I-Classic of Calchic Calch yindlu yezitini - ihlala isidingo futhi ngezinsuku zokuthuthuka okusheshayo kobuchwepheshe obusha bokwakha. Amakhasimende awayeki isikhathi eside ngokwanele (kuze kube unyaka owodwa) umjikelezo womsebenzi, noma omkhulu, uma uqhathanisa nezakhiwo eziphakeme, izindleko zendlu. Umbiko wethu wokuthi indlwana yesikhashana evela ezitini nokhonkolo yakhiwa kanjani

Udinga ukuqala kusuka ekuqaleni

Ipuleti lesisekelo. Ngemuva kokuba umgodi, abasebenzi benziwa kuwo, ukuchitheka kweSandy ngobukhulu baka-200mmm, ngaphezulu kwalo kwabeka ungqimba lukakhonkolo (okuthiwa okuthiwa yi-sweet) ubukhulu be-100mm. Ukuvikela indawo engaphansi yesikhathi esizayo kusuka ekufundeni kwamanzi angaphansi komhlaba (ekwindla nasentwasahlobo), i-drainage (uhlelo lokuhlinzekwa kwamanzi) lahlelwa ngasendaweni yesakhiwo, futhi "ukushanela" kwambozwa ngamanzi ngezendlalelo ezimbili. Ngemuva kwalokho, ngokuya ngemininingwane yephrojekthi, ukufakwa kwepuleti lesisekelo kuboshwe futhi kuphonse kukhonkolo.

Isizinda I-mporhy ivela emapuletini asetshenziselwe ukuqiniswa okusele ngokuqondile ngokuxhumeka kwepuleti yesisekelo kanye nezindonga ezakhiwe, okufana nohlobo lwesitsha esikhulu sekhonkolo esiqinisiwe. Lapho ukhonkolo ebamba, abakhi babopha ngohlaka lokuqinisa izindonga zesisekelo bese lufaka ifomu lesikhathi esigcwele. Ukuze uphinde unikeze ukonga emsebenzini wokufaka, amafomu afakwa ngangokunokwenzeka. Esigabeni sezinkoloni, kulayishwe kuze kufike kumathani ayi-2,5-3 nge-1m2 nge-1M2, ngakho-ke kulungiswe ngokuqinile kuzo zontathu ubukhulu ukuze ukukhishwa kodonga akwenzeki. Iqhaza lama-clamps enze ama-jacks mechical, tie bolts kanye okubizwa ngokuthi ukufakwa kwezinga.

Ngemuva kokusayina izenzo zomphathi wezobuchwepheshe ukwenza umsebenzi ocashile kanye nokuqinisekiswa kokunemba kokuqiniswa kwaqala inqubo yokubabaza. Kusuka ku-batch ngayinye yama-Concrete cast control Cubes, abhale futhi angena kwimininingwane emsebenzini womsebenzi. I-node e-fucking yathatha ipasipoti enezimpawu zikakhonkolo. Ekupheleni kokhonkolo, ukhonkolo wanikezwa ukuma isonto lonke futhi ushayele amandla esiteji, okwathi ngemuva kwalokho baqala ukudilika kabusha. Kumele kwaziwe ukuthi ukushuba kwezindonga ezingaphansi komhlaba kuvame ukwedlula i-200-300 mm, enikeza ukonga okukhulu ezintweni eziqhathaniswa nezisekelo ezivela kumabhulokhi kakhonkolo we-precast. Ukonga ukhonkolo kungama-30-50%. Iqiniso ngukuthi ezinhlakeni ezenzelwe ukuqanjwa kabusha zokwenza izindonga zobukhulu obufanayo, kanye namabhulokhi wesisekelo, akunakwenzeka ngokweqiniso. Izitshalo zethu azivezi amabhlogo wesisekelo anciphile kune-400mm. Ukwakhiwa kokuvutha amakamelo kuvame ukusebenzisa amabhlogo ngobukhulu obungu-500 kuya ku-600mm.

Ukuvimbela amanzi kanye ne-insulation. Ukususa amafomu, izindonga zangaphansi ziphathwe ngeBitumen Mastic, lapho kufakwa khona ngamanye amangalo (i-hydrohotelloisol). Ngakho-ke, izingqimba ezivundlile nezimi mpo zakhiwa ngokuphelele ivolumu eyi-hearter, futhi izingqimba ezine zokuphamba amanzi zazixhunywe emalungeni amalunga! Izindonga zangaphansi zafakwa ngaphakathi kusuka ngaphakathi nge-10-centimeter ungqimba we-polystyrere e-polystyrene (strodur idr) futhi wamboza udonga oluhlanganisiwe lweplywood, ipulangwe noma amashidi we-asbestos. (By the way, ikhasimende laxoxwa nenketho ehlukile yokufakelwa kwesisekelo. Besinganquma ungqimba lokufakelwa kwezinyembezi ezindongeni ezingaphandle.) Izindonga zangaphandle zesisekelo zaziyi-hydroling (ngokusho kolunye lwanamuhla ubuchwepheshe). Ku-parallel, yaqala umsebenzi ekufakweni kwamafomu kanye nokuqiniswa kabusha.

Imisebenzi kakhonkolo. Ngemuva kokuthola isixazululo sokulungiswa kwezobuchwepheshe ukwenza umsebenzi ocashile, wathatha indawo yokubhalwa kosimende. Njengoba imisebenzi iholwa ngaphansi kwamazinga okushisa amabi, izintambo ezikhethekile zokufudumeza zinamathiselwe ezinhlakeni zensimbi. Lapho ukhonkolo ephenduka, ashiywe emzimbeni wokwakhiwa okubunjiwe. Ngaphezu kwalokho, ukhonkolo wasebusika wawubandakanya izengezo ze-polymer ezikhulisa ukumelana nezithelo zalo.

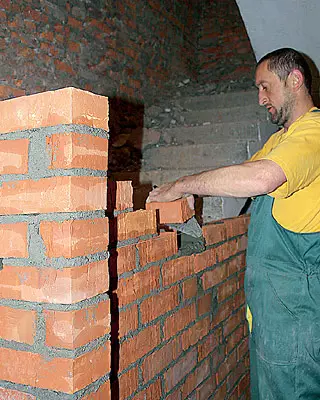

Ngakho-ke ukuthi ukhonkolo oboshwe ukhokhelwe ngokwanele imisebenzi yokwakha elandelayo iyadingeka okungenani amaviki ama-2. Ukuze banciphise isikhathi sokuqala kwama-masonry, baye ku-trick: ukugqama akuqalanga ukubiza, baqala ukusebenzela izinsuku ezingama-2-3 ngemuva kokuthululwa kokhonkolo. Umphumela wasindiswa isikhathi esiningi, ngenkathi ikhwalithi yokugqagqana ayizange ihlupheke futhi, okubaluleke kakhulu, ubuchwepheshe bokwakha abuphulwa. Isinqumo esinjalo silungile, ngoba ngesikhathi sokwakhiwa kokugcwala kwesinye isikhathi sihlangabezana nemithwalo emikhulu, ngakho-ke ama-jacks ngaphansi kwawo ahlala eshiywe ngaphambi kokubeka isitini sokugcina se-cottage yesikhathi esizayo.

Beka isitini ngengqondo

Izindonga. Ngezisekelo ezithembekile futhi wenze kahle ama-masonry, izindonga zezitini ngeke zibe yiminyaka eyikhulu. Ngasikhathi sinye, izitini, ikakhulukazi ezigcwele, ezimfanelweni zayo zokuvikela ukushisa ziphansi kwezinye izinto eziningi zodonga. Ukwehlisa ukusetshenziswa kwezitini, ukunciphisa isisindo sezindonga nomthwalo kulezi zisekelo, izindonga zangaphandle zinqume ukubeka izitini eziyize (ezisebenzayo). Ukubekwa okuqinile kwezitini ezigcwele ezigcwele ngobukhulu bezitini ezingaphezu kuka-38cm (1.5 izitini) zine-inexpedient yezomnotho. Lapho ugcwalisa imithambo yomoya nge-foam, ukusebenza kahle kwamandla kodonga kuphakama ngo-200%. Ukusetshenziswa kwezixazululo ezifudumele ze-masonry (kususelwa ezinhlanganisweni ezinhle kusuka ku-slag, ubumba, i-tuff, i-trid, i-perlite, sawdust it.) Futhi kwandisa izakhiwo ezishisayo zezindonga ngo-10-15%.

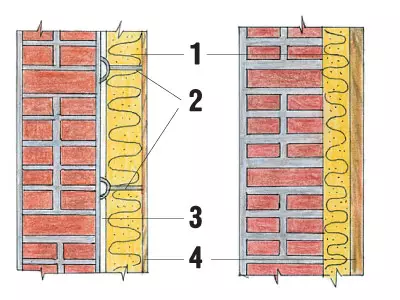

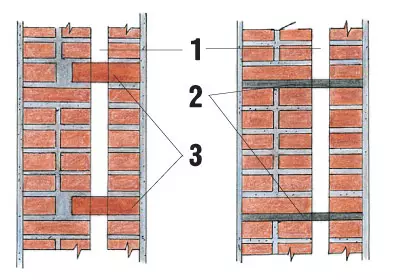

Ama-masonry ezindongeni ahola izingqimba zombili eziqinile nezindiza ezigcwele ukufakwa. Ngokubekwa okuqhubekayo okuqhubekayo, isixazululo esithe xaxa ukwakhiwa kwezindonga ngokufakwa kwangaphandle. Kulokhu, ukushuba odongeni kwenza okuncane (25cm), futhi ukuvikeleka kokushisa kunikeza ukufakwa. Lapho isendlalelo sokufakwayo sitholakala, kuvikelwe ekufakweni kwamanzi emphuleni wamanzi, uma kungaphandle - ukusuka emathonyeni asemoshweni yi-facade ebekiwe noma ngodaka. Izindonga zezitini ezinokufakwa kwangaphakathi noma kwangaphakathi kwenze lula inqubo yokuhlehlisa futhi ivumele umsebenzi ngokufudumala kwawo endaweni yesibili. Ukufakelwa kokufakelwa, njengomthetho, sebenzisa amapuleti eboya amaminerali anjengeR Rockwool noma i-rivid polystyrene foam (Foam).

Izindonga ezinongqimba womoya zazigoqwa ezitini ezisebenzayo. Ngale ndlela yama-masonry, ebusweni (izipuni) imigqa iboshwe ngodonga oluyinhloko ngemigqa emi-4-6 ngemigqa ye-tile yezitini noma ukuxhumeka kwensimbi. Ukuze ugweme ukuhlanza izindonga, kuvame ukufakwa ngodaka kusuka ngaphandle noma ukubeka ngaphandle kwe-sathe yemisipha ngokulawulwa kwekhwalithi okuqinile. Ukuxhumeka kwensimbi (ama-wire amahange anobubanzi obungu-4-6mm) avikelekile ekugcekeni ngoButume, ikhambi likasimende noma i-epoxy resin. Ukusebenza kahle kwe-Thermal kwezindonga kwanda ngokugcwalisa ungqimba womoya ngokukhishwa kwe-Foam Styrodur.

Izinketho ze-Brickwork:

|

|

| 1. Ukufakwa 2. Izilonda ezivela kwikhambi 3. Ungqimba womoya 4. Ukugcotshwa | 1. Izendlalelo Zomoya 2. Ukuxhumana kwensimbi 3. Outdoor Masonry kusuka ezitini ze-tiley |

Ukwahlukaniswa. Izindonga zangaphakathi eziphakeme ziphakanyiswe ku-Clay Brick Brick Brand 100. Ubukhulu bawo obuncane ngu-25cm, isigaba sesiphambano samakholomu okungenani ama-3838cm, akukho ngaphansi kwama-2551 cm. Ukuthwala izigxobo nokulula okuqinisiwe nge-mesh mesh kusuka ocingweni onobubanzi obungu-3-Bmm ngokusebenzisa imigqa engu-3-5 yama-mason. Ukuhlukaniswa okwenziwe ngo-12 cm obukhulu (ku-polkirpich) no-6.5 cm ("Mount" Brick). Ukuhlukaniswa "kokumaka" okubangelwa ubude obungaphezu kwama-1.5 m nabo baqiniswe ngocingo ngemigqa emi-2-3 yobumbano ekuphakameni. Ukubhekana nama-facades asebenzisa izitini zobumba zobumba. Ama-masonry aholele kusixazululo sikasimende-sandy. Isixazululo seMark sokuthwala izindonga nezinsika, kanye ne-Plaster Facades - 25, ngezindonga ezingezinhle nezingxenye - 10.

Umhlobiso wangaphandle. Ama-masonry aphezulu aphezulu akusona ukuphela kwesimo samandla odonga. Kuhle ukugcizelela isici esisodwa. Indiza yokwakhiwa kwaleli bhiya kufanele ibe yindiza ejulile yodonga lwezitini. Kwabonakala sengathi kuyisimo esincane kakhulu ukukhulisa impilo yenkonzo yetshe lasendle noma enye into esetshenziselwa ukuqeda isisekelo. Iqiniso ngukuthi ngesikhathi sokushintshana kwezimvula namafriji, ngedivaysi yokuhlehlisa, amanzi angeke athole phakathi kwetshe elibheke phezulu nesisekelo kanye, nokuqhwaka, abhubhise ababhekene nawo. Njengoba isisekelo ngaphandle sihlala sibhekene nomphumela omubi wemvelo yangaphandle, yafakwa emanzini amaningi ukuphakama kwe-15-30 cm. Eduze kwesisekelo esibekiwe ukuwohloka nobubanzi obungenani okungenani abangama-70cm, okuvela ku-svetor ka-cornice kaSvetor kanye nokubandlulula ezindongeni zendlu. I-CESPPool enobukhulu be-10cm yenziwa kusuka kukhonkolo ongu-100 ngokhonkolo we-rubble noma amatshe amatshe amatshe, ayiqinisile ngegridi yensimbi yensimbi.

Ukugoqa. I-capital Build igoqwe kusuka ezindongeni zezitini iyakwazi ukuthwala imithwalo esindayo kunamapulangwe. Ngakho-ke, okweqile ekwakhiweni kwezitini kwenziwa ngamapuleti ukhonkolo aqinisiwe noma aphonswe ezindaweni kusuka kukhonkolo eceleni kohlaka oluqinisiwe. Ukusetshenziswa kwamapuleti kulungisiswa yiqiniso lokuthi ikhwalithi yabo ilawulwa ngesikhathi senqubo yokukhiqiza futhi iyaqinisekiswa. Imikhawulo yamapuleti anobukhulu be-160mm yaqala ezindongeni zokujula okungu-12 kuye ku-30 cm (kuya ngobude besikhathi sokugcwala). Izitofu zisebenzisa okujwayelekile, zisukela ku-2.4 kuye ku-7.4 m. Amapuleti e-attic inqola avele abekwe ezindongeni eceleni kwengxenye yesisombululo. Amalunga amade ende phakathi kwawo athambekele ngesisombululo sikasimende-sandy. Amapuleti akhonkolo aqinisiwe ane-haditudinal canditive. Ukumelana nokushisa okushisa okuphezulu kanye nekhono lokuthola umsindo kuvunyelwe abakhi ukuthi benze izindlela ezincane ekushiseni nasekufakweni okuzwakalayo kwe-Snderlaps. Amapuleti aphansi angenazitolo angenamanzi nge-mastic ne-hydroatiecloxy, bese efaka uthayi wesihlabathi wesimende, owaba yisisekelo sokuhlanzeka ebhodini lemigodi. Indiza yophahla yophahla we-attic yabekwa ngengqimba yokufakwa kwe-vapor "Yutafol-n", ngaphezulu kwayo - ukufakwa (i-ceramzite).

Ukuhlola

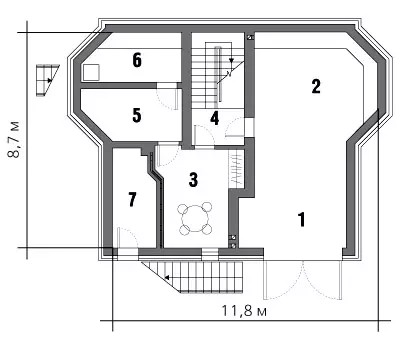

Phansi komhlaba

1. IGarage 2. Indawo yokusebenzela 3. I-restroom 4. IHholo Lokwengamela 5. Ngokuzumayo 6.Saun 7. Igumbi Lezomnotho

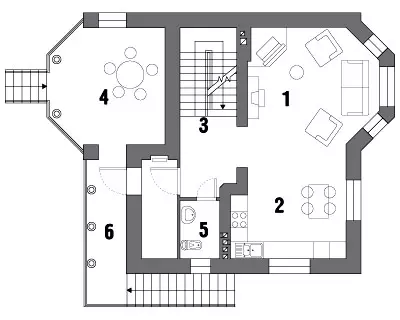

Phansi komhlaba

1. Igumbi lokuhlala 2. Ikhishi 3. Staircase Hall 4, 6.Tranda 5. USanusel

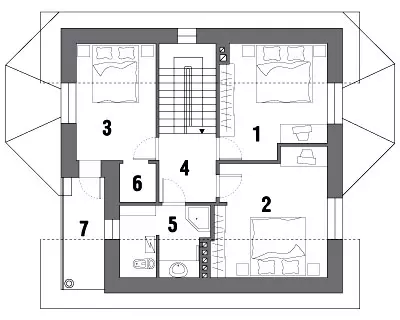

I-Mansard floor

1-3. Amakamelo okulala 4. STAIRSECON ANDWANE 5. Igumbi lokugezela 6. Ikhabethe 7. I-Loggia

Idatha yezobuchwepheshe

Indawo ephelele yendlu ......................................7m2

Phansi kwesikwele ......... 73.8M2

Indawo yaphansi ......................7m2

Isikwele se-attic floor ....... 71,2m2

Uphahla kumele lwenze

Ama-rafter kanye nophahla. Uphahla lophahla lungama-rafters noma amapulazi ahlukahlukene adlulisela umthwalo wophahla ezisekelweni (izindonga, ukwahlukaniswa, izinsika). Kulokhu, i-House Design ihlinzeka ngamatshe alengayo, asuselwa ezindongeni zangaphandle zesakhiwo. Ngokwenziwa kwezingxenye, i-rafter yasetshenziswa yisikhathi sokuphakama sikaphayini ngesigaba esingu-150150mm, kanye nesigaba sesiphambano esingu-50150 no-50200mm. Izinto zepulazi ziboshwe izipikili, kubakaki kanye nama-bolts. Ukuxhuma imilenze ye-rafting ngokhuni noma ukuqina kwensimbi kutholakala ezingeni lesimo se-attic. Imikhawulo ephezulu yemilenze ye-rafter isuselwa ekugijimeni kwe-ski, futhi, ngaphezu kwalokho, asekelwa uhlelo lwama-racks kanye nama-splines. Ngezansi kwemigoqo ye-rafter ayibekwa ezindongeni ngokwazo, kodwa ku-flush efakiwe enodonga lwangaphakathi lodonga lwe-timber (i-mauerlat), ebiyelwe ngaphandle komphetho wesitini. Phakathi kwe-mauerlat kanye nesitini - ungqimba olungena ngaphansi kwamanzi. Ukubhekana nemithwalo yomoya esebenza phambi kwangaphambili, emthambekeni ngamunye ophahleni olugasele izibopho ze-diagonal ezivela emabhodini anobukhulu obungu-30- 40mm. Ukuze uphahla lungadilikihlisi umoya, imilenze ye-rafting kanye ne-mauerlat iboshwe ngokuqinile ngezindonga. Ukuze wenze lokhu, kuma-masonry ngaphansi kwemilenze esheshayo, izinto ezibambisene nazo, lapho abazidonsela khona ngentambo yocingo lwensimbi olunodaka olungu-6mm. Uphahla lwenziwe kusuka ku-Metal Tile ngobuchwepheshe obujwayelekile.Ukuxhumana kobunjiniyela kumele kuthembeke

Umhlinzele endlekweni Ngokuhlelwa kwekotishi, kubalulekile hhayi ukunaka ubuhle be-facade kanye nabangaphakathi, kodwa futhi bahlomisa kakhulu ukuxhumana. Isisekelo sohlelo lokusekelwa kwempilo ukufakwa kukagesi kwendlu. I-Votychychi evela ezakhiweni zokhuni, esakhiweni sezitini nasokhonkolo, i-wiring wiring kanye ne-electrooter ibanzi. Ngakho-ke, izintambo namakhebuli akunakubekwa amapayipi ensimbi noma kwizinsimbi. Zifakwe kuma-cuttings cuttings ezindongeni, ziqinisa emgodini wezitezi zokhonkolo eziqinisiwe. I-wiring ingathathelwa indawo (isidingo esinjalo sivela kwinqubo yokusebenza okuthe xaxa kwezintambo ngemuva kweminyaka eyi-10-15). Ikhasimende lethu lakhetha inketho eshibhile - ukubeka ikhebula ezindongeni (kwalokhu kwasetshenziswa ikhebula le-nym) ngaphandle kokusebenzisa imikhono ye-PVC. Abasebenza ngogesi bayazi ukuthi ukuqina emikhombeni efakwe odongeni yezintambo ezintsha esikhundleni salokho kungenzeka kuze kube nini nanini kwawo wonke amacala. Kodwa-ke, lapho izintambo ziyintambo enkabeni yephansi, zazisebenzisa imikhono yokuvikela ama-PND-yamandla akhuphukayo angawonakalisi, noma ngabe eza ukuzogcwalisa i-screed. Izindonga ezijwayelekile kanye nezingxenyeni ezifakiwe amabhokisi akhulayo amakhulu kunokujula okujwayelekile (62mm). Ukusetshenziswa kwabo kwenza kwaba nokwenzeka ekushisweni nasekuhlukaniseni amabhokisi, ngoba konke ukuxhumana kwenziwa ngokuqondile emabhokisini akhulayo. Ama-Microprocessors ohlelo lokukhanya kokukhanya okukhanyayo atholakala.

Ukuqinisekisa umsoco onokwethenjelwa kanye nogesi osezingeni eliphakeme, umthombo wamandla wokuphazamiseka (UPS) (isigaba se-inthanethi) ngokuguqulwa kwamandla kagesi okuphindwe kabili kwama-40 kW asetshenziswa. Iguqula ukuguquguquka okungenayo kwangaphandle, kuyazinza, bese wenza ushintsho olubuyela emuva. Idivayisi iqinisekisa ngokuphelele umsebenzi ozinzile ngaphandle kokuphazamiseka kwamandla okuphakelwa kwamandla, izinguquko zemvamisa yamanje, ubukhona be-hamormic, njll. Isiqiniseko sokuthi i-automation yemishini ye-boiler kanye neminye imishini ye-elekthronikhi endlini ngeke inikeze ukwehluleka. I-UPS yafakwa ebunjiniyela.

Ukufudumeza nomoya omncane. Ukushisa kwesakhiwo sezitini kunezimpawu zalo. Izitini nokhonkolo zithola imfudumalo futhi inqobo nje. Uma esikhathini esibandayo sendlu enjalo isikhathi eside sokuhamba ngaphandle kokushisa, bese uqala ukuvusa futhi, kwakhiwa ama-condensate ezindongeni. Ukubukeka kwayo kuzothinta kabi isimo sezakhiwo zokwakha kanye nekhwalithi yempilo yezakhamizi zasekhempini. Ngakho-ke, uhlelo lokushisa lwendlu yezitini kufanele lusebenze njalo. Uhlelo lokufudumeza lwamapayipi amabili nge-wiring beqoqo lwalufakwa emucu. Esitezi ngasinye kwikhabethe lokusatshalaliswa, kunomqoqi wayo lapho ipayipi elibeke khona ukufudumeza kumadivayisi. Lolu hlelo likuvumela ukuthi ulawule kangcono imishini yokushisa, uma kunesidingo, cisha izixhumanisi ngazinye ukuvikela nokulungisa, ngaphandle kokumisa ukusebenza kwama-boiler namaphampu.

Ukushisa i-cottage, amazinga okushisa aphansi we-iron gas boiler logano G215 (Budrus, eJalimane) enomthamo wama-45 kw ayasetshenziswa. Uphethiloli ngoba kungaba yinto yemvelo, i-liquefical gas, uphethiloli wedizili ngisho nowoyela odlwengule (lapho uhlome ngokushisela okuhambisanayo). Idivayisi ifakwe idivaysi yokulawula ebushelelezi yokushisa kwamanzi ama-boiler futhi iqinisekise ukusebenza okuthembekile kohlelo lokushisa ngaphandle kokulawula izinga lokushisa lomugqa. I-Logano G215 inegumbi lokuhlangana elipholile lamanzi elinomthwalo omncane we-thermal. Ukuhlukaniswa kwamagesi we-flue kwenzeka emgomweni wokukhethwa okuphezulu kwalolo okushisa esiteshini se-histiserd. Ukuphathwa kwe-boiler kwenziwa kusuka kuphaneli elikude ngezindlela ezizenzakalelayo nezinakwenziwa ngesandla. Idivayisi ifakwe i-shirter yegesi ye-logatop vm eluhlaza okwesibhakabhaka ngokuxuba okuqala okusebenza buthule, akudingi imisebenzi eyengeziwe engenamqondo ngakho-ke, ilungele ukufakwa egumbini lokubiyela elisegumbini eliseduze. Ngenxa yenjini yezomnotho kanye ne-air Supply fan enemvamisa yokushintshana okuguqukayo, i-burner idla inani eliphansi likagesi.

I-boiler ixhumeke ngepayipi nge-boiler yokushisa engaqondile yevolumu ye-logaluxst ye-200l. I-boiler ethe mpo ifakwe isilawuli sokushisa ngesibonisi sedijithali kanye nedivayisi yomthelela. Ukukhiqizwa okuphezulu kwensiza kunikeza i-Exchanger ye-Smooth-tube yangaphakathi yokushisa okushisayo ngendawo enkulu yokudlulisa ukushisa. Kufakwe izinzwa ezimbili zokulinganisa zokushisa: kwisembozo esiphezulu futhi phakathi kwethangi, okubalulekile ukulawula ukusebenza kwe-boiler.

Uhlelo lwe-Wiring no-Water Heathsing of the Floor lwenziwa ngamapayipi wensimbi-ne-dimensional (Kisan, Poland). Ukwehlisa izinga lokushisa lamanzi elifudumele lifinyelela kuma-45 s (ngaphandle kwalokho liba lishisa kakhulu) emgqonyeni wamandla abo asebenzisa umxube futhi afaka i-oventrop (germany) Regulator. Njengoba amakhono okufudumele phansi afudumele ukuze afudumele endlini ayenele, ama-radiator wensimbi (UKermi, iJalimane) enama-thermostatic valve afakwe ngaphansi kwamafasitela (Danfoss, Denmark) ngaphansi kwamawindi.

Ukusebenza okugcwele kohlelo lwesimanje lokushisa lwendlu yezitini kungenzeka kuphela ekuxhumaneni nohlelo lokupholisa umoya kanye nomoya womoya. Ngakho-ke, ukulethwa okungokwemvelo kanye nomoya omncane ngeminyango kanye namafasitela anama-valve ahlinzekwe kumiswe ekotashi. Ukuphazamiseka kokuphazanyiswa kufakwe ukugeleza kwama-grees averation. I-Napanese nasekhishini yafaka ugesi kagesi abalandeli.

Ukuhlinzekwa kwamanzi nokukhucululwa kwendle. Ukuhlinzekwa kwamanzi kanye nezinhlelo zokuthuthwa kwendle ezakhiweni zezitini nazo zinokucaciswa kwazo, kepha lo mehluko, uma uqhathanisa nezakhiwo zokhuni, zibaluleke kakhulu. Amanzi anikezwa indlu evela ekunikezelweni kwamanzi okuphakathi noma umthombo. Ngokusebenzisa i-hydroaccumulator (ihlinzeka ngengcindezi yamanzi eqhubekayo ekunikezelweni kwamanzi angaphakathi) ingena esitshalweni sokwelashwa kwamanzi. Ngokwemiphumela yamasampula angaphambilini, amanzi afakwa ezinhlotsheni ezahlukahlukene zokuhlanza. Ingxenye yayo yayo iwela egumbini le-boiler yokondla uhlelo lokushisa, elinye liye kuma-boiler aqongelelayo, okwesithathu kuthunyelwa kumadivayisi wamapayipi futhi kudliwa izidingo zasendlini. I-Sketch elondolozwa emanzini endlini yasungulwa ama-Flowters Amanzi Abandayo Namanzi, Izindlu zangasese ezingenazindleko ezinezinyathelo ezimbili zokukhipha. I-Wastewater isethwe kabusha kwiyunithi yokuhlanza ye-biotal (Czech Republic). Ukufakwa kwe-biotal-1.5 kwenzelwe umndeni wabantu abangu-4-6. Ukuthekelisa kwemikhiqizo yokucubungula, umshini wokuhlola awudingeki. Umphumela wokuhlanjululwa wakhelwa imikhiqizo emibili yokugcina efanele ukusetshenziswa: Amanzi wezobuchwepheshe wamanzi wesibili nomanyolo we-organic. Ukulawulwa kwenqubo yokuhlanza kwenziwa kusetshenziswa i-microcomputer, okuvumela ukuthi wenze kahle ukusebenza kokufakwa kusuka endaweni yokubukwa kwamandla nokusetshenziswa kwenqubo. Lapho ugesi unqanyuliwe, i-biotal-1.5 iyaqhubeka nokusebenza njengesigaxa esinezinyathelo ezi-5, namanje ukuhlinzeka ngokwelashwa kwamanzi ongcolile, kuphela ngokuhamba kancane. Lapho amandla avuselelwa, idivaysi ishintsha ekusebenzeni okujwayelekile. Ubuchwepheshe obusetshenziswa kwi-biotal-1.5 buqeda ukwabiwa ngesikhathi sokusebenza kokufakwa kwe-methane ne-sulfurgesi. Akukho phunga elingathandeki nalokhu kuzo zonke izigaba zokuhlanza, futhi, ngakho-ke, idivaysi ingabekwa endaweni eseduze yendlu.

Ukubalwa okukhulisiwe kwezindleko zomsebenzi nezinto zokwakha indlu ngendawo ephelele ka-225.7m2

| Igama lemisebenzi | Amayunithi. phendula | Inombolo ye | Intengo, $ | Izindleko, $ |

|---|---|---|---|---|

| Umsebenzi weSisekelo | ||||

| Ukuhlelwa kokuqala kanye nodoti | M3. | 217. | 6. | 1302. |

| Ukucwengwa kwenhlabathi yesandla | M3. | 74. | Okuthenyalwayo | 740. |

| Ukuhlela isayithi ngumhlabathi osele | M3. | 143. | isishiyagalombili | 1144. |

| Ukwakhiwa kwamapuleti wesisekelo wekhonkolo eqinisiwe (amafomu, ukuqiniswa, ukukhomba) | M3. | 61. | amashumi amahlanu | I-3050. |

| Idivaysi yokugcina izindonga, izindonga ze-cellars zokuphakama kokhonkolo okuqinisiwe kuze kube ngu-3m | M3. | 32. | 75. | 2400. |

| Idivayisi yezitebhisi zeMonolithic | M2. | 4,4. | 95. | 418. |

| Ukuvuleka kwamanzi okuvundlile futhi okulandelayo | M2. | 232. | isihlanu | 1160. |

| Ingqikithi: | 10 220. | |||

| Izinto ezisetshenzisiwe esigabeni | ||||

| Ukhonkolo esindayo | M3. | 98. | 62. | 6076. |

| I-granite yamatshe echotshoziwe, isihlabathi | M3. | 25. | 28. | 700. |

| Izinkuni zeSawn | M3. | isihlanu | 110. | 550. |

| IHydrosterClozol, Bitumen-Polymer Mastic | ukubeka esikhathini esithile | - | - | 1330. |

| I-Armature AI III, i-wire kniting, izihlangu zefomu | ukubeka esikhathini esithile | - | - | 1780. |

| Ingqikithi: | 10 440. | |||

| Izindonga, ukwahlukaniswa, ukunqwabelana, ukuphapha | ||||

| Ama-Masonry of izindonga zangaphandle nezingaphakathi zezitini | M3. | 122. | 32. | 3904. |

| Izitini zibheke ebusweni be-extender | M2. | 258. | ishumi nesishayagalombili | 4644. |

| Amadivayisi we-Brick Cartitions aqinisiwe | M2. | 122. | Okuthenyalwayo | 1220. |

| Idivaysi yekhonkolo ekhonkolo eqinisiwe ngaphezulu kwezindonga zamatshe | M3. | 33. | 75. | 2475. |

| Ukufakwa kwe-Rafter Design | M2. | 190. | Okuqophele imali | 2280. |

| Idivayisi ye-vaporizolation yekhambi | M2. | 190. | 2. | 380. |

| I-Metal Coating insiza | M2. | 190. | Okuthenyalwayo | 1900. |

| Ukwehlukaniswa kwezindonga, ukumboza kanye nokungena ngaphakathi | M2. | 500. | 2. | 1000. |

| Ukugcwalisa ukuvuleka ngamabhulokhi ewindows | M2. | 28. | 35. | 980. |

| Ingqikithi: | 18 780. | |||

| Izinto ezisetshenzisiwe esigabeni | ||||

| Izitini ze-Ceramic, ama-Conccrete Jumpers | izingcezu eziyizinkulungwane. | 48. | 190. | 9120. |

| UBrick Ceramic ubhekene | izingcezu eziyizinkulungwane. | 13 | 310. | 4030. |

| Ukhonkolo osindayo, isixazululo se-masonry | M3. | 60. | 65. | 3900. |

| I-Metallic Effered Sheet | M2. | 190. | Okuqophele imali | 2280. |

| Izinkuni zeSawn | M3. | amashumi amabili | 110. | 2200. |

| Paro-, Wind-, amafilimu we-hydraulic | M2. | 190. | 2. | 380. |

| Uhlelo lokukhipha | ukubeka esikhathini esithile | okukodwa | 1470. | 1470. |

| I-Polystyrere Foam PSB | M3. | amashumi amahlanu | 85. | 4250. |

| Amabhulokhi e-Plastice Window (amafasitela amabili acwebezelayo acwebezelayo) | M2. | 28. | 260. | 7280. |

| Ingqikithi: | 34 910. | |||

| Izinhlelo Zobunjiniyela | ||||

| Ukufakwa kohlelo lokuhambisa indle (septic) | - | - | - | 3500. |

| Kususelwa kudivayisi esekelwe endishini | - | - | - | 3900. |

| Umsebenzi kagesi nowokuphambanisa | - | - | - | I-6800. |

| Ingqikithi: | 14 200. | |||

| Izinto ezisetshenzisiwe esigabeni | ||||

| Imishini ye-boiler (Germany) | ukubeka esikhathini esithile | - | - | 8400. |

| I-biotal wastewater ukwelashwa kokwelashwa (Czech Republic) | ukubeka esikhathini esithile | - | - | 5900. |

| Amapayipi nemishini kagesi | ukubeka esikhathini esithile | - | - | 9200. |

| Ingqikithi: | 23 500. | |||

| Izindleko eziphelele zomsebenzi: | 43 200. | |||

| Izindleko eziphelele zezinto zokwakha: | 68 900. | |||

| Ingqikithi: | 112 100. |

Abahleli babonga i-estroy ne-uraspromom ukuthola usizo ekulungiseleleni lokho okuqukethwe.