Phansi phansi okufudumele egumbini lokugezela: izinhlelo zikagesi nezokushisa kwamanzi, ikhithi yemishini edingekayo nezinto zokwakha. Incazelo yomsebenzi wokukhulisa.

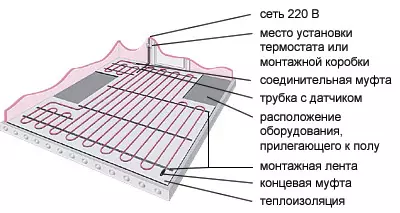

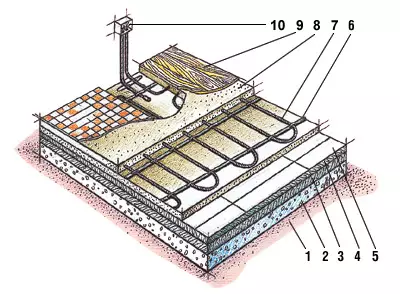

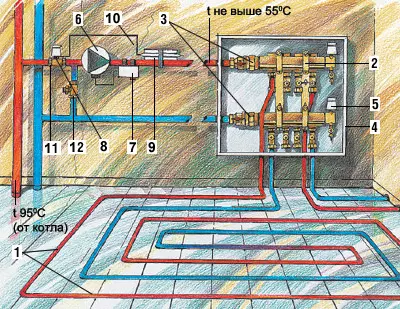

I-Layout DIAGRAM NOKUXHUMANA CHECK COUT-CORE CARD

1. Inhlabathi

2. Ukuvalwa kwamatshe

3. Ukushisa kokushisa

4. Ifilimu yepulasitiki

5. Iplate ekhonkolo eqinisiwe

6. Ukukhwela Planca

7. Ukushisa ikhebula

8. Ukuvumelanisa ukhonkolo

9. Izinto ezingaphezulu

10. Thermostat

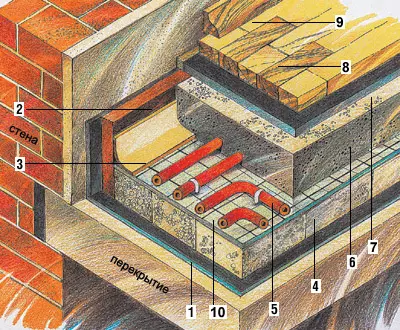

1. Ukuvimbela amanzi

2. I-Gemal-Linguing Gasket

3. Ukuhlukanisa ifilimu

4. Amapuleti wokushisa afudumele

5. Amashubhu wokushisa umjikelezo

6. Isikali sikakhonkolo

7. Mastic

8. Hlanza phansi

9. Plininthus

10. Ukushisa Komboleko Wokushisa

1. Ukushisa i-contour

2. Ukusatshalaliswa kwendandatho

3. Ball crane

4. IKhabhinethi yokuhambisa

5. Umgwaqo Omoya

6. Iphampu yokujikeleza

7. I-Electric Pump Thermostat

8. Thermostat

9. Inzwa yokushisa yakwamanye amazwe

10. I-Capillary Tube

11. I-Thermost-Offic Valve

12. I-Bypass valve

A - u-A - Odar;

B - Kuvunguza

Uhlelo lokufudumeza oluphansi egumbini lokugezela luyadingeka, mhlawumbe, njenganoma yiliphi elinye igumbi ekhaya. Ngokubambisana kanye nojantshi wethawula elifudumele, lisekela i-microclimate ekhululekile kunazo zonke endaweni yokuhlala ebhulayo kakhulu. Izinga lokushisa elingaphansi komhlaba lingu + 26C, futhi esigabeni sekhanda +22 ... + 24C. Ngokusho kochwepheshe, ukusatshalaliswa kwezinga lokushisa okuphakeme kakhulu kwegumbi kulungile futhi kunzima kakhulu ukufeza ukusetshenziswa kwamanye amadivayisi wokushisa.

Uhlafuna ngohlelo lokushisa ngisho nokubanda kakhulu ebusika akuzwakali luhlaka. Ama-splashes ashaya phansi phansi womile ngokushesha, ngakho-ke ngaso sonke isikhathi kuhlala komile futhi kufudumele futhi kunzima ukushelela kukho. Ngaphezu kwalokho, ukuhlanza kwegumbi kuvuselelwa kanye namathuba okuvela kokubukeka kwezindonga kanti phansi kwezindonga kucishe kwaqedwa, kuvame ukuthola ezindaweni ezimanzi ekhaya.

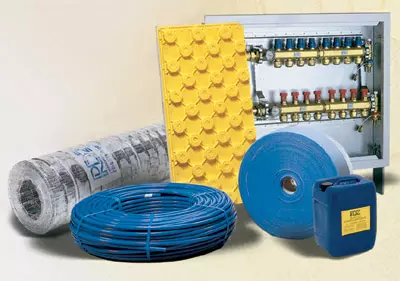

Izinhlobonhlobo zezinhlelo zokushisa phansi

Namuhla, amasistimu wokushisa kagesi nowamanzi athandwa kakhulu eRussia. Zifakiwe zombili ezakhiweni eziphakeme zasemadolobheni nasezindlini zezwe, kuzoba nogesi kanye nezimali zokukhokhela izinsiza. Indlu encane yokugezela enendawo engu-2-4m2, i-wiring ehlukile iyadingeka ngomshini wayo kanye ne-RCD, amandla cishe angu-0.2-0.5kW. Izakhiwo zombango ezakhiwe eminyakeni engaphezu kwe-10 edlule nalapho kwenziwa khona izinto kanye ne-eyeliner yamazinga amadala (cishe ama-2,5kw ngefulethi ngalinye), singakhuluma ngokushisa kwezitezi kuphela njengokushisa okwengeziwe. Yebo, futhi kufanele isetshenziswe ngokucophelela, ngoba kungenzeka ukuthi kulayishe ikhebula lokuphakelayo (uma bonke omakhelwane befaka kanyekanye izinto eziningi zikagesi zasendlini). Kepha noma amandla adingekayo kumandla okuxhuma (ezindlini zesimanje, kungu-7kw), kuyadingeka ukubheka ukuthi i-wiring ekhona ivumela ukuxhumana kwe-flam floor kuya komthwalo wamanje. Uma kungenjalo, ungancoma ukufaka uhlelo ngamandla angaphezu kwe-2KW ngokusebenzisa i-wiring ehlukile nomshini ohlukile.Ngokuqondene nohlelo lwamanzi, ludinga umthombo wamanzi ashisayo ngalolu hlobo lokushisa phansi: i-boiler for ugesi, uphethiloli, e-angle, ugesi (ezifundeni ezinesimo sezulu esifudumele kulolu hlu, ungangeza abaqoqi abafudumele futhi amaphampu we-thermal). Ngakho-ke, kuvame ukusetshenziswa emaphepheni anohlelo lokufudumeza lwamanzi ozimele, lapho, ngaphezu kokugezela, phansi okufudumele nakwamanye amakamelo. Okwesitezi sokufudumeza kwamanzi, efulethini lase-Urban Model, kuyadingeka ukuthola isixazululo se-dez ukuxhuma kwinethiwekhi yokuhlinzekwa kwamanzi okushisayo noma ukufaka i-boiler encane kagesi ngokuqondile yokondla uhlelo lokushisa, olungadingekile.

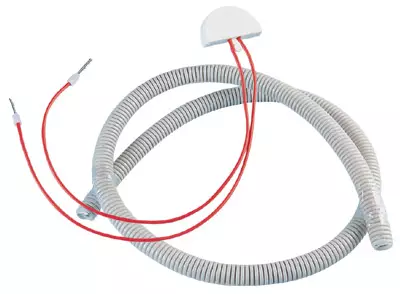

Ama-Maelro Burls

Umthombo wokushisa ohlelweni lwendlu yokugezela ugesi kagesi yikhebula lokufudumeza, eliguqula indawo ibe yiphaneli enkulu yokushisa, ngokuzuzisa kakhulu ukushisa. Intambo ixhumeke ku-thermostat ezenzakalelayo, ngenxa yokuthi uhlelo lulawulwa khona. I-thermostat ihlelwe odongeni (uma inokwakhiwa kwamanzi, khona-ke ngqo egumbini lokugezela, uma kungenjalo, ngale kwalokho, ngokwesibonelo, ekukhanyiseni kwephaneli) futhi ukuphela kwengxenye ebonakalayo yohlelo. Ukufundwa kwamazinga okushisa kuza kuyo kusuka enzwa yokushisa efakiwe, njengomthetho, kushubhu elikhethekile elicwengekile endizeni yokubekwa uphawu kwentambo (ukuze iguqulwe ngesikhathi sokuphuka).

Yonke imishini edingekayo yohlelo lokufudumeza lukagesi ithengiswa ngentambo yokushisa, i-thermostat, inzwa yokushisa kanye nokulungiswa. Amasethi aqediwe wokufaka inqwaba noma emculweni omncane. Lapho ukhetha imishini, kuyadingeka ukuthi uqhubeke kusuka ekutheni uphawu lungaphakanyiswa kanjani egumbini lokugezela, kudingeka ngokuphuthumayo kanjani ukubeka uhlelo nokuthi lusebenze kangakanani ikhasimende lezomnotho isici sezomnotho sokusetshenziswa kwalo. Faka phansi okufudumele ngesikhathi sokulungiswa kwendlu yokugezela kungakwazi ngokuzimela noma ukusebenzisa izinsizakalo zochwepheshe (ozoxhumana naye, abathengisi bazothuthukiswa). Ngasikhathi sinye, kuyadingeka ukulandelela ngokuqinile izincomo zezobuchwepheshe zomenzi. I-AVOT Xhuma uhlelo ekuhlinzekeni kwamandla nangokuthi isisekelo kufanele kube ngogesi ofanelekayo.

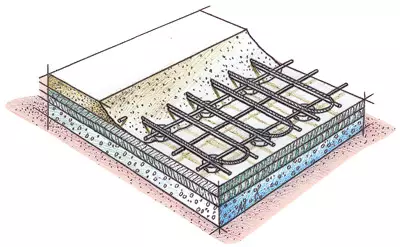

Ubukhulu be-concrete screen kuya ngokuthi imithwalo emibi kamashini. Ngokusatshalaliswa kwamazinga okushisa okufanayo ngaphezulu komhlaba, amazinga amaJalimane e-DIN4725 anconyelwa ukwenza i-screed enobukhulu okungenani be-65mm. Ngokwezidingo zeRussia SP41-102-98, ukushuba kwalo kufanele okungenani kube ngu-30mm. Ukubhoboza phansi egumbini lokugezela kufanele kusetshenziswe ama-cellamic tile, imabula noma enye into enesikhombi sokumelana okushisayo r = 0.02m2k / W.

Montage emculweni omncane

Lapho kungekho mkhawulo obalulekile ekuphakameni kophahla egumbini, kungenzeka ukuthi uguqukele ohlelweni lwendabuko, olubandakanya ukuguqulwa kogesi okusebenzayo kakhulu ekushiseni kwegumbi lokugezela, ukufaka uhlelo lokushisa ku-screen obukhulu. Uma phansi egumbini lokugezela ubumba (emaphepheni amakhethini livame ukutholakala emafulethini angaphansi), umcamelo uhlanganiswe kusuka kumatshe amatshe acwebezelwe kahle kanye nokungena kwamanzi. Esisekelweni sokhonkolo esenziwe ngomumo sokwenza amatshe, ngokwemvelo, akusetshenziswanga, kulokhu, "i-lining" yohlelo luhlombe oluhlanjululwe kahle futhi oluhlanganisiwe. Ngaphezulu beka ungqimba lwezinto ezisetshenziswayo ezifudumele ezifudumele ngobukhulu obungu-50-100mm, lapho kwenziwa khona isisulu sokuqala. Izingxenye ze-ribbon ekhuphukayo noma ukwakheka okuqinisisiwe kocingo okungakaze kube yiqhwa kuze kube sekupheleni kwendawo ekhonkolo, eyenza kahle ukwakheka kwentambo (ngethrekhi). Okulandelayo kuza isigaxa sikakhonkolo sesibili, ukushuba kwayo ngokushisa okuqondile kusuka kuma-30 kuye ku-50-70mm. Empheni wekamelo, ezingxenyeni eziphansi zodonga, kuhlelwa imichilo yokufakelwa, ukuvikela ukonakala phansi lapho kufuthelwa ngenxa yokwandiswa kokhonkolo. Phansi, kwakhiwa nge-Cement Mixtures, yoma okungenani izinsuku ezingama-28, kwenziwa kusetshenziswa ukuhlanganiswa okuguqukayo - izinsuku ezingama-2-3. Ekugcineni, ukuqedwa kokugcina kubekwa uthayi, njengamathayili e-ceramic.Ukuthenga iqoqo lemishini yokufaka uhlelo lokushisa kagesi ku-screen screen, kuyadingeka ukukhumbula ezinye izici zekhebula lesisekelo. Ngobubanzi kanye namandla entambo wamandla (okungukuthi, ngamandla alo okunikeza isikhala esiseduze, lokhu noma lelo nani lokushisa elivezwe kuma-watts nge-metres ngayinye) AKUKHO imingcele. Ukubeka esihlahleni esikhululekile, izintambo zingasetshenziswa ngesilinganiso esingu-5-10mm ngesigxobo esivela ku-17 kuya ku-21w / m mm amakhebuli ama-2-3 mm anesilinganiso esingu-5-12. Amakhoyili e-Cable anamandla amancane ahamba ngomzila asondelene komunye nomunye, ngokuhambisana nezincomo zomkhiqizi. Kubalulekile ukuthi amandla ekhebula lonke anele ukushisa okunethezekile kwekamelo elithile (cishe anqume amandla adingekayo, akhuphule igumbi lekamelo le-100w).

Akubalulekile ukuthi ikhebula litholakala endaweni ephelele noma ebekiwe (umehluko phakathi kwazo ukuthi izindlu azenzelwanga isizinda se-electromagnetic futhi zibiza nge-10-20%). Ukuba khona kwezinhlelo eziyinhloko ze-electromagnetic zesizinda se-electromagnetic, kunoma yikuphi ukubizeka kwe-soryer noma i-wiring efihlekile, ngaphandle kwalokho, umuntu uza endlini yokugezela kaningana ngosuku, futhi lokho akukude.

Lapho ukhetha ikhebula lokufudumeza lendawo "emanzi", kuyadingeka ukunaka iqiniso lokuthi empeleni ube nesikrini kusuka ku-Steel noma i-Aluminium Foil, i-Foil noma ukuhola, okusebenza ngokuyinhloko izinhloso zokuphepha. Ukulalela umonakalo wekhebula noma amanzi ashaya kuwo, isikrini sidlala indima 'yokugaya', ngaphezu kwalokho, kunciphisa kakhulu imisebe ye-electromagnetic eyenziwe ngentambo. Ukukhipha amasistimu ngentambo ye-Shieved eyodwa-Core, isikrini sisetshenziswa zombili njenge-wire okuphakelayo (emuva), kepha sitholakala kuphela ngokuhlalisana ngokushisa, ngenxa yokuthi imisebe ye-electromagnetic ye-acleated inciphisa kakhulu.

Kuyisici sokuthi ikhebula eliseqoqweni lesistimu yokushisa eliphansi alikho njengesiqeshana socingo, kepha ngesimo sengxenye ephelele yomkhiqizo ngobude obuthile bokushisa imithambo yokushisa namandla afudumele. Ukuze kube lula ukukhwela nokwandisa impilo yenkonzo yalo lonke ukwakhiwa kwengxenye yekhebula lokushisa ezimweni zefekthri, okubizwa ngokuthi ama-emples akhuthazayo angenayo, okubizwa ngokuthi yintambo uqobo, kungaholwa noma ukunciphisa uma kunesidingo. Isigaba sekhebula elilodwa-ikhebula liqukethe iziqobelo ezimbili kanye nokuphela okubandayo okubili, ngenkathi ingxenye yekhebula lezindlu ezimbili endaweni eyodwa yenqatshwa yi-cap cap, nakwezinye izindlela ezibandayo kanye nemikhawulo emibili ebandayo yokuxhuma kwinethiwekhi (Ngenxa yedivaysi enjalo ukubeka izigaba ezivela ku-COUR-COLECRICE elula).

Izinga le-coupling kungenye yezindlela ezibaluleke kakhulu zokukhethwa kohlelo oluphumelele. Ukuhlangana kufanele kunikeze othintana nogesi othembekile iminyaka eminingi yekhebula nokuqina kweyunithi yokuxhuma. Amafemu ahlukene asebenzisa izinketho ezahlukahlukene zezinhlanganisela (i-soldering, i-welding, ukunqena) nokubekwa uphawu Ukwethembeka nokuqina kunqunywa yibo bobabili ukuphelela kobuchwepheshe kanye nekhwalithi yenhlangano yoMkhandlu, ngakho-ke inkomba engcono kakhulu lapha iyisipiliyoni eside senkampani yomenzi emakethe yezezitezi ezifudumele kanye nesevisi yamawanti yamahhala.

Inqwaba yezinkampani zibandakanyeke ekukhiqizeni izingxenye zokushisa ngesisekelo sezintambo ezingabazodwa nezimbili, phakathi kwazo (Spain), i-ALCATEL (Sweden), i-DeVi (iDenmark), i-Nokia (Germany), i-Nokia (Germany), i-Nokia (Germany), i-Nokia (Germany), i-Monto (Finland), kanye namafemu aseRussia "WSS", "Chuvashkabel", "THUSTA" kanye "ne-Eltech electronic".

Screed Fight

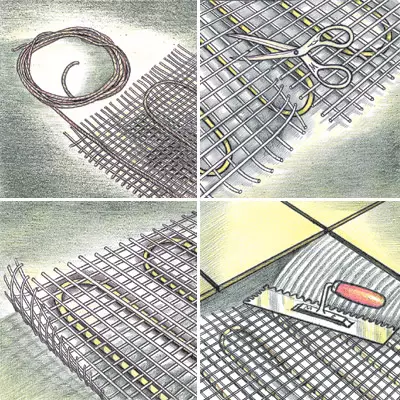

Muva nje, ngokushisa phansi egumbini lokugezela, ikhebula lenziwa ku-Screed Screed (0.5-1,5 cm) - Ngakwesokudla ngaphezulu kwethayela elidala noma phansi kokhonkolo. Kusuka ekusetshenzisweni kokufakelwa okushisayo, njengomthetho, wenqaba. Ngaphandle kwawo, ukufudumeza indlu yokugezela ngeke kube nomnotho ngokungathi nge-screeph aminyene, kepha ngeke kudingeke ukudela ama-5-10 cm okuphakama kwegumbi, okubaluleke kakhulu kwinani elikhudlwana lamafulethi amakamelo. Yebo, futhi isikhathi sohlelo sincishiswa amahlandla ambalwa. Ikhebula ligoqwa ngenyoka noma nge-spiral futhi ilungiswe kwangaphambilini okubheke phezulu. Ukusuka phezulu, esikhundleni se-screed, ungqimba lwe-glue lusetshenziswa kulokhu (ngokuya ngentambo yezobuchwepheshe ehlongozwe ngumenzi) unikeza ukomisa izinsuku eziyi-1-2, khona-ke ukuqeda ukunamathela sekuhlangene. Noma faka i-tile entsha ngokushesha, kwi-glue esetshenzisiwe nje.

Izingxenye ezingcolile ezingcolile nezimbili zingahlinzekwa kwikhasimende ema-bays noma ngendlela yama-mat, abekwa ikhebula lenyoka elinamathele kumagridi aphethe ama-fiberglass grids ngobubanzi obungu-50 noma ama-90c naku-10m ( Ubude bulingana namandla). Uma ikhebula elincanyana, njengoba sekuphawuliwe ngenhla, lifanelekile ukufakwa kokubili ngomunyu bese kukhiqizwa ama-Screeds ancishiswe ngalezi zakhiwo, lapho kungenzeki ukukhulisa izinga laphansi nge-0.6-1 cm ngaphandle kokucabanga ukuqeda ukunamathela (kukhona kuphela isisulu esincanyana). Igridi ingagawulwa kalula ibe yizicucu ngaphandle kokuphazamisa ubuqotho bekhebula, okuvumela ukuthi udumise ama-main endaweni yanoma yikuphi ukucushwa (kufaka phakathi isithiyo).

Ukushisa mat kanye nezigaba ezisuselwa kwizintambo ze-Sourting Courting Fire-Core-Core-Courle-Courding-Courhit (Spain), i-DEVI (INorway), i-Nokia (i-Arnold, i-Arnold Rak neStiebel Eltron ( Germany), Kima (Sweden).

Ama-hermostators we-elektroniki

I-thermostat enenzwa yokushisa yaphansi, kanye nekhebula lokushisa, yinto ebalulekile yohlelo lokushisa kagesi. Izinsimbi ezinjalo zikhiqiza i-microline ye-OJ (iDenmark), i-Eberle (Germany), i-Devi (Denmark), i-Elnesto (Finst), "CSTECH electronic" (Russia) nabanye.Akulungisiswe kabi ngokuthenga isethi yemishini ene-thermostat ehlelekile yokushisa phansi kwekamelo elincane lokugezela efulethini lasemadolobheni. Kuyimodeli engokwesiko elifanelekile elifanelekile kusuka ku- $ 40 kuya ku- $ 120. I-thermostat enjalo ingabhekana kalula nokulungiswa kwamazinga okushisa ahleliwe isikhathi eside - kuze kufike ekushintsheni okulandelayo kwamapharamitha omsebenzisi. Ngokubona amazinga okushisa esitezi kuya kuphawu, olungaphansi kuka-0.1-2c (kuya ngemodeli), ithuluzi lihamba ngohlelo, elinokunyuka kwenani elifanayo, liyacishwa. Ukuhlelwa kwamazinga okushisa kuma-thermostats angenamisebenzi afakiwe kwenziwa ngesinyathelo ngesinyathelo, usebenzisa switch esikhuphukayo, noma ngokushelela, ngokusebenzisa ukumelana okuhlukile. Inkomba yombala ibika umsebenzisi ukuthi uhlelo lokushisa lungaphansi kwamandla kagesi.

Vele, uma igumbi lokugezela lifana nehholo lobukhosi lesigodlo sasebukhosini, futhi ungathenga okubiza kakhulu (izikhathi ezi-2-3), kepha futhi no-thermostat ohlelekile ohlelekile. Iyakwazi kuphela ukugcina amazinga okushisa acacisiwe, kepha futhi nokuyishintsha ku-algorithm efakwe ngumsebenzisi: ngokwesibonelo, ukufudumeza okumazinga okushisa athile kuphela ekuseni kusuka kumahora ayi-7 kuye kwayi-9 nakusihlwa ukusuka Amahora angama-23. Ukwanda isikhathi uhlelo luzoba sesimweni esinqunyiwe. Amadivayisi anjalo akuvumela ukuthi ukhiphe inzuzo ephezulu ngohlelo lokukhokha lukagesi kwemibili, kufaka phakathi ukufudumeza nokuqongelela ukushisa ngesikhathi sezihloko zentela eshibhile.

Imithwalo yehadiwe kagesi evunyelwe (ngokusho kukaPeu)

| Okubonakalayo okubonakalayo | Inani lezindlu, MM2 | Umthwalo omkhulu wamanje, futhi | Amandla aphezulu aphelele, kw |

|---|---|---|---|

| Ithusi | 21. | ishumi nesishiyagalolunye | 4,1 |

| 21.5 | 27. | 5.9 | |

| 22.5 | 38. | 8.3 | |

| Aluminiyamu | 22.5 | amashumi amabili | 4,4. |

| 24. | 28. | 6,1 |

Konke kufudumele

Ngokusho kochwepheshe abaningi, ukukhetha okulungile kokufakelwa okushisayo kuholela emnothweni obonakalayo kagesi ngesikhathi sokusebenza kohlelo lokushisa oluphansi, futhi izindleko zalo zokuqala zikhuphuka kancane. Ukufakwa kokushisa kunciphisa ukusetshenziswa kwemali okungenamsebenzi kokushisa ukushisa okugcwele, inhlabathi kanye nezinye izakhiwo eziphansi kwegumbi elifudumele. Lapho kwahlelwa phansi phansi phansi phansi emhlabathini phansi, kunconywe ukuthi ukufakwa kokufudumala kunconyelwe ukusebenzisa izinhlobo eziqinile ze-polystyrene 50-100mm ubukhulu. Ukushisa amapuleti afaka i-foil nge-polymer coatis ajwayele ukusetshenziswa. I-Foil, uma ixhumana nokhonkolo ukhonkolo, ngenxa yokuvuselelwa okushisayo, ukushisa okuvela kukhebula ngaphezulu komhlaba wonke, futhi kubonisa ingxenye yemisebe eshisayo ibuyela egumbini elifudumele. Ngaphezu kwalokho, i-foil yi-polypoletor enhle ye-polypoletor enhle. Ifilimu le-polymer livikela ekubhujisweni kwe-alkaline ngenxa yokuxhumana nothayi lukakhonkolo.I-insulilator esebenzayo ekushiseni kakhulu yedivayisi yokushisa phansi ephansi ku-screed emnyama yi-cork slabs ngosayizi obukhulu obungu-2 kuya ku-10 mm.

Ukukhethwa kwezinto zokufaka ukushisa zibanzi kakhulu. Phakathi kwabakhiqizi kufanele baqashelwe i-LLC PKP Stroy-PAST, (Hard Hardeness Chemical Basf, iHanalon (South Korea), Bubble Foam Industries N.V (Belgium, Foil kanye ne-FOICED FOCE). I-Folyethylene yasekhaya ye-Foil Foam ikhiqizwa esitshalweni se-lit-isonovation. Intengo ejwayelekile ingu-1m2- kusuka ku- $ 2 kuya ku- $ 4.

Malini induduzo?

Izindleko eziphansi zeqoqo lemishini nezinto zokwakha (ngedivayisi esiklini esikhulu) sokushisa phansi endaweni yokugezela engu-3M2 ngendawo yohlelo lokukhiqizwa kwasekhaya no-120-140 kusetshenziswa imikhiqizo engenisiwe. Ukukhethwa kwemishini kukhulu ngokwanele.

Intengo ephelele (i-mat noma isigaba, i-thermostat enezinzwa zokushisa zaphansi, ishubhu elihlanganisiwe lenzwa) ukuze indlu yokugezela nendawo ye-30-130.

Ngaphansi "Imifula"

Uhlelo lokufudumeza lwamanzi egumbini lokugezela linobungani bemvelo (akukho ukuphuma kwe-All) kanye nezomnotho (amanzi afudumele (amanzi afudumele ashibhile ashibhile kunogesi, ngaphandle kwe-electrocotel esetshenziswa njenge-generator yokushisa). Izinto eziphambili zokushisa okushisayo ohlelweni lwamanzi zihlala isikhathi eside futhi zilula ukufaka amapayipi e-polymer (kusuka ku-polyethylene, i-metal-polymer idr.). Sika amapayipi (abizwa nangokuthi ama-contours) awanawo amalunga (izingcezu eziphelele zinqunywe eBay). Zitholakala ngendlela yamakhoyili emzimbeni wesimende uthayela wesimende futhi axhunywe kokuphakelayo kanye nabaqoqi bokubuyela emuva kohlelo lokushisa. Ngokuvamile, icala le-contours (elinye lilinye, amabili noma amathathu egumbini) elixhunywe kulowo oyedwa angaba maningi. Abaqoqi, bafakwa engxenyeni yeKhabhinethi Collector efakwe odongeni noma edonswe ngodonga endlini yokugezela noma ngaphezulu (uma ukufudumala kwamanzi kuhlelwe emakamelweni amaningana).Lapho amapayipi ebekwe phansi ajikeleza amanzi ashisayo, ingaphezulu laphansi liyakhanya ukushisa. Kusukela, njengoba sekuphawulwe ngenhla, ezindlini zasemadolobheni ngokushisa okuphakathi, amanzi angeke athathwe ngokuqondile ohlelweni lokushisa, noma ohlelweni lwe-DHW, lokhu kufakwa kunconyelwa ukufakwa ezindlini zezwe. Lapho, ngaphezu kwemishini yokufudumala (ukusika ipayipi le-polymer, ikhithi yomqokeleli, ukufakwa kwezinto, ama-fasteners nezinye izinto), kusetshenziswa ithangi lokunwebeka, kanye nedivayisi yokulawula.

Iyunithi yokulawula eyinhloko yohlelo lwamanzi lusebenza njenge-crane eyingxenye ehlukahlukene nge-thermostat. Iguqula ukufudumala phansi, ukuxuba amanzi ngezilinganiso ezifunwayo, ezivela ku-boiler noma komunye umthombo wokushisa nokubuya ohlelweni olufudumele lwaphansi ngokushisa kwamanzi ku-35-50c. Kuyinto elula ukusebenzisa i-node eqediwe ye-thermostat ene-faucet ehlanganisiwe ebiseduze, ukuxubana kanye nokunisela ama-valves kanye nokujikeleza kwepompo. Izinsiza ezingezekile zomsebenzisi zinikeza inhlanganisela ye-thermostat enesikhathi esinikezela ngomsebenzi ngosuku noma isonto ngesonto elizayo.

Yenza ukukhethwa kanye nokufakwa kwemishini yokushisa kwamanzi phansi egumbini lokugezela ngamandla alo kungenzeka kungakuhle - lokhu kudinga ukubalwa kwamakhompyutha, ulwazi oluthile kanye namathuluzi. Kungcono ukuguqula izinsizakalo zamafemu amele ngokusemthethweni imikhiqizo nobuchwepheshe babakhiqizi abaholayo bezinhlelo zamanzi ezifudumele ze-boples overrop, iRehau, i-Belgium), i-purmo (i-veneland), iWirsbo (Sweden ), "Ghent" (Russia) nabanye. Izindleko zokuhlelela ukufudumala kwamanzi egumbini lokugezela elinendawo engu-3-4m2 lingadlula inani le-1000. Kodwa-ke, uma kukhona ukufudumala kwamanzi endlini emakamelweni ambalwa, lokhu kuzobiza umsebenzisi Ku-40-60 imitha ngayinye yendawo evuthayo.

Ngokusho kochwepheshe abaningi, ukuphepha kwezemvelo kokushisa kukagesi akunakungabaza. Ngokusho kwamazinga wokuhlanzeka kanye nemithetho yeRussia (Sanpine2971-84), amandla enkambu kagesi ezakhiweni zokuhlala awakwazi ukwedlula ama-500v / m, nezinga lokungeniswa kwamandla kazibuthe wemvamisa yezimboni (nge-sanpin2.1.2.1002-00) akufanele ifinyelele ku-10 mkl. Amanani wangempela walezi zinhlaka zamakhamera we-electromagnetic ngaphezulu kwama-gels anezintambo ezivikelekile angaphansi kaningana. Abakhiqizi bakhombisa ukucindezelwa kukagesi kusuka ku-10 kuye ku-300V / m. Ubufakazi be-APO babasebenzi be-Electromagnetic Security Center of Ministry of Health of the Russian Federation, ezakhelwe ezakhiweni zezilinganiso ziveze ukuthi izingcaphuno kanye namanani wokungeniswa adalwe phansi. Kubalulekile futhi ukuthi izinto ezisetshenziswe kudivayisi zitholakala kalula emlilweni kune-wiring kagesi ejwayelekile.

-Manzi

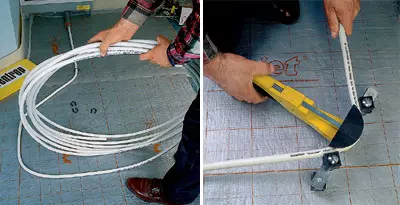

Ukushiya ngaphesheya kohlaka lwalesi sihloko mayelana nokuhlelwa kohlelo lokushisa lokushisa kanye nokuhlangana komthombo wokushisa nohlelo lokushisa oluphansi egumbini lokugezela, cabanga ngokufakwa kwangempela kwamapayipi ekwakhiweni komhlaba. Kulesi sigaba, iwizadi livame ukwenza amaphutha, kepha ikhasimende lingabheka kahle inqubo futhi lenze imibono yalo.

Ubuchwepheshe obujwayelekile obusetshenzisiwe namuhla busho ukufakwa okubizwa ngokuthi okuthiwa yiWet lapho amapayipi okushisa abunjiwe emzimbeni wekhonkolo. Uhlelo olufanayo lungahlelwa egumbini lokugezela, ukugcwala okuzomelana nomthwalo owengeziwe we-250-300kg nge-1 m2. Ukusho umenzi wemishini yokushisa kwamanzi phansi inentuthuko yayo yokuqaliswa kwenqubo yokubekwa kwamanzi, kepha ukungafani kobuchwepheshe obuphambili kwezobuchwepheshe kungenzeka.

Empeleni, ukufakwa kohlelo kuvame ukwenziwa kwandulelwa isikhathi eside sokulungiselela lapho indawo yesisekelo yedivaysi yokushisa amanzi iqonde kahle futhi ibushelelezi. Uma kunesidingo, imbozwe ngokhonkolo okhonkolo omncane, imigodi emincane (akukho ngaphezu kwe-0.5 cm) kwezinye izimo kungafakwa esihlabathini esomile.

Uma ipuleti eyisisekelo eqondanisiwe lihlangana nomhlabathi, ukubhekana namanye amazwe kusuka ku-waterpress noma okunye kufakwa kukho. Okulandelayo kuza ungqimba wokufakwa okushisayo, ubukhulu bokubalwa lapho uhlela uhlelo. Kudivayisi yokufudumala kwamanzi ekufakweni kwamanzi, ayiphendulwanga kuphela ezindlini zokugeza, imingcele emngceleni kanye namakhaza ngaphansi komhlaba, kodwa futhi nasemakamelweni aphansi. Abahlinzeki bezinhlelo 'be-Compliers bahlanganisa amaqabunga enziwe ngeqabunga futhi agoqa ama-etvared aterating impahla. Ukufakwa kweshidi kungukufakwa kweplate noma iphaneli ye-polystyrene, i-basalt fiber noma i-polyurethane enobukhulu obungu-30 kuya ku-70mm. Zingambozwa nge-foil ekhombisa ukushisa nge-markup ngesimo se-mesh noma enikezwe abaphathi ngokubeka kanye nokulungisa amapayipi. Ngaphezulu kwesendlalelo sokushisa sokushisa, kunconywa ukubeka ifilimu le-polyethylene ukuze ikhambi lesikhumba lingangeni phakathi kwamapuleti futhi alizange lidale amabhuloho okushisa nama-acoustic.

Ukuze uvikele i-deformation, imifantu kanye nokuvuvukala kwesembozo esitezi ngenxa yokwandiswa kokushisa kokhonkolo, kanye nokuvikela ngokubonakala kokuvela kwamabhuloho ashisayo nakwezwakalayo, ngemuva kokufaka ukufakwa kwe-thermal, kuyadingeka ukwenza ukuhlela kwesikhumulo esifudumele esifudumele. Kwenziwa yiRibbon yeFoam Polystyrene noma enye into, efakwe odongeni kanye nezinye izinto zokwakha. Kulandela imishini yokushisa emakamelweni yefomu eliyinkimbinkimbi futhi kuleli cala lapho osayizi be-Ceiling Slab bedlula khona 8m.

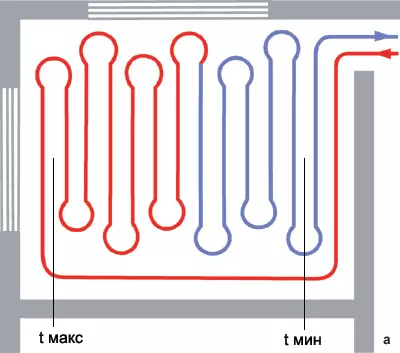

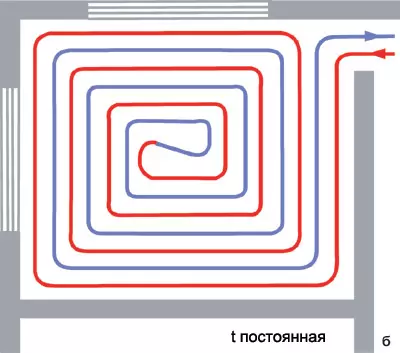

Ngemuva kokubeka izinto ezisizayo (ukufakwa kwe-thermal, i-vaporizolation, ukuhlela, ukulinganisa, izinga lokushisa leams it.d.) Ungaqala isigaba esikhulu somsebenzi. Okokuqala, kufanele ufake abaqoqi bokondla nababuyela emuva. Ipayipi lixhumeke kumqoqi wokuphakelayo, ngemuva kwalokho aqala ukungavuli i-bay futhi akha umjikelezo wokushisa endaweni elungiselelwe. Lapho kusetshenziswa idivaysi yokushisa kwamanzi, enye yezinketho ezintathu eziphambili zokubeka ipayipi liyasetshenziswa. I-Schema "Stone Snake" enikezela ngokufakwa okulula nokuvinjelwa kokushisa okufanayo ngaphezulu komhlaba. Lobu buchwepheshe bungasetshenziswa ekufuneni izindawo ezi-oblique. Indawo ehambisanayo yokuhlinzekwa kanye namapayipi okubuyisa iqinisekisa izinga lokushisa eliphakathi elifanayo. Yebo, i-parallel spiral inconyelwe izindlu zokugezela ngemigqa emikhulu yokushisa.

Lapho ukhetha indlela yokubeka ipayipi, kufanele kukhunjulwe ukuthi ukulahleka kokushisa kusatshalaliswa endaweni yegumbi ngokungalingani. Isibonelo, izindonga zangaphandle ziphakeme. Izindawo ze-waich kufanele zihlele amapayipi eduze komunye nomunye ngaphandle kwezinye izigaba.

Ukulungiswa kwamapayipi esisekelweni esilungiselelwe kwenziwa kusetshenziswa igridi yokuqinisa kanye ne-wire, ngosizo lwamabakaki ekhuphukayo, ojantshi, phakathi kwezici zokufakwa kokushisa okufakwe esikhundleni (BOBS). Inketho yokuqala ibonakala ngokulula, ngoba i-GRIDCEENT GRID inemifanekiso, ngakho-ke akudingeki ukuthi ichithe isikhathi esiphaketheni, kanye nokhonkolo ukhonkolo ngenxa yokuqiniswa kuqina. Ngaphezu kwalokho, ngenxa yegridi, ishubhu lokushisa ngokuphelele (umhlaba wonke) othintana nabo ngezinto eziphansi phansi, uqinisekise ukudluliswa okuphezulu okuphezulu. Igridi yenziwa ngebha yensimbi enobubanzi obungu-3 kuya ku-6 mm. Usayizi weseli ngokuvamile uvame ngo-150150mm, ngaphansi kuka-225225 noma 300300mm. Amapayipi anamathele kugridi okungenani ngo-0,5-1r ngosizo lwamasingi epulasitiki, i-wire esheshayo, esontekile nge-hook ekhethekile, noma iplasithi yokuqinisa ipulasitiki.

Ukufakwa kumele kwenziwe ekushiseni komoya okungaphansi kune- + 10c. Isifunda ngasinye esifudumeza kufanele sibe nocezu olulodwa lwepayipi, ngaphandle kokuwela, ukusonteka nokugoqa, kanye nokuncipha kanye nokunye ukulimala. Kubalulekile ukusebenzisa kuphela ukufakwa kwamathuluzi nabakhiqizi abaqinisekisiwe abaqinisekisiwe. Sika ipayipi elivela echibi lilandela kuphela ngemuva kokubeka i-loop bese ulinikeza umqoqi wokubuyela emuva. Ngenani elikhulu lamapayipi eduze komunye nomunye, ngokwesibonelo, eduze komqoqi, udinga ukuhlukanisa abanye babo, mhlawumbe bondle, ukuze kuvikeleke ukushisa kwendawo.

Isigaba esilandelayo sezinhlaka ezifudumele zikakhonkolo, okuhloswe ngazo ukuqinisekisa umfaniswano wokufudumeza phansi komhlaba. Kodwa-ke, ngaphambi kwaphakade Fihla amapayipi e-polymer ngaphansi kongqimba lukakhonkolo, kuyadingeka ukwenza izivivinyo ze-hydraulic zohlelo. Ngokwemithetho yokwakha, ukuhlolwa kokushisa phansi kokuqina kwenziwa ngengcindezi, izikhathi eziyi-1.5 ziphakeme kunokuba zisebenze (kodwa hhayi ngaphansi kwe-0.6 MPA), kanye nokushisa kwamanzi njalo. Ngaphansi kwengcindezi yokusebenza, ipayipi kufanele libe ngesikhathi sokugcwaliswa, lizonciphisa amathuba okuxinaka kwezingcindezi ezingafuneki.

Imvamisa, izinkampani ezihlinzeka ngemishini efanelekile nezinto zokwenziwa kokufakwa kwamanzi okushisa kwamanzi kunikeza isilinganiso esinembile sokulungiswa kwesisombululo sokuhleleka, okuncike ekusebenzeni kwabahlinzeki bewaranti. Ukufingqa idatha evela kubakhiqizi abahlukahlukene, kungashiwo ukuthi ingxubevange esinambitha kasimende kufanele ifakwe kudivayisi engaphansi kwama-400. I-dormitory ivame ukwengezwa epulasitiki ebizwa nge-fluodity. Ngenxa yalokhu ngepayipi elimbozwe ngokhonkolo ngokuqinile, ukuthuthuka okushisayo namandla okukhuphuka kwe-screen. Ukuze kungabikho maphakethe womoya phansi, ukhonkolo ozungeze amapayipi kufanele aphonswe ngokucophelela. Ngokuzikhohlisa, kubalulekile ukugwema ukuthunyelwa kanye nokugoba okuqondile kwamapayipi.

Ukuhlinzekwa kwamanzi ashisayo ohlelweni akufanele kwenziwe ngaphambi kwamasonto amathathu. Ngalesi sikhathi, i-concreses screed izothayipha amandla adingekayo. Akunakuvunyelwa ukuthi kuvunyelwe ohlelweni lwamanzi afudumele afudumele ngamazinga okushisa akwakheka kuze kube yilapho i-screed ilukhuni, ngoba ukufudumeza kwayo kuzoholela ekwakhekeni kwemifantu. Ngemuva kwesikhathi esibekiwe, okupholile okunamazinga okushisa ka + 25c kungahanjiswa, futhi ezinsukwini ezi-4 ezizayo kufanele zikhuliswe kancane kancane.