Inhloso yemibuthano yokusika ebabazekayo, imininingwane, imithetho yokufundisa, izincomo ezisebenzayo zomsebenzi.

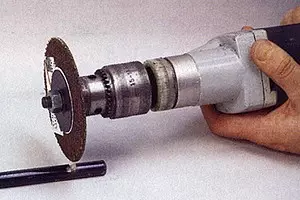

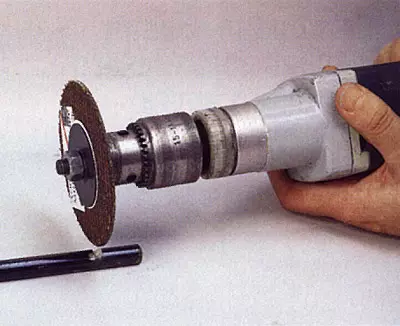

Ukufakwa kanye nokuhlanganiswa kwendilinga yokusika e-abrasive on the shaft "Bulgaria":

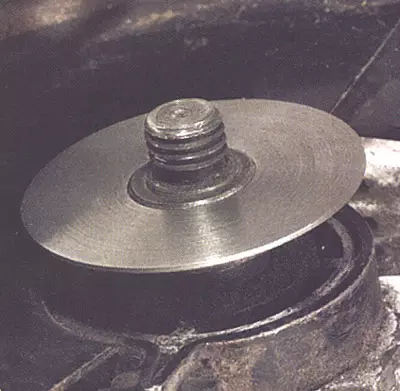

munye. Beka i-puck yensimbi enobubanzi obungaphandle bengaphansi kwe-1/3 yobubanzi bendilinga kwi-drive shaft.

2. Thatha i-gasket kusuka ku-Cardboard noma nge-elastic impahla, ubukhulu bawo bungu-0.5-1,0 mm.

3. Vikela umbuthano nomgodi wepulangwe, ubeke i-gasket yesibili, bese kuthi i-washer yesibili yensimbi, futhi i-gasket ngayinye kufanele yenze ngaphansi kwe-washer ngenani elilingana nobukhulu bawo, bese uqinisa le "khekhe le-bulgaria" ne-nati "yaseBulgaria".

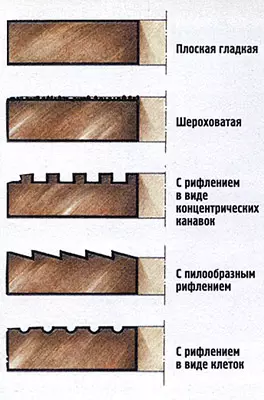

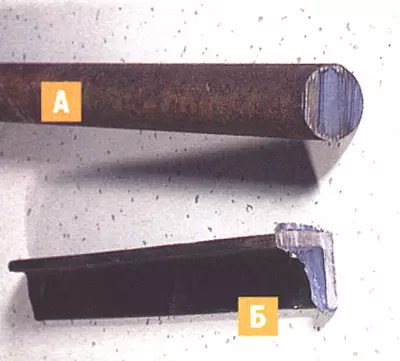

Ukuqhekeka embuthanweni ohlukumezayo (a), umkhawulo we-chip wokusika (b) kanye "nokushanela" kombuthano (b), ukusetshenziswa kwawo kunganconywa ngawo

Ngabe kufanele unqume ekhoneni lensimbi lama-35x35mm ukuthola amapayipi abamba ukushisa noma amapayipi wensimbi we-semi-amaqabunga epayipi lamanzi ekhasini lezendlu? Uma kunjalo, khetha phakathi kwensimbi yokuhoxiswa, i-disk saw, i-electrode ye-welding, noma umbuthano wokusika ohlukumezayo, mhlawumbe okuthandwayo kunikeze lokhu okusheshayo futhi okulula.

Imibuthano yokusika yokuhlukumezeka inikezela amafemu anjenge-Austrian Terolit, iCzech Carborundum ka-Electite, iDronco yaseJalimane, iBosch kanye neCarborundum, i-Zugoslav Suma, amabhizinisi aseLiechtenstein, kanye naphakathi Yikuphi "moshlifififingtrijent" (iMoscow), i-OJSC "isitshalo esithi" iLuzhsky Abrasive ", i-JSC" ISMA "(i-Ivanovo), isitshalo" Montajabrasivinstrument "(i-Perm).

Abrasive (abalekayo. I-Acbrasio-Scrapiting) isondo lokusika selihloselwe ukusika okunempilo kanye nekhwalithi ephezulu yezindlela ezahlukahlukene zemikhiqizo efana nensimbi, i-Iron Iron Alloys (ibha, amapayipi, i-coner, kanye nezitini), kanye nezitini , isilayidi, ubumba, ama-ceramics, i-drywall, kanye nemabula, i-granite, itshe kanye nokhonkolo ngamanani amancane. Sidinga kuphela umshini wokusika ophathekayo noma ukugaya okungejwayelekile, okubizwa nge-bulgaria ".

Kuyadingeka ukuxwayisa ngokuthi amabhizinisi amaningi akhiqiza imishini yokusika anikezela nokusika imibuthano kubo ngaphansi komkhiqizo wabo, hhayi abakhiqizi.

Ijubane lokujikeleza kombuthano likhulu, ngakho-ke ikhwalithi ephezulu kuphela yokwenziwa kwayo ingaqinisekisa ukusebenza okuphephile. Imibuthano yenziwa ohlwini lwemikhiqizo nezinsizakalo ezisetshenziselwa isitifiketi esigunyaziwe. Ngakho-ke, ikhwalithi yemikhiqizo ye-aoot "MoskslififinCrument" (kuzoxoxwa ngakho) okuqinisekiswe yisikhungo sezitifiketi esivunywa yi-State Standard of the Russian Federation.

Imithetho eminingi yokukhetha umbuthano wokusika

Bheka ukuthi umbuthano ungaguquki, futhi kwakungekho imifantu nama-chips ngaphezulu.Kuyinto efiselekayo ukuthi inani eliphakeme elicacisiwe lejubane lokujikeleza kombuthano ngeke libe ngaphansi kwesivinini sokujikeleza kwesiBulgaria esisetshenzisiwe.

Qaphela ukuthi ukusika kusetshenziswe kuphela ngo-2/3 ububanzi bendilinga ebabayo.

Into eqinisayo ayihlinzekelwe njalo ngokwakha umbuthano ohlukumezekile, futhi ingahlulelwa yilebula. Ngakho-ke, kubakhiqizi basekhaya, incwadi ethi "BU" isho ukuthi "iBakelite Bunch ngento enzima". Uma i- "y" ingekho, ayikho into enjalo futhi ibeka umbuthano ohlukumezayo ku- "Bulgaria" ayinconywa.

Uma kuncane ukuphakama kombuthano, kube lula ukusika nokungcola okuncane, kepha futhi ugqoke okuningi. Ngokuphakama okuncane kombuthano (osayizi abangu-5 wezinhlayiya), kusetshenziswa okukudla okuhlaziyele okuncane futhi, ngakho-ke, ukusebenza kuyancipha.

Isondo lokusika elihlangene, elivame ukusetshenziswa endlini, idiski elincane elinomhlaka 100 kuya ku-500mm ngokuphakama kusuka ku-1 to5mm nge-resing hole ukulinganisa umkhono. Isibonelo, nge-grinder "yokusika" ngenxa yenani elikhulu le-torque, ububanzi bombuthano awedluli 230mm. Ungahlangana nombuthano wokusika onobubanzi obungu-100 no-80mm nge-10mm efanelekile, efakwe emnyango kagesi wasekhaya nge-mandrel.

Umbuthano ohlukumezayo usika izinhlayiya zensimbi zezinto eziphakeme ezibucayi obukhulu (ezinolaka), ezifana nosayizi kanye nohlobo olusanhlamvu olujwayelekile. Zihlanganiswe okokuqala, bese zicindezelwa ngesisindo se-Jethetic Synthetic, izindlu eziphambili zazo yiBakelite (Plastic) noma i-Vulcanite (irabha). Iziqongo ezibukhali ze-porrude ezibukhali ngaphezulu kobuso be-ligament futhi, kulimale ngensimbi, uthathe ama-chip amahle kakhulu. Ekwenzeni inhlanganisela yezinqwaba, abrasive kanye nama-filler abekwa efomini, kutshalwe futhi kusetshenzwe kahle. Ama-compas ane-bakelite bunch asetshenziselwa ukusetshenziselwa ukusika kwama-carse of zensimbi nokwakha izinto ezingezona zensimbi. Imibuthano ngokusebenza okuncane kwenjoloba futhi yenzelwe ukusika i-iron, ama-talium alloys kanye nokuthola imiphetho ebushelelezi yokusika (ayisetshenziswa empilweni yansuku zonke).

Ukusebenza kahle kombuthano ohlukumezayo kuncike ngosayizi nobulukhuni bezinhlayiya: izinhlayiyana ezinkulu kanye nokuhlukumezeka uqobo, i-metal yensimbi inganqunywa. Ukuhlaziywa okumangazayo, noma ubukhulu bezinhlayiyana, kungasukela ku-10.1 kuya ku-2 mm (100-2000 microns). Ihlala ikhombisa ukumaka kumayunithi ajwayelekile, naseRussia nakwamanye amazwe ngezindlela ezihlukile.

Ngemuva kokuhlola imibuthano emandleni emishini kanye nokungasebenzi ekubhalweni kwawo ngakunye kwawo, okuqukethwe kokusikwa kukhonjisiwe noma ilebula lemibala linamathiselwe, ngokwesibonelo, okuluhlaza okotshani) noma okuluhlaza okwesibhakabhaka (amafometha). Imininingwane eyengeziwe ibikiwe lapho.

Emikhiqizweni yasekhaya, okuhlaziywa okungaphezulu kwe-50 mkm kuvezwa njengezinhlangothi ezingama-0,1 zesitokisi sesakhiwo esidabukisayo lapho izinhlayiya ezihlangene zihlungwa lapho zihlelwa ngosayizi. Isibonelo, ukudliwa okungu-32 kubonisa ubukhona bezinhlayiya zosayizi omkhulu ka-320mkk nenani elincane lezinhlamvu zolunye osayizi.

Ukudla okuhlaziywa kwama-5 kuye kwangama-63mkm kuboniswa usayizi omkhulu wezinhlayiyana (m). Ukunemba, i-M28 ibonisa ubukhulu obukhulu bezinhlayiyana ezingama-28 μm. Ngokuya kwamazinga wamazwe aphesheya, okuhlaziywa okuhlangene kunikezwa emayunithi ajwayelekile angakhombisi usayizi, kanti kunamazinga amabili ahlukile: ekuhlazimeni kwamathuluzi angenamsoco, ama-skins ahlanganayo (P). Ngakho-ke, i-F54 iphakamisa ukuthi ubukhulu bezinhlayiyana eziyizinhlayiyana ezisetshenziswe ekwakheni umbuthano wokusika yi-300 mkm, nesikhumba esifanayo ngosayizi ofanayo wezinhlayiyana kuzokhonjiswa ngu-P50. Ngokwejwayelekile yaseRussia, futhi ngenxa yokusika umbuthano, nokuhlaziywa ngosayizi omkhulu wezinhlayiyana ka-320mkm kanye nokuqokwa okukodwa 32 (bheka ithebula) kufana nesiketi sokugaya.

Lokhu kuqokwa kokusanhlamvu okuhlangene kumazinga we-IS Russian ne-Iso I-Iso lamazwe aphesheya (ngaphandle kweDayimane neBoron Nitride)

| Gost 3647-80 (ED. 1994), kunoma yiliphi ithuluzi elihlangene | Iso 8486-1.2: 1996 (e) ngaphandle kwezikhumba ezi-abrasive | I-ISO 6344-1.2: 1998 (e), kuphela iziketi ezihlukumezayo | |||

|---|---|---|---|---|---|

| Ukuqamba | Ubukhulu bezinhlayiyana eziyizinhlayiyana, μm | Ukuqamba | Ubukhulu bezinhlayiyana eziyizinhlayiyana, μm | Ukuqamba | Ubukhulu bezinhlayiyana eziyizinhlayiyana, μm |

| - | - | F 4. | 4750. | - | - |

| - | - | F. | 4000. | - | - |

| - | - | F. | 3350. | - | - |

| - | - | F 7. | I-2800. | - | - |

| - | - | F. | 2360. | - | - |

| 200. | 2000. | F 10. | 2000. | - | - |

| 160. | 1600. | F 12. | 1700. | P 12. | 1700. |

| - | - | F 14. | 1400. | - | - |

| 125. | 1250. | F 16. | 1180. | P 16. | 1180. |

| 100 | 1000. | F 20. | 1000. | P 20. | 850. |

| - | - | F. | 850. | - | - |

| 80. | 800. | F 24. | 710. | P 24. | 710. |

| 63. | 630. | F 30 30. | 600. | P 30. | 600. |

| amashumi amahlanu | 500. | F 36. | 500. | R 36. | 500. |

| - | - | F 40. | 425. | P 40. | 355. |

| 40. | 400. | F 46. | 355. | - | - |

| 32. | 320. | F 54. | 300. | P 50. | 300. |

| 25. | 250. | F 60. | 250. | P 60. | 250. |

| amashumi amabili | 200. | F 70. | 212. | - | - |

| ishumi nesithupha | 160. | F 80. | 180. | P 80. | 180. |

| - | - | F 90. | 150. | - | - |

| Okuqophele imali | 120. | F 100. | 125. | P 100 | 150. |

| Okuthenyalwayo | 100 | F 120. | 106. | P 120. | 106. |

| isishiyagalombili | 80. | F 150. | 90. | P 150. | 90. |

| 6. | 63. | F 180. | 75. | P 180. | 75. |

| isihlanu | amashumi amahlanu | F 220. | 63. | P 220. | 63. |

| M 63. | 63-50 | F 230. | 55.7 | P 240. | 58.5 |

| - | - | F 240. | 47.5 | - | - |

| M 50. | 50-40 | F 280. | 39.9 | R 280. | 52,2 |

| M 40. | 40-28. | F 320 | 32.8. | P 320. | 46,2 |

| - | - | F 360. | 26.7 | P 360. | 40.5 |

| M 28. | 28-20. | F 400 | 21,4. | P 400. | 35.0 |

| M 20. | 20-14. | F 500. | 17,1 | P 500. | 30.2 |

| M 14. | 14-10. | F 600. | 13.7 | P 600. | 25.8. |

| M 10. | 10-7 | F 800. | 11.0 | P 800. | 21.8. |

| M 7. | 7-5 | F 1000. | 9,1 | R 1000 | 18.3 |

| M 5. | 5-3. | F 1200. | 7.6 | R 1200. | 15.3. |

| - | - | - | - | P 1500. | 12.6 |

| - | - | - | - | R 2000. | 10.3 |

| - | - | - | - | P 2500. | 8,4. |

Imikhiqizo nokusanhlamvu okuhlangene kokusika imibuthano

| Igama no-Brand Brand | Okumangazayo okumangazayo | |

|---|---|---|

| I-BakeLite Bunch | Inqwaba ye-vulcanitic | |

| I-ElectroCorundant evamile 13a, 14a | 125, 100, 80, 63, 50, 40, 25, 16 | 46, 25, 16, 12, 10, 8, 6 |

| I-ChromotyTomatic ElectroCorundant 93a, 94a | 125, 100, 80, 63, 50, 40, 25, 16 | - |

| I-White electrocarundant 25A. | 50, 40, 25, 16, 12 | 40, 25, 16, 12, 10, 8, 6 |

| Zirconium electrocorudum 38a. | 125, 100, 80, 63 | - |

| IBlack Silicon Carbide 53c, 54C | 160, 125, 100, 80, 80, 63, 50, 40, 25, 16 | - |

| Silicon Carbide Green 63с, 64с | 16, 12, 8, 6 | - |

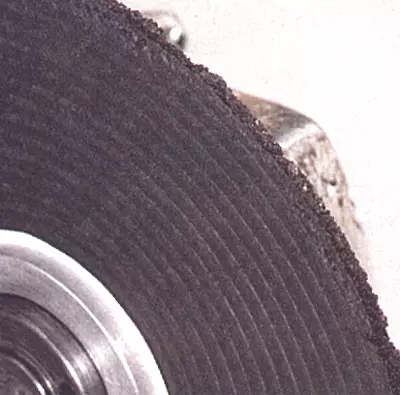

Ukuze unciphise ubungozi bokuphula umbuthano lapho usika imvamisa ephezulu yokujikeleza, into enzima yangeniswa emzimbeni wayo ngendlela eyindilinga yengilazi. Into eyodwa enjalo ye-mesh phakathi kokuphakama kombuthano (noma ngasekupheleni komhlaba) isethwe ekwenziweni. Le grid futhi igcina ukwakheka nokuguquguquka kombuthano wokusika.

Izincomo Ezisebenzayo

Umbuthano omusha wokusika uqiniseka okokuqala ukupheqa cishe ngo-5min, ubambe i- "Bulgaria" enombuthano ogqoke ngokwakhe. Iqiniso ngukuthi ngenxa yokudutshulwa okungenzeka ngesikhathi sokuhamba esigabeni sombuthano, imifantu emikhulu yemicroscopic ingakha, okuholele ekunwebisweni kwezingcezwana ezincane.

Ukugqokwa kancane kancane kombuthano wokusika ohlukumezayo kuhambisana nokwehliswa kobubanzi bendilinga, ngakho-ke esimweni sokusetshenziswa okuphindaphindiwe, kancane kancane kunciphise ukujula kokusika.

Ukuze kupholise amanzi ngamanzi asetshenziswa kakhulu (ngokwesibonelo, lapho insimbi yokusika ifudunyezwa), yayisebenza ngempumelelo, ihamba ngejubane isivinini sombuthano ngo-30-50%.

Ukusika insimbi kuhlanganisa uhlangothi olulodwa kuphela. Ngokuphambene nalokho, kusuka ekushiseni okunamandla, kukhubazekile futhi kungajaja umbuthano ohlukumezayo.

Ukuhlinzekwa kombuthano lapho ukusika induku eliminyene kufanele kuncishiswe ngo-15-20% ngesikhathi sokudlula kwengxenye yobubanzi, ngemuva kwalokho kungandiswa nenani lokuqala futhi.

Gcina umbuthano ohlukumezayo ngesigaxa se-bakelite ulandela endaweni eyomile, ngoba amandla wenqwaba ancipha kumswakama.

Umbuthano we-Abrasive unezinzuzo ezimbili eziqhathaniswa nedayimane. Okokuqala, lapho umsebenzi ungadingi ukupholisa ukuphoqelelwa ngamanzi, ngoba izinga lokushisa laso ngokuvamile alidluli ku-70-80c. Ukupholisa okuhle kwemvelo kuhlinzekwa ngenani elikhulu lama-pores akhiwa embuthanweni wokwenza kwawo. Bona, kanye ne-filler ekhethekile engezwe kwinqwaba kanye nokusola lapho ukusika, kufaka isandla ekususweni okusheshayo kwama-chips wensimbi.

Okwesibili, umbuthano onjalo awufihli, njengoba besho, "ukuzibangela", ngenkathi ububanzi bokuqala buncishiswa kancane kancane ngokubhujiswa kwezinhlayiya zebhondi elinolaka futhi oluvuthayo. Amaphupho avumelekile embuthanweni wedayimane, ukusika nombuthano ohlukumezayo kuhlale kuhambisana nezihlangu ezijulile zezikhala, izinhlayiya zama-ligaments nama-chips amancane wensimbi avuthayo, andiza ngokuqondile ekuzuzeni ukujikeleza. Zincane kakhulu futhi azikwazi ukulimala ngendlela yokushiswa noma ukushiswa.

Izindlela zokusika ngokusika okusanhlamvu okusanhlamvu okusanhlamvu 63

| Ububanzi votadiametrum., Mm | Isivinini sokusika, m / s | Ukusika ukujula, mm | Okuphakelayo * Circle, M / Min | Amandla adingekayo, kw |

|---|---|---|---|---|

| 1153,022. | 60 noma 80. | Kungabi ngaphezu kwe-0.15d | 0.2-0.8 | 1.0 |

| 1503,022. | « | « | « | 1,4. |

| 1803,022 (32) | « | « | « | 1,6 |

| 2003.022 (32) | « | « | « | « |

| 2303,022 (32) | « | « | « | 1.9 |

| 3003,032. | « | « | « | 2,2 |

| 4004,032. | « | « | « | I-2.6 |

| 5005,032 | « | « | « | 3,2 |

Ukusebenza kombuthano kunqunywa ngejubane layo nokuphakelayo (ukunyakaza). Isivinini esiphezulu kufanele sikhonjiswe kumbuthano ukumaka noma kwilebula. Emikhiqizweni yasekhaya, inani lejubane liqokonyiswa ngombala we-band ye-diametral: ophuzi (60m / s), obomvu (80m / s) noma oluhlaza (100m / s). Ngakho-ke, ngenxa yenombolo ekhawulelwe yokuthola imali ye- "Bulgaria" enenani lesigamu sejubane, insiza yalo incipha ngo-30-50%.

Ukuhamba kufanele kube ngokuqinile ebangeni kusuka ku-0,2 kuya ku-0.8 m / imizuzu. Lapho ufaka imali engaphansi kwe-0.2 m / min, ukuhlukaniswa kokushisa ngesikhathi sokusika kuyanda kakhulu, okunomthelela ku- "speezes" yensimbi nokushisa i-ligament futhi kuphoqe ukusetshenziswa kokupholisa ngamanzi. Lapho usebenza ngaphezu kwe-0.8 m / imizuzu, noma ngabe inqubo ihamba ngaphandle kwamandla aphansi ngokomzimba, izinhlayiya ezinzima ziqala ukulola ngokushesha kwinqwaba ("Crumm") futhi ngenxa yokushisa okukhulu kwensimbi, Kungenzeka ujoyine umbuthano ongaholela ekuphumeni kusuka ekwakheni injini "Bulgaria". Ubukhulu besikeki sensimbi akufanele budlule ku-15% inani lobubanzi bombuthano. Ukwehluleka ukuhambisana nalomkhawulo kuholela kwinsimbi "yesine", ukuncishiswa komthombo wombuthano nokukhiqiza.

Ukunciphisa ukufudumala kwendilinga ebabayo, indawo yayo yokugcina iyisicaba, kepha i-coarse kakhulu, inesiqeshana sezingxabano ezinzima, ngokwesilinganiso semibuthano engajulile. Lokhu kunciphisa ukuhlukaniswa kokushisa kanye nokusetshenziswa kwamandla ngo-60-80% uma kuqhathaniswa nendawo ebushelelezi. Lapho usika i-groove, ikakhulukazi kwinsimbi, isiyingi sisetshenziswa ngu-0.1-0.2 mm omncane enkabeni kunokulandelana kwangaphandle. Imibuthano ehluphayo inokuthuthuka kakhulu kunamadayimane, vumela ama-snieft wesikhashana, yize ku-sniaks ezingafuneki e-groove futhi ngempumelelo kwezomnotho. Lokhu kubonakala kakhulu lapho usika impahla eqinile yokwakha, njengokukhonkolo. Umbuthano ohlukumezayo unesisetshenziswa esifushane esikalwa yindawo esezingeni eliphakeme engxenyeni engu-1m2 yokusikwa. Lokhu kuqinisekiswa ukwehla kobubanzi bendilinga.

Ukusebenza kokusikwa kokhonkolo ngombuthano ohlukumezayo we-aot "MoskslifinIfinstroment" kanye nombuthano wokusika wedayimane wenkampani "Splitstone"

| Uhlobo lwe-Circle (ububanzi 230mm) | Intengo Circle, $ | Izinsiza, m2. | Izindleko 1M2, $ |

|---|---|---|---|

| Umbuthano obrasive | I-0,6 | 0.05 | 12.0 |

| Umbuthano wedayimane "turbo" | 38. | 13 | 2.9 |

| Ingxenye yedayimane Circle | 95. | 25. | 3.8. |

Njengoba kungabonakala etafuleni, izindleko zombuthano eziphikisayo ziphindwe kaningi. Ngakho-ke, uma udinga ukusika okuncane, khona-ke kuyazuzisa kakhulu ukuthenga isondo lokusika elixakile, futhi uma udinga ukuba nombuthano ngaso sonke isikhathi, ukusika idayimane. Sigcizelela ukuthi isitatimende esinjalo asikhathaleli ukusikwa kwezinsimbi, lapho umbuthano wokusika ohlukumezayo uphume umncintiswano.

Ngaphambi kokusebenza, funda futhi ngokufundiswa kokusebenzisa i-Bulgaria, okufanele kubhekwe ngendlela ephelele yokugwema ukulimala ngesikhathi senqubo enesivinini esikhulu.