Kuyaziwa ukuthi lapho uqeda noma yimuphi umphezulu, umphumela wokugcina uncike kwikhwalithi yokulungiselela isisekelo. Lokhu kuyiqiniso ikakhulukazi ngezitezi okufanele kungabi bushelelezi futhi kuzinhle kuphela, kepha futhi kunokwethenjelwa, okungukuthi, ukubekezelela imithwalo ebalulekile yemishini

Kuyaziwa ukuthi lapho uqeda noma yimuphi umphezulu, umphumela wokugcina uncike kwikhwalithi yokulungiselela isisekelo. Lokhu kuyiqiniso ikakhulukazi ngezitezi okufanele kungabi bushelelezi futhi kuzinhle kuphela, kepha futhi kunokwethenjelwa, okungukuthi, ukubekezelela imithwalo ebalulekile yemishini

Uma kukhulunywa ngokulungisa indlu yasemadolobheni, ngaphansi kwamagama athi "okusalungiswa phansi" kuvame ukuchaza ukwakheka okukhona phakathi kokuqothuka kwe-haring slab kanye nokuqeda phansi phansi. Kuyaqabukela ukwenza ngaphandle kwalolu bambiseki, okokuqala ngoba ukugqama cishe akukaze kube bushelelezi ngokuphelele. Noma ngabe awekho amaconsi abonakalayo phakathi kwamapuleti, isheke elilula le-level, njengomthetho, libona amagagasi "kanye nokucwaswa okuzoholela kuma-defillas. Ngaphezu kwezendlalelo zokuqondanisa ze- "Cake" of the Draft Floor ingafaka i-hydro, umsindo, ukushisa okufaka ukufudumeza kanye nokungaphansi. Ngabe bahlala bedingeka? Ungayinciphisa kanjani izindleko zokuklama futhi usheshise ukwakhiwa kwayo ngaphandle kokulahleka kwekhwalithi? Yimaphi amaphutha ajwayelekile ekusunguleni phansi phansi phansi? Sizozama ukuphendula le mibuzo sisebenzisa i-athikili, njengesibonelelo esibonakalayo esiyingqayizivele, izimo ezine zangempela ezivela emkhakheni wokwakha.

|

|

|

|

Ngaphandle kwezindleko ezikhethekile

Kungenzeka ukuthi zingaki izinto ezingaphikisa ukuthi "kungabizi kakhulu" futhi "uMsizi ukhokha kabili," kodwa, iningi labantu lisafuna ukunciphisa izindleko zokulungisa, kodwa hhayi nakancane, kodwa ngenxa yezizathu zenhloso. Lapha namaqhawe endaba yethu yokuqala - umndeni osemusha onezingane ezimbili - kwadingeka ngilungise indlu enamakamelo amabili endlini yochungechunge lwe-P-44T, nginesabelomali esinqunyelwe. Abalingani banqume ngokushesha ukuthi bazosebenzisa izinto ezingabizi, kodwa ezisebenzayo kakhulu futhi eziqinile. Ngengozi, kuhlelwe ama-lamimore alengayo ama-lamimor ahlelwe phansi ezindaweni zokuhlala nasezindaweni zokugezela, nasendlini yokugezela ekhishini ukulele amatshe e-porfelian angenamthungo. Amakhosi amenyiwe ahlolisise lokho okusobala okuthathwe ngesikhathi kwakhiwa indlu, futhi kulinganiselwa isimo sawo esanelisekile. Ngokuyinhloko, izimbobo ezikhethiwe zingabekwa ngqo kukho uma bekungengenxa yezinga leleveli (cishe 8mm), kutholakale "amagquma" ambalwa "amancane" ashile "emakamelweni.

|

|

|

|

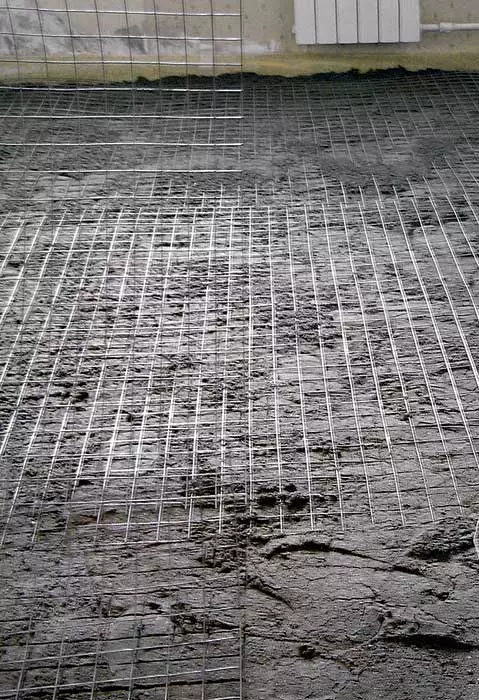

Idivaysi yokushisa kwamanzi ekhishini: Ku-slab alllap kwafakwa amanga amanzi kusuka kwifilimu ye-polyethylene, ukushisa kanye nama-mats ahlanganisiwe avela ku-fiber zokwenziwa kanye nokuqinisa igridi yomgwaqo (a); Ngaphezulu kwazo kwakukhona amapayipi amanzi kanye nolunye ungqimba lwegridi (b); Isixazululo sathululelwa, kwathi lapho isicubu somile, saqala ukubeka amathayili (g). Lo mklamo uhlinzeka ngokuncipha okwengeziwe komsindo oshaqisayo ngo-25- 30db, futhi uma kukhona ungqimba owengeziwe ovela ku-basalt fiber (b) - ngo-36DB

|

|

|

|

Ukufakwa kwe-SoundProofing "entantayo" ye-SoundProofing Floor: Ibekwe ezingxenyeni ezimbili ze-matte kusuka kumaminerali fiber "shuyap-C2", ihlelwe eceleni kwezindonga "e); Ngaphezulu kwama-mat abeka ungqimba lwe-sandcant esomile ngobukhulu obungu-30mm (e); Kuqiniswe i-Screed (G) futhi wayibeka ngesisombululo somugqa ofanayo kakhilimu-efana (ungqimba oluncane - 20mm) (ama). Lo mklamo uqinisekisa ukwehla okwengeziwe komsindo ongemuva ngo-42DB futhi uvikele ukungeniswa kokungena ngaphansi komsindo womoya, yize kubi kakhulu ngenxa yokuhanjiswa komsindo odongeni amaphaneli odonga.

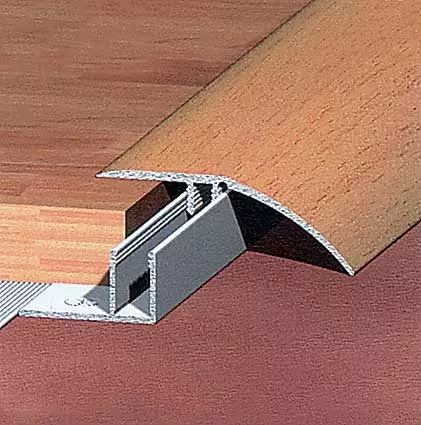

Abakhi bathembisa ukuqeda konke ukulimala kwimishini eyodwa, ingxube yokuzilinganisa ibhodlela phezulu. Babize amanani (ama-ruble angama-550. Okwe-1m2) futhi masisha ngokushesha izindleko zomsebenzi - ama-ruble ayizinkulungwane ezingama-22. Umnikazi wabuza ukuthi akunakwenzeka yini ukwenza ukulungiswa kwasendaweni kwe-screed. Abasebenzi bavumile lokhu, bathi umphumela wawukude nokuhle. Ama-prorrusions adutshulwa yi-perforator ene-nozzle ekhethekile. Ukuvala ukujula nokuqeda "umkhawulo", wasebenzisa izinga le- "Wetonite 5000 yokwakha Rus", eRussia). Indawo asetshenziswa ngayo yayicishe ibe ngu-6m2. Umsebenzi wawufanele ama-ruble ayizinkulungwane ezinhlanu kuphela. Kuyiqiniso, kwamukelwa indawo evundlile ephaseji, kodwa ithambeka, kodwa ngokushelela, ukuthi ngemuva kokubeka phansi phansi, yacishe yabeka phansi (abasebenzi baxwayisa ngokuthi ibha ye-lamiate "kodwa ayizange kwenzeke). Kodwa-ke, ngokuphelele ngaphandle kwe-chagrin namanje akuzange kubiza. Isitezi sokubhuka kwe-porcelain sasingaphansi kwe-4mm ngezansi kwe-laminate ngenxa yomehluko ekubumbeni kwengubo. Ihlaya bekufanele livale kahle. Ngaphezu kwalokho, ukufakwa komsindo oshaqisayo kulezo zindawo, lapho i-porcelain Shoneware ifakwe khona phansi, ihlala ingagculisi.

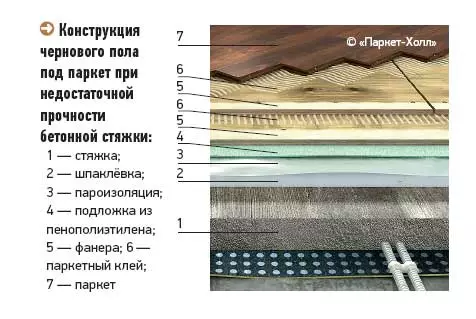

Umbono we-Specialist

Phansi okuhlukile kwethulwa izidingo ezahlukahlukene zesitezi esibi. I-APPIAN, i-tile kwesinye isikhathi ingabekwa ngqo ku-ceramzite-ukhonkolo screen, yize ingaphezulu lokuthi ingaphezulu lalesi sikhathi linokuphinda okufakiwe. Inkosi enolwazi akunzima ukuqeda ukungahambi kahle okuncane, ukuguqula ubukhulu bengqimba enamathela. I-Linoleum ivunyelwe ukubeka ngqo kwisigaxa se-sand-ukhonkolo, uma umswakama wawo ungadluli ku-9%. I-Lamiate idinga i-cork noma i-polyethylene engezansi ngaphezulu kwesisu esibushelelezi. I-Wooke Flooring - I-Piece Parquet, ibhodi enkulu ne-parquet - inhlabathi eyengeziwe. Kubo, kuyadingeka ukuhlomisa isisekelo esithembekile nesibizayo esibizayo se-lag kanye / noma ubukhulu beplywood.

Andrei Khrustalev, Umqondisi we-AY DI STRIINA

Izitayela nezinkinga zokomisa

Azikho izindaba zezindaba ezifundeni ezintsha zokuhlela ifulethi. Umnikazi wezindlu ezihlale yena uqobo. Ngasikhathi sinye, unesibopho sokunakekela omakhelwane abavela ngezansi, okubandakanya ungqimba olunemisindo ekwakhiweni. Indaba yethu yesibili imayelana nokuthi akudingekile kanjani ukugcwalisa uthayi lwesihlabathi sikasimende.

|

|

|

|

|

|

Idivaysi ye-ceramic ekhonkolo yekhonkolo ekhishini: I-slab ye-slab ye-swele yaqhuma i-polymer-bitumen mastic, nasezindaweni zezigxobo nokuhlangana kwazo kwakungewona amabili, futhi ngezingqimba ezintathu (a); Usebenzisa izinga le-laser, ufake ama-linthouses kusuka kumaphrofayili ensimbi akhethekile kwikhambi (b, b); Lapho ikhambi liqandisiwe, lihlola okuvundlile nge-bubble level (G); faka ungqimba oluyinhloko lwe-ceramzitobetone (d); Ezigabeni eziningana, kufakwe i-liquid cement-sandy solution (e)

Umnikazi wefulethi elibanzi endlini ye-monolith-brick entsha wayefuna ukusebenzisa i-parquet exegayo njengendawo ephambili. Kepha esikhundleni sokubonisana ngokushesha nochwepheshe kulokhu okuqukethwe, baphuthume ukumema i-brigade yokuqedwa kokusalungiswa - ukuqondaniswa phansi kwezitezi nezindonga, zimi ngaphansi kwe-wiring. Ngemuva kokuphela kwale misebenzi, ukwakhiwa kwakuqandisiwe cishe unyaka, kwabe sekuqala enye inkampani. Lapho ngifika phansi phansi, amakhosi aphansi weqembu, eqhuba ukuhlolwa kwezizathu, ahlukaniswe kuphela ezandleni zawo. Ukuhlola ukusebenzisa i-sclerometer kubonise ukuthi amandla okucindezela ungqimba olungaphezulu kungaphansi kwama-mpla angama-50; Kwezinye izindawo, ukhonkolo wambozwa ngegridi yemifantu, kwathi kwelinye lamakhona, lesi sigameko saphakanyiswa ngenxa yokubulawa kwalesi sisekelo, kwathi lapho selaba khona, kwazwakala ukuthi kuqhume izithulu. Kwakungekho ukufakwa okuzwakalayo ngaphansi kwethayi.

|

|

|

|

Ngaphambi kokukhalipha, udinga ukunisela ukugqagqana. Lokhu akusebenzi kuphela kwizindawo "ezimanzi", kodwa futhi nasefulethini lonke. Ukuvimbela amanzi kudingekile ngokuyinhloko ukuqinisekisa ukuthi amanzi aqukethe ukhonkolo kukhonkolo ayingene ama-microcracks kanye namalunga amapuleti futhi awavelanga ophahleni komakhelwane abahlala ngezansi. Okufanayo, i-slab eyomile yokugcwala iyakwazi "ukukhipha" amanzi kusuka engxenyeni engezansi kusuka ku-settlest - ngenxa yalokho, ukhonkolo uzokuthola amandla adingekayo. I-hydraulic eyenziwe yasungulwa ngokuzayo: Uma kwenzeka incane, ngesikhathi sokuvuza okufihliwe, ngeke inikeze amanzi ukungena ngaphakathi.

Nquma imbangela eyinhloko yeziphambeko bekungenzima: ukhonkolo omiswe ngokungalungile. Isisekelo asikhonjwanga - ngenxa yalokhu, ungqimba olungezansi; Azange amboze ngaphezulu futhi azange anisele amanzi - ngenxa yalokho, ungqimba olungenhla lwalahleka ngenxa yalokho. Ukwelapha okungalingani (emaphephelo kwenzeka ngokushesha) kwaholela ekuguqukeni kwama-castings. Ukusatshalaliswa okugcwele kwesisulu esivele esikhona kwakuwumsebenzi onzima kakhulu, ngakho abakhi bathembisa ukuyilungisa. Ukulungisa zonke iziphambeko ezitholakele, kwathatha isikhathi esiningi. Kwakudingeka ukuthulula izingqimba ezintsha zengxubevange ye-cent-polymer, nakwezinye izindawo ukushayela izimbobo bese uthele isixazululo se-liquid ezimpahleni. Ukulungiswa kwe-1M2 Pread Floor, umnikazi kufanele akhokhe ama-ruble angama-450., Okungukuthi, cishe ingxenye yesigamu semali yokuphosa i-Screed entsha.

|

|

|

|

Ukwakha indawo ebushelelezi yezimbozo zobukhulu obuhlukile, kungcono ukuhlinzeka ngokuhlinzekelwa kwangaphambili kwangaphambi kwezindawo ezisalungiswa. Uma lokhu kungenziwa, imibundu kuzodingeka ifakwe (a).

Amapuleti wobuso we-isover enziwe asetshenziswa ubuchwepheshe be-TET anokufakwa kwamanzi okuphansi futhi alungele ukufakwa kwesiteki sokuqala (b).

Umbono we-Specialist

Ikhono elinomsindo lokugqagqana libonisa inkomba yeleveli encishisiwe yomsindo oshaqisayo ngaphansi kwalomklamo (lnw) lapho usebenza imishini evamile ye-LNW, i-stove esebenza kangcono i-LNW. Ngokusho kwe-SNIP 23-03-2003 "Ukuvikelwa komsindo", ezakhiweni zokuhlala zesigaba B (ezinezimo ezintofontofo) Le nkomba akufanele idlule i-58DB akufanele idlule i-58DB. Maye, ezakhiweni ezijwayelekile, ukugqagqana kokuqaqa akuvamile ukwanelisa lesi sidingo. Kodwa-ke, kwanele ukubeka ngaphansi kwesendlalelo se-screed of the ferting matering Ngakho-ke, endabeni yamaminerali wool slabs ngokukhuluphaka kuka-30- 40mm, lokhu kuncipha kungafinyelela ku-38DB. Uma kukhulunywa ngezitezi emasontweni, umsebenzi wokwenza ngcono ukufakwa komsindo kuyinkimbinkimbi kakhulu. Ukuyixazulula, kufanele ufake ama-lags we-vibrooporas ekhethekile.

UNikolai Eremin, Inhloko Ye "Acoustics"

Izinkampani "Saint-Goben Eau

Ukuxubeka okuhlukile okunjalo

Ngokuqondanisa okuqediwe kophahla lwe-slab, kanye nokhonkolo wesihlabathi noma ukhonkolo-ukhonkolo, izixazululo ezilungiselelwe kusuka kuzingxube ezikhethekile ezisuselwa kuso usimende ne-gypsum ngezithasiselo ze-polymer zisetshenziswa. Bahlukaniswe baba uPutty nobuningi. Owokuqala uzunguzela ngamanzi ukuze uguquguqulwe ukuguquguquka futhi usebenzise i-spatula ebanzi; Kusuka kwesibili, kwenziwa isixazululo se-kewuthi, esikwazi ukusakazeka ngaphezulu kobuso uqobo. Lawo macala agxile kuma-beacons aboniswa ngeleveli (imvamisa kakhulu laser). Ukukhethwa kwendlela ethile yokubuka komhlaba kuvame ukuncike ezintweni ezikhohlisayo, njengokuthanda komuntu kwamakhosi enkampanini ethile yokulungisa. Ngokuqondene nezimo zenhloso, izitezi eziningi zibiza zibiza kakhulu, zifuna ngokwengeziwe kwikhwalithi yomsebenzi: Isixazululo silukhuni ngokushesha okukhulu, ukuze sibe nesikhathi ngokulinganayo siwusebenzise futhi ususe ama-bubble omoya, amakhono ochwepheshe ayadingeka. Kukholelwa ukuthi izixazululo eziningi zilungele kangcono ukulinganisa izindawo ezibalulekile. Enye i-nuance inqwaba yemakethe engelona iqiniso kanye nokuxutshwa okwedlulele kwezitezi eziningi (isikhathi sazo sokugcina angeqi izinyanga eziyi-6, futhi kwesinye isikhathi kunezinyanga ezintathu kuphela). Ungqimba olungaphansi lwesixazululo esingesihle alunawo amandla adingekayo acindezelayo. Ngaphezu kwalokho, ngemuva kwalokho kungacindezelwa ngokwengxenye kusuka kukhonkolo ukhonkolo, noma kuhlanganiswe ne-primer yokuxhumana. Kusongela inkathazo enkulu, ikakhulukazi uma ukuqedwa okubizayo okubi kakhulu kufakwa esisekelweni, ngoba-ke akunakwenzeka ukukususa ngaphandle kokulimaza.

|

|

|

|

Ukufakwa kwesitezi esisalungiswa kususelwa kumakamu avela e-Stone Wool "Flor Batts" (RocKwool): Esitofini faka amataks (a, b); Kwakunezendlalelo ezimbili zePlywood 12mm zikhulu futhi zigcwele ibhodi lemiphunga (b, d). AbakwaMates banamandla amakhulu acindezelayo (3.5 MPA), ngakho-ke umklamo umelana kalula nesisindo sefenisha nokulayisha lapho uhamba, uhlinzeka ngokuncipha okwengeziwe ku-36 dB

Umbono we-Specialist

Imvamisa, umthelela wemishini esisekelweni saphansi esenziwe ngokuhambisana ne-parquet esicwaningisi noma iBhodi enkulu edlula imithwalo ejwayelekile (ukuhamba, isisindo sefenisha). Ngakho-ke, izakhi zesisekelo (screed, ungqimba kusuka plywood) kufanele amelane ngempumelelo nemizamo yokwehlukana nokugoba. Lokhu kumele kubhekwe lapho kuklanywa phansi okunzima. Ngengozi, amandla okucindezela i-cent-sand screed kufanele okungenani ibe yi-15 MPA, amandla esicothayo sengqimba ephezulu ye-putty okungenani i-plywood, i-pured to the screed, is okungenani 3/4 of the coation nye. Ekwakhiweni kokuthumela, umbuso wokushisa kanye nomswakama egumbini kufanele futhi ubhekwe, ukutholakala kwezokuxhumana kwi-Screed, efformation Seams ekuqedeni nakwamanye ama-nuances.

UVadim Smirnov, umqondisi wezobuchwepheshe we-Parquet Hall

O, leli Belch!

Izakhamizi zezindlu eziningi ezitholakala ezitezi zokuqala zingena ebusika. Enye yezizathu zalokhu ukufakwa okuphezulu okushisayo kokugqwala okuphansi okuhlukanisa efulethini kusuka engaphansi, izinga lokushisa lapho lidlula ku-10 ° C. Sizotshela ngokulungiswa kwendlu enamakamelo amathathu kwiNdlovu yePanel ye-II. Abanikazi bayo (Chau abathathe umhlalaphansi abasebenzayo) bashiwo ngokushesha inkampani yokwakha isidingo sokufakelwa phansi kwaphansi futhi bavuma ukudela ama-70mm okuphakama kwegumbi ukukhwela "okufudumele". Ochwepheshe benkampani belulekwe ukuthi babeke amathayili egumbini lokuphumula kanye nezindawo "ezimanzi", zibeka ama-mats ngentambo yokushisa ngaphansi kwayo, nakuwo wonke amakamelo ukuvimba phansi ngoboya be-basalt (lapha kuhlelwe ukusebenzisa ibhodi le-parquet njenge-coating). Abanikazi bafuna phansi ukuba babushelelezi ngokuphelele, ngaphandle kwemikhawulo evikelayo. Ukuze wenze lokhu, kwakudingeka ukubala ngokunembile ubukhulu bokuthi "uphaya" amabili ahlukene futhi acabangele ukungahambi kahle kwesisekelo.

|

|

|

|

Ukufakwa kokwehla kwesitezi ku-Lags eguqukayo: Ama-Lags atholakala ku-300mm ukukhuphuka, ngenkathi usebenzisa ithempulethi ekhethekile (a); Ukudonsa kwangaphambilini phezu komgodi epuletini yophahla, okunamathiselwe kuwo ama-dowel-nails of lags (b); Faka imigoqo ngokuvuselelwa, ukuguqula ukuphakama kwemikhono esekela ngopulasitiki, bese uklebhula amashidi e-plywood angavunyelwe nge-15 mm (b); Saqala ukubeka indawo yangaphandle (g)

Okokuqala ephaseji nasekhishini kwaphonsa i-ceramzite-kukhonkolo kakhonkolo ngobukhulu be-70mm. Ngenkathi egcinwe, baqala ukufaka izinsizakalo kuwo wonke amakamelo (iPallenge Pallet abayithintanga indlu yokugezela. I-Conment-Polimeriric Ngamanzi "Glims-Waterstop" (Glims, Russia) isetshenziswe ku-Cement-Polymer wantproofing (ama-glims) ukuvikela ukufakwa okuvela emphuleni wamanzi okuqhamuka egumbini elingaphansi. Ngemuva kwalokho kufakwe ama-lags enziwe emigoqweni egcotshwe ngengxenye yesiphambano ye-40x40mm, enesinyathelo sika-300mm. Banamathele ekuzidonseni njalo nge-500mm. Ngokuqondanisa kwangaphambilini, kusetshenziswe amadayisi avela ku-Plywoof Plywoof, futhi anembile - amapuleti ensimbi enziwe ngensimbi. Phakathi kwama-lags, ama-mat aqhamuka amatshe okukhanya amatshe ama-batts (rockiwool, ukukhathazeka kwamazwe omhlaba) ambozwe lonke umklamo ngefilimu le-polyethylene, elizovimba ukugeleza kwezinhlayiya zezinto. Ngaphezulu kwakusetshenziswa ezingxenyeni ezimbili ze-FSF Brand of the 12mm obukhulu (ephansi) no-9mm (phezulu), kushiya izikhala zobubanzi be-3-5mm emaceleni (ngaphandle kwalo amashidi, bazokhuphuka komunye nomunye futhi ukhuphule). Izikhala zesinxephezelo sobubanzi be-10mm bashiye bazungeza umngcele wamakamelo okuhlala futhi emhlanganweni ophansi. Phambili, bavalwa ngamapulangwe, kwelesibili, isinxephezelo se-cork sasinamathisela phakathi kwe-slit. Mat ngentambo yokushisa ibekwe ngaphansi kwethayela (ku-glue ungqimba). Izindleko ze-1m2 zesafeso langalo okhuni kanye ne-plywood kwakungama-ruble ayi-1250, futhi 1m2 of the floor floor (kufaka phakathi intengo yemishini kagesi) - ama-ruble angama-2700.

Umbono we-Specialist

Lapho kudingeka ukufakwa kwezitezi phansi, sivame ukuncoma ukusebenzisa ama-lags lokhuni, phakathi kwaso ungabeka noma yiziphi izinto zokufaka okushisayo: amashidi e-polystyrere Foam, i-matte kusuka ama-mineral fiber, amapuleti athambile ama-fibrous, ukugcwaliswa kwe-polyurethane Foam. Inzuzo yobumba no-foams ukuthi ayinangqondo: uma amanzi ezokwehla ekwakhiweni kwesitezi esisalungiswa, ngeke kubambezelwe lapho, futhi udlule ngokukhululeka. Ngenxa yalokho, izakhiwo zokhuni zizohlupheka kancane. Ngokuqondene nengxenye ebalulekile yezinto ezingcolile, amanzi abambezeleka isikhathi eside kuma-pores abo, okuholela ekubunjweni kwesikhunta kanye nesikhunta, kanye nokuwohloka okuyinhlekelele kwe-microclimate efulethini. Uma ukwakheka kwesitezi esinguhlaka kufaka phakathi ungqimba olufudumele olufudumele, asikukhuthazi manzi isitofu sokweqa okuhlanganisiwe. Enye inguqulo ye-Heat-Insulating Floor Floor is the sand-ukhonkolo ekhonkolowe ngaphezulu kwamashidi e-foam noma i-cork yezobuchwepheshe ngobukhulu okungenani okungenani 30mm.

USergey golovochko, umphathi we-programmer

Awukho umthetho wotshwala

Sengiphetha, sizotshela ngokubuyisela ukwakhiwa kwesitezi esihlakalwe endlini esakhiwe ngama-60s. Xx in. Into yokuqala eyayishaya abanikazi abasha befulethi kwakuwukudonswa kwengxenye lapho behamba. Ukususa phansi phansi kwakudala, kwathola i-slab ye-slab elahlekile. Phezu kwalo kwakulele, isikhala phakathi kwabo sagcwala ingxube yesihlabathi, izicubu kanye nodoti wokwakha. Ufa ngaphansi kwama-lags, noma asuka ezindaweni zawo, noma ngabe abolekile, nemigoqo ngokwayo yacishe yaphenduka isijobelelo. Ngokushesha kwacaca ukuthi kwakudingeka ukushintsha lonke uhlelo.

|

|

|

|

|

|

Montage of a screed esomile kubuchwepheshe be- "Knauf": Indiza yasakaza ifilimu le-polyethylene, "uhlangothi" lwalunamathiselwe ezindongeni ezizungeze umngcele wekamelo kusuka ezintweni ezidangele - a); wathela ungqimba we-clamzit encane, wayiphonsa ngokucophelela (b) futhi ivezwe (c); okuqoqwe phansi kusuka kumaphampu we-gypsum fiber (D), okwenza ukuba kube ne-sealant (e) emalungeni; Ngokuqinisa amapuleti komunye nomunye ngezikulufo ezijwayelekile ezisetshenzisiwe (e)

Kodwa-ke, akulula ukuthola uhlobo oluhle futhi olubizayo lwenguqulo ye-screed. Ama-Lags "anyamalale" ngokwawo: Ukwakha isisekelo esithembekile, adinga ukugxila ngokuqinile, futhi ubukhulu be-slab phakathi kwezimbambo walingana no-95mm kuphela, futhi lapho edonsa izimbobo ngaphansi kwe-dowel, kukhona ubungozi ngokuhlukana nakho. Ukulayisha ukunqamula okudala kwethayi ekhonkolo kwakuyingozi nje ... IVitoga iyeke ukukhetha eqenjini elomile le- "OP 135" ("Knauf", Russia). Kuyipuleti yama-gypsum-fiber angqimba ama-puzzle amabili afakwe ngaphezulu kwesendlalelo esingaphansi (isihlabathi sobumba). Uma amalunga amapuleti alondwa, ingaphezulu lizobe lilungele ukunamathela i-linoleum - lisehlali elinjalo elikhethe abanikazi kulo lonke indlu (i-tile entsha yabekwa ngaphezulu kweyakudala). Ngobukhulu be-80mm, isisindo se-1m2 eyomile screed inge-30kg kuphela. Umklamo uhlukanisa umsindo oshaqisayo - Uma kusetshenziswa, i-LNW incishiswa ngo-18-22DB (kepha i-RW inyuka kancane - 2-4DB) kuphela. Izindleko ze-1m2 eyomile screed yayingama-ruble ayi-1050.

Ukubheja esihlahleni

Ibhodi lokuhlela libonga inkampani ethi "Ay Di Striy", "I-Parquet Hall" Rus "," Indoda Endala Ukukhishwa ", Ukufakwa Kwama-Old HortAbych", i-KNAUFT, i-Rockwool, iTarkett icela usizo ekulungiseni okuqukethwe.