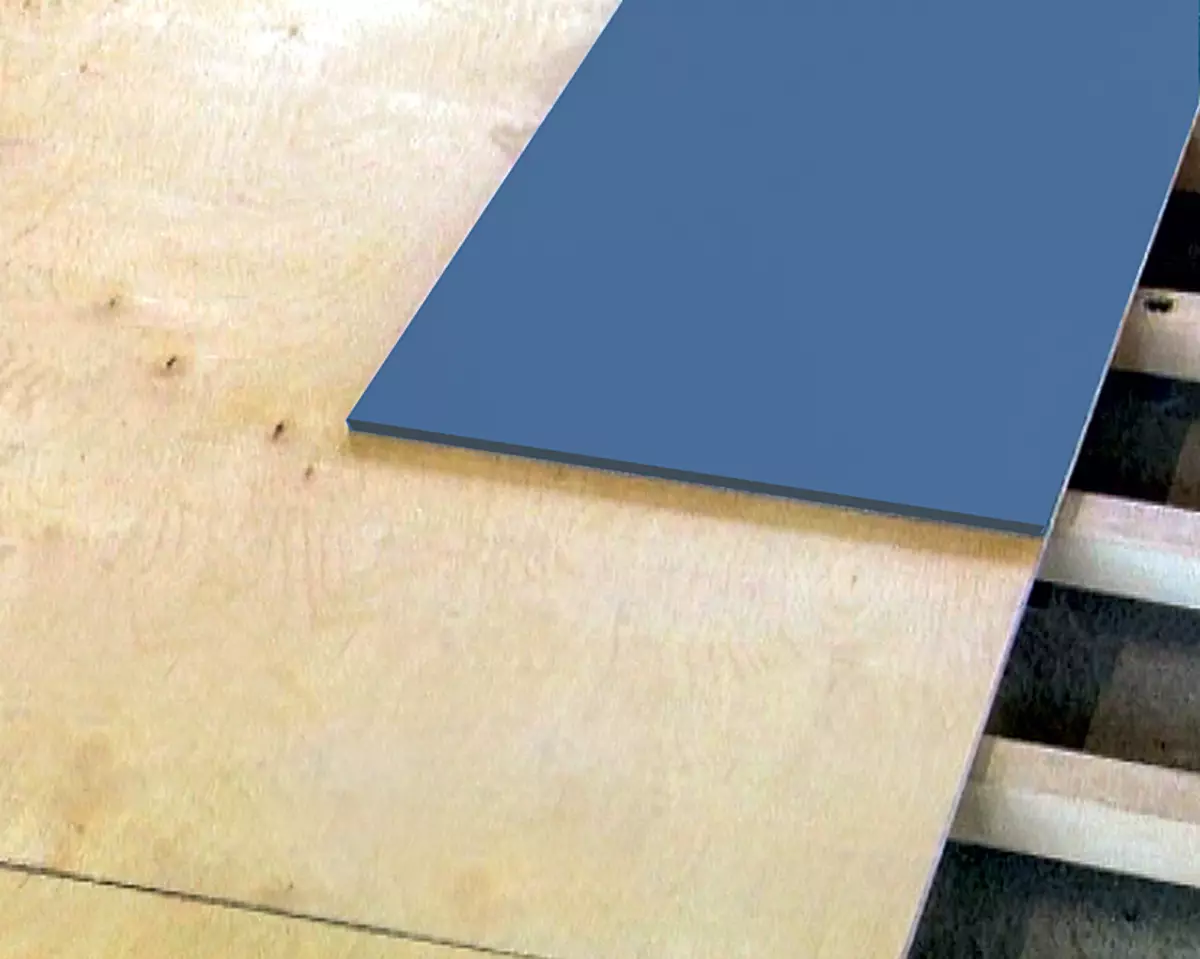

Uma kuhlelwe ukusebenzisa i-laminate, i-parquet board, i-parquet ye-puice noma i-ceramic tile njenge-coatic yangaphandle, ngaphezulu kwe-lag yanelisekile ngokugcwaliswa okuqinile okuvela ku-16 mm kusuka munye, futhi kungcono kunezendlalelo ezimbili ze I-Plyproof Plywood. Ngasikhathi sinye, phakathi kwamashidi, kanye nasendaweni ezungezile, kuyadingeka ukushiya izikhala zesinxephezelo sika-4-6 mm.

Phansi phansi ekhaphethi noma i-linoleum kufanele kwenziwe kusuka ku-chipboard emelana nomswakama (emphemeni osheshayo kanye nama-analog awo); Lags kuleli cala zivame kakhulu - ngesinyathelo esingadluli ku-400 mm, kanti imvume ezungeze umngcele wegumbi inyuke yaba ngu-10 mm (amapuleti afakwa ngaphandle kwezikhala, i-PVA, i-latex, i-latex, polyurethane).

Ibhodi elikhulu elinobukhulu obungu-35 mm lingalungiswa ngqo ema-lags, lisindisa kakhulu kusizinda sedivayisi.

Photo: Brozex Group, Saint-Gobain Weber, Daüer, Knauf

Ukuqondanisa phansi ngesendlalelo esincanyana sendawo esheshayo kudinga ubuchwepheshe. Ukuxubana okulomile kokuqondanisa okuyisisekelo kukuvumela ukuthi uzuze ukhonkolo osezingeni eliphakeme ngisho nangokwenziwa ngemanuhlo

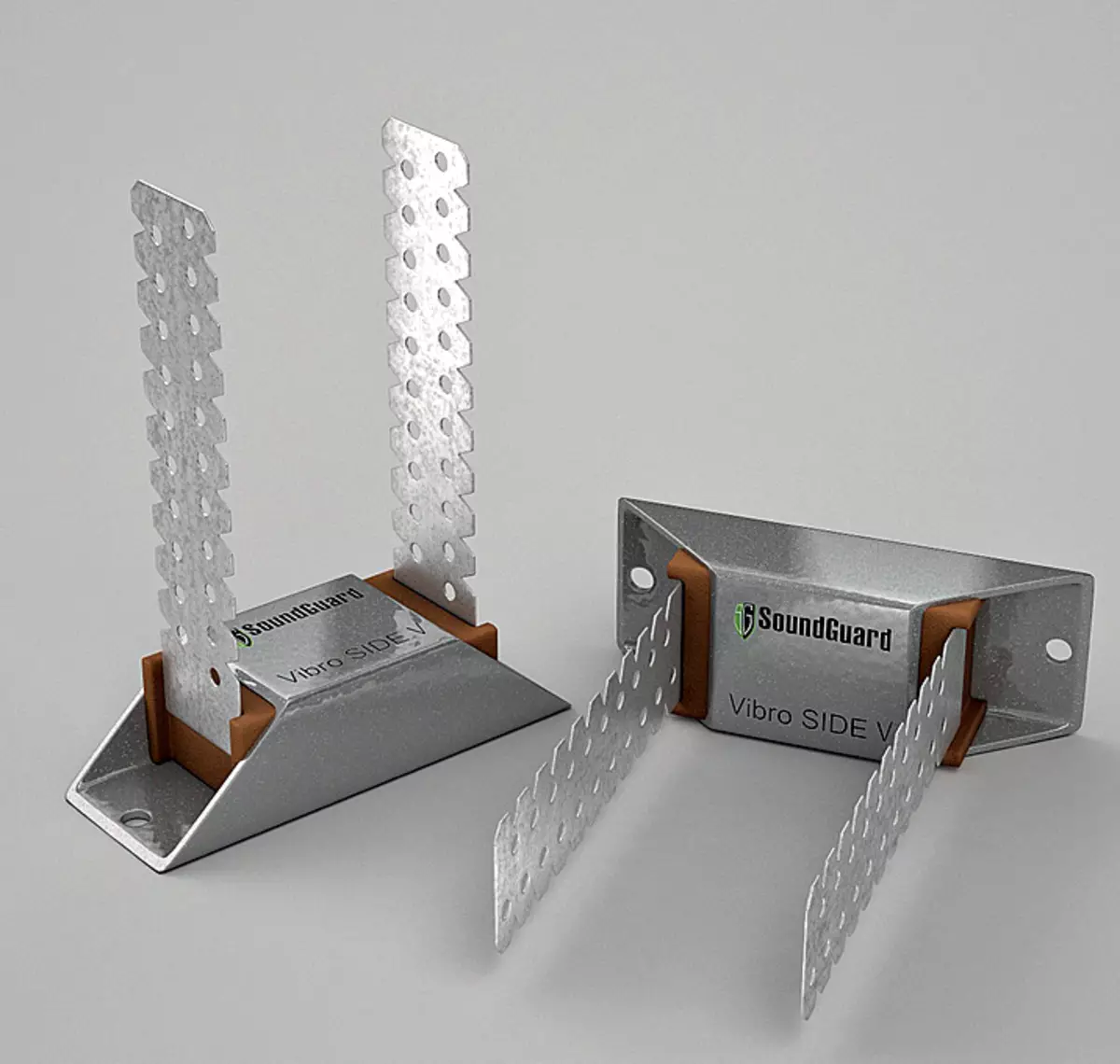

Ukuze ugweme izingxabano nomakhelwane, kuyadingeka ukubeka ekwakhiweni kwesendlalelo sokulungiselela phansi

Ukulungiswa kokulungisa.

Efulethini elithenge emakethe yezindlu zesibili, ngaphansi phansi kungatholwa uthayela ukhonkolo owenziwe ngesikhathi kulungiswa kwangaphambili. Imvamisa, ikhwalithi yayo ishiya ukufiswa okuningi noma kunomshado ongashonile. Susa ukwakhiwa okusindayo kunzima futhi kuyabiza, ikakhulukazi uma kuqiniswa yigridi. Kufanele ulungise iziphambeko. Imifantu iyandiswa, bese ithululelwa nge-polymeric noma ukulungiswa kwesimende-polymer. Ezindaweni zamaphutha amakhulu, i-screed kumele iqiniswe izikhonkwane zothando lwezezimali. Uma izindonga zikakhonkolo zisemuva phansi (ezenzeka ngokumiswa okungalungile), izimbobo ziyakhiwa futhi zifakwe ku-cavity ukulungisa. Ukweqa ngokweqile kubushelelezi nge-plaque yephansi kasimende, njenge-vetonit 4100 (Weber.vetonit) noma "indawo" ("UNICET" ("UNIC"), noma i-Pheqa ungqimba oluncane lwengxube elula.

Photo: Saint-Gobain Weber

Ukuze uhlomise isisulu esiyisisekelo, ingxube, ingxube isatshalaliswa ngaphezulu (a), gingqa umgomo (b) kanye ne-cooler (b). Kuvunyelwe ukukhombisa izintambo esikhwameni esivikelayo, kanye namapayipi ensimbi nama-polymer.

Ku- "Khrushchevka"

E-Brick, iphaneli kanye ne-block yezakhiwo ezinezitezi ezinhlanu ezakhiwe ngasekupheleni kwawo-1950s - ingxenye yokuqala yawo-1960s, okwenziwa yi-Confung amapuleti ukhonkolo aqinisiwe, futhi amafulethi okusalungiswa ajwayele ukugcwaliswa nge-sandy backfill. Izendlalelo eziphambili zekhekhe laphansi zihlukaniswe yiRusbeoid noma i-Pergamine.Ngemuva kokuphula isisekelo esidala, kungenzeka ukuthi ugcine ukunqwabelana ngezinto ezingenamanzi, ubeke indawo emisha bese uthele isikhala phakathi kwawo ngo-clay gravel (ukufakwa komsindo womthelela kukhuphuka ngo-4-6 dB). Izisombululo zokususa yilezo zindawo zokulala kuzofanela zifakwe kukhonkolo ye-dowel, ezokwenza buthaka ukugcwala.

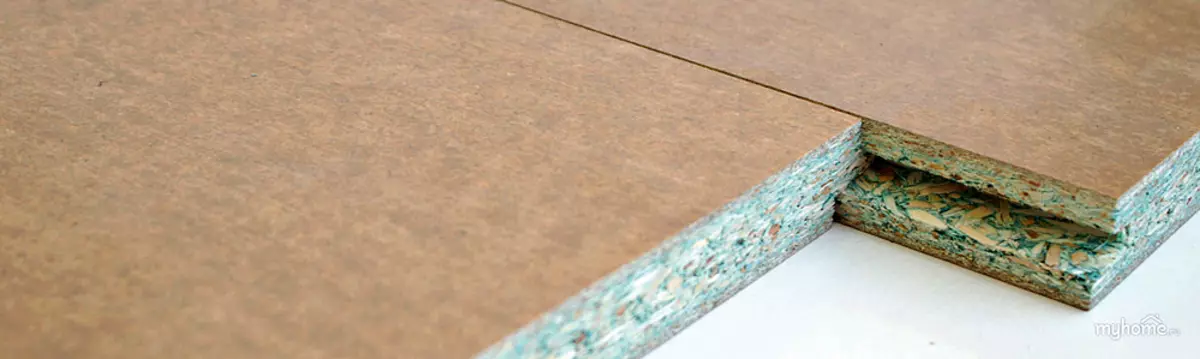

Enye into (ethandwa kakhulu) yokwakhiwa kabusha yidivaysi yeqembu eyomile screed, ngokwesibonelo, ngesisekelo sezinhlelo eziphelele zenkampani i-Knauf - Op 131 noma i-Gypsum fiber amashidi ( noma enziwe kusuka ku-GVL yezinto ezikhethekile zaphansi), kanye nokubeka izinto zokwakha kanye nokubekwa uphawu. Ubukhulu obuncane be-screed enjalo bungama-40 mm. Umklamo ucisha kahle umsindo oshaqisayo (inzuzo emandleni akho anezinhlaka ezinomsindo we-overlap kuzoba okungenani nge-18 dB), isisindo esincane (kusuka ku-15 kg / m2) futhi itholakala ngama-ruble angama-600 ngentengo 1 I-M2 ithatha ukufakwa kwe-akhawunti). I-Screed eyomile ingasebenza njengesisekelo sezimbali eziningi, okuhlukile yibhodi enkulu kanye ne-parquet exegayo.

Isisulu se-semi-eyomile asinamandla amancane kunalokho okumanzi, kepha silukhuni kabili ngokushesha, ngaphandle kwalokho, lapho kuyithuluzi, ubungozi bokuvuza kule ndawo elandelayo buncane

Izibopho ezikhanyayo

Ngokubheja okungalingani kakhulu, ubukhulu obudingekayo be-screed bungadlula ama-40 mm. Kulokhu, ukusetshenziswa kokhonkolo okukhanyayo. Okungabizi kakhulu ngokhonkolo we-ceramzite, okungekho nzima ukulungiselela indawo usebenzisa amathayi e-compact kagesi. Izindleko zika-1 m 2 Ceramzite-ukhonkolo-ukhonkolo onobukhulu obungu-50 mm ngama-ruble angama-500-700. I-monolith evela engxenyeni eqediwe enomfutho okhanyayo (ngokwesibonelo, iseli legwebu) lizobiza izikhathi ezingama-2-2.5.

Izibopho zikakhonkolo ze-FOAM zicishe zibe lula futhi kube lula futhi isixazululo kunzima ngabo ukulungiselela into, ngoba izingxenye ezithile kanye / noma imishini iyadingeka. Kulula ukusebenzisa ukuxubeka okulomile nge-polystyrere foam crumb. Ukhonkolo onjalo uqhathaniswa ngokushesha okukhulu futhi cishe awunciphise.

Photo: Saint-Gobain Weber

Ukuqondanisa kokugcina kuyadingeka ngokushesha, ngoba ukusebenza kwesixazululo se-liquid akwedlule amahora ama-2. Ngakho-ke, kuyadingeka ukulungiselela ngokucophelela ngaphezulu komsebenzi: Ukunquma ukwehla okuphezulu kweleveli (a) nokufaka iplastiki yamaphuzu beacons (b). Isixazululo sisakazeka kahle ngaphezulu kobuso (b), kepha kufanele 'sisize' i-rakel scraper futhi asuse ama-bubble omoya nge-roller yenaliti. Isendlalelo sokuqeda sizoma kusuka ezinsukwini ezimbili kuya kweziyisikhombisa

Endlini yephaneli yango-1970-90

Ezindlini ezandisiwe (9-17), ezakhiwe kusukela ekuqaleni kwawo-1970s, ukugcwala kuqoqwe kusuka kumapuleti ukhonkolo aqiniswe nxazonke ngobukhulu obungama-220 mm. Isikali sikakhonkolo singagcwala izikhukhula, kepha kwesinye isikhathi abakhi babeka umqulu wepakethe futhi bathela i-linoleum ngqo ekuqedeni, ngandlela thile bashelela umehluko umehluko wezinga.

Ezakhiweni eziningi zophahla zisesimweni esigculisayo, ngakho-ke kuvunyelwe ukuhlela uthayela omanzi wephansi. Kodwa izikhuthazo zamapuleti azivaliwe nhlobo, ngaphandle kwalokho, ukhonkolo ukhombisa imisindo eshaqisayo, ngakho-ke, ngaphambi kokuthulula ukhonkolo, kuyadingeka ukubeka ukhathi wekhaphethi we-hydraulic ovuthayo wezinto zokwakha "AKUFLEX Super", "mbuzon-100 hydro "Futhi ama-analogue abo afanelekile.

Uma ukwehla okuphezulu kwe-Overlap kwehla yi-20 mm (okungukuthi, ubukhulu obudingekayo bengqimba elisezingeni eliphansi bungama-40 mm noma ngaphansi), isendlalelo sesisekelo senziwe ngesisombululo sensimbi ngaphandle kokuqiniswa kwensimbi. Emakamelweni amamanzi, ngeke kuvimbele ukwengeza isengezo se-hydrophobic, isibonelo i-CC 92 (Cerisit) noma uhlobo ("Sasi" uhlobo).

Ngobukhulu obaliwe be-screen ngaphezulu kuka-40 mm, ukhonkolo okhanyayo (uthi, ukhonkolo we-clamzite, ubuningi bawo buka-1.5-1.7-1,.

Kanye namanzi muva nje, okubizwa ngokuthi yi-semi-tiests esenziwe ngesisombululo senhlama esenziwe ngenhlama enesixazululo se-polypropylene fibers. Zilukhuni ngokushesha futhi ziqinile ngokwanele, kepha kunzima ngokwengeziwe ukuvumelanisa ingxube obukhulu neze-viscous, ngakho-ke kufanele ubheke ungqimba olulodwa (kuze kube ngu-20 mm) we-liquid levelvel, njenge-vetonit 5000 (ama-vetonit 5000 (amaTeton.vetonit ) noma i-CN 68 (Cerisit), noma ukugaya ingaphezulu ngomshini okhethekile.

Photo: "DNT"

Lapho ufaka ama-lags, kuyadingeka ukuvumelanisa ngokuphelele. Ngale njongo, thayipha ama-wedges asethiwe, kanye nezisekeli eziguqukayo - Plastiki

Photo: "DNT"

Ukuxhaswa okwethembekile kwensimbi ethembekile

Photo: "DNT"

Izembatho eziningi zesimanje zibekwe esisekelweni esiqinile okungezona nzima ukudala ngosizo lwe-plywood obukhulu

Photo: "DNT"

Amasheya

ISITHOMBE: I-Quick Deck

Esikhundleni se-plywood, ukuqina kwe-chipboard engavikeli kusuka ku-16 mm - kwaqedwa

ISITHOMBE: I-Quick Deck

Ukunyakazisa izinhlangothi ezinde zamapuleti, ngisho nokuhlinzekwa ngemifino kanye nama-crests, kufanele kutholakale ekusekelweni (i-lag)

ISITHOMBE: I-Quick Deck

Chipboard ngaphandle kwe-coating

Photo: Knauf.

Lapho ufaka i-screed eyomile, i-knauf iqala ukusakazeka kwifilimu ye-polymer bese ibekwa ezindongeni zeteyipu yonqenqemeni, okuphazamisa umsindo wokushaqeka nokwehlela kusuka ezindongeni zezindonga nokuphikisana nalokho

Photo: Knauf.

Photo: Knauf.

Emva kwalokho, amatshe obumba olulinganisiwe alala

Photo: Knauf.

Imigqa yamatshe amatshe anama-lightouses kanye nokubusa okude nge-bubble level

Photo: Knauf.

Ngaphezulu kokubuyiselwa emuva, isisekelo esiqinile esivela kuma-superlists amancane we-knauf noma izinto ezikhethekile zaphansi zifakiwe

Photo: Knauf.

Amahlaya ahlakazwa yi-mastic futhi abeke ukwakheka kwe-Knauf-Figen GW

Photo: "Soundgard"

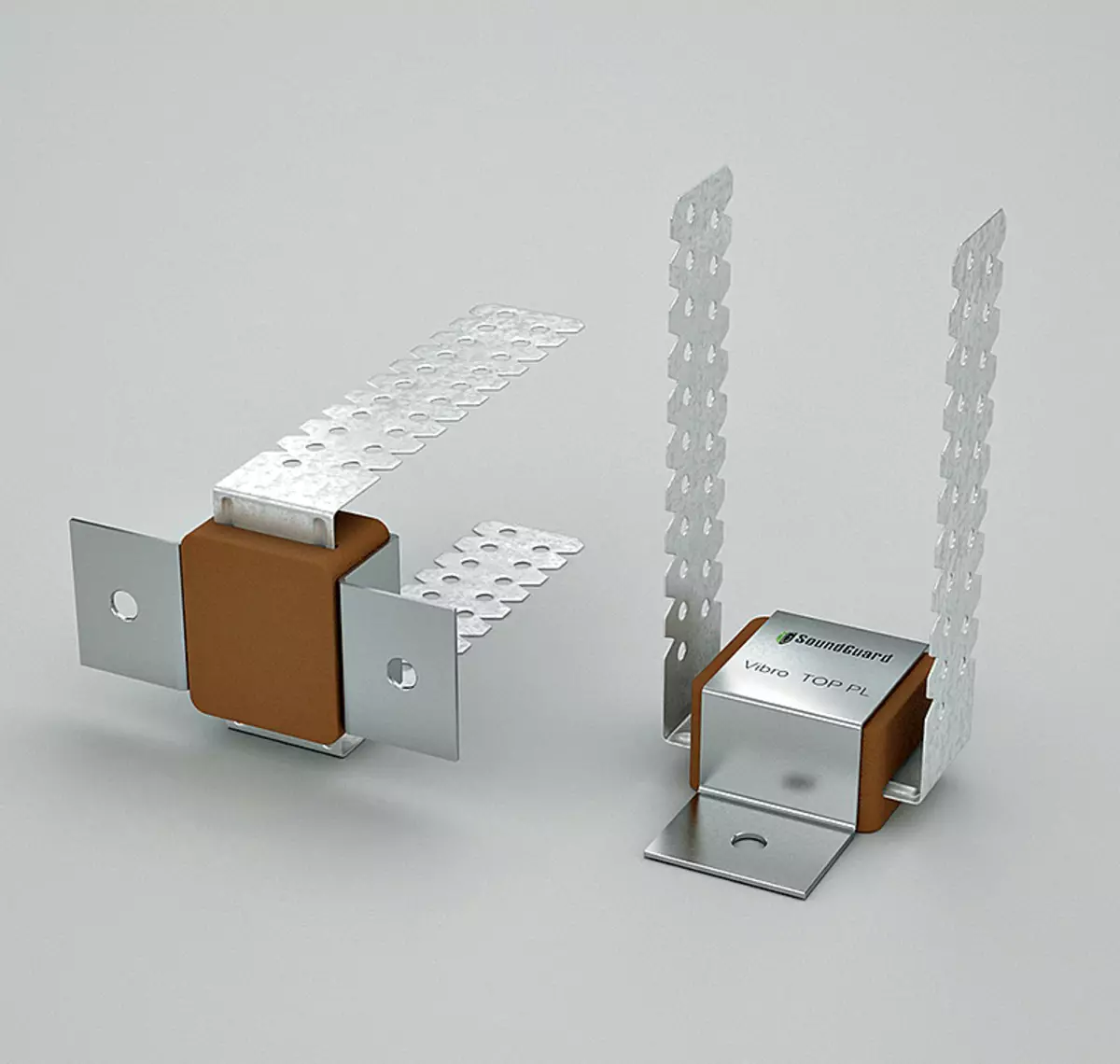

Ngokufanelekile, lapho ufaka i-lag, isithandwa esinerabha "umcamelo" kufanele sisetshenziselwe, okuvimbela ukusakazeka kokudlidliza, futhi kufanele kube nezinto zokunciphisa umsindo phakathi kwama-lags

Photo: "Soundgard"

Photo: "Soundgard"

Photo: "UMaxfort"

Amaminerali wool slabs

Photo: "intambo"

Amaphaneli we-Multilayer

Photo: Texa.

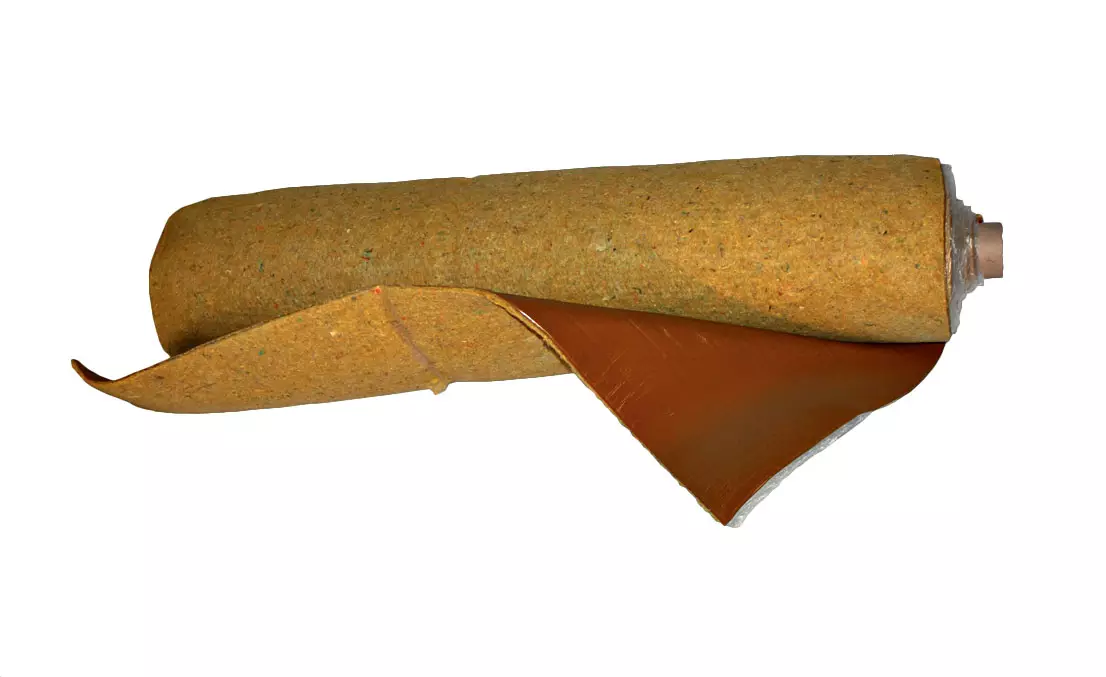

Ama-substrates ahlanganisiwe

Photo: Vladimir Grigoriev / Burda Media

Izindleko ze-Parquet zibiza kakhulu ngenxa yesitayela sokugoqa isikhathi. Ukukhala ngakunye kufanele kuthathwe ku-plywood

Photo: "I-Parquet Hall"

Photo: Vladimir Grigoriev / Burda Media

Kungcono ukusebenzisa izingoma ezenzelwe ama-moppmer. Lapho-ke ingaphezulu liphenduka kabili

Photo: I-Legion-Media

I-Surface Roopy enamafutha akhethekile

Photo: Kährs.

Isisekelo esibushelelezi nesihlala isikhathi eside - isimo esiyinhloko sokubukeka okungenakuqhathaniswa nempilo ende yenkonzo yesembozo saphansi

| Uhlobo lwesisekelo | Iqembu lokhuni (lags + plywood noma i-chipboard) | Ukuqoqwa kokugeleza (Clay Gravel + GVLV noma i-CSP) | Isisulu esimanzi |

| Amandla engqimba | Phezulu, imvamisa ngaphezulu kwe-20 MPA | Phansi, ngaphansi kwama-20 MPA | Okuphakathi noma okuphezulu, kepha kuphela ngokusetshenziswa okufanele kwesendlalelo sokuqondanisa |

| Ukuzwakala komsindo | Egculisayo (ukuncishiswa komthelela ngomsindo nge-10 db engaphezu kwe-10) lapho usebenzisa ama-fasteners okuvuselela ama-vibration kanye nokutatazela phakathi kwama-lags we-messproofing mats | Kuhle (ngaphezu kwe-15 db) ngisho nobukhulu obuncane bama-40 mm | Kuyanelisa noma kuhle lapho usebenzisa i-vibration-fixing substrates |

| Ukushisa kokushisa | Uyanelisa lapho ugcwalisa isikhala phakathi kwama-basalt ukotini lags | Egculisayo (ngobukhulu be-50-60 mm) noma okuhle (ngaphezu kwe-80 mm) | -Ngalungile |

| Ukumelana nomswakama | Ephansi. Akunconyelwe ukufaka isicelo kumakamelo amamanzi. Njengomthetho, ngemuva kokuthi "uzamcolo" kufanele ushintshe isisekelo | Ephansi. Ayikwazi ukusetshenziswa emakamelweni ama-wet | -Phezulu |

| Impilo Yenkonzo | 15-25 | 20-30 | Ngaphezulu kwama-50. |

| Intengo (kufaka phakathi umsebenzi wokukhuphuka), hlikihla. / M2 | Kusuka ngo-1800. | Kusuka ngo-650. | Kusuka ngo-1100. |