Sibutsetelo semakethe yempompo yokushisa nezinhlelo zamanzi ashisayo: izici zobuchwepheshe zemishini, imigomo yokusebenza nokufakwa.

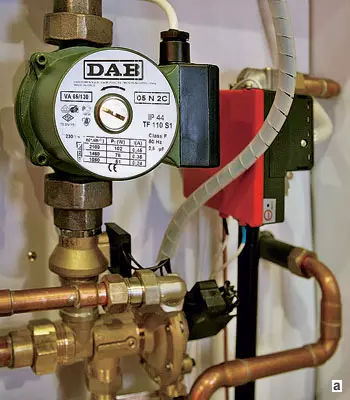

A- vaDA65 / 130 (DAB) ngengcindezi enkulu ka-6.3 m futhi ahlinzeke nge-3M3 / h;

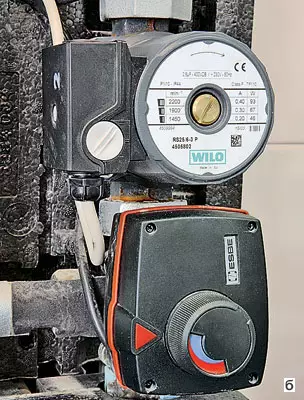

I-B-Three-Speed Pump ye-Star Rs25 / 6P Uhlelo Lokushisa (iWilo) inengcindezi engu-6m kanye nokudla okungu-3,5m3 / H

Akunjalo kudala, uhlelo olunokusakazwa okuphoqelekile kwe-coolont lwalunabanikazi bezindlu ezizimele okungenakufinyeleleka. Imishini enjalo yasetshenziselwa kuphela kumanethiwekhi kamasipala nakumasipala. Manje, ngezidingo ezandisiwe zokududuza kanye nokusindisa amandla, amaphampu wokujikeleza asetshenziswa kabanzi empilweni yansuku zonke.

Kungani udinga iphampu yokujikeleza?

Ngokwemithetho ye-physics, ukusebenza kohlelo lokushisa kwamanzi kususelwa ekusakazweni kwe-coolant. Ukuze amadivaysi okushisa anikeze inani elidingekayo lokushisa, ukusakazwa okupholile kumele kwanele (lokhu kunqunywa ukubala). Ukujikeleza kwe-coolont kungaba ngokwemvelo futhi kuphoqelelwe. Imvelo iyatholakala ngenxa yomehluko ekunciphiseni kwamanzi uketshezi olufudumele futhi olupholile, oluphoqelelwe ngosizo lwepompo ekhethekile yokujikeleza.Izinhlelo ezinokujikeleza kwemvelo zidinga ukusetshenziswa kwamafutha okubalulekile ngenxa yesidingo sokugcina izinga lokushisa eliphakeme lamanzi emugqeni wokuphakelayo. Ngemuva kwakho konke, kuphakama izinga lokushisa lamanzi, okungaphansi kobukhulu bayo futhi, ngakho-ke, ngaphezulu kwejubane lamapayipi. Lapho usebenza uhlelo oludumisayo, kunzima ukulondolozela izinga lokushisa elinethezekile ezakhiweni, njengasezinhlelweni ezinokusakazwa kwemvelo kuyinkinga yokusebenzisa i-armostatic avat armature. Kufanelekile ukusho ukuthi phansi okufudumele kuyathandwa namuhla ngaphandle kwephampu yokujikeleza ukusakazwa okungahlomisi?

Iphampu yokujikelezwa kohlelo olushisayo lwamanzi (DHS) liyadingeka ngokuyinhloko ukuze litholwe ngamanzi ashisayo ngokushesha, ukuvula i-crane nganoma yisiphi isikhathi sokwelashwa kwamanzi. Futhi, ojantshi bethawula elifudumele bangaxhunywa ohlelweni lwe-DHW, lapho kudingeka ukusakazwa okupholile ukusakazwa.

Ukuba semthethweni ekuphakamiseni kwamanzi, okuphakamisa amanzi ukuphakama okuthile, ukujikeleza amaphampu kuphoqa kuphela ukuhambisa umbuthano ovaliwe. Umsebenzi wemishini enjalo ukupompa umthamo odingekayo we-coolant, ukunqoba ukumelana kwe-hydraulic kwamapayipi kanye nezinto zohlelo.

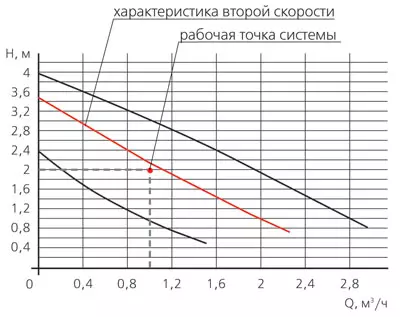

Ukukhetha kwephampu kanye nombono omncane

Amapharamitha amakhulu wephampu yokujikelezwa yingcindezi (H), elikalwe kumamitha ekholamu wamanzi, futhi okuphakelayo (q), noma ukusebenza kukalwe yi-VM3 / h. Ukucindezela okukhulu ukumelana okukhulu kwe-hydraulic kohlelo olukwazi ukunqoba ipompo. Kulokhu, okuphakelayo kwalo kungu-zero. Okuphakelayo okuphezulu kubizwa ngokuthi inani elikhulu kakhulu le-Heat Carrier, engadluliselwa ku-1 HP ukumelana kwe-hydraulic kohlelo, ufuna zero. Ukuthembela kwengcindezi ekusebenzeni kohlelo kubizwa ngokuthi yi-Pump Accient. Kunesici esibi ngesinye isici, ngejubane lamabili nantathu, ngokulandelana, amabili nantathu. I-UNASOSOV enemvamisa eshintsha ngokushelela yokujikeleza kwe-rotor kunezici eziningi.

Ukukhethwa kwepompo kwenziwa, kunikezwe okokuqala kwayo yonke ivolumu edingekayo ye-coolant, ezogingqa ngokunqoba ukumelana kwe-hydraulic kohlelo. Ukusetshenziswa okupholile ohlelweni kubalwa ngokususelwa ekulahlekelweni kokushisa komjikelezo wokushisa kanye nomehluko wokushisa odingekayo phakathi kwemigqa eqondile neyaphendukela emuva. I-Heatlopotieri, nayo, incike ezintweni eziningi (ukuthwala okushisayo kwezinto zokwakha ezifakiwe, izinga lokushisa elikhona, ukuqondiswa kwesihlobo sesakhiwo kumaqembu e-idr elikhanyayo) futhi kunqunywa ukubalwa. Ukwazi ukulahleka kokushisa, ukubala ukusetshenziswa okulungile kokuphola ngokuya ngefomula q = 0.864 / (TPR.t-teb.t), lapho isilinganiso se-q / h; I-PN - Kuyadingeka Ukuthola Ukuhlawuliswa Ukulahlekelwa Amandla wesekethe lokushisa, kW; I-TPR. Izinga lokushisa lokuphakelayo (Direct) Pipeline; I-Treight-Izinga lokushisa ipayipi. Ngezinhlelo zokushisa, umehluko wokushisa (i-TPR-T-Tob.t) imvamisa ingu-15- 20 ° C, ohlelweni olufudumele lwaphansi, 8-10s.

Ngemuva kokucacisa izinga lokugeleza elidingekayo lokuphola, ukumelana kwe-hydraulic komjikelezo wokushisa kunqunywa. Ukumelana kwe-hydraulic kwezinto zohlelo (i-boiler, amapayipi, ukuvalwa okuvaliwe kanye nokuvalwa kwe-thermostatic) kuvame ukuthathwa kumatafula ahambisanayo.

Njengoba ibale izinga lokugeleza kwesisindo se-coolant kanye nokumelana kwe-hydraulic kohlelo, amapharamitha we-lo-ebizwa ngokuthi yiPhoyinti Lokusebenza ayatholakala. Ngemuva kwalokho, kusetshenziswa amakhathalogi abakhiqizi, ipompo iyatholakala, ijika elisebenzayo lalingenalo liphansi kunephuzu lokusebenza. Amaphampu wesivinini amathathu, ukukhetha kuholayo, kugxile esiqwini sesibili ukuze ngesikhathi sokuhlinzwa kunesitoko. Ukuthola ukusebenza kahle okukhulu kwensiza, kuyadingeka ukuthi iphuzu lokusebenza liphakathi kwezimpawu zamaphampu. Kumele kwaziwe ukuthi ukuze ugweme ukwenzeka komsindo we-hydraulic emapayipini, izinga lokugeleza kwe-coolont akufanele lidlule ku-2m / s. Lapho isetshenziswa njenge-antiforee epholile yokuba ne-viscosity encane, ipompo itholwa ngendawo yokubuyiselwa kwamandla ka-20%.

Ukuze kucacelwe, cabanga ngesibonelo sokukhethwa kwepompo yekotishi nendawo yendawo ka-200m2, lapho kufudumeza khona amapayipi amabili okushisa kusuka kumapayipi we-polypropylene kanye nobude obungu-50m. Isheduli lokushisa lohlelo lokushisa- 90 / 70s. Ake sithi ukulahleka kokushisa kwendlu kungu-24kw. Lapho-ke i-Quansing Flow Rate Q = 0.8624 / (90-70) = 1.03M3 / h. Ukumelana kwe-Hydraulic kutholakala etafuleni - kuyi-1,8wbar / m. Ukuze uthole ipayipi elinobude obungu-50m, ukumelana kuzolingana no-90 Mbar, noma cishe 0,1bar = 1md. Sifaka kulokhu kumelana kwezinto zohlelo, zilingana, zithi, 1mvod.st. Amaphakethe wamaphoyinti: q = 1.1 m3 / h, n = 2m. Sizokhetha ipompo Ngokusho ikhathalogi ye-Grundfos (Denmark). Ngezinhloso zethu, imodeli yejubane elithathu i-UPS25- 40 ilungile, uhlelo lungu-108.

Amaphampu asebenza kahle kwamandla

Njengamanje, abakhiqizi bemishini yokupompa baya ngokuya bekhokha ukusebenza kahle kwemikhiqizo yabo. Ngokusho kwale nkomba, yonke imishini kagesi ihlukaniswe izigaba, eziphawulwa ngezinhlamvu zezinhlamvu zesiLatini, kusuka ku-KClasses A kufaka amadivaysi anomnotho kakhulu namuhla. Amaphampu wejubane elijwayelekile noma amathathu anokusetshenziswa kwamandla ezingeni le-classical. Kulokhu, amandla amadivaysi aphansi: aqhathaniswa nokusebenzisa amandla ngamalambu we-incandescent ngo-75 noma we-100W. Amakilasi a angaba ngamaphampu kuphela imvamisa yokujikeleza nge-elekthronikhi ye-rotor yemoto kagesi. Ngaphezu kwalokho, kungaphawulwa izinga eliphansi lomsindo elikhiqizwe yimoto yabo kagesi.

Amaphampu okujikeleza ngokulawulwa imvamisa ngo-50-70% abiza kakhulu kunokujwayelekile, ngakho-ke ukusetshenziswa kwawo kufanele kulungiswe. Isibonelo, akunangqondo ukusebenzisa ipompo yokulawula i-elektroni uma kungekho-i-armostatic avat-off armature ohlelweni lokushisa, kanye nokushisa kwesifunda sokushisa (idivaysi) akuguquki ngokunciphisa izinga lokugeleza kwesisindo se-coolant , futhi ngenxa yoshintsho ekushiseni kwamanzi emugqeni wokuphakelayo (usebenzisa i-crane yezindlela ezintathu noma ezine nge-servo).

Insiza yokumpompela

Amaphampu wokujikeleza ahlukaniswe ngamaqembu amabili amakhulu: nge-rotor emanzi neyomile. Ngokulandelayo kusuka kusihloko, kuzinsimbi zeqembu lokuqala, i-rotor ijikeleza ngqo endaweni epholile, okulesi simo esidlala indima yokugcotshwa. I-STAT ihlukaniswe ne-rotor yesikhonye. Izinzuzo zephampu enjalo zilula zokwakheka, ubukhulu obuncane nesisindo, umsindo ophansi, okuhlukahlukene kwamamodeli akhiqizwayo. I-KEDNOSTATS ifaka amathuba okuthi amathuba e-rotor ngenxa yokuqongelelwa kokuncipha ebusweni bayo, kanye nobubanzi obuncane bokushisa okukhona lapho idivaysi ingasebenza khona ngokujwayelekile. Izindlu ezifakiwe zisetshenziswa ikakhulukazi amaphampu nge-rotor emanzi.Amaphampu ane-rotor eyomile ahlukaniswa ngokuthi i-rotor yemoto kagesi ixhumeke emgodini we-pump impeller ngokusebenzisa uphawu lokugcina futhi ayixhumana ne-coolant. Inzuzo ye-Design enegama ebizwa ngokuthi yikhona lapho kusetshenziswa amanye amagesi kagesi kagesi futhi, ngenxa yalokho, ekukhiqizweni okukhulu kwamadivayisi. Kufanele kuqashelwe uhla olubanzi lokushisa okukhona, ngoba injini imisiwe kancane kusuka ku-coolant. Ububi bamaphampu anjalo buyizilinganiso ezihlaba umxhwele futhi obuphakeme kunaleso amadivayisi ane-rotor emanzi, umsindo.

Ububanzi obujwayelekile bokushisa okusebenzayo kwalawo kanye namanye amaphampu wokujikeleza - 2-110C. Izinkomba ezinjalo zihambelana, ngokwesibonelo, imodeli i-UPS25-60 (Grundfos, Denmark; Intengo - 130) noma i-VA 25/180 (DAB, Italy 82). Amadivayisi ekwakhiweni okukhethekile ayakwazi ukusebenza emazingeni okushisa aphezulu asuka ku-25 kuya ku-140c. Amathuba wesenzo sepompo ane-coolorant enokushisa okungalungile ilusizo kulabo abashiya indlu isikhathi eside ngesikhathi sonyaka obandayo, ukunqamula ukufudumeza (kuyadingeka ukuthi umthwali wokushisa ongewona owoqisayo embozwe ku uhlelo). Ukwethulwa kwensiza enjalo emazingeni okushisa endlini - 10-15s izoba ngaphandle kwezinkinga, ngenkathi ipompo enebanga lokushisa elijwayelekile lingachithwa. Izindlu zamaphampu ngezinhlelo zokufudumeza zenziwe nge-cast iron, kanye nama-GVS-kuphela amasistimu wensimbi noma ngensimbi kuphela. I-Impoller imvamisa yenziwa kusuka epulasitiki engamelana ukushisa.

Ezinye izinhlangano zomhlangano ezingathembekile zifakwa kumaphampu ohlelo lwe-DHW nge-cast iron Houseng, evumela ikhasimende ukuthi ligcine inani elincane. Imali ekhokhwayo yokonga okunjalo kokuqukethwe kwe-iron ohlelweni lwe-DHW kanye namathuba okushona kwe-rotor yepompo ngenxa yokuqongelelwa kwemali, kuze kuphume emotweni kagesi.

Ukuze kube lula ukukhwela kokufaka kanye nokuphuma kwama-nozzles wepompo kubekwe kulayini owodwa (okubizwa ngokuthi yi-in-line version).

Ukuvikela injini lapho i-rotor ikhona, amanye amamodeli epompo ahlinzekwa ngesifunda samandla esephula ama-arheating. Kunamaphampu angesabi ukufuduka - nge-rolor okuthiwa yi-spherical rotor. Amamodeli wokubuka amandla kazibuthe adluliselwa esitobhini aya e-rotor esimisweni esisele, ngezingxenye ezisebenzayo zepompo. Amaphupho avumelekile aqhamuka kumadivayisi wendabuko we-rotor we-spherical kagesi awanazo izibopho. Ikhamera ene-rotor ihlukaniswe nge-hermetically kusuka esitokisini ngengilazi eyindilinga yensimbi engenasici. Ngenxa yalokhu, lolu hlobo lwamaphampu luvela ukuthi lube ngaphansi kwemiphumela yokungcola kanye namadiphozithi we-lime aqukethe emanzini. Ukuhlanza idivaysi kulula kakhulu ukudicilela phansi, ngaphandle kokususa icala kumapayipi. Ngasikhathi sinye, udinga nje ukunqamula imoto kagesi emzimbeni, ujike indandatho ebekiwe. Qaphela ukuthi amaphampu ane-rotor eyindilinga akhiqizwa kuphela ezinhlelweni ze-GVS.

Amacala angcolile ukwandisa ukwethenjwa kohlelo asetshenziswa lokho okubizwa ngokuthi amaphampu amabili. Kune-impeller eyodwa, eshukumisela ngokuhlukile, bese enye imoto kagesi. Okokugcina kutholakala esakhiweni esijwayelekile. Ekwehluleke komunye wabo kuvula okwesibili. Ngaphezu kwalokho, ngentuthuko efanayo, izinjini zithatha ezinye ngezikhathi ezithile. Kukhona umbhangqwana onjalo oshibhile kunezinsimbi ezimbili ezijwayelekile. Isibonelo, imodeli yokuvuselela32-80 f (grundfos) inikezwa ngentengo engu-644.

Izici zokuqhathanisa zokujikeleza kwamaphampu we-Heating Systems (Voltage- 230V)

| Umenzi | Igama lemodeli | Ikhanda, M. | Okuphakelayo, M3 / H | Ukusetshenziswa kwamandla, w | Izindleko |

|---|---|---|---|---|---|

| Grundfos. | Phezulu 25-60 | 6. | 3.8. | 90. | 130. |

| Alfa 25-60 | 6. | 3.8. | 90. | 170. | |

| U-25-60 | 6. | 3,3. | 100 | 242. | |

| Wilo. | Star Rs 25/6. | 6. | I-3.5 | 99. | 122. |

| Phezulu-e 25 / 1-7 | 7. | 6,4. | 200. | 521. | |

| Dabhazwa | VA 25/180 | 2,5 | 3. | 55. | 76. |

| Vea 55/180 | 5,2 | 3. | 91. | 82. | |

| Amaphampu we-nocchi. | R2S 25-70 | 7. | 4.8. | 140. | 129. |

| KSB. | Rio 25-7 | 7. | 7,2 | 185. | 235. |

| Vortex. | HZ 401-25 | okune | 3,2 | 78. | 75. |

| Umugqa we-Wester | Wp 425. | okune | 2,3. | 78. | 62. |

Izici zokuqhathanisa zamaphampu wokujikeleza ama-Hot Water Systems (Voltage - 230V)

| Umenzi | Igama lemodeli | Ikhanda, M. | Okuphakelayo, M3 / H | Ukusetshenziswa kwamandla, w | Izindleko |

|---|---|---|---|---|---|

| Grundfos. | Induduzo ye-UP15-14B. | 1,4. | 0.73 | 25. | 113. |

| Up 20-30 N. | 3. | I-2.7 | 95. | 214. | |

| Ups 25-60 B. | 6. | 3.7. | 90. | 283. | |

| Wilo. | Wilo star-z 15 c | 1.24. | 0.46 | 28. | 177. |

| I-Wilo Star-z 20/1 | 1,7 | 1,1 | 38. | 147. | |

| Dabhazwa | Vs 16/150 | 1,58. | 1,8. | 48. | 135. |

| Amaphampu we-nocchi. | R2x 20-30 | 3. | 2,4. | 87. | 184. |

| Vortex. | BW 401. | okune | 3,2 | 78. | 220. |

Izici zokusebenzisa amaphampu ezinhlelweni ze-GVS

Imvamisa, ukusakazwa kwamanzi okushisayo akudingi ukusebenza okuningi. Kepha izimo zomsebenzi wemodeli enjalo ziyehluka kakhulu ezimeni zezinhlelo zokushisa. Okuqukethwe okuphezulu komoya-mpilo emanzini kampompi akuvumeli ukuthi idivaysi isetshenziswe kuleli cala ngecala lensimbi.Amanzi alungiselelwe kabi (anokuqukethwe okuphezulu kukasawoti wobulukhuni) kuholela ekwakhekeni kwama-lime deposits kuma-rotor. Okukhulu kakhulu kwenzeka ekushiseni kwamanzi ngaphezu kwama-55-60. Ukuvikela imishini esuka ebubini enjalo, abakhiqizi abaningi bahlinzeka ngamadivayisi abo ngama-thermostators acisha iphampu lapho kuphole kutholwa okupholile "okuyingozi" okupholile. Ukusebenziseka kalula nokunciphisa ukusetshenziswa kwamandla, kungakuhle ukufaka futhi ukucisha iphampu yokujikeleza kwesistimu ye-DHW ngohlelo oluthile.

Uma ipompo ixhumeka kwiphaneli yokulawula yama-boiler yanamuhla, le nkinga ixazululwa ezingeni lohlelo. Uma iphaneli yokulawula ejwayelekile noma iphaneli ifakiwe kwi-boiler engasekeli ukuxhumana kwephampu yokujikeleza kohlelo lwe-DHW, ungathenga ipompo nge-timer eyakhelwe ngaphakathi, ngokwesibonelo, imodeli BWZ152 (Vortex, Germany) ebiza u-120.

Ngokusebenza kwe-boiler yohlelo lokushisa nokushisa okushisa ku-boiler, uGrundfos wenza iphampu ehlanganisiwe ye-UPP15-50. Siqukethe amaphampu amabili ecaleni elijwayelekile. Enye yazo yakhelwe ukujikeleza okupholile ohlelweni lokushisa, kanti enye yiphampu ye-boot ye-boiler yokushisa engaqondile. Isitatimende esibonisa i-valve eshintshayo. Izindleko zemodeli zingu-228.

Abakhiqizi kanye namanani

Imakethe yaseRussia imelelwa kabanzi ngamaphampu anjenge-Grundfos (Denmark), i-Vortex, KSB, iWilo (Germany), I-Dab, I-Westerner Line (United Kingdom) IDR. Izindleko zokujikeleza kwamaphampu ngezinhlelo zokufudumeza ziphansi: 70-80 ngedivayisi enejubane lokujikeleza kwe-velocity, elinomthamo we-2-3M3 / h kanye nengcindezi 4-5m. Amaphampu anokulawulwa imvamisa yamandla afanayo azobiza umthengi ngo-120-150. Intengo yamadivayisi anamandla asetshenziswa ezinhlelweni zokushisa zamakamelo okushisa angama-700-800m2 angafinyelela kuma-500-700 noma ngaphezulu. Kepha impilo yenkonzo yepompo okungenani iminyaka eyishumi ngokusebenza okuqhubekayo, ngakho-ke izindleko ezinjalo zingabhekwa njengezingabalulekanga. Amanani okusakazwa kwamaphampu we-GVS amasistimu aqala kusuka ku-80-90.

Ipompo ekhuphukayo

Iphampu ifakiwe kwipayipi lokuphakelayo, ekusikeni kwepayipi. Ngokuxhumeka, amakhompiyutha aqhekekayo asheshayo ane-cape nati ("American") noma ama-cranes akhethekile okukhipha. Ama-tur-off ama-valves wokufaka ama-pump akenting anikela nge-oventrop (Germany), Germany), Gia Comcomini, i-Bugatti (Italy) nabanye abakhiqizi. Izindleko ze-crane eyodwa enobubanzi obungu-1 dyum- 7-10. Lapho ufaka, kubalulekile ukuthi i-axis yokujikeleza kwenjini isendizeni evundlile. Uma kunethangi lokunwetshwa kwe-membrane ohlelweni lokushisa, iphampu libekwe ngemuva kwephuzu lokuxhumana kwalo ekuhambeni kwe-coolant. Ukuhlelwa kwemishini okunjalo kukuvumela ukuthi ususe umoya ngempumelelo.Ekupheleni kokufakwa kwalo lonke uhlelo, kukhiqiza ukugcwaliswa kwalo. Akumele ukhohlwe ukuthi ngemuva kokuqala ipompo nge-rotor emanzi, kuyadingeka ukususa umoya kusuka kwikhamera yayo. Ukuze wenze lokhu, setha imvamisa ejikelezayo ye-Enjini ephezulu bese usula i-cap evikelayo. Amanzi anama-bubble amoya aqala ukushiya umgodi. Lapho kuphuma ngaphandle, i-cap iyaqhubeka futhi. Ngendlela, ukuba khona komoya ephampu kungadala umsindo.

Ukuvimbela i-rotor jamming

Kwesinye isikhathi amaphampu ahlala ngaphandle komsebenzi. Ukuvimbela ukubiyelwa kwe-shaft, kufanele kufakwe ngezikhathi ezithile isikhashana. Uma kunephaneli yokulawula yanamuhla, efana ne-loga-matic 4211 (Budrus, eJalimane; Izindleko- 1300), isidingo sezindlela zokuvimbela, ngoba konke kuzokwenza ezenzakalelayo. Kepha uma ama-rotor encoblings ayengagwenywa, akufanele uphelelwe yithemba. Susa i-cap evikela ekugcineni kwe-shaft, faka i-screwdriver eyisicaba ibe slot emgodini bese ubheka amahlandla amahlandla amaningi.

Ngiyabonga ngosizo ekuhleleni okubonakalayo kweRusklimat, i-STK-Group kanye nehhovisi elimele iGrundfos.