Izinzuzo nokubi kwamanzi afudumele ngaphandle uma kuqhathaniswa ne-radiator, uhlelo lokufaka kanye nezici zokusebenza.

Ukufaka ekufakweni kwe-Thermal nge-Bobbs kukuvumela ukuthi unciphise isikhathi sokufaka ngenxa yokungabikho kokusebenza okusheshayo kwepayipi kokushisa okufakwayo

Impahla ebaluleke kakhulu ubude obukhulu bepayipi elinikezwe ema-bays

Ibanga letheyipu ukunxephezela izakhi zokushisa ezi-screen

Amapayipi anamuhla:

I-a- i-polymer;

IPolybutene;

I-polyethylene engamelana nokushisa kwe-pht kusuka ku-aquaterm

Inhlamba yokuhlola ngokusho kwe-snip 2.04.05-91 * "Ukushisa, umoya omncane kanye nomoya omoya" kungabhekwa ekwakheni izakhiwo

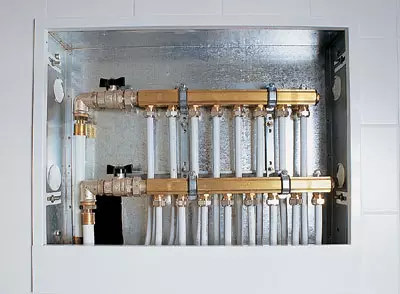

Amakhabethe ahlanganyelwe ngokungena ngaphakathi kwengaphakathi

Izigaba ezifudumele ezikhuphukayo: I-Titting Rardder Tape bese ubeka ungqimba lwezinto ezisetshenziswayo zokushisa

"Amapayipi e-RASK" enziwa ngokusho kwephrojekthi

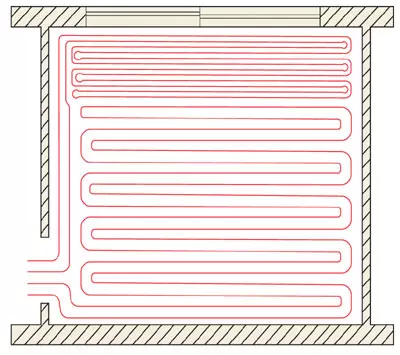

Isitoko sesinyathelo - Inani libalwa, akufanele lidlule ku-30cm. Esimweni esiphambene, ukwakheka kwe-zebra yokushisa, kukhombisa ukushintshana ngemivimbo efudumele nebandayo phansi

Umthungo wesinxephezelo uvimbela ukuqhekeka ngenxa yokwanda kwayo kokushisa

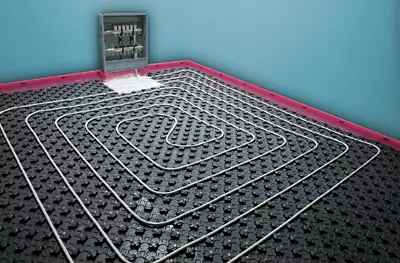

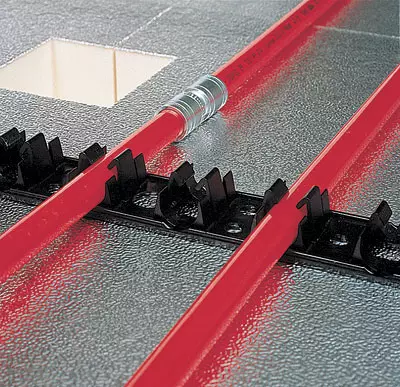

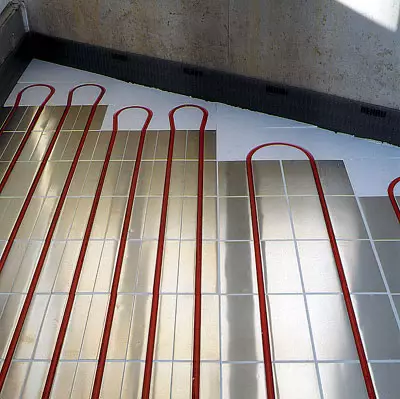

Ukubeka amapayipi kubuchwepheshe be- "Occuctational" kwenziwa kwi-grooves yamapuleti akhethekile e-polystyrere foom

Ukufakwa kwamapayipi usebenzisa igridi yokuqinisa. Amapayipi anamathele kugridi ngama-clamp epulasitiki noma intambo yokungena

Ukubeka amapayipi kungenziwa kumaplanethi afakiwe

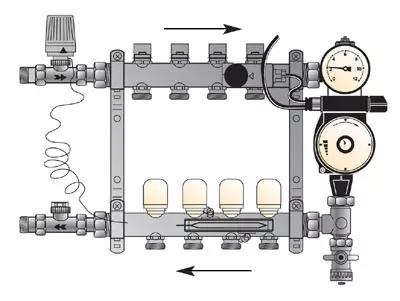

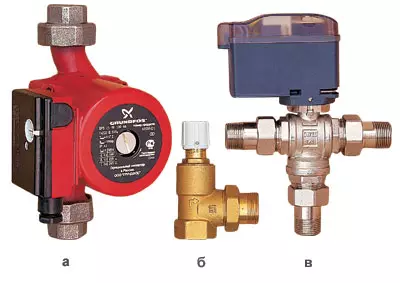

Ukujikeleza kokujikeleza kukhuphuka ngo-32-80 (a) kusuka ku-grundfos (a) kusuka e-valve yebhola elinezindlela ezintathu nge-modulo compact servo (b) kusuka e-Emmeti naseBypass Valve (B)

Amaphaneli okulawula ama-boilers anamuhla akuvumela ukulawula amasekethe amaningi okushisa. Njengomthetho, izinga lokushisa kule mibuthalo lisethwe yiphaneli yokulawula ngokuzenzakalelayo ngokuya ngokushisa kwangaphandle

Njengamanje, izitezi ezifudumele zamanzi ziya ngokuya zithandwa ekwakhiweni komuntu ngamunye. Okokuqala, lokhu kungenxa yesifiso sabathuthukisi banamuhla ukuthuthukisa imibandela yokuhlala ekhaya labo futhi, uma kungenzeka, banciphise izindleko zokushisa.

Izinzuzo ezifudumele phansi

Ukufudumeza kwangaphandle, ngokungafani ne-radiator, kwaziwa ngombuthano obanzi wabafundi hhayi kudala, yize kungukusungulwa kwasendulo. Ukuvuvukala kwemivubukulo kubonisa ubukhona bohlelo olufudumele lwaphansi kubantu basendulo, okuthi, ngokungafani nobuchwepheshe besimanje (amasistifu), wafuthelwa ngentambo kagesi noma amapayipi anamanzi afudumele, kodwa ngomoya ofudumele, odlulile esuka esithandweni senethiwekhi iziteshi. Kuyathakazelisa ukuthi enye iminyaka eyishumi nanhlanu edlule, umthengi waseRussia mayelana namathuba okufudumele kwacishe kube yilutho olungaziwa.Ngakho-ke, uhlelo olusebenza ukushisa phansi komhlaba futhi luyisebenzisa njenge-accumulator yokushisa kanye ne-howerover yokushisa, ibizwa ngokuthi uhlelo "olufudumele".

Isitezi esifudumele uma siqhathaniswa ne-radiator heating sinezinzuzo ezilandelayo:

Ngokushisa kwangaphandle, ukusatshalaliswa kokushisa egumbini kusuka endaweni yokubuka kwe-physiology kusondele kakhulu kwabaphelele. "Gcina ikhanda lakho emakhazeni, futhi imilenze ifudumele." Kodwa-ke, lesi sithi esidala asichazi kahle isheduli yokusabalalisa yokushisa ngokuphakama kwegumbi;

Ingxenye eyinhloko yokushisa (kuze kufike ku-70%) idluliswa ngemisebe, ebonwa kahle kakhulu;

Ukugcina amandla afudumele - ezakhiweni zokuhlala ezingama-20-30%, emakamelweni anophahla oluphezulu (kusuka kumamitha amathathu aphezulu) kuya ku-50% nangaphezulu;

Ukungabikho kwamadivayisi wokushisa wendabuko kukuvumela ukuba usebenzise kahle indawo yokuhlala;

Ukungabikho kwemifudlana yokuziphatha kuholela ekwehleni kwenani lothuli emoyeni wegumbi elivuthayo;

Ngenxa yokushisa okuphansi kwe-coolant, kumayelana ne-25-50c, izitezi ezifudumele ziwuhlelo lokushisa oluphansi olungafaki ukwenzeka kwe-ionization enhle.

Iphrezentheshini enokuthola njalo abantu ukufudumala okuphezulu kwendawo yaphansi emazingeni aseYurophu kufanele kube + 29c, emakamelweni okugeza, amakamelo okugeza anokutholwa kwesikhashana kwenkathi yokushisa Iyahlukahluka ngaphakathi kwemingcele kanye ne-24-26c.

Inkinga yokuzikhethela

Izitezi ezifudumele zingamagesi namanzi. Okokuqala, indawo efudumele ikhebula lokufudumeza, lapho amandla kagesi aguqulwa khona abe yi-thermal, futhi satshelwa ngakho ngokuningiliziwe esihlokweni sethu sangaphambilini esithi "ukufudumala". Ngokwenguqulo engazelelwe, umthombo wamandla yiyona epholile evuthayo (imvamisa yamanzi), okuthi, edlula emapawini abekwe phansi, inika ukushisa. Kumele kwaziwe ukuthi ubuchwepheshe bokufudumeza kwamanzi "Floor Floor" busetshenziselwa kuphela ekusakazweni okuphoqelekile, njengoba kudingekile ukuhlela iyunithi yokuxuba ukuze kutholwe izinga lokushisa eliphansi lamanzi, futhi akunakhono ngaphandle kwephampu. Iyunithi lokuxuba lihlinzeka ngokushisa okuncishisiwe kokuphola okunikezwe ohlelweni ngokuxuba amanzi kusuka kumazinga okushisa afinyelela ku-90 ° C, abuyiselwe kumapayipi anamanzi (avela "okuletha" okufuywayo "). Intaba yohlelo olunjalo ngokususelwa ohlelweni lokushisa nge-Natural (Graverational) yokuphola inenkinga yemvelo ngokwanele, ngaphezu kwalokho, indawo eshisayo phansi evuthayo enohlelo olunjalo luzoba mincane.

Izitezi ezifudumele zamanzi zivame ukusetshenziswa kakhulu ezindlini zangasese. Ekufudumaleni okuphakathi nendawo ezinhlanganisweni zokufudumeza okuphakathi, ukuhlelwa kwalezitezi ezinjalo akuvunyelwe ngokuphelele - ngenxa yokwanda kokuphikiswa kwe-hydraulic kohlelo. Ngaphezu kwalokho, akwamukeleki futhi kuxhuma kumapayipi amanzi ashisayo. Ngemuva kwakho konke, amanzi aqhamuka e-DHW Riser, edlula emjikelezweni wamaphansi afudumele, abuya esebuyile manje, ngeke athande abathengi bamanzi ashisayo avela kwezinye izindlu ezivuthiwe ngemuva kohlelo olunjalo. Ngaphandle kwalokhu, izingcweti eziningi zisaqhubeka nokuxhumana okufanayo, yize izenzo zazo zijeziswa ngokuqinisekile. Okuhlukile kungabhekwa njengezakhiwo ezithile zanamuhla, lapho kunezimpikiswano ezihlelwe ngokukhethekile zokuxhuma phansi okufudumele.

Ngokusekelwe kulokhu okungenhla, uhlelo lokushisa likagesi lungabhekwa njengemukelekile kakhulu. Ngisho nezindlu kungakuhle ukusebenzisa izitezi zamanzi.

Izinzuzo zokusetshenziswa kwezitezi zamanzi, uma kuqhathaniswa nogesi ekwakhiweni kwezwe, akunakuphikwa. Okokuqala, ukwehla kwamandla okufakwa kukagesi kwendlu futhi, ngenxa yalokho, ukunciphisa izindleko zokukhokha ama-akhawunti wezinkanyezi kagesi (ngokushisa indlu encane ka-150-200m2, cishe ama-45,000 kph kagesi Ngonyaka kuzodingeka, izindleko zazo ezizoba ngaphezu kwama- $ 1550). Mayelana namandla okufakwa kukagesi ngokuvamile, ingxoxo ihlukile. Kwesinye isikhathi la mandla awathathi nje. Ake sithi ukufakwa kukagesi kwendlu kunamandla agqanyisiwe ama-5 kW, futhi kwahlelwa phansi okufudumele kufakwe ku-100M2 futhi kusetshenziswe u-100-120w / m2 njengokubala amandla aphelele wohlelo olunjalo kuzoba yi-10-12 kW.

Enye inzuzo yezitezi zamanzi ukungabikho ngokuphelele kwamasimu kagesi neyazibuthe, izingozi zazo ezisazoba izingxabano. Kodwa-ke, ngosizo lwamanzi afudumele amanzi, kunzima ukuthola amandla athile adlula ama-80-100w kusuka kumitha yesikwele ebusweni, ngakho-ke ukusetshenziswa kokushisa okunjalo njengento esemqoka eRussia kungenzeka kuphela lapho isakhiwo sifakwe kahle.

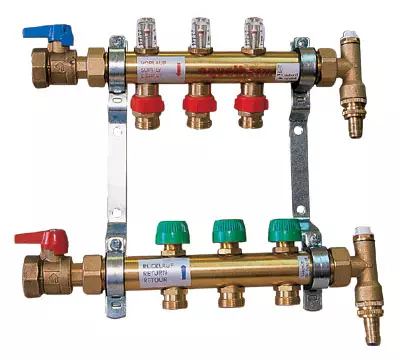

Izici zamaqembu abaqoqi

| Umenzi | Inani lama-loops axhunyiwe | Ububanzi, amayintshi | Okuqukethwe ukulethwa | Intengo, |

|---|---|---|---|---|

| I-Aquaport. | Kusuka 2 kuye ku-12 | okukodwa | Ama-cranes avaliwe, amabakaki okuqinisa, ama-2-hand air vent, ama-2 cranes amnandi | Kusuka ngo-120 kuya ku-476 |

| Emmeti.(I-ITALY) | Kusuka 2 kuye ku-12 | ; okukodwa; okukodwa | Ama-Cranes, amabakaki okuqinisa isilonda, ama-2 automatic air vent, ama-cranes ama-2-okumnandi kanye nokuqondisa ama-thermometers | Kusuka kuma-60 kuye kwangama-230 |

| Oventrop. | Kusuka 2 kuye ku-12 | okukodwa | Amabakashi e-Brackets yokuqinisa, 2RD Air Ver, ama-Cranes ama-2, amamitha okugeleza | Kusuka ku-100 kuye ku-400 |

| Isiqu (I-ITALY) | Kusuka 2 kuye ku-12 | ; okukodwa | Amabakaki okuqinisa, amamitha okugeleza, i-2automatic air vent, ama-cranes amabanga ama-2 kanye nokufakwa kwamapulangwe okunamathiselwe kwepayipi 162.25 | Kusuka kuma-80 kuye ku-360 |

| URehau. (Germany) | Kusuka 2 kuye ku-12 | okukodwa; okukodwa | Ama-cranes avaliwe, amabakaki okuqinisa, ama-2-hand air vent, ama-2 cranes amnandi | Kusuka ku-100 kuye ku-430 |

| I-TC (Germany) | Kusuka 2 kuye ku-12 | okukodwa | Pair of kubakaki yokuqinisa | Kusuka ngo-110 kuya ku-315 |

| Tiemme. (I-ITALY) | Kusuka 2 kuye ku-12 | ; okukodwa | Ama-cranes avaliwe, amabakaki wokuqinisa, ama-2automatic air vent, ama-2 cranes amnandi | Kusuka ku-68 kuya ku-270 |

| I-WIRSBO. | Kusuka 2 kuye ku-4 | okukodwa | Ama-gaskets, aphatha kanye nokufakwa kwama-crimp kwe-rech pipe 20 | Kusuka kuma-72 kuye ku-126 |

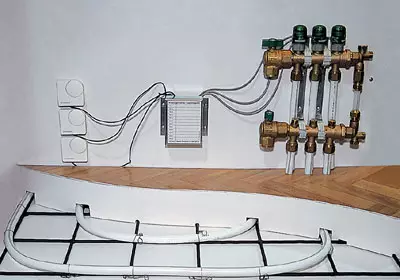

Izesekeli zokukhwela phansi

Cishe bonke abakhiqizi bamapayipi banamuhla (i-aquaport ne-oventrop, germany; i-wirsbo, iSweden; i-purmo, i-purmo, i-idr) nikeza uhla oluphelele lwezinto nezinto ezisizayo zokufaka izitezi ezigcwele. Lawa ngamapayipi, ukufakwa okushisayo (njengomthetho, nge-markuup), isinxephezelo (i-rant) tape, ama-fasteres, ama-places serepres, kanye nabaqoqi abanezinkulumo zokuxhuma ama-hinges phansi okufudumele ohlelweni lokushisa. Abaqoqi batholakala ngokuxhumana okungenzeka kusuka kusuka ku-loops ezimbili kuya kweziyishumi nambili ohlelweni. Izindleko zabo zingu-80-140 umqoqi ngamunye ama-hinges amabili futhi eza ku-400-480 nge-trelve-steppete.

Abaqoqi bangabekwa bobabili bavuleke futhi babheke phezulu noma amakhabethe ahlanganisiwe ahlanganisiwe. I-tape rant iyi-strip ye-polyethylene ye-folyethylene enobubanzi obungenabubanzi obungu-5mm no-120-180mm futhi ukhonza ukunxephezela ukwanda kwezinga lokushisa kwe-screen. Futhi, amafemu amaningi anikeza amaqembu e-POMP ahlanganisa izindawo ezisebenzela ukuhlela ukusakazwa kwe-coolant kuma-hinges of the flame afudumele.

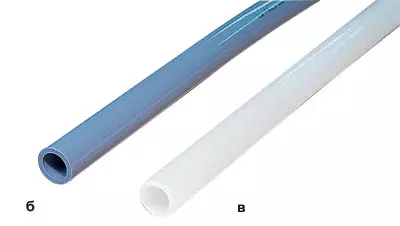

Ipayipi

Phambilini, ngaphambi kokuvela kwama-polymer namapayipi wensimbi-polymer, ezweni lethu bazama ukwenza phansi okufudumele kwezingxenye zepayipi lensimbi yensimbi, eyayingena enyoka nge-bender yamapayipi. Kamuva, lezi zingxenye zifakwe i-welding efudumele, futhi wonke umklamo wabekwa phansi futhi wabekwa ngodaka kasimende. Ababekhona akufanele bakhulume njengalolu hlelo.Isimo sesishintshile kakhulu ngokuqala nge-polymer namapayipi wensimbi-polymer. Banenzuzo eminingana, basheshe basabalele futhi, njengamanzi afudumele amanzi, baba cishe kuphela impahla yokwenza kwabo. ENtshonalanga, ukufudumeza kwangaphandle kusetshenziswa amapayipi anjalo kwaziwa iminyaka engaphezu kwamashumi amabili nanhlanu. Ngenhlanhla, abanakho ngaphansi kokugqwala, ungqimba lwangaphakathi wangaphakathi alunakumelana nokuhlukumezeka futhi akunasigalelo ekuqondeni kwemali, ngaleyo ndlela kulondolozwe ububanzi besigaba sepayipi njalo ngesikhathi yonke insiza (okungenani iminyaka engama-50) . Impahla ebalulekile ukumelana nokuphikisana okuphelele komoya-mpilo, okuvimbela ukugqwala ngaphambi kwesikhathi kwemishini yokushisa kanye nenhliziyo yalo lonke uhlelo lwe-boiler.

Inani elithile yi-footage enkulu yamapayipi ahlinzekwa ngama-bays. Ngokuya ngohlobo olunikeziwe, ubude bepayipi echibini kuyahlukahluka kubakhiqizi abahlukahlukene ebangeni ukusuka ku-50 kuye ku-500m. Lokhu kukuvumela ukuthi uyibeke ezindaweni ezinkulu endaweni yomfaniswano, ngaphandle kwamakhompiyutha aphakathi nendawo, okususa amathuba okuvuza kohlelo. Kodwa-ke, ungaba kanjani, uma kusekhona isidingo sokwenza ukuxhumana okuphakathi? Ingabe kuvunyelwe? Ngokusho kwesigaba 3.34 * Snip 2.04.05-91 * "Ukushisa, umoya omncane kanye nomoya ongenisa umoya" okuvunyelwayo kuphela (kuzodingeka ukuthi kube neLuchs). Okwezitezi ezifudumele, kusetshenziswa izinhlobo ezilandelayo zamapayipi: i-metal-plastic, polythethylene (bobabili i-pex ne-pe-rt) ne-polybutene.

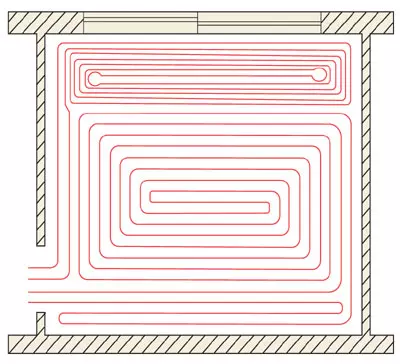

Izinhlelo zokuqalisa

Kunezinhlelo ezimbalwa zokubeka amapayipi zokwakhiwa kwe-loop esebenzayo (Heating). Le yinyoka, inyoka ephindwe kabili (noma "i-Meared"), i-Spiral and Spiral ngesikhungo esidingisiwe. Lapho ufaka i-hinge ngesimo senyoka, ukuhanjiswa kwamanzi okushisayo kuhlelwe kusuka ohlangothini lwadonga lwangaphandle, eduze kwalona ukulahleka kokushisa kuphakeme kunasenkabeni yegumbi. I-Stroke Contour Ukusatshalaliswa kokushisa okungekho emthethweni. Ukuze uyilungise, udinga ukufaka ama-loops ngendlela yenyoka ephindwe kabili noma kuvunguza. Isifunda esiseduze nezindonga zangaphandle zesakhiwo sibizwa ngokuthi izindawo zemingcele. Kunconywa ukunciphisa igxathu lokubeka ipayipi ukuze kunxephezele ukulahleka kokushisa. Isinyathelo sokufaka inani elibaliwe, kepha kunoma yikuphi akufanele lidlule i-30cm - ngaphandle kwalokho ukufudumeza okungafanele komhlaba kuzovela ngokubonakala kwemichilo efudumele nebandayo. Ukuze "i-zebra yokushisa" ingabonakali ngonyawo lwenyawo, umehluko omkhulu wokushisa eduze kobude bonyawo akufanele wedlule i-4C.

Ukugeleza kwamapayipi endaweni eyi-1m2 yephansi ngesikhathi esiteji 20cm cishe amakhilogremu ama-5. m. Kuhlotshaniswa neqiniso lokuthi ngenxa yokulahleka kwe-hydraulic ku-loop loop loop akusekho, akunconywa, kulula ukubala ukuthi esinyathelweni sokubeka ipayipi endaweni ye 20m2. Izingxenye zendawo enkulu kufanele zifudunyezwe ngama-hinges amaningana, ngalinye nalo, lixhumeke ekusakazweni manifold. Ngamanzi afudumele amanzi, ngokungafani nogesi, akudingekile ukubheka indawo yefenisha. Iqiniso ngukuthi ikhebula likagesi elingaphansi kwefenisha lingangenza ngokweqile futhi lehluleke, amapayipi apholile alokhu kuntuleka ancishwe.

I-Heating System Floor Floor usebenzisa njengokushisa okususelwa egumbini elincane ingafakwa ngaphandle kokubala izibalo ezibucayi. Kepha ukufakwa kohlelo olufanayo olusetshenziswe njengomthombo omkhulu wokushisa akunakwenzeka ngaphandle kokucabanga ukulahleka kokushisa kwesakhiwo, kanye nolwazi lwemithetho ye-hydraulics. Azikho ochwepheshe ngaphandle kosizo. Amafemu amaningi anikela ngemiklamo nokufakwa kwezinhlelo zangaphandle zokufudumeza kwe-turning. Ukubalwa kwalezo zinhlelo kuvame ukwenziwa kusetshenziswa izinhlelo ezikhethekile zekhompyutha.

| Umenzi | ikhodi yomthengisi | Ukujikeleza kwegazi | Amaphakethe wepompo | Incwajana | Intengo, | ||

|---|---|---|---|---|---|---|---|

| Ikhanda leMax, m | Ukusetshenziswa max, m3 / h | Ububanzi bokuxhuma, intshi | |||||

| I-Aquaport. | 94008. | Wilo rs 25-60 r | 6. | 3,2 | okukodwa | - | 630. |

| 94028. | Wilo rs 25-70 r | 7. | 3.8. | okukodwa | Ngesilawuli esithembele sezulu | 1470. | |

| UBudorus. (Germany) | HSM-25. | Wilo rs 25-60 r | 6. | 3,2 | okukodwa | Yakhelwe ukwabiwa nge-boiler efakwe isilawuli | 406. |

| De Dietrich. (France) | EA 63. | Grundfos. Phezulu 25-60 | 6. | 3,2 | okukodwa | Yakhelwe ukwabiwa nge-boiler efakwe isilawuli | 634. |

| Meibes. (Germany) | Mk 32. | Ngaphandle kwephampu (ipompu ithengwe ngokwahlukana) | - | - | okukodwa | Yakhelwe ukwabiwa nge-boiler efakwe isilawuli | 520. |

| I-WIRSBO. | 410080387. | Grundfos. Phezulu 25-60 | 6. | 3,2 | - | 570. | |

| 410803881. | Grundfos. Phezulu 25-60 | 6. | 3,2 | okukodwa | Ngesilawuli esithembele sezulu | 1560. |

Ubuchwepheshe beMontaja

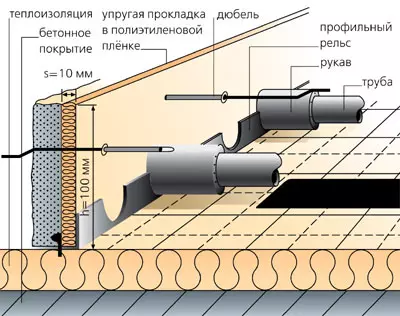

Ubuchwepheshe bokufakwa kwamanzi ama-autdoor systems kubakhiqizi abahlukene buyehluka, ukuhluka okuncane kwezitezi zikakhonkolo kufaka izinyathelo ezilandelayo. Okokuqala, ukuwohloka kwezakhiwo ezicebeni noma, njengoba kubizwa nangokuthi, amasimu. Inani lamasimu lincike endaweni yegumbi nejometri yalo. Indawo enkulu yensimu ingu-40m2 ngesilinganiso okungenani esingu-1 uhlangothi lwamaqembu: 2. Isidingo sokwenza amasayithi anjalo kubangelwa ukunwetshwa kwezinga lokushisa kwe-screed, okufanele kwenzeke - kungenjalo kuzokwenzeka. Ngakho-ke, emigqeni yokuqhekeka kwesikhala, ngemuva kokukhuphuka kwamapayipi, kuyadingeka ukuhlinzeka ngemishini yesinxephezelo esenza umsebenzi wokuheha amazinga okushisa.Umthungo onjalo uyigebe phakathi kwezingxenye ezimbili zezakhiwo ezihleliwe noma ezikhuphukayo (izindonga, amakholomu) agcwele izinto ezilinganayo. Nge-Seams Yesinxephezelo, kuphela okuphakelayo nokunciphisa ama-loops angaphasiswa, futhi la mapayipi kufanele avikelwe yi-tube ehlanganisiwe kusuka ekulimaleni okungenzeka. Amakamelo anesimo se-G-no-P ahlukaniswe ngezindawo ngaphandle kwale ndawo.

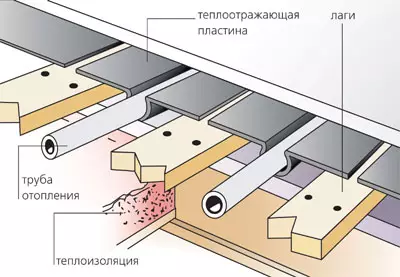

Ngemuva kwalokho, ukufakwa kwe-thermal kufakwe esisekelweni sangaphambi kokuhlanzwa, futhi itheyiphu evuthiwe igcotshwa eceleni kwegumbi, elisebenza ukunxephezela ukunwetshwa kwe-thermal of the screed. Kumele kuqashelwe ukuthi akekho noyedwa kubakhiqizi ongadingi ukufakwa emanzini okufudumele. Amapayipi, ngokuya ngephrojekthi ethile, "agingqikala" ngaphezulu kwesendlalelo se-warpest ye-infation futhi anamathele kuwo noma ama-harpudchers akhethekile, anamathele ngqo ekufakweni noma alungiselelwe kwigridi eqinisiwe eyandulelayo. I-WIRSBO inikezela ngamapayipi okuqinisa kugridi ukuze usebenzise i-wire ekhethekile yokuqinisa, ukuphotha uzungeze ipayipi lapho ufaka ithuluzi elikhethekile.

Abanye abakhiqizi, njengeRehau kanye ne-aquaport, bakhiqiza ukufakwa okushisayo ngama-bolsters akhethekile, phakathi kwawo iphiyithi elitshaliwe. Kunyamalala isidingo sokukulungisa, ukunciphisa kakhulu isikhathi sokufaka. Izindleko zalolu hlobo lokuhlukaniswa nobukhulu obungu-73mm nge-aquerproofing 10mm kuse-aquaport 8.94 nge-1m2 ngayinye. Futhi, ipayipi lingalungiswa ngemichilo ekhethekile enobuhlakani, okuyi-rack yepulasitiki enezithombe zokubeka nokulungisa amapayipi.

Esigabeni esilandelayo, ngemuva kokukhuphuka, amapayipi akhiqiza ukwakheka kwezinto zesinxephezelo emigqeni yokuqhekeka kwesikhala. Ngokushesha ngaphambi kokugcwaliswa kwesikrini, uhlelo lokushisa lucindezelwe. Ukucindezela kwengcindezi kwenziwa ngengxenye eyodwa nesigamu ngaphezu kwengcindezi yamapayipi e-auminal, ekhonjiswe kukho. Ukugcwaliswa kwesikrini kukhiqizwa emazingeni okushisa asekamelweni, kanti uhlelo lungaphansi kwengcindezi yokusebenza ebaliwe (ngaphansi kwemibandela ye-cottage imayelana ne-2-2.5 ATM).

Ngedivayisi, ama-screen ajwayele ukusetshenziselwa isixazululo sesihlabathi sikasimende noma i-sandbetone m-300. Amanye amafemu, anjenge-purmo, anikezwa ukwengeza ipulasitiki ekhethekile kwisikrini (izindleko ze-25-litre canister kusuka ku-12). Lesi sidakamizwa sinciphisa ukungezwani kwamanzi okusetshenziselwa ukulungiselela isixazululo, futhi sinomthelela ekwandeni kwesisindo se-volumetric se-coating, okukhulisa ukwanda kokusebenza kwalo okushisayo futhi ngasikhathi sinye amandla okucindezela kwanda ngasikhathi sinye. Ukusetshenziswa kwepulasitiki kuvame ukuba ngu-10% we-Volumetric Mass of Cement emsulwa, okuyingxenye yengxube. Imvamisa, ukushuba kwesendlalelo esenziwe nge-screen, okuphezulu ngenhla kwamapayipi, ngokususelwa ekubalweni okushisayo, okungenani ama-50mm (ekushiseni kwe-CoolAnt 50c kanye nobuso bephansi 30c). I-Plistic ikuvumela ukuthi unciphise leli nani lifinyelela ku-30mm, kepha kuzofanela ukwehlisa izinga lokushisa elipholile, ukuze lingashizi phansi. Uhlangothi oluqinile, ukwanda kokuvuselelwa okushisayo kwesiketi kuholela ekunciphiseni kwamathuba we- "lokushisa zebra".

Ungafaka uhlelo kuphela ngemuva kokuthi "ukuvuthwa" okuphelele kwesixazululo (izingoma ezisuselwa kuso usimende, le nqubo ithatha okungenani izinsuku ezingama-28). Noma ngemuva kokuthi isixazululo sithola amandla ngokuphelele, kuyadingeka kancane kancane futhi ukhulise ngokushelela izinga lokushisa lamanzi ohlelweni, ngokuphuma kancane kancane kwimodi yokusebenza izinsuku ezintathu.

Kunamacala akhethekile wokufakwa phansi kwamanzi afudumele amanzi, lapho ubuchwepheshe obugcwele "obumanzi" (isisulu sesimende) asisebenzi. Isibonelo, uma izitezi zingezinkuni noma lapho ukwakhiwa kwezitezi ezomile zenziwa kusetshenziswa ubuchwepheshe be-Knauf (Germany), kuncishiswe kakhulu isikhathi somsebenzi (kungenxa yokukhishwa kwezindlela zonke "ze-WET" Uma kwenzeka ukwanda okungamukeleki komthwalo ngokugcwala. Nawa ubuchwepheshe obubizwa nge- "Occuctational" Technologies.

Ngokufakwa kwezitezi zamanzi esisekelweni sokhuni, kuthuthukiswe ubuchwepheshe obukhethekile. Kubandakanya ukusetshenziswa kwamapuleti abonisa ukushisa, ngokwesibonelo, kusuka eWirsbo, ebekwe phakathi kwe-lag, ngemuva kwalokho ipayipi le-polymer lifakwe emapuleti. Kusekwengeziwe, ngaphezulu kwemishayo, kufakwa isembozo sokhuni. Kuyinto efiselekayo ukuthi ubukhulu bokuhlanganiswa okunjalo abungeqi 15mm ngenxa yokuvuselelwa okuphansi kwesihlahla.

Uhlangothi oluqinile, abakhiqizi bamanye amafulethini afudumele amanzi, njenge-thermotech scandinavia ab (Sweden) noRehau, anikele ngemikhiqizo ebaluleke kakhulu kulowo msebenzi wezobuchwepheshe bezobuchwepheshe "bokwenziwa" kokwakhiwa "kwe" owomile ". Izinto zokubekwa e-Dry kungamapuleti e-polystyrere foam anezinto zamapayipi. Kula mapuleti ezimeni zefekthri kusetshenziswa iphrofayili ye-aluminium eshisayo eqhuba. I-Thermotech Scandinavia AB inikezela ngokutholwa okufanayo kwephrofayili ngokuhlukile futhi kufakwe ngesikhathi senqubo yokufaka. Kusuka phezulu, izakhi ezinjalo zivaliwe ngamapuleti asuselwa ku-plaster (GWL).

Ngokwehlukana, kufanele ukhulume ngezimbotshana ezifakwe ohlelweni lwamakamelo afudumele amanzi. Okokuqala, lokho okuqukethwe kumele kube nokudluliselwa kokushisa okungekho ngaphezulu kwe-0.15m2k / W. Vele ngenxa yalokhu, ukumbozwa okuthandwayo njengamanje ngeke kwemukeleki. Ngeke kube nezinkinga nge-Surname Slab nezinye izinto ezifanayo, kepha ukufakwa kwephaphu, cishe akuzona zonke izinkampani ezizothatha. Okokugcina, akuzona zonke izinhlobo ze-elastic futhi amakhaphethi alungele izitezi ezinjalo. I-ASH evunyelwe ukuyisebenzisa kufanele ibe nokuqokwa okukhethekile.

Imishini nezinto zokwakha zokubeka amasistimu afudumele phansi ngendlu enezitezi ezimbili ze-250m2 (indawo yokubeka i-210m2)

| Ukukhonjwa kwemishini | Ukuqamba | Inombolo ye | Amayunithi. phendula | Intengo, | Izindleko |

|---|---|---|---|---|---|

| I-Polystyrere Thermal Insulation 12006003m | Pennoplex. | 292. | PC. | okune | 1168. |

| Itheyiphu ye-wempfer | I-Aquaport. | 75. | RM. M. | 0.8. | 60. |

| Into yedivaysi ye-seams yesinxephezelo | I-Aquaport. | 2. | Izingcezu eziyi-10. I-Pog.m. | 28. | 56. |

| Mesh ukuqinisa i-5050mm | 210. | M2. | 1,8. | 378. | |

| Iqembu eliqoqiwe kuma-loops ama-5 | Emmeti. | 2. | PC. | 146. | 292. |

| IKhabinethi Collector 744700150mm | I-SHRV-3. | 2. | PC. | 51. | 102. |

| Isiphetho sokufaka ipayipi kumqoqi | Emmeti. | Okuqophele imali | PC. | 1,3 | 15.6 |

| Ikhanda Thermoelectric 10 PCS. | Emmeti. | Okuthenyalwayo | PC. | 23. | 230. |

| Igumbi thermostat | Emmeti. | isihlanu | PC. | 65. | 325. |

| I-Clamps Plastic for ukuqinisa amapayipi kugridi | Umdobi. | 1200. | PC. | 0.03 | 36. |

| Ukufakwa okuthe xaxa | Oventrop. | 2. | ukubeka esikhathini esithile | 192. | 384. |

| I-Thermostat Yezokuphepha | Oventrop. | 2. | PC. | 38. | 76. |

| I-Pipe Metal-Plastice 16. | Henco | 1100. | RM. M. | 1,2 | 1320. |

| Ukujikeleza kwepompo | Grundfos. | 2. | PC. | 117. | 234. |

| Ucingo | Shvvp | 150. | RM. M. | 0,2 | amashumi amathathu |

| I-Peskobeton | M-300 | 450. | Bag 50kg | 2,1 | 945. |

| Umuthi ovukushelile enqubo nepulasitiki | I-Aquaport. | okune | Kanistra 25l. | 24. | 96. |

| -Nke | 5747.6 | ||||

| Umsebenzi okhuphukayo | |||||

| Ukufakwa phansi okufudumele | - | 210. | M2. | Okuqophele imali | 2520. |

| Amaqembu aqoqiwe | - | 2. | PC. | amashumi amahlanu | 100 |

| Idivayisi ye-Tie | - | 210. | M2. | 6. | 1260. |

| -Nke | 2620. | ||||

| -Nke | I-8367.6 |

Ukulawula nokubusa

Lunjani ukulungiswa kwamazinga okushisa kokuphola kuyo yonke indawo yokushisa, "kusebenza" izihibe eziningana? Ukuxazulula le nkinga, ukuqiniswa okukhethekile kwe-thermostatic nokuvalwa kwe-shut-off kudaliwe, okunikezwa ngabakhiqizi abaningi bamapayipi e-polymer kanye nezinto zokufakwa phansi kwamafulethi afudumele amanzi. Njengomthetho, ama-thermostatic ukuxuba ama-valves anikezela ngokuphola kwamazinga okushisa afunekayo kumqoqi. Ngokwehlukana, ukuqiniswa okunjalo kukhiqiza ama-cornea anjalo emakethe yokuqiniswa kwe-thermostatic kanye nokuvalwa kwe-turronics, njenge-ta-hydronics (iSweden), i-herfoss (i-denmoss (iDenmark). Lokhu kuqiniswa kufakwa ngaphambi kwabaqoqi emgwaqweni omkhulu wokuhlinzeka. Amanye amamodeli okufakiwe okunjalo anamandla okugcina hhayi kuphela amazinga okushisa womugqa wokuhanjiswa kwe-contour, kepha ngasikhathi sinye nokushisa kwegumbi, ngokwesibonelo, i-Unibox e Plus kusuka ku-Oventrop ebiza ngo-192.

Ngokusebenza kwezitezi ezifudumele, njengoba kushiwo ngaphambili, kwakudingeka iphampu yokusakazwa, engafakwa zombili egumbini lokubilisa futhi ifakwe kwi-node Collector. Leli mpompi lihambisana nokuqiniswa kwe-thermostatic kwamazinga okushisa alungiswa semomoni amafomu okuthiwa yiyunithi yokuxuba, mayelana nomgomo esiwutshelile ekuqaleni kwendatshana. Ukwenza lula ukufakwa, amafemu amaningi abucayi akhiqiza izindawo zokuxuba ukucushwa kwefekthri okuqediwe. Iphampu kwimodyuli efanayo ingalawula okujwayelekile ne-elektroniki thermostat ngekhono lokukhetha uhlelo lokushisa. Izindleko zalezi zindawo ziyahlukahluka ngaphakathi kwama-800-1600.

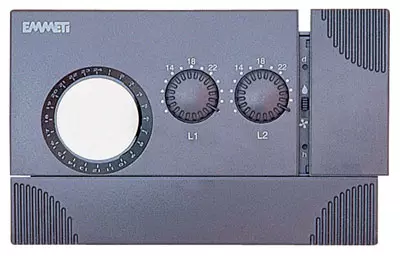

Hlukanisa Ukunakwa kokulawula amaphaneli okulawula ama-boilers amaningi anamuhla, anjengoButerus, iViilman, impisi (i-Wolf (i-All Germany), i-CTC (Belgium), i-ACV (Belgium), uDe Districh nabanye abaningi. Lawa madivayisi avumela ukulawula okuphelele kohlelo lonke lokushisa kuphelele, kufaka phakathi amandla okuphatha ama-contours amaningi. Imvamisa igcwaliswe ngezinhlelo zokulawula zamafulethi afudumele anamuhla, esikhundleni sokufakwa kwendabuko kwendabuko, kusetshenziswa ama-cranes wokuxubana amathathu noma amane, ahlome nge-servo drives. I-servo ngayinye enjalo ishayela i-crane ehambisanayo, ukulalela imiyalo enikeza iphaneli yokulawula. Ukuqapha izinga lokushisa komugqa wokuphakelayo kwenziwa kusetshenziswa inzwa yokushisa. Izindleko ze-crane enezindlela ezintathu ezinobubanzi obungama-32mm cishe abangama-85, kanti i-servo izobiza ngo-150-200. Futhi, kukhona futhi ukupompa okulungiselelwe ukupompa kanye namaqembu okuxuba okuqukethe empompini yokuxubana kathathu nge-servo drive, iphampu yokujikeleza nokuvalwa kwama-thermometer. Okokusebenza okufanayo, ngokwesibonelo, okwenziwe ngabakwaMeibes.

Njengomthetho, izinga lokushisa lokuphola kule mibuthalo lisethwe yi-boiler ngokuzenzakalelayo- ngokuya ngokushisa kwangaphandle. Ngamanye amagama, i-contour ilawulwa yi-meteo noma, njengoba ochwepheshe bathi, kuncike isimo sezulu. Ngokunjalo, ngokwesibonelo, amaphaneli okulawula ama-logmatic 4211 avela ku-Buderus, R16 Digi induduzo evela eWolf noma eVitotronic 200 KW2 evela eViessmann. Ukulungisa umjikelezo wokuxuba usebenzisa iphaneli yokulawula ama-boiler kuyinto youne, okukuvumela ukuthi ulungiselele yonke i-contour ephelele futhi, ubheka iqiniso lokuthi lingaxhunyaniswa kulo, lingaxhumeka emakamelweni afudumele, afudumeza amakamelo ahlukene ingaxhunywa.

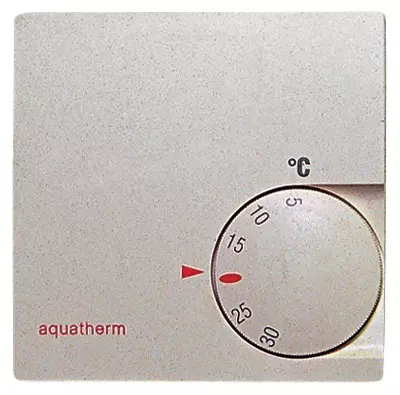

Ukulawulwa kokushisa kwasendaweni kwama-loops kwenziwa kusetshenziswa ama-thermostats afakwe ekusakazweni manifolds. Ama-thermostats yizinhlobo ezimbili zesenzo se-thermomechanical (amakhanda ajwayelekile esisetshenziselwa ukusibona kuma-radiator afudumele) noma ama-hermostats e-elekhtronikhi ngekhanda le-thermoelectric (servo). Imvamisa itholakala ku-comfer ye- "reverse" collecteror ikamu (nge-loop ngayinye ikhanda elihlukile le-armal liyadingeka). Esimweni esilandelayo, ukuhlelwa kwezinga lokushisa kuma-hinges of the furm floor kwenziwa ngesandla. Kulokhu, isikhathi ngasinye lapho udinga ukusondela kwi-node Collecteror futhi, ujikeleze ikhanda le-thermostatic, usethe imodi edingekayo. Embonweni wesibili, i-heating degree incike kwiyunithi ye-elekthronikhi, engatholakala ngqo egumbini lapho kwafakwa khona phansi okufudumele. Inzwa ehambisanayo ilinganisa izinga lokushisa lekamelo, hhayi phansi, okulula kakhulu. Ngasikhathi sinye, okupholile okuhlinzekwe ku-loop of the Flate Floor akufanele kufuthelwe ngenhla kwe-55c.

I-armostat ye-codcan ye-elektroniki ingaxhunywa ku-servo drives eminingana. Isidingo soxhumano olunjalo senzeka emakamelweni amakhulu kakhulu, angenakukwazi "ukumbozwa" kuphela loop. Kulokhu, ama-elekthronikhi alawula ama-servos ama-loops ambalwa ngasikhathi sinye, okusho ukuthi izinga lokushisa laphansi lizoba okufanayo kuyo yonke indawo yalo. Ngaphezu kwalokho, ama-thermostat afanayo anesici sezinhlelo. Isibonelo, bakuvumela ukuthi ukhethe imodi yokufudumeza ebusuku ngokushisa okuncishisiwe noma setha uhlelo lokusebenza lwe-timer ukufaka nokucisha ukufudumeza ngezikhathi ezithile.

Umkhawulo wokuphelela yi-radio bermostats efakwe ezakhiweni ezahlukahlukene futhi udlulisele isibonakaliso kumakhanda we-thermoelectric, njengakubo bonke, kumqoqi, ngamagagadi omsakazo. Vele, amasistimu anjalo alungele umsebenzisi, ngaphandle kwalokho, kumane nje kulula ukukhweza (kuyanyamalala isidingo sokubeka izintambo). Ukudonswa kwemali kuphela kwalawa ama-thermostats kuyindleko yabo ephezulu. Isibonelo, isethi enezishayeli eziyisithupha ze-servo, ama-radiothermostats ayisithupha (egumbini ngalinye kukhona i-thermostat eyodwa), iyunithi elilodwa elawula umsakazo kusuka ku-aquaport lizobiza umthengi ngo-1550.

Ukukhipha okuphakelayo okungahleliwe kumqokeleli we-coolant nge lokushisa ngaphezulu kwama-55s, kusetshenziswa ama-thermostats okuphepha. Baxhuma ipompo yokujikeleza ukusakazwa uma uketshezi lubathulula luzofudunyezwa ngenhla komkhawulo obekiwe.

Kufaka phakathi engifisa ukusho amagama ambalwa mayelana nezindleko ezifudumele. Inkambu efudumele yamanzi ayishibhile. Endlini ecishe ibe ngu-200-250m2, izindleko zokuthola lonke uhlelo kanye nokufakwa kwalo kuzoba ngu-30-60 nge-1M2. Ngokumelene nalokhu, indawo efudumele kagesi engu-15-20 nge-1M2 izobukeka ithandeke ngokwengeziwe, kepha kufanele ikhunjulwe ukuthi izindleko zokuthola nokufaka phansi ukushisa kwamanzi zisesikhathi esisodwa futhi, ngokusho kochwepheshe be-boiler Khokha eminyakeni eyisithupha eyisithupha.

| Umenzi | Ukuqokwa Kwezentengiso | Uhlobo | Uhlelo lokufakelwa | Ububanzi obungaphandle, mm | Ingcindezi yokusebenza max, ibha / lokushisa, nge | Intengo yepayipi ye-1pog / efanelekile ye-PC ngayinye, (ngepayipi 16) | Incwajana | |

|---|---|---|---|---|---|---|---|---|

| "I-Altais" (Russia) | "I-Altais" | I-nke | Crimp kanye nezinto zokucindezela | Kusuka ku-16 kuye ku-32 | 10/95 | Kusuka ku-0.5 / kusuka ku-1.0 | I-Aluminium ungqimba uqweqwe olungu-0.2mm, welded | |

| Co.S.S. (I-ITALY) | Coeskima Super K. | I-nke | Crimp kanye nezinto zokucindezela | Kusuka ku-14 kuye ku-32 | 10/95 | Kusuka ku-1.4 / kusuka ku-2.2 | I-Aluminium ungqimba uqweqwe u-0.4mm, uJack we-Welded | |

| UGeberit. (Switzerland) | UGeberit Mepla | I-nke | Uhlelo olufanelekile olufanele ngaphandle kokubhalwa ama-bushings | Kusuka ku-16 kuye ku-63 | 10/95 | Kusuka ku-2.8 / kusuka ku-6.5 | Ungqimba lwe-aluminium uqweqwe olusuka ku-0,8 mm, u-welded jack | |

| Oventrop. | Qopha | I-nke | I-COFIT CRIMP bese ucindezela ukufakwa | Kusuka ku-14 kuye ku-32 | 10/95 | Kusuka ku-2.2 / kusuka ku-5.7 | I-Aluminium ungqimba uqweqwe u-0.4mm, uJack we-Welded | |

| Prandelli. (I-ITALY) | Multirama. | I-nke | Crimp kanye nezinto zokucindezela | Kusuka ku-14 kuye ku-32 | 10/95 | Kusuka ku-1.6 / kusuka ku-2.3 | I-Aluminium ungqimba uqweqwe u-0.4mm, uJack we-Welded | |

| Tc. | Teceflex. | I-nke | Uhlelo olukhethekile olufanele ngemikhono eshukumisayo | Kusuka ku-16 kuye ku-63 | 10/95 | Kusuka ku-1,8. | I-Aluminium ungqimba uqweqwe u-0.4mm, uJack we-Welded | |

| I-Valsir. (I-ITALY) | Pexal, okuhlanganisiwe | I-nke | Crimp kanye nezinto zokucindezela | Kusuka ku-14 kuye ku-32 | 10/95 | Kusuka ku-1.0 / kusuka ku-2,5 | I-Aluminium ungqimba uqweqwe olungu-0.2mm, welded | |

| Ubhogalo (EFinland) | I-Unise. | MP ngesendlalelo sangaphakathi se-PE-RT | Crimp kanye nezinto zokucindezela | Kusuka ku-14 kuye ku-110 | 10/95 | Kusuka ku-1.6 / kusuka ku-3.1 | Ungqimba lwe-aluminium uqweqwe olusuka ku-0.2mm, u-Welded | |

| Bir Pekc (Russia) | - | Pex. | Crimp kanye nezinto zokucindezela | Kusuka ku-16 kuye ku-63 | 6/95 | Kusuka ku-0.8. | - | |

| URehau. | Rautitan flex | Pex. | Uhlelo olukhethekile lwe-rababic Fittings | Kusuka ku-16 kuye ku-32 | 6/95 | Kusuka ku-1.8 / kusuka ku-4.2 | - | |

| Tiemme. | - | Pex. | Crimp kanye nezinto zokucindezela | Kusuka ku-16 kuye ku-32 | 6/95 | Kusuka ku-1.4 / kusuka ku-2.2 | - | |

| I-WIRSBO. | Peex. | Pex. | Uhlelo Olukhethekile Lokuqina Quikeasy Fittings | Kusuka ku-16 kuye ku-32 | 6/95 | Kusuka ku-2.0 / kusuka ku-5.3 | - | |

| I-Aquaport. | 90300. | PB. | Ukufakwa kwama-crimp | Kusuka ku-16 kuye ku-20 | 6/95 | Kusuka ku-1.38 / kusuka ku-3 | - | |

| Infombatha Systemtechnik. (Germany) | Infombatha I-Curta. | PB. | I-Thermal Welding, Crimp kanye Nezindaba Zokucindezela | Kusuka ku-6 kuye ku-20 | 6/95 | Kusuka ku-1.6 / kusuka ku-2.3 | - | |

| Universa. | - | MP ngesendlalelo sangaphakathi sePolybuthen | I-Thermal Welding, Crimp kanye Nezindaba Zokucindezela | Kusuka ku-16 kuye ku-32 | 10/95 | Kusuka ku-3.8 / kusuka ku-6.5 | - | |

| I-MP-Metal-Plastic ngesendlalelo sangaphakathi se-pex; Pv- polybutene; Rehot - kusuka ku-polyethylene eqinile |