Izinhlelo zesimanje zokulawula okuzenzakalelayo: Izinzuzo zazo, izici nokusebenza.

Ukuhlanza okuhlangene

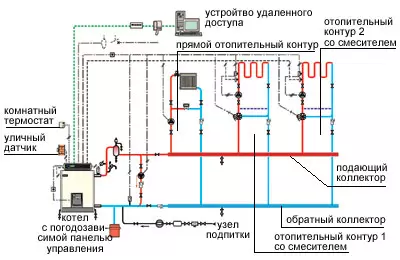

Isikimu sokwenza igumbi le-boiler sisebenzisa umsabalalisi we-thermohydra-lyric athuthukiswe ngu-de Dietrich

Umndeni wokushisa amajika. Imigqa enokuthambekela okukhulu isetshenziselwa izakhiwo ezinomfaki we-thermal ophansi kanye okuphambene nalokho

Ukuhlela ukufudumeza ekhaya, abambalwa kuphela ababheka ukuthi kungenzeka yini ukusebenza kwemishini ye-boiler enezinhlelo zesimanje ezenzakalelayo. I-aveted systems njengamanje isatshalaliswa kabanzi futhi yakhelwe ukukhulisa induduzo yezindlu futhi inciphise kakhulu izindleko zokushisa kwayo.

Izinzuzo zokulawula okuzenzakalelayo

Igumbi lesimanje le-boiler akunakwenzeka ukuthi licabange ngaphandle kwezinhlelo ezenzakalelayo ezihlanganisa zonke izimpumelelo zakamuva emkhakheni we-Heat Flux Control. Kuyaphawuleka ukuthi kubantu abaningi kuze kube manje, ngeshwa, inqubo enkulu yekhwalithi yohlelo lokushisa ihlala umgomo "Ukufudumeza akushiyeli." Akasebenzi ngokuphelele ezinhlelweni zokushisa ezenzakalelayo, bambalwa abantu abahlola ukubaluleka kokufakwa kwe-automation yabo ekhethekile, obuzohlinzeka ngezinga eliphakeme lenduduzo eshisayo endlini.Kuze kube manje, kuncishiswa kakhulu ngezindleko zokushisa futhi ngasikhathi sinye ukwakha isizinda sokushisa esihle endlini ngohlelo lwesimanje lwe-thermostat. Lokhu kungenxa yokwenziwa kahle komsebenzi wazo zonke izingxenye zemishini yokushisa. Qaphela ukuthi cishe wonke ama-boilers ekuhlelweni kwawo okuyisisekelo anokuzenzakalelayo okulawula ukushisela, kuthatha amasiginali avela kumadivayisi wokuphepha we-boiler, futhi asekela amazinga okushisa apholile afunekayo. Uyacelwa ukuthi uqaphele: Yi- "boiler" lokushisa, hhayi igumbi. Yini engagcini umsebenzisi esidlekeni ukuze aguqule lokhu njalo ngokuya ngesidingo sokushisa.

Ngokufaka imishini engaphelele enjalo, uzikhuthaza ngokuzithandela "ku-Watch" yaphakade "esibangelweni se-thermostat: lapho amazinga okushisa emigwaqweni ehla, amanzi ohlelweni azodinga ukushisa ngamandla, futhi lapho kufudumele emgwaqweni . Kungenzeka ukusebenza lokhu kusebenza ngokukhohlisa nge-thermostat kuya ku-infinity. Kepha uma ekuqaleni kwesimo sezulu esibandayo "discontinuity", i-boiler iwela ngentando yentando yentando yentando (indawo yokuhlala (ngenye indawo yokuhlala endlini iba yinkinga), njengoba kwenzeka kaningi, ukunciphisa izinga lokushisa kwamanzi ama-boiler, kubonakala hhayi empeleni. Ngemuva kwakho konke, njengoba wazi, ngazimbili zamathambo ngeke kuqambe amanga. Yebo, futhi akazange adlulise okuningi phakathi kwabathandi baseMelika ukuvula iwindi lapho igumbi lishisa kakhulu.

Ngokwemvelo, le ndlela yokushisa nokusindisa kwamandla izobona umnikazi wendlu ehlangana ngemuva kwesikhashana. Nje ngenxa yokungapheli amandla kaphethiloli. Umkhuba we-Avede wamanani akhuphukayo wabathwali bamandla ayisisekelo, aboniswe ngokusobala eminyakeni yamuva, ngokusho kochwepheshe, bazoqhubeka ngokuzayo. Vele, akunakuba khona ukukhuluma nganoma iyiphi induduzo eshisayo ngezindlela ezinjalo ze-thermostat. Ngokusho kochwepheshe, umsebenzisi we-boiler, engafakwanga uhlelo oluzenzakalelayo, uchitha amahora angaphezu kwama-210 esikhathi somuntu siqu ngonyaka kuphela ekusethweni kokushisa okupholile ku-boiler!

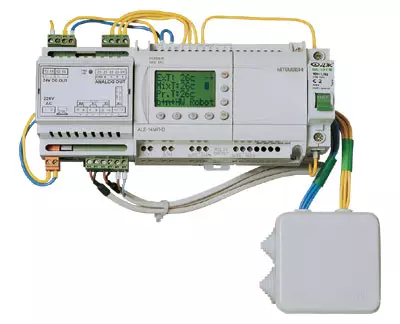

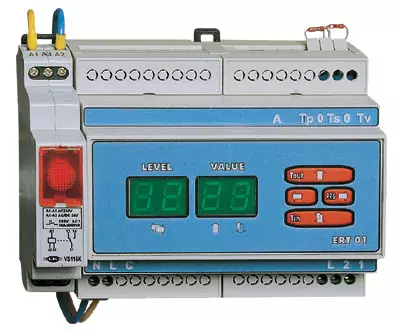

Elinye ibhizinisi lingamaphaneli wesimanje wokulawula ama-microprocessor. Bakuvumela ukuthi ulondoloze amazinga okushisa ahlukene ngokushesha emibuthanweni embalwa yokushisa. Ngaphansi kwe-contour enjalo kuyingxenye yohlelo olusebenza ngezindlela zalo zokushisa kanye nezimpawu zalo ze-hydraulic futhi unethuba lokulungiswa kwazo. Lokhu, ake sithi i-contour yokushisa kwe-radiator noma eyodwa ye-contour efudumele yamanzi. Isibonelo, uhlelo R 3 33/4 induduzo ye-digi kusuka ku-wolf ilawula izifunda ezine ezimele, kanti umbala matic kusuka ku-vaillant unamandla okulawula umsebenzi weshumi nanhlanu, futhi izinga lokushisa lokuphola ngaphakathi kwalo lincike esimweni se isimo sezulu esitaladini. Amasistimu anomgomo onjalo wokulawulwa abizwa ngeMeteo-alawulwa noma, njengoba ochwepheshe bathi, kuncike isimo sezulu (mayelana nomgomo wokulawulwa kokuncika kwesimo sezulu sizokhuluma ngenhla). Ukulawula amazinga okushisa angaphandle kulezi zinhlelo, kusetshenziswa inzwa yomgwaqo, efakwe esakhiweni esingaphandle, kusukela ohlangothini olusenyakatho. Isilawuli (uhlelo) sohlelo futhi sinesibopho ngokuphelele senqubo yokupheka amanzi ashisayo ku-boiler.

Khipha amasistimu abeka umgomo wokwakha modular. Ikuvumela ukuthi uhlome uhlelo lwesimo esithile nezidingo zamakhasimende, futhi uxhumeke eminye imigqa bese ulawula ukusebenza kwawo ngokufaka imodyuli ehambisanayo, ngaphandle kokufaka i-Contrence Panel.

Namuhla, imakethe yaseRussia imelelwa kabanzi ezenhlelo ezivela kumafemu amaningi angaphandle, ngokwesibonelo iKomeXtherm (iCzech Republic), i-Germany (iSpain), i-Honeywell (Italy), futhi amanye amafemu.

Ngokwehlukana, kufanele kushiwo ngezinhlelo ezizenzakalelayo zokulawula ezinikezwa ngabakhiqizi bemishini yokushisa efana neViessmann, I-Vaillont, Junkers (BUKERS (FRANCEN), CTC (Sweden), kanye nakwabanye. Izinhlelo ezihlinzekwe yilezi zinkampani namuhla zihambelana nemiqondo yesimanjemanje kakhulu "yokuphathwa kokushisa" futhi ihlukaniswa ukuthembeka okuphezulu. I-automation enjalo ikuvumela ukuthi uxazulule cishe noma yimisebenzi ehlotshaniswa nokulawulwa kwezinqubo ezishisayo, futhi iqinisekise ukusebenza okuphephile kwemishini. Ukuthathwa kwalezi zinhlelo kufaka izindleko eziphakeme kakhulu - kusuka ku-650-700 kuya ku-2000-2500 noma ngaphezulu.

Ukufudumeza contours

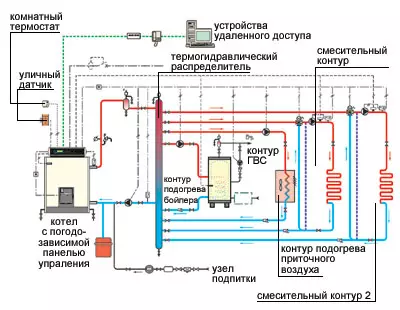

Ukuqaliswa kokushisa okuzenzakalelayo kwesimo sezulu kunzima yinkimbinkimbi yokuthi ekusebenzeni kwanamuhla kuyadingeka ukuphatha i-contour engeyona eyokuhlanza indlu, kepha uhlelo olunemidwebo eminingana. Ake sizame ukuzibonakalisa.

Cishe ngaso sonke isikhathi kukhona i-radiator heating contour. Ukuyiphatha ngempumelelo, kuyadingeka ukugcina izinga lokushisa lokugeleza ebangeni le-50-85c. Kwesinye isikhathi ama-contours anjalo afakiwe, ngokwesibonelo emafulethini ahlukene wendlu, futhi izinga lokushisa kuzo nalo lingehluka.

Uma ama-heater kagesi azimele noma egesi engafakwanga-ke, njengomthetho, ahlinzeka ngokushisa okuphezulu (kuze kube ngu-70-85c) ukufudumeza amanzi ashisayo ashisayo. Izinga lokushisa lokuphola kulo kufanele lihlale njalo.

Izimfuneko zentendula zikhula njalo, futhi namuhla abathengi abaningi bayala ukufakwa okwengeziwe kokunye noma ngaphezulu kwezitezi ezifudumele zamanzi. Lokhu kuyizinhlelo zokushisa eziphansi ezinokushisa komugqa okuguqukayo (30-55c).

Uma kukhona ichibi lokubhukuda, amanzi kuwo mhlawumbe ufuna ukufudumala. Ukuze wenze lokhu, umjikelezo okhethekile wesistimu yokufudumeza amanzi echibini angafakwa. Kukushisa okuphezulu, okushisa njalo kwama-coolant 70-85s.

Ngokufanayo, ukufudumeza ichibi kuhlelwe i-contour yokushisa komoya ovuthayo ekushiseni kohlelo lokushisa umoya. Kepha, kulo msebenzi, izinga lokushisa lokuphola lapha akudingekile ukuba lihlale njalo.

Ukusetshenziswa kwamanzi nge-radiator kanye nomjikelezo wezitezi ezifudumele kungahluka. Lokhu kwenzeka ezimweni lapho, ngokwesibonelo, ama-thermostatic ama-valves anamakhanda afudumele afakwe kuma-radiator, umsebenzi wawo wokushintsha isilinganiso sokugeleza kokuphola ngawo futhi, ngokufanele, kuwo wonke umjikelezo wokushisa uwonke. Ngokufanayo, ama-thermostators ahlukene angafakwa kwi-Camshaft Collector yohlelo olufudumele lwaphansi.

Umgomo wokulawulwa kwesimo sezulu

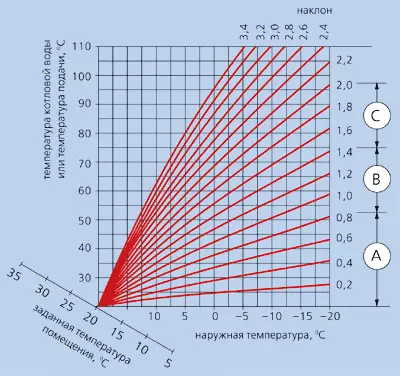

Ake sichaze ukuthi kugcinwa kanjani izinga lokushisa kwekamelo, kucatshangelwa ushintsho emgwaqweni. Lapho usetha isilawuli, ijika elibizwa ngokuthi izinga lokushisa lisethiwe, libonisa ukuthembela kokushisa okupholile esifundeni sokushisa kusuka ekushintshiwe kwezimo zezulu ngaphandle. Le curve ingumugqa, iphuzu elilodwa lalihambelana no-20 ° C emgwaqweni (ngenkathi izinga lokushisa lokuphola esifundazweni sokufudumeza libuye libe ngu-20 ° C, ngoba kubhekwa ukuthi akunasidingo se ukufudumeza). Iphuzu lesibili lokushisa le-coolant (lithi, 70c), lapho ngisho nosuku olubandayo kakhulu lwesikhathi sokushisa, izinga lokushisa egumbini lizosala lichaziwe (ngokwesibonelo, 23c). Ngaphandle kwalokho, uma ngabe isakhiwo sifakwe ngokwanele, ukunxephezela ukulahlekelwa ukushisa, kukhona izinga lokushisa elikhulu lokuphola endaweni yokushisa. Ngokuvumelana nalokho, ukuthambeka kwejika kuzoba ngcono. Futhi, uma konke sekuhlelekile ngokufakwa kwendlu. Ekwenziweni kwesilawuli kwimemori yedivayisi, ama-curve amaningi afanayo akwenza kube khona lapho ukhetha kuwo wonke umndeni womugqa ofanelekile wemibandela yekhaya lakho.

Njengomthetho, ukudala izinga eliphezulu lenduduzo eshisayo, kanye nokusindisa uphethiloli, inzwa eyodwa yomgwaqo i-One-Sole akwanele. Ngakho-ke, inzwa eyengeziwe ivame ukufakwa ngaphakathi egumbini elivuthayo. Ukuba khona kwezinzwa ezimbili, negumbi nangaphandle, kukuvumela ukuthi ulandelele ngokunembile futhi ulungise ngokushesha izinga lokushisa emakamelweni ekhaya.

Imvamisa, inzwa yokushisa yegumbi ifakiwe egumbini loku-preferembo okuthiwa, izinga lokushisa kulo lizofanela umqondo wakho ngesizinda esihle sendawo eshisayo. Leli gumbi akufanele lifudunyezwe ngemisebe yelanga eliqondile futhi lifiphele ngento ekhokhelwayo. Njengomthetho, izingane kanye namakamelo okulala akhethwe njengereferensi. Ukufaka inzwa yegumbi kwenza kube nokwenzeka ukunika amandla imodi yokuzivumelanisa nezimo, lapho ijika lokushisa likhethwe khona i-compart yokulawula ye-microcomputer efanelekile. Ngaphezu kwalokho, inzwa egumbini elivame ukuhlanganisa i-thermostat, lapho ungasetha khona amazinga okushisa afunekayo nezinga lawo eliphakathi nendawo. Ukulungiswa kwezinga lokushisa kwendawo egumbini elihlukile ngasikhathi sinye kutholakala ngokubeka ama-thermostatic valve ama-thermostatic valves.

Isici esibaluleke kakhulu sokusetshenziswa kwe-thermostat futhi sigcina ukonga. Ake sichaze ukuthi kwenziwa kanjani. Ake sithi egumbini lapho kufakwa khona inzwa, izivakashi zibuthene futhi kwaba nokwanda kokushisa kwe-2c ngenxa yesizukulwane sokushisa sabantu. Iphaneli yokulawula ibamba lezi zinguquko futhi inikeze umyalo wokunciphisa izinga lokushisa lokuphola kulesi sifunda, yize inzwa yomgwaqo ingadinga ukubuyela emuva. Ukunciphisa ukusetshenziswa kokushisa kokushisa le ndawo ngokwemvelo kugcina uphethiloli. Kepha kunezinkinga lapha. Uma ukhukhula egumbini lapho kufakwa khona i-thermostat, indawo yomlilo noma ushiye iwindi elivulekele isikhathi eside, kungaholela ekushintsheni kwezinga lokushisa kuyo yonke indlu. Ngokubalwa kwezinto ezinjalo, amasistimu amaningi ahlinzekela amathuba okuchibiyela i-algorithm yokulawula ngokubeka i-coefficient yethonya lenzwa yegumbi ngomlingiswa wejika lokushisa. Kepha ngokuvamile, ochwepheshe bamane nje abakuncomi ukufaka amadivaysi okushisa okushisa asemakamelweni aseduze kwezindawo zokucima umlilo, iminyango yokungena, amawindi kanye neminye imithombo yokushisa noma ukubanda okukwazi ukwenza iphutha emiphumeleni yokulinganisa.

Kufanele futhi kubhekwe eqinisweni lokuthi ukufakwa kwegumbi i-thermostat yedwa, ngaphandle kwenzwa yokushisa yangaphandle, kwandisa kakhulu i-inertia yohlelo lokulawula okushisayo. Izinguquko ezingemuva ezishisayo zizokwenzeka ngerisidi, ngoba ezenzakalelayo zizoqala ukusebenza kuphela lapho amazinga okushisa endlini, ngokwesibonelo, futhi lokhu kuzokwenzeka, futhi lokhu kuzokwenzeka ngokuhamba kwesikhathi kupholile kwangempela emgwaqweni.

Izilawuli zanamuhla azilandeli isimo sezulu kuphela, kepha futhi zinenani elikhulu ngokwanele lemisebenzi, ezinye zazo eziyinkambiso, kanye nenkonzo yengxenye. Uma owokuqala enogada, owesibili ulandelwa yisimo sohlelo futhi uqinisekise ukusebenza okulungile nokuphephile kwemishini.

Amacebo okukhipha ama-boiler kanye nemigomo yokuphathwa kwe-contour

Ukuze uhlele umsebenzi wesekethe owodwa noma ngaphezulu wokushisa ohlelweni lwe-hydraulic, kufanele axhunywe emvuzweni yokushisa generator-boiler. Lo msebenzi ungaxazululwa ngezindlela ezihlukile, ochwepheshe bababiza ngokuthi amacebo wokukhipha amakamelo we-boiler. Cabanga ngokujwayelekile kubo, kanye nemigomo yokuhlela inqubo efanele yokuphatha ngayo yonke inzuzo yazo nobunzima.

Imibuthano yokushisa ngendlela yokuthola izinga lokushisa kuzo ihlukaniswe ngokuqondile nokuxuba. Izinga lokushisa lamanzi ku-Direct Circuit litholakala kuphela lapho nje kuncipha futhi kuncike esikhathini sokusebenza kwalo. Izinga lokushisa le-coolont lizimisele zombili ukusebenza komngcwabo kanye nesikhundla se-valve ye-actuator-mixer ne-servo. Ngemuva kokuguqukela ekuhlolweni kokuqala, ungahlobanisa kalula i-boiler yokushisa ephansi nge-loop eyodwa yokushisa i-radiator futhi unikeze ukulawula okuzenzakalelayo kwayo ngokuya ngokushisa kwangaphandle. Iphuzu lilula futhi alibizi kakhulu. Uma kudingekile ukuhlela, ngaphezu kokushisa, kanye nokuhlinzekwa kwamanzi okushisayo, futhi ngaphandle kokuguqukela ekuxubeni izindawo, izinhlobo ezimbili zezinhlelo zisetshenziswa. Owokuqala yi-crane yezindlela ezintathu, uhlelo lwesibili olunamaphampu amabili.

Okulula kakhulu ngumdwebo onokushintshwa kwezindlela ezintathu okufakwe nge-servo. Amanzi avela ku-boiler athunyelwa kwi-crane, okuthi, okuqondise kuyo noma esekelweni lokushisa noma emjikelezweni wokushisa we-boiler. Ukushintshwa kungenziwa ngesandla, okuvame ukuchitha isikhathi futhi ku-boiler control panel umyalo. Ukulawulwa kokushisa kwamanzi ku-boiler kuthwala ezenzakalelayo usebenzisa inzwa yokushisa efakwe kuyo. Lapho amanzi epholile ngaphansi kwezinga elidingekayo, umyalo usondliwa ukuguqula i-crane yezindlela ezintathu. Uyacelwa ukuthi uqaphele ukuthi naleso sikimu sokugxuma nokulawula ngesikhathi sokushisa kwamanzi ku-boiler, ukufudumeza kucishiwe (okuthi, akunakwenzeka ukuhlela ukulawulwa kokuhlinzekwa kwamanzi okushisayo nge-Interid.

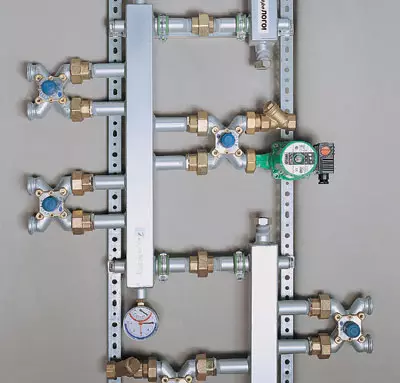

Isikimu somqoqi, ngokulandelayo egameni, kubandakanya ukusetshenziswa kwabaqoqi bezendlu boiler, okungamapayipi ngeziphetho ngenani elidingekayo le-contours. Lolu hlelo, ukubalula impela, lwalugcwele kakhulu ngenxa yokubonakala kwezinto ezibizwa ngokuthi izingxenye ezisheshayo zokufaka. Ukwakheka kufaka amaqembu okupompa manje akhiqizwa abakhiqizi abaningi bemishini yokushisa, kufaka phakathi i-CTC, iBuderus, i-Ditrich, i-Viesmann, i-Vaillant, kanye neMebies (Germany). Lawa madivayisi akuvumela ukuthi ngokushesha (ukubopha kwegumbi le-boiler kuthatha izinsuku ezimbalwa) ukuhlanganisa uhlelo olunemibuthano embalwa yokushisa. Kodwa-ke, kufanele kuqashelwe ukuthi amamojula afanayo asetshenziswa kakhulu kumandla amancane e-boiler - aze afike ku-85 kW. Noma kunjalo, zilula kakhulu lapho zifaka futhi zinciphise kakhulu ubungozi bephutha ngenxa yento eyaziwayo yomuntu, ngoba ziqoqiwe futhi zihlolwe ukusebenza kwezimo zefekthri.

Inketho ethokozisayo yokugibela ama-boilers abo inikeza iTeleyane Laars (USA). Lokhu kusho umdwebo wamasongo aphambili nawesibili, umgomo wokusebenza kwawo: Amanzi e-boiler ahlala ejikeleza kwi-contour encane (indandatho eyinhloko), okuvela kulo, kutholwa okupholile. Abathengi abashisekayo (ama-contours ahlukahlukene). Ithuba lalesi sikimu yikhono lokuxhuma inani elikhulu lemigodi yesibili ngenkathi kuqinisekisa ijubane elikalwe i-duct ngokusebenzisa ama-boiler kanye nokulula okulinganiselwe komklamo. Ukwenza lula inqubo yokufaka yegumbi le-boiler ngokusho kwalolu hlelo, ama-kits asulungiselelwe anikezwa (ngokwesibonelo, "i-hydraulic", ekhiqizwe yi-hydromontazhh yaseRussia).

I-De Dietrich (France) incoma ukusebenzisa umsabalalisi we-thermohydraulic (ofushanisiwe kanye ne-TGR) ukuze isetshenziswe ekuphuleni amabhuluri ayo. Lapho isetshenziswa, ukusetshenziswa njalo kwe-coolant kutholakala ngedivaysi yokufudumeza, noma ngabe yiliphi inani lokusebenzisa amanzi emibuthanweni yokushisa, lapho le nkomba ingahluka khona. Ngenxa yalokhu, kungenzeka ukufezekisa ama-boileits alinganiselayo alinganiselayo kanye nokushisa.

Kubalulekile ukuqaphela ukuthi ezenzakalelayo zabakhiqizi abaningi zikuvumela ukuthi ulawule ama-boiler kanye ne-contours ezinhlobonhlobo zezinhlelo zokukhipha amakimu. Kodwa-ke, ukusesha kwenketho efanelekayo kakhulu futhi ukukhethwa kwe-automation kusafundiswa kangcono uchwepheshe.

Imisebenzi yangokwezifiso

Imisebenzi yomsebenzisi ngokuyinhloko phakathi kwezinhlelo ezahlukahlukene zokushisa ezikuvumela ukuthi uvumelanise imodi yokushisa ekhaya kuya ngesigqi sempilo yabahlali bakhona (ukulala nokuhamba komsebenzi, umsebenzi ongenamthungo). Ngokufanayo, kukhethwe izinhlelo zamanzi ashisayo. Uma umsebenzisi engahambelani noma iyiphi isethi ejwayelekile, ehlongozwayo ngumenzi, kungenzeka ukuzakhela eyakhe ngokushisa nokuhanjiswa kwamanzi okushisayo.Imodi "Ubusuku Obuhle" . Cishe zonke izinhlelo zinekhono lokufaka okubizwa ngokuthi yi-Night Light. Ososayensi bafakazele ukuthi umuntu olele uzwa ukhululekile kakhudlwana lapho izinga lokushisa egumbini lincipha kancane (ngokuvamile ngo-4c) okuhlobene negumbi lendawo yosuku (ngokusobala, ukusabela kwakhe kwakhiwa kubantu ngesikhathi sokuvuselelwa kwemvelo ngaphakathi amahora nobusuku amahora). Manje, zonke izinqubo ezishisayo zingama-inertia, futhi uma, ngokwesibonelo, zibeka isikhathi sosuku sohlelo lwezinsuku ngesikhathi sokuvuka kwakho, khona-ke, uzozwa ukungaphatheki kahle ngenxa yokuthi Igumbi alikaze libe nesikhathi sokufudumala ngemuva kobusuku. Ukuqeda lobu bunzima, ezilawuli eziningi zanamuhla sebenzisa imodi yangaphambi kokufudumeza yegumbi (kwesinye isikhathi okubizwa ngokuthi ukuphuma okubushelelezi kusuka kwimodi yasebusuku), ngokusho kwalapho amahora ambalwa ngaphambi kokuphakamisa kwakho, izinga lokushisa endlini liqala ukukhula kahle. Isibonelo, umsebenzi onjalo unawo, ngokwesibonelo, abalawuli bomndeni ongokoqobo kusuka ku-de Dietrich noma i-Odamatic 4000 kusuka kuBhurerus.

Izinhlelo zokushisa eziphansi . Ezingeni lamanje lokuthuthuka kobuchwepheshe bokufudumeza, kunokuthambekela kokuguqukela kumbuso wokushisa lokushisa okuphansi. Ngamanye amagama, ukunciphisa izinga lokushisa lokusebenza lamadivayisi wokushisa. Lokhu kuholela ekuboneni okunethezekile kwemisebe ye-thermal ngendoda. Inzuzo ebaluleke kunazo zonke yombuso wokushisa ophansi ukunciphisa ukusetshenziswa kwamafutha. Sebenzisa uhlelo lokushisa kwimodi yokushisa ephansi futhi ikuvumela ukuthi ufake i-automation.

By the way, imiqondo enjalo njengombuso wokushisa ophansi kanye ne-boiler yokushisa ephansi kufanele ihlukaniswe lapha. I-boiler ephansi yokushisa iyithuluzi lapho, ngenxa yezindawo ezithile zezinto zokwakha ezisetshenziswa ekukhiqizweni kwayo, noma ngenxa yezixazululo zangempela zobuchwepheshe, kungenzeka ukuthi ulondoloze izinga lokushisa lomugqa wokuphakelayo ezingeni kuya ku-40 ° C (Kanje, ngokwesibonelo, e-Irovit VKO boilers kusuka ku-vaillant) ngisho nangaphansi- kuya ku-30s (kuma-boilers we-GT 210 avela eDe Dietrich). Kulokhu, izinga lokushisa le-reverse alilawulwa nhlobo.

Imodi yokushisa yokushisa ephansi ingatholwa futhi ingasebenzisi i-boiler yokushisa ephansi, kepha kulokhu uzodinga abenzelizi - ama-cranes amathathu noma amane axubana ne-servo, okuzoxoxwa ngayo ngokwahlukana. Ukuphuza nabo i-beating boiler kuzosebenza kwimodi ehlala njalo ngamazinga okushisa amanzi aphezulu, futhi izinga lokushisa emibuthanweni yokushisa kuzoncika ekuvuleni kwe-crane yokuxuba, lapho amanzi ashisayo ahlanganiswa khona nokubanda, okubuyisela emuva.

Uhlelo olubaluleke kakhulu . I-codec yemisebenzi ebalulekile yezinhlelo zokulawula ezenzakalelayo ifaka amathuba okuhlela ukuphathwa kwamanzi okushisayo. Kubaluleke kakhulu, kuxutshwe futhi okungekho. Indlela evame kakhulu, ebaluleke kakhulu ayinawo amaphutha: Ngesikhathi sokusetshenziswa kwamanzi ashisayo, uhlelo lokushisa luvele lucishiwe. Lokhu kuvame ukungaholeli endlini endlini. Indlela ye-Okuhlanganisiwe ikuvumela ukuthi usebenzise ukufudumeza ekhaya le ngxenye yamandla we-boiler, engasetshenziselwa ukulungiswa kwamanzi ashisayo. Kodwa-ke, ngokuntuleka komthamo, wonke umthombo uchithwa ekugcineni. I-AhTTO kanjena "ukuhanjiswa kwamanzi okuphezulu okuphezulu" kungaqondakala egameni.

Ukujezisa . Isoftware yamaphaneli amaningi okulawula ivumela ukubulala amagciwane ashisayo we-boiler kanye ngesonto. Lokhu kwenziwa ngokwandisa izinga lokushisa ku-boiler kuya ku-80c imizuzu engama-20-30. Inqubo enjalo iqeda ukuba khona okungenzeka kwamagciwane e-legionelosis emanzini, kubangele i-pneumonia.

Ukuvikelwa okubandayo . Lapho nje amazinga okushisa angaphandle ehla ngezansi kwenani elithile, ezenzakalelayo zizokwethula ama-boiler futhi zizogcina izinga lokushisa elithile ohlelweni lokushisa ukuvikela i-defrosting yayo.

"I-Smart House" . Amamodeli wakamuva wezilawuli anikela ngethuba lokufinyelela okukude kocingo noma ekuxhumaneni kweselula kwe-GSM Standard kanye nokuhlanganiswa kwayo ohlelweni lwasekhaya oluhle. Le nketho inamadivayisi walabo abakhiqizi abasebenza ngemishini yokushisa, efana neViessmann, Budherus, de Dietrich IDR. Amadivayisi anjalo akuvumela ukuthi ulawule izinga lokushisa endlini kude nangesikhathi ukuthola ukuthi yikuphi ukungasebenzi kahle.

Amadivayisi aphezulu

Ukuze uhlele umsebenzi wezindawo zokushisa eziningana ezinamazinga ahlukile, hhayi amazinga okushisa aphakade, asebekhuthazi adingekayo. Okuvame kakhulu yimibhalo yokuxuba yezindlela ezintathu nene-ezine). Umgomo womsebenzi wabo uqukethe ukulungisa izinga lokushisa lokuphola endaweni yokushisa ehlukile ngokuxuba amanzi kusuka ku-boiler ngamanzi avela emugqeni wokubuyela emuva. Ngakho-ke, izinga lokushisa lokuphola kulayini wokuphakelayo lingahlukahluka kusuka kubuncane, ngokwesibonelo esilingana negumbi, kuze kube sezingeni eliphezulu elilingana nokushisa kwamanzi ama-boiler, kepha hhayi ngaphezulu. Ukuguqula i-crane kungenziwa ngesandla (akudingekile ukuthi kukhulume nganoma iyiphi i-automation automation!) Noma ngosizo lwe-Engineer-Servos ekhethekile.

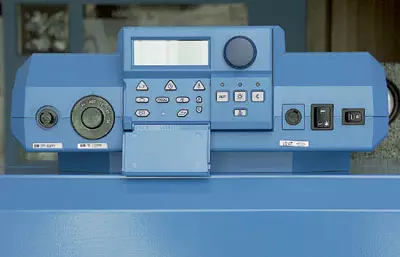

Imvamisa, amapharamitha amaningana e-servo drive aboniswa kwiphasiphothi yezobuchwepheshe. Lona voltage yamandla ahlinzekwa, i-torque ephezulu eyakhiwe emgodini, kanye nejubane le-drive. Isikhombi sokugcina sibonisa isikhathi soshintsho se-serlo ukusuka kwesinye isikhundla esibi kakhulu kwesinye. Lokhu kuvame ukusuka kumasekhondi angama-60 kuye kwangama-300. Kufanele kukhunjulwe ukuthi isikhathi esincane sokuphendula se-servo asisiqinisekisi ngokuphelele ukushintshwa kokushisa okusheshayo esisekelweni sokushisa. Khumbula ukuthi zonke izinqubo ezishisayo ziseqedizane kakhulu. Kungenxa yalesi sizathu ukuthi abasebenzayo ngokuvamile abasetshenziswa ngejubane lemizuzwana engaphansi kwama-60. Cishe leli nani lesikhathi liyadingeka ukushintsha inzwa efakwe kwipayipi lokuphakelayo, izinga lokushisa lalo alikwazi ukushintshwa ekushiseni okupholile, izinga lokushisa lalo alikwazi ukushintsha ngokushesha. Imenyu enamasondo e-All-Wheel of Amaphaneli amaningi okulawula inepharamitha yokufaka, ibheka ijubane le-servo. Isibonelo, kumaphaneli okulawula ochungechunge lwe-4000 ovela ku-Buderus olubiza ngo-1270 ekucushweni okuyisisekelo, isikhathi sokuvula se-valve yokuxuba yezindlela ezintathu sisethwe ngqo ngemizuzwana. Le nkomba iphazamisa ukusabela kwe-servo ethile futhi iboniswa ebhizinisini lobuchwepheshe.

Ukuxuba ama-cranes kanye ne-servo kushayela kubo kukhiqizwa abakhiqizi abaningana, njengeRoca, Komexferm, Wolf. Isidumbu se-crane singenziwa ngobabili sensimbi ne-zethusi. Kuhle kanti okunye ukwaziswa kukufanelekela ukusebenza ezinhlelweni zokushisa. Ama-mixers afakazelwe ngokuphelele enkampani yaseSweden Esbe. I-valve yokuxuba yezindlela ezintathu enobubanzi obungu-32mm, eyenziwe yile nkampani, ingathengwa ngo-60-70, i-servo drive izobiza kakade ku-150-170.

Imisebenzi yesevisi

Umoya omusha . Ukunciphisa inani lokukhishwa okulimazayo emoyeni, ezishintshayo ezisebenzayo ziyakwazi ukwenza kahle ukusebenza komsele. Isikhathi esincane sokushiswa sabalawuli besimanje sichazwa ekuqaleni. Lokhu kuqeda ukusebenza kwe-burner kumodi ye- "Start-Stop", kuthinta kahle izinsiza zemishini kanye nezemvelo. Iqiniso ngukuthi iningi lawo wonke ama-Emions ayingozi akhiwa ngesikhathi sokulahla. Lokhu kungenxa yokuhlangana okungaphelele kwamafutha. Ngokuzenzakalelayo, isikhathi esincane sokushiswa sivame okungenani umzuzu owodwa. Ngakho-ke, ukuthenga uhlelo lwanamuhla lokuphatha, awukhathaleli kuphela ngesikhwama sakho, kodwa futhi nangempilo yakho.

Ukuqala kahle . Umsebenzi othokozisayo ukubizwa okubizwa ngokuthi ukwethulwa kokukhipha. Ukuqala kokuqala (kubanda) kushintsha ku-boiler noma ngemuva kokuma kwayo isikhathi eside esithandweni somlilo kuvame ukuba khona ukwakheka okuqinisiwe. Njengomthetho, lokhu kuyingxubevange ye-acid ethinta izinto zangaphakathi zedivayisi. Kungukuqeda into engemnandi kangaka, izinhlelo eziningi zokulawula futhi ikuvumela ukuthi ukhiqize ukulayisha okuqala. Umnyombo wayo ulele eqinisweni lokuthi ngesikhathi sokufakwa kokushisa kwamaphampu okushisa asasebenza, ngakho-ke okupholile, okuku-boiler, kushukunyiswa ngokushesha kuze kube ngu-40-60C. Yilolu banga olubhekwa njengeliphephile ngomqondo wokwakheka kwe-condensate, okusho ukuthi isikhathi semiphumela elimazayo yalezi zinto zokugcina sincishiswa kakhulu. Ngemuva kokufinyelela emazingeni okushisa afunekayo, amaphampu wokushisa amasekethe futhi uhlelo luqala ukusebenza kwimodi ethile.

"Nick" Pumps . Kuzinhlelo eziningi zesimanje, ungabeka isikhathi "esiphansi". Lesi sici sivimbela ukwehla ngokweqile kwe-boiler. Iqiniso ngukuthi kuma-boilers (ikakhulukazi i-pig-iron) kukhona ukwanda kokushisa kwamanzi ama-boiler vele ngemuva kokunqamula okushisayo. Iwayini livela ngaphakathi kokushintshaniswa kokushisa kwensimbi okuqondiswe ebusweni elibheke esithandweni somlilo kulowo ogeza okupholile. Le nqubo izokwenzeka kuze kube yilapho amazinga okushisa angaphakathi nangaphandle alingana, futhi ukugcwala ngokweqile kwe-boiler kungenzeka. Kungakho kubalulekile ukuthi ungayeki ukujikeleza amaphampu ngokushesha, kodwa ubanikeze isikhathi sokusebenza.

Indlela ethokozisayo yokuxazulula le nkinga yanikezwa ochwepheshe abangamaBuderus kumaphaneli we-Logamatic 4000 Series, adala ukusebenza "ukusetshenziswa kokushisa okusele". Lapho kufudumeza okupholile, i-boiler ingenawo izinga lokushisa eliphakeme, kepha kuphela okubaliwe, lapho ezenzakalelayo zivala khona ukushisa, futhi ukushisa kuyaqhubeka ngezindleko zomphumela ochazwe ngenhla. Amandla abelwe, vele, awanyamalali ngeze, kepha asetshenziselwa ukuthola amanzi ashisayo ku-boiler.

Ihlobo . Izinhlelo eziningi zokulawula zinomsebenzi wokukhishwa kwamaphampu. Kuqaliswa, ngokwesibonelo, kulawulo lwe-E6 Series kusuka eKromschroder (Cost- 382), kumaphaneli okulawula amaVitotronic aqhamuka eViessmann, induduzo ye-Digi kusuka ku-Wolf nabanye abaningi. Iphampu ende engasebenzi yokujikeleza ukujikeleza ingasebenza, yingakho ehlobo, phakathi nokungasebenzi okude, mhlawumbe kufanelekile isikhashana ukufaka.

Ukubonisa ama-boilers

Omunye ufunda i-athikili yethu usazoba nesikhathi sokusebenza nabahlinzeki bohlelo lokushisa ukuze basebenzise i-boiler nge-automation yanamuhla. U-Akak ukuba ngumuntu osuvele unayo i-boiler ethembekile engenisiwe enephaneli yokulawula noma idivaysi yasekhaya nakancane ngaphandle kohlelo lokulawulwa, kepha ufisa ukukuhlomisa nge-automation yesimanje yokuthembela isimo sezulu?

Okokuqala, ngithanda ukweluleka ukuthi ngithinte inkampani ethengisa ama-boilers akho omkhiqizo. Cishe wonke umenzi ongathi sína wemishini yokushisa anokuzenzakalela okufanayo ku-assortment yawo. Kepha uma lokhu kungenzeki ukuthola noma uma amapharamitha awo angakuvumeli ukuthi uxazulule imisebenzi ebekwe yikhasimende, kufanele uthathe uhlelo lomunye umenzi.

Kunezinketho ezimbili zokuphinda usebenzise ama-boilers. Owokuqala uphakamisa ukuthi ukulawula okuzenzakalelayo kwazo zonke izingxenye zohlelo. Ngasikhathi sinye, iziqu eziphakeme ze-automation zitholakala futhi zinciphise kakhulu ekusebenziseni uphethiloli. Isibhedlela, ukuhlomisa ama-boilers ngenketho yokuqala akayona njalo. Kunzima ukwenza uhlelo ngesimanjemanje nokushisela komkhathi. Isibonelo, ama-boilers athandwayo asekhaya asekhaya afakwe i-burner enelangabi elithi "laphakade", lingcolisa ngesandla, elingavumeli ukwenza inqubo yokushisa. Kulezo zimo, kunikezwa inketho yesibili, efaka ukugcina izinga lokushisa emibuthanweni yokushisa usebenzisa abasebenza nge-actuilers ngokuzenzakalelayo. I-boiler enale nketho izosebenza ngokuqhubekayo, imvamisa ephezulu kakhulu, okuzwakalayo kokudla, futhi ngokungathi kunjalo, "phila impilo yakho", kanye nemibuthano yokushisa elawulwa ngumlawuli.

Abaphathi abakhiqizwayo benzelwe ukufakwa kuzo zonke izinhlobo zemishini ye-boiler, abahlomele bobabili ukushaya kanye nabashisi bezulu. Kuyiqiniso, kufanele kuqashelwe ukuthi ukuhlomisa kabusha i-boiler akunakuphumelela, umsebenzi onjalo kufanele ufundiswe nguchwepheshe wenkampani ethembekile enesipiliyoni sangempela sangempela.

Ngamagama engingathanda ukuqaphela ukuthi ukutholwa kwe-automation yanamuhla akukona nhlobo inkokhiso kwimfashini, kepha ukutshala imali enenzuzo. Isibonelo, ngokweNkampani "HydroMontazh", kuma-boilers kawoyela owuketshezi, ezenzakalelayo zesimanje kukuvumela ukuthi ugcine kuze kube yi-30% kaphethiloli futhi uzokhokha ngemuva kweminyaka eyi-1-3, ikakhulukazi ngamanani wamanje amanani entengo enkulu izinsiza.

Abahleli babonga inkampani ethi "hydromontazh", "rusklimat", "termtudia", i-STK-Group, ihhovisi elimele uBhudoru ngosizo lokulungiselela lokho.