Ukufaka ubuchwepheshe bohlelo lokushisa olungaphansi olungemuva lokushisa phansi izigaba ezingenhla zezindlu namakamelo ezakhiweni ezinama-overlaps "abuthakathaka".

Photo e.lichina

Izithombe ngu-A.MedDev

Izakhi zezinhlelo "ezomile" zokushisa kwangaphandle

Njengomsebenzi wokushisa afudumeza amaphampu apholile, asebenza kahle kakhulu afudumele aya ngokuya esetshenziswa kamuva nje

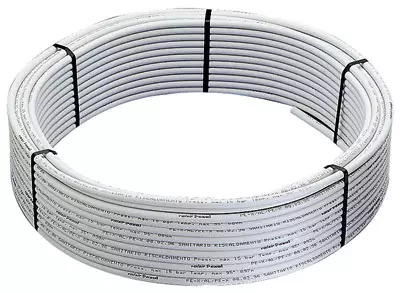

Amapayipi e-Metal-Polymer wezinhlelo ezifudumele phansi

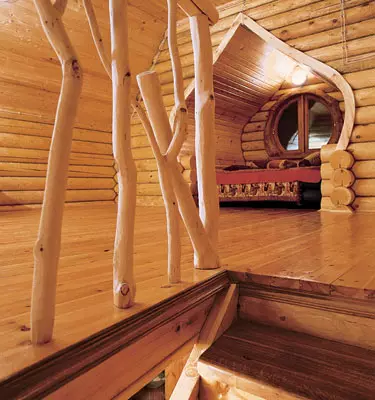

Ukushisa phansi okuphezulu kwezindlu zezwe lokhuni noma amanye amakamelo ezakhiweni ezinama-overlaps "abuthakathaka", njengomthetho, kwenziwa kusetshenziswa ukushisa kwe-radiator. Kodwa-ke, kungenzeka ukuwafudumeza ngendlela ehlukile, ngokwesibonelo, ngosizo lwesistimu engasindi efudumele. Mayelana nale ndlela encane ehlelweni lokufudumeza kwangaphandle eRussia, sizotshela.

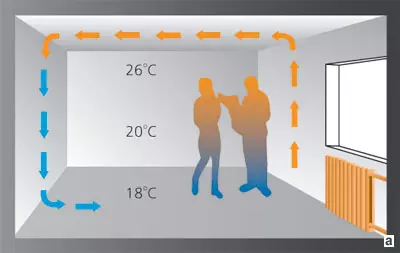

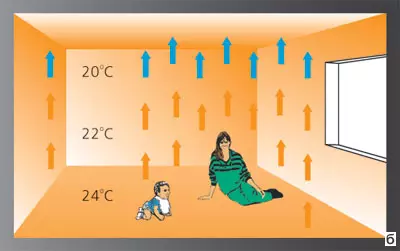

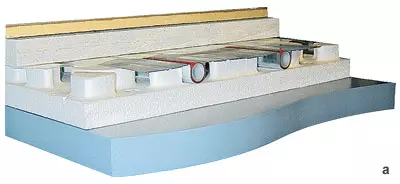

Okunye okuhlukile

Ngokushesha kufanele sithi phansi okufudumele usebenzisa ukuthandwa kufanelekile. Ngemuva kwakho konke, ngale ndlela yokufudumeza igumbi, ingaphezulu lingenayo ifenisha ngaphansi kwemilenze ibala ukushisa. Ama-Ophones isilinganiso esihle kakhulu samazinga okushisa aphezulu egumbini. Isibonelo, emakamelweni okuhlala angu-24-26c phansi kanye no-20-22C ezingeni lekhanda. Umbuso wokushisa onjalo mhlawumbe awukwazi ukugcina amadivayisi wokushisa wendabuko. Yebo, ngokungafani nezinhlelo ezijwayelekile, indawo efudumele ayiqali ngomoya wokujikeleza wokujikeleza, ngakho-ke, umoya awugcwele uthuli. Kuyaphawulwa ukuthi ukufudumeza kwangaphandle kuyathandeka kakhulu empilweni yabantu asebekhulile nezingane, ikakhulukazi abahlushwa yizifo ezahlukahlukene zomuntu.Kodwa-ke, ngokuvamile abathuthukisi kufanele balahle ukusetshenziswa ezindlini zabo zokushisa kwangaphandle. Isizathu yikhono lethrekhi elanele lokugqwala, ikakhulukazi ezitezi ezingaphezulu kweyokuqala. Ngempela, ngokwesiko kusetshenziswa ekwakheni futhi kuvame ukubekelwa yikhasimende njengekuphela kokunokwenzeka, "amanzi" wokushisa kwangaphandle kungukukhohlisa. Uma kudalwe ngaphezulu kwesendlalelo esimnyama sokufakwa kwe-thermal (50-200mm), i-screen yokulinganisa ivame ukuthululwa, bese kuthi, enye isendlalelo sikakhonkolo, ngaphakathi lapho kufihlwe khona ukushisa. Okulandelayo, isithiyo se-vapor kanye nesembozo esiphansi sokuqeda (tile, parquet it.p.). Ubukhulu obuphelele be "Ikhekhe" elinjalo lifinyelela ku-150-300mm, lilayisha isisindo esinesisindo esingu-250-300kg / m2, futhi kwesinye isikhathi ngaphezulu. Lesi sisindo sisetshenziswa kuphela ezakhiweni, lapho kwenziwa khona izitezi zekhonkolo ezinamakhonkco anomthamo ongenayo ngaphezulu kwe-500-600kg / m2. Ubuze, ngokhuni noma eminye imiklamo efanayo ehambisa umthwalo obalulekile ivame ukungakwazi.

Ngaphezu kwalokho, uhlelo lwe- "olumanzi" alugcini nje ngokugqagqana, kepha kwezinye izikhathi ngokubonakalayo "kudla" ukuphakama kwamakamelo. Lokhu kuyabonakala ikakhulukazi ezakhiweni ezakhiwe kabusha zokwakhiwa kwama-70-80s. ngekhulu leminyaka. Ngokuqondene nezindlu zezwe, endabeni yokulungiswa kwezimonyo, akubona bonke abanikazi abakulungele ukulinda inyanga yonke, ngenkathi ungasebenzisa uhlelo lokushisa (kusukela ngesikhathi esidingekayo sokumiswa okuphelele kwekhonkolo).

Maye, bambalwa kubathuthukisi bethu abakwaziyo ukuthi kanye nohlelo lwe- "olumanzi" lokushisa kwangaphandle kukhona "owomile", noma abesabi. Ihanjiswa ekushishweni kozakwethu esindayo. Esikhundleni sekhonkrithi ekhonkolo kuleli cala, kusetshenziswa amapuleti akhethekile wensimbi noma i-foil, kusatshalaliswa ukushisa kusuka kukhefu lokushisa noma ngentambo yokufudumeza noma ngqo ku-coating phansi. Umehluko omkhulu phakathi kohlelo lwe- "Dry" kusuka ku- "Wet" ukunciphisa umthwalo onqenqemeni (ngokwesibonelo, ezakhiweni zokhuni ezingaba ngu-30kg / M2, ezicishe zibe ngaphansi kwezikhathi zekhonkolo). Sesebekele inketho "eyomile" esigabeni sokuqamba indlu yezwe, ungakwazi ukunciphisa amandla ajwayelekile, ukwenqaba izakhiwo ezingadingekile. Ungenzi ngaphandle kohlelo lwe- "Dry" futhi, uma kunesidingo, ukunciphisa ubukhulu besitezi "ikhekhe". Ukuphakama kwayo okuncane ngale ndlela yokushisa kusuka ku-13 kuye ku-50-60mm. Ukuntuleka kwenqubo "emanzi" kunciphisa kakhulu isikhathi sokufakwa. Futhi masinyane emva kokuphothulwa kwayo, uhlelo lulungele ukusebenza.

Uhlelo lwe- "Dry" ngenxa yezici zokwakhiwa kwalo (amandla afudumele, angadluliselwa endaweni efudumele yezakhiwo ezifudumele, imvamisa ayifinyeleli ku-100w) kuvame ukusetshenziselwa ukufudumeza okwengeziwe. Kwenza amakamelo apholile, afudumele phansi ekushiseni okunethezekile ngokomzimba. Kodwa-ke, ezifundeni ezinesimo sezulu esiphansi, kusetshenziswa inketho engesibindi futhi njengohlelo oluphambili lokufudumeza (ukwanelisa isidingo sokufudumala kwawo wonke amakamelo efulethini noma indlu yezwe). Ibangelwa imishini enjalo ingafakwa egumbini lezingane, ehhovisi, egumbini lokuhlala, igumbi lokulala, egumbini lokulala namanye amakamelo.

Ubuchwepheshe obunconyiwe besikhathi esinconyiwe busetshenziswa ngqo ezitezi zokhuni ezikuLags, kanye nobuchwepheshe obusebenza kuzo zonke izinhlobo zezitezi ezikhona ngesisekelo esiqinile esinezisekelo eziqinile (i-ukhonkolo slab, phansi okuguqukayo kusuka ku-plywood IT.p.). Ukwakhiwa kwakamuva kubizwa ngamanani. Futhi abanye bangadalelwa bobabili ngokusekelwe kumapayipi we-polymer (ngokuhlinzekwa okupholile) kanye nokusebenzisa izintambo zokushisa. Okulandelayo, sizokhuluma ngezindlela zokupheka ze- "Dry" Zokwenziwa Kwezindlela Zokushisa Kwangaphandle.

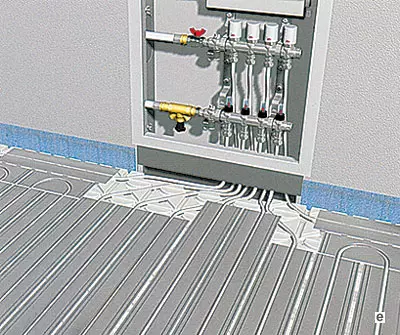

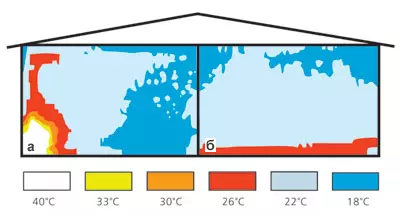

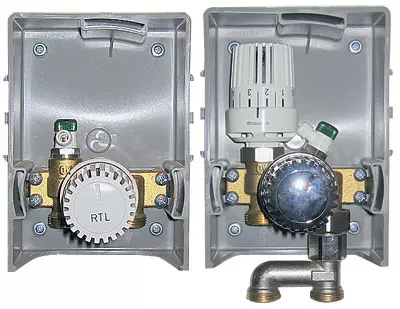

I-anatomy yokushisa

Ngokuthola "ukondliwa" kwezinhlelo ezingenamanzi ekotishini, kufanele kunikezwe i-boiler, umqoqi, amaphampu okujikeleza (ngokujikeleza ngakunye), ithangi lokunwebeka, kanye nohlelo lokulawula. Ngokuvamile, indawo ephezulu yendawo efudumele yaphansi yi-thermostat (iyunithi yokuxuba). Kuthinta izinga lokushisa lamanzi endaweni yokujikeleza, ukuxubana emanzini e-boiler noma komunye umthombo wokushisa (lokushisa kuya ku-90c) ngezilinganiso ezifunwayo (izinga lokushisa kuya ku-90c) nokubuya ohlelweni olufudumele lwaphansi ("ukubuyela emuva"). Dala i-contour egumbini lapho amanzi ashisayo esevele exhunyiwe ku-boiler, nokwakhiwa kabusha kwekamelo, ungakwazi, ngokwesibonelo, usebenzisa idivaysi ekhethekile yokufaka i-oventrop.

Amanzi afudumele

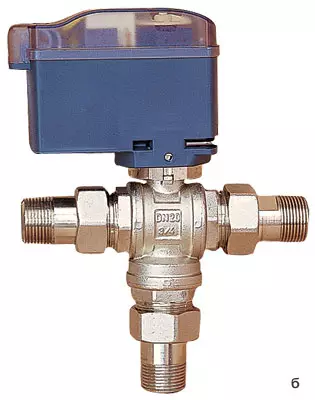

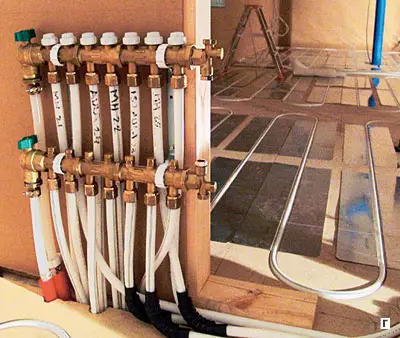

Ububanzi bamaphansi "elomile" elifudumele ngokuhlinzekwa kwezindlu eziyimfihlo ezipholile ezifakwe izinhlelo zokushisa kwamanzi ngokujikeleza okuphoqelekile. Izinto eziphambili zokushisa okushisa zihlala isikhathi eside futhi zifaka kalula amapayipi e-polymer kusuka ku-polyethylene noma i-flux yensimbi (indiza yensimbi), kanye nomthombo wamapholi afudumele (avame kakhulu amanzi), okuvame ukudlula, adlule amapayipi alele phansi , unikeza ukushisa okuphelele noma i-substrate.

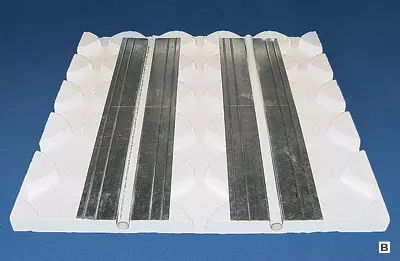

Ingxenye eyinhloko yezinhlelo eziningi "ezomile" ezinepayipi eline-coolant-metal (aluminium, galvanized) nge-groove yesembozo esiminyene sepayipi. Zimbozwe nge-70-90% yendawo evuthayo yaphansi (amapuleti atholakala ngaphansi kokuqedwa kwama-coating noma ngaphansi kwe-substrate). Ngakolunye uhlangothi, bangena esikhundleni sikakhonkolo, bahlinzeka ngokusatshalaliswa komfaniswano okuvela kumapayipi anamanzi ashisayo ngaphezulu kobuso bonke. Amapuleti angahlukaniswa izingxenye, ezenziwe ngokwezifiso kanye nobude begumbi. Ngokusobala kusuka kumenzi, noma ngabe bane-bloduration yokufaka okusheshayo, noma okuyisisekelo kunqunywe izingcezu ngensimbi ye-fitter (hacksaw, isikhafu sensimbi it.p.). Ngokubeka kahle, amapuleti e-aluminium awafaki amathuba okubukeka phansi kwesitezi se-zebra (ukushintshwa kwamabhendi akhuphukile futhi ancishisiwe amazinga okushisa aphezulu, okuholela ekulimaleni kwe-coating (okuholela ekulimaleni kwe-coating (okuholela ekulimaleni kwe-coating ).

Izinhlelo ze- "Dry" zibonakaliswa ubungane bezemvelo (akukho ukuphuma) kanye nomnotho. Izindleko zokushisa ze-coolant zivame ukuba zincane, ikakhulukazi uma zisetshenziswa ekotishini, i-boiler yegesi yemvelo, noma iphampu ye-thermal. Kodwa-ke, izindleko zokuqala zokwakha ukufakwa okunjalo zivame kakhulu futhi zibaluleke kakhulu. Ngakho-ke, ukudalwa kohlelo olunomqondo wamanzi egumbini elilodwa nendawo ye-10m2 kuvame ukubalwa ngama-ruble angama-21500-40500. futhi nokuningi. Kodwa-ke, uma ukufudumala kuhlelwe emakamelweni amaningana endlu yezwe, izindleko zincishiswa kakhulu: Ungenza inani lama-ruble angama-215-90. Yendawo eyi-1m2. Ngaphezu kwalokho, usebenzisa uhlelo olunomqondo wamanzi, kunzima ukuthola amandla athile adlula ama-60-80w / m2.

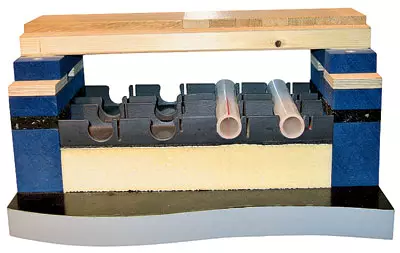

Ukubonisa ubuchwepheshe bokufaka Uhlelo lwe- "Dry" ngokuhlinzekwa okupholile esitezi sokhuni ezihlahleni Cabanga ngohlelo lwe-WRSBO (i-ANTOR, FINNLAND). Ingasetshenziswa kuleli cala lapho ibanga phakathi kwezingezo ze-lag angeqi ku-600 mm.

Ekuqaleni, kuyadingeka ukubeka ukufakwa phakathi kwama-lags, imvamisa lolu voya lwamaminerali. Eduze kwe-Lags Ound Board Board ngesigaba esingu-9522mm ngokuqukethwe komswakama kwe-10%. Kufanele kube negebe phakathi kwamabhodi (okungenani angama-25mm, inani elithile linqunywa lapho siklama lonke uhlelo). Ngobude beBhodi, kuyadingeka ukusika ngaphezulu kwe-30cm kusuka ezindongeni eziguqukayo ukushiya isikhala samahhala sokuguqula amapayipi ngakolunye uhlangothi (lapho ubeka i-contour). Ezinhlangothini ezingenasisekelo, eziseduzane nezindonga zegumbi, ukuvumelanisa phansi, kuyadingeka ukuzulazula emabhodini ngesigaba esingu-9522mm.

Ngemuva kokuphothula kwale misebenzi, kwakhiwa ama-lags ukuze kufakwe amapuleti okushisa okushisa okushisa a-aluminium. Kufanele zibekwe ngokuya ngohlelo lokubeka amapayipi, kusukela odongeni lwangaphandle, bese ubopha ngezipikili ukuze ama-grooves amapayipi acwiliswe ezigatsheni eziphakathi kwamabhodi futhi akhiwe ngemali. Okulandelayo, khweza ipayipi leWirsbo-Pepex nge-20mm. Ngemuva kwalokho, engxenyeni ye-vaporiozolation ungqimba, kufakwa ipuleti eliwugqinsi lwe-Pupil 2mm (kubuchwepheshe bokuqala, kusetshenziswa amapuleti akhethekile) noma amapuleti kusuka eRussia (lokhu okuvame ukusetshenziswa eRussia, uma kungenzeki ukuthenga i-chipboard yangempela ). Ungqimba lwamapuleti ubeka ngaphesheya kwamabhodi ngezigaba ezingama-600mm ububanzi (alingana nokujika kwe-lag) nokulungisa ngezikulufo, izingodo kanye nama-grooves adinwe. Isembozo esiphansi sokubhoboza singasetshenziswa yibhodi yezocansi, i-parquet, tile.

|

|

|

|

|

|

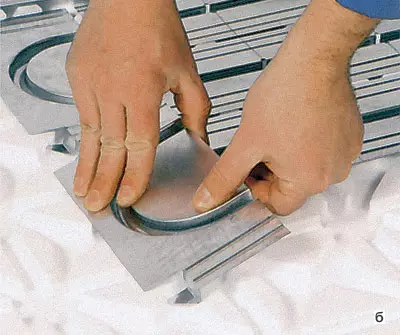

Uhlelo lwePolystyrene (Oventrop): Ukufakwa kwamapuleti okuhlalela amapuleti okushisa kumakamu anobukhulu be-25mm (a); Ukufakwa kwamapuleti abuyela emuva (b); Ukubeka i-capipe ye-metal-propaper (b, d); Ukudlula kwamapayipi ngomgodi odongeni (d); Imibuthano yokushisa iyabekwa futhi ixhumeke kubaqoqi (e). |

Ubuchwepheshe obuhlukahlukene obuchaziwe buvumela ukubekwa kwephaphu le-lamined ngqo ukuvalwa ngamapuleti we-aluminium we-vapor, ngaphandle kwe-chipboard. Ngasikhathi sinye kuzoba nokuwina okuncane ekuphakameni kwekamelo, kepha ukwakheka kwesisekelo kumele kuthuthukiswe. Ingxenye yesiphambano yamabhodi afanele awaphansi kwama-7028mm. Kade, kufanele banciphise lonke igumbi (kusuka odongeni liye odongeni) bese bebethelwa kuwo wonke ama-lags, ngaphandle kokuphela. Ngesikhathi sokufakwa kwamapayipi, iziphetho zamabhodi zisukuma, izihibe zamapayipi zidonswa ngaphansi kwamabhodi, ngemuva kwalokho amaphethelo abethelwe ukugcwala ngezipikili. I-lamondid parquet efakwe emabhodini.

-Qobo Uhlelo lwe-Nonstil Polystyrene Inikeza inkampani iThermotech (Sweden). Imishini ifakwe isisekelo esibushelelezi, esihlanzekile neyomile. Uma kunesidingo (emakamelweni anomswakama ophezulu noma lapho ubeka isisekelo), phansi kumbozwe ungqimba lokufakwa kwe-vapor kusuka ku-polyethylene engazweli ka-80-100 mkm. Amapuleti aphezulu akhethekile e-polystyrene akhethekile anamandla we-200KPA. Ngaphezu kokulahleka kokushisa kwesitezi, ukushuba kwabo kungaba ngu-30, 50 noma 70mm. Ama-grooves abunjiwe amapuleti e-aluminium anesinyathelo sika-150mm (ubukhulu bepuleti - 12001450,5mm) noma 300mm (12002700,5mm).

Amapuleti abekwe emiphongolweni ye-polystyrene slabs ngaphandle kwe-gluing. Amapuleti anamabala ane-slage acindezela umshini omncane acindezele ipayipi le-thermotech kusuka ku-polyethylene 172mm (lapha nokuqhubeka: udonga lwamadayimane odongeni). Ine-coating ekhethekile evimbela izikrini ezingenzeka ngesikhathi sokusebenza ngenxa yezingxabano. I-parquet ejwayelekile noma ye-lamined, kanye nebhodi le-parquet elinobukhulu okungenani obungu-9mm obekwe ngqo kumapuleti we-aluminium ngokubekwa kwamakhadibhodi noma okugwetshiwe. Lapho usebenzisa i-linoleum, i-ceramic tile noma i-pvc coating, kulandela amapuleti e-aluminium okokuqala faka ukubhidlizwa kwamashidi e-GVL (ngokusho kobuchwepheshe, kunconyelwe ubuchwepheshe be-Knauf, iJalimane.

Ukuhluka kohlelo lwe-Thermotech's Polystyrere olubizwayo okuthiwa Uhlelo lwe-Fortation (Ukuvuselelwa) . Amawele asetshenziswa amapuleti e-polystyrene anobukhulu obungama-20mm kuphela ngamapuleti we-aluminium avele afakiwe. Ungayikhetha le nketho, ngokwesibonelo, ngesikhathi sokwakhiwa kabusha kwekotishi, lapho ufaka ukushisa esitezi esidala (kusho, uhlanganiswe nama-cellamic tile).

Vele, izingxenye zezinhlelo eziphansi ze-polystyrene zokushisa kwaphansi azikhiqizi kuphela i-thermotech. Isixazululo sobuchwepheshe esithakazelisa kakhulu sinikeza i-giacomini (italy). Uhlelo lwayo likuvumela ukuthi ubeke i-tile ngaphandle kokusebenzisa i-chipboard noma i-GWL. Esikhundleni sazo ngemuva kokufaka amapuleti e-polystyrene, amapuleti okusabalalisa okushisa avela ku-galvanized, amapayipi axhumene ne-polyethylene pe-x161,5mm noma amapuleti wensimbi engu-162mm) amashidi we-galvanized steel 500250 noma 500500mm abekwe ku-vaporizet. Bakha isikrini se-monolithic metal phansi, sihlinzeka ngokusatshalaliswa okufanayo kokushisa futhi cishe akunabukhulu 'bekhekhe'. Ukuqedwa kwama-coating kufakwe nge-glue ekhethekile ye-tile. Ngokungangabazeki, amasistimu we-polystyrene floor flooring of norom, roth, oventrop, uRehau (wonke amaJalimane), Henco (Belgium (Belgium) IDR kufanelekile. Singakhuluma nalawa mamodeli ngemininingwane eminingi, futhi nakanjani sizokwenza ngokuzayo.

Ngaphezu kwalokhu okuchazwe ngenhla ngenhla, kunezinye izinketho zokuhlelwa kwezinhlelo ezifika emsebenzini. Isibonelo, i-polystyrere ivame ukushintshwa yi-chipboard ekhethekile, lapho ama-grooves asikwa khona ekusakazeni amapuleti asabalalisa ukushisa. Kuyavela Isistimu yokhuni ephansi . I-Screen yeqembu layo eyomile screed ifaka phakathi isendlalelo esisodwa samashidi we-GVL ngobukhulu obungama-10mm. Izesekeli zezinhlelo eziphansi zokhuni zikhiqizwa yi-noror, i-thermotech idr.

Kulula kakhulu ukuyifaka Uhlelo lwe-Hypotocarton Flooring (Ubuchwepheshe obunjalo bethulwa emakethe yaseRussia eminyakeni embalwa edlule nge-pexep, eFinland). Esicaba (lokhu ngokuyisisekelo!) Indawo eyomile ibekwa emsipha e-Shrauntint omelana (uma kunesidingo, isithiyo somusi) kanye nendlela yokubeka ipayipi iyasetshenziswa. Ngaphezu kwalokho, kukhona imichilo yepulangwe. Zihlotshiswe nge-screw sisebenzisa izikulufo zokuzishaya kungqimba lokuqala le-HCCV ukuze ama-grooves wepayipi eliboshwe ngo-12mm. I-Heating Circuit yenzeka, ilungisa ipayipi ngeplastiki izingxenye zepulasitiki kanye nezikulufo. Okulandelayo, i-groove eneshubhu ivaliwe ngesisombululo se-gypsum. Ngemuva kokumsoma, kufakwa olunye ungqimba lwamashidi alomile amelana nomswakama, bese kuthi lapho u-steamproofing futhi uqede ukunamathela (ngokwesibonelo, ama-laminate).

I-Parquet ngaphandle kwama-caprises

Izinga lokushisa elingaphezulu kwesitezi se-parquet esivuthayo akufanele lidlule ku-27c (kufaka phakathi amakhaphethi). Uma kungabi ngaphezu kwe-15-20% yendawo egumbini, khona-ke ukulondolozwa kokhuni oluphansi, kufanelekile ukugcina izinga lokushisa le-23c ezindaweni zamahhala, ezizohlinzeka ngamazinga okushisa komoya acishe abe yi-21c.

Ngokomthetho Ohm

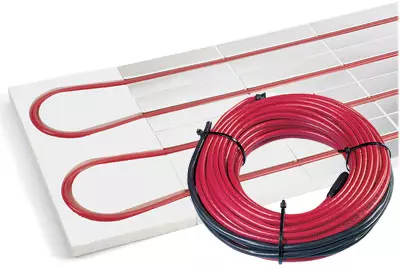

Umthombo wokushisa ohlelweni lokushisa olungaphansi lukagesi luvame kakhulu ikhebula lokushisa elifudumele litholakala emklamweni wephansi. Uhlelo lunikwa amandla yi-voltage ka-220v / 50hz. Isetshenziselwa ukufeza induduzo ephezulu kakhulu emakamelweni anezitezi ezibandayo, ezitezi zokuqala zezakhiwo, kanye nanoma yiziphi ezinye izindawo zokuhlala nezingahlali. Isibonelo, ekhishini, izingane, igumbi lokuhlala noma umtapo wezincwadi. Sebenzisa amasistimu angenamabhizinisi kagesi ezindlini zezwe nasezindlini zasemadolobheni.

Izinzwane zemishini enjalo zifaka amandla aphezulu aphezulu we-thermal (kufika ku-100W / M2) nezindleko zokuthenga eziphansi. Ngempela, uhlelo lokufudumeza lukagesi lwe-1m2 luzobiza ikhasimende ngama-ruble angama-2700- 4050, ngenkathi esendaweni eyi-10m2 ungabeka ngo-675-810. / M2. Uma indawo yokubeka ikhebula ilinganiswa ngamashumi namakhulu amamitha-skwele, izindleko zokuqala zincipha kakhulu. Kepha inani eliphelele lohlelo lukagesi kuyo yonke insizakalo yalo kungenzeka liphakeme kakhulu kunezindleko zamanzi, ngenxa yezindleko eziphakeme zikagesi.

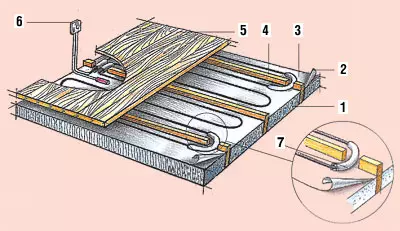

Uhlelo kagesi ezitezi zokhuni eziseLags. Amandla wekhebula lokushisa akufanele adlule kwe-10W / M (60-80W / M2), ngaphandle kwalokho ingozi yokulahla kwenyuka. Isisekelo sePunch sokubeka ikhebula lokushisa kulezi zinhlelo, kusetshenziswe igridi yokuqinisa insimbi, ibekwe ngaphezu kokufakwa okushisayo phakathi kwama-lags. Usayizi weseli le-mesh awekho ngaphezu kwe-5050mm, ububanzi bentambo bungaphansi kwe-2mm. Isimo esibalulekile: ukuxhumana okungamukeleki kwekhebula lokushisa ngokufakwa okushisayo kanye nezakhiwo zokhuni. Ibanga kusuka kukhebula elinqunyelwe kugridi (ukulungiswa - njalo nge-30cm) ukuze libe yi-lag kufanele okungenani libe ngu-30mm, futhi lihlanganise okungenani i-50mm. Ngokuwela ikhebula ne-lag, kuyadingeka ukuqhubeka kuwo (ububanzi bungama-30 mm, ukujula okungama-25 mm) futhi kuyaphoqelelwa ukukuvikela nge-aluminium foil noma ezinye izinto ezingezinhle. I-slot yamanzi ingenzeka kungabi ngaphezu kwentambo eyodwa yekhebula lokushisa.

Kuyadingeka ukunakekela ukuphepha kukagesi. Lapho ubeka ikhebula lokushisa ngqo kugridi yensimbi, okwedlule kufanele kuxhunywe noma kuhlelo lokulinganisa olungalingani, noma kumqhubi we-zero okuvikelekile (ngokuya ngezidingo ze-GL.1.7PEE).

Ukulawula uhlelo lubekwe esitezi sokhuni esiseLags, ama-thermostators afanelekile kakhulu, afakwe inzwa yokushisa eyakhelwe ngaphakathi egumbini elingakhelelwa ngaphakathi futhi exhunywe kwinzwa yokushisa yaphansi. Inzwa enjalo itholakala emklamweni wephansi futhi ilinganisa izinga lokushisa komoya phakathi kwama-lags. Ukuxhumeka kwenzwa ye-thermostat kufanele kwenziwe kuphela ngocingo lwethusi olubekwe endaweni yensimbi noma eluhlaza okonakele enombala onobubanzi obungu-10-16mm (kuya ngohlobo lwezinzwa). I-thermostat inconyelwe ukufakwa egumbini elivuthayo endaweni evuthayo engu-0.5-1,5 m kusuka endaweni yaphansi. Ukubhoboza i-Perching Coang kulungele i-parquet yephakethe, ibhodi eliphansi lensimu yezinkuni eziqinile, i-multilayer plywood ngokubekwa okulandelayo kwe-laminate i.p.

Phakathi kwabakhiqizi bemishini ama-Kits, angasetshenziselwa ukubeka phansi phansi okufudumele ezitezi zokhuni ezihlahleni, kuyadingeka ukugqamisa i-Ennesto (Finland); Kunengqondo ukunaka inqubo ye-devi (denmark), i-ceilhit (Spain), i-Kima, i-thermo (i-obrlenium) idr.

I-Wood Floor Heating eLags (Ennsto):

Ukufakelwa oku-1- okushisayo;

2- I-Aluminium Foil (Ngokuzithandela);

Igridi eli-3 lokuqinisa;

Intambo yokushisa engu-4;

5-floor floor;

6-Thermostat;

7- Ukudlula kwe-lagi.

Kumaphansi abushelelezi ezinhlobo ezahlukahlukene angasetshenziswa. I-Floor Heading System kagesi . Lokhu kufakwa, kufanelekile kuphela amakhethini, kepha futhi namakamelo amadolobha, okunikezwayo emakethe yaseRussia Devi. Amashidi aphezulu akhethekile e-Devicell omile akuvumela ukuthi uthole uhlelo lwentambo olufudumele lwaphansi lwe-devi ngaphansi kwe-liminate noma i-parquet bese uqala ukuyisebenzisa ngosuku olufanayo. Umthamo we-Muntrum Execcient - 100w / M2.

Lapho kudala phansi okufudumele, kuyadingeka ukulungiselela isisekelo esisetshenziswa ngokucophelela yi-vacuum cleaner. Ngemuva kwalokho, udinga ukubola amashidi wokufaka we-devicell womile endaweni evuthayo ngokuya ngomdwebo olungiselelwe kusengaphambili. Amashidi wokubeka (100050013mm) enziwe nge-polystyrere expred expystyrene, amelana nodoti ngaphansi komthwalo ongafika ku-3670 kg / m2, futhi ahlome nge-aluminium coatis efakwe ku-aluminium. Badinga ukuhlanganiswa nomunye ngama-latches epulasitiki (afakwe kwiphakheji). Amashidi abekwa endaweni eyodwa ukuhambisa ama-grooves ngekhompiyutha yawo. Uma kunesidingo (ngokwesibonelo, ngefomu lekamelo eliyinkimbinkimbi), zingasikwa yi-electroll Q noma elinye ithuluzi, libanikeze izindlela ozifunayo.

I-Deviflex Heating Cable (DTIP-10 ne-DTIE-10) Ukucindezela okukhanyayo kufakwe ku-grooves okwenziwe kumashidi anezikhuphu eziyi-100mm. Ngokubambisana, ukufakwa kwesendlalelo sokushisa esiphansi kufanele kwenziwe eshidini elikhuphukayo le-cutout futhi ngosizo lwe-aluminium scotch ukulungisa ishubhu elihlanganisiwe kanye nokuhlangana kwekhebula lokushisa. Kulezo zindawo lapho kufakwa khona amashidi okushisa kanye nekhebula lokufudumeza, kukhona amashidi aqinile avimbela umswakama noma amashidi weplywood (ngokuqondakala phansi).

Esigabeni esilandelayo, hlola ukusebenza kohlelo kanye nokuxhunywa ngogesi ngokuya nge-PUE nemiyalo yokufaka ikhebula lokufudumeza kanye ne-thermostat. Umhlangano wesitezi sokhuni kufanele senziwe ngokuya ngemiyalo yomenzi (Ake sithi, Spread substrate kusuka ku-polyethylene bese ubeka i-laminate). Uhlelo lungasetshenziswa cishe kuzo zonke izinhlobo zokhuni oluphansi.

Isixazululo esicashile

Ngaphezu kwezinhlelo ezingenamsebenzi ezisuselwa kukhebula lokufudumeza, kungasetshenziswa i-heater floor floor. Lokhu okukhethekile okukhethekile (akukho ngaphezu kwe-1 mm obukhulu) kukhiqizwa ngendlela yombukiso. I-roll icishiwe, ifilimu ihlelwe phansi kweteyipu, futhi ngaphezulu kwanoma yisiphi isembozo saphansi (ukhaphethi, i-linoleum idr). Ekufakweni kwe-heater, imizuzu embalwa iyahamba. Ubukhulu besitezi abukhuphuli. Uhlelo lusebenza kunethiwekhi kagesi. Izinga lokushisa elifunekayo lisethwe kusetshenziswa i-thermostat. Uma ufisa, i-heater ingadluliswa ngokushesha endaweni entsha.

Ibhodi lokuhlela ngiyabonga u-Devi, encesto, henco, i-oventrop, uReau, uRehau, uRehau kanye nokushisa kwempahla yezithombe ezinikezwe nokulungiselela i-athikili.