Ukuhlobisa okubhaliwe okuhlosiwe: Izakhiwo eziphambili kanye nezici zokusebenza nezinhlobo ezahlukene zezimbali, ukulungiswa kwesisekelo namathiphu we-Master.

Ukukhumbula izinkathazo eziphindaphindekayo ekuvuseleleni amaphephadonga amadala kanye nopende olungafakwanga, kuqala ukungaphupha okuthile okuphakade futhi okuhle odongeni lwefulethi lalo. Sizokhombisa ukuthi izinyathelo ezimbalwa zisondela kanjani ekuhlolweni kwaleli phupho. Kuzoba mayelana nokuhlanganiswa kokuhlobisa odongeni.

Ama-Coatings angafakwa esisekelweni sikakhonkolo, izitini, eyomile, udaka, amathayili we-ceramic, insimbi, insimbi nezinye izinto. Zisetshenziselwa zombili zokuqeda kwangaphakathi nangaphandle (lokhu kufanele kukhonjiswe kwiphakheji).

Ukuhlobiswa okuhlobise emakethe yaseRussia kunikeza abakhiqizi abangaphezu kweshumi, njengeViero (Italy), uMarkem, eTurkey), iCaparol, iTexSA (Spain), i-SPANSA , I-plastone (eRussia) nabanye. Ubanga lifinyelela ezinhlotsheni eziningana eziyishumi nambili, ngalinye lalo elinemibala emi-5 kuya kwangama-25.

Izici zezimbali ezenziwe ngombhalo

Izinhlobo ezahlukahlukene zezimbali zingahlukaniswa yizakhiwo ezintathu eziyisisekelo eziyisisekelo:- Isisekelo sokubopha okubophayo.

- I-Punching Filler isebenzisa izinto zemvelo: imabula imvuthuluka (i-granulat), isihlabathi se-quartz, lime. Umthamo we-filler ezinhlotsheni ezahlukene zezimbali zisukela ku-40 kuye ku-85%, ukuguquguquka kwawo kuncike kulokhu.

- Isisekelo se-Liquid sazo zonke izimbobo - amanzi.

Izakhiwo kanye nezici zezakhi ngakunye ekwakhiweni kokwakheka zinikeza ukunamathela kwezakhiwo ezithile zabathengi, futhi ngokujwayelekile, kuyimvelo nezinto zokwakha zemvelo. Ekukhangiseni amathemba, amafemu ahlangabezana nemigomo ethi "Acrylic Binder" kanye ne- "Latex Binder". Ngaphandle kokuthola imininingwane, siyaphawula ukuthi kulezi zimo sikhuluma ngamaphoyisa afakiwe ngendlela ye-emulsions ehlakazekile kahle. Into esemqoka ukuthi la ma-emulsion anamanzi. Ngemuva kokuhwamuka kwamanzi, i-polymer nclayf ngaphansi kwesenzo se-oksijini nokukhanya kuguqulwa kube yinqwaba eqinile, ethembele ngokuthembekile izinhlayiya zeflicker futhi zibabambe phansi. Ngemuva kokuqina, i-polymer ayisachithwa ngamanzi futhi ibekezelela umphumela wamakhemikhali, isithwathwa kanye nomthwalo wemishini.

Ngaphezu kwalokho, ngenxa yamanzi asuselwa, ukuhlanganiswa akunaphunga. Ngakho-ke, ukulungiswa kungenziwa nganoma yisiphi isikhathi sonyaka futhi ungavuli amawindi ukwenza ingozi yokubanda.

Kodwa-ke, isisekelo samanzi sibangela eminye imikhawulo. Okwezimbobo, zombili izinto ezengeziwe kanye nokuntuleka kwamanzi kuyingozi: kungangezwa ngaphezu kwama-3-5% (imvamisa ilitha elilodwa elisezingeni eliphakeme lama-25 kg). Kuyadingeka ukufaka izigqoko endaweni eyomile, futhi umsebenzi wangaphandle awukwazi ukwenziwa ngesimo sezulu esinemvula noma esinomoya. Njengoba yomile, izinto ezibonakalayo zilukhuni futhi ziguqula i-plasticity, ifakazela ukutholwa kokuthungwa okuzungu kulo lonke udonga. Ngakho-ke, kuyadingeka ukusebenza nayo ngokushesha, ngaphandle kokuphazamiseka, emazingeni okushisa angaphakeme kune-35S futhi hhayi ngaphansi + 5c. Kuliqiniso, izakhiwo ezifanayo zingasetshenziswa ngqo ukudala imiphumela ethokozisayo ezingxenyeni ezihlukene zodonga, kepha ukwamukelwa okunjalo kufanele kuhlelwe kusengaphambili.

Gcina lezi zinto zokwakha esitsheni esivaliwe ngokuqinile ngokufinyelela komoya okuncane. Isitoreji nokuhamba kwemikhiqizo ye-Coatings eningi ngaphansi kwamazinga okushisa amanga angathandeki, futhi kwesinye isikhathi akwamukeleki (izidingo zabakhiqizi). Kepha uma impahla igcinwe kahle, ngemuva kokuqina kuyo kuzoba khona.

Ama-Coating anokuvimbela okuphezulu, amelana nosawoti, amanzi angenamanzi, abekezelele umehluko wokushisa kusuka ku--55sdo + 60C, awapheli amandla, noma ngabe awonakalisi awonakalisiwe uma enza ugwayi. Ngaphezu kwalokho, babalulekile ngokwanele ukumelana nokulimala kwezindonga ngaphandle kokwakhiwa kwemifantu. Kukhona nezembatho ezinezakhiwo ezinomsindo kanye nezithasiselo ze-antifungal.

Umbala wabo nokuthungwa kuncike ezintweni ezintathu: uhla lwekholomu ye-filler, ukwakheka kwesisekelo esibophayo kanye nobuchwepheshe bokusebenzisa izinto. Uma ufisa noma udinga, zingambozwa kalula nge-paint noma i-varnish engeyona eye-acidic.

Amahora angama-4-6 ngemuva kokusebenzisa ukunamathela ezindongeni, sekuvele kuthinte, ngemuva kosuku, izakhiwo sezilungele ukusebenza, kepha ukuqina kokugcina kwenzeka ezinsukwini ezimbalwa (kusukela ezinsukwini ezingama-24 kuya kwezingu-24, ngaphansi kwemibandela ye Umkhiqizi).

Zonke izimbobo kufanele zibe nesitifiketi esifanele sokuhlanzeka seRussia Federation.

Abathuthukisi bezinto ezintsha zokuqeda basebenzise ngempumelelo izakhiwo eziphawuleka zamatshe emvelo kanye nezinto ezimbiwa phansi lapho bedala izigqoko zokuhlobisa ezisuselwa ku-polymer ezihlala isikhathi eside, ezinemibala futhi zisebenzise kalula.

Yini okufanele uyikhethe?

Okokuqala, kuyadingeka ukunquma ukuthi kuwe kuyathandeka: izinhlobo zendabuko zokuqeda, okungukuthi, amaphephadonga, amaphephadonga, amathayili obumba, noma impahla entsha yokuhlobisa.

Ama-Wallpaper alahlekelwa ngokusobala ukumboza okufundwayo ngokusebenza, kepha anqotshwe ngohlelo lokuhlobisa. Njengopende, badinga ukulungiswa kahle kwesisekelo, kanye nezingubo ezifundwayo zimaka kalula imifantu emincane futhi zifihla iziphambeko zodonga. I-Peints yezakhiwo eziningi azithathi phansi ukumboza, kepha amathuba abo okuhlobisa akhawulelwe kuphela ububanzi bemibala. Ama-maause anwetshwa yi-feature yosizo nokuthola indawo.

I-Ceramic tile kwizakhiwo eziningi iqhathaniswa nokugqoka okutheshwayo, kepha kusebenza kanzima futhi kudinga amakhono amahle. Izambatho ezihleliwe ezihleliwe zinobuchwepheshe bokuthi ngisho nakulesi sikhathi esisha kufaneleke ngokushesha, futhi sinesikhala sobuciko.

IHholo, indlu yangasese, indlu yangasese, izitebhisi, udonga, okhetha "izintandokazi zakho ezinemilenze emine zonke izinto ezifanelekile zokusebenzisa izimbatho ezinjalo. Ukuhlanganisa ukuthungwa nombala, bangasetshenziswa ngempumelelo ukudala amaphaneli wombala we-copyright, ikakhulukazi uma usebenza ngento equkethe izinhlayiya ezinemidwebo.

Ngokuya ngohlobo, izimbobo zisetshenziswa ezindongeni ngamathuluzi ahlukile. Usebenzisa i-Steel Smooth, ungathola indawo eyisicaba enokuthungwa okunqunywe ngosayizi nombala we-granule. I-ironing yepulasitiki idala izindawo ezenziwe ngepulasitiki, i-roller-khulu impumulo kanye nosizo lwe-wavy, nohlobo lokufafaza "lwamajazi" woboya ".

I-Class Coatings yiyona elula kunazo zonke kusici esikhulu esikhandlekwa sefektri, usayizi wamagreyivu (okusanhlamvu). Kunezinhlobo ezilandelayo:

- C amamabula alinganiselwe (kwesinye isikhathi amagagasi) granules;

- okuhlangenwe nakho okuxubile, lapho inani elincane (5-15%) lengxenyeni ehlanganayo (1-2mm) lisatshalaliswa esigabeni sama-granules ahlelwe kahle (0.2-0,5 mm);

- ngamagreyivu angenamikhawulo angenamikhawulo;

- Ngama-Fineral amaminerali.

Njengengxenye yalezi zinhlobo, iziqubulo zingaqhubeka (ngokwesibonelo, ukudliwa okungu-1.5-2.0mm, 0.9-1.5mm, 0.2-0.5mm, njalonjalo). Singasebenzisa ukuvumelana okuhlukile nge-subgroup (diading isisindo samanzi esiqediwe) futhi siguqule ubuchwepheshe bokuqeda.

Ungasebenza kanjani ngezinhlobo ezahlukene zezimbali?

Kufanele kukhunjulwe ukuthi izici ezine kuphela ezithinta ukuthungwa komhlaba:- Uhlobo lwamathuluzi;

- Isikhathi sokuphumula phakathi kokupholisa kanye nokuphela kokugcina (imvamisa kusuka ku-21 kuye ku-30);

- Inqubo isebenza ngethuluzi;

- I-fantasy master (ukuphela kwento engakhawulelwe).

Ukumboza ngemigqomo yemabula elinganiselwe. Izinto ezibonakalayo zinokungaguquguquki kwe-pasty esimweni esishukumisayo. Kusetshenziswa odongeni ngensimbi yensimbi ebushelelezi. Ubukhulu obungqingili ecaleni elikahle kufanele bulinganiswe nosayizi wokusanhlamvu, kepha uma kudingeka ukufihla iziphambeko zodonga, faka ungqimba kuya ku-3-4mm. Ngemuva kokukhanya okunamalambu phezulu, kushiswe nge-ironing efanayo.

I-Grancerate idlulisela ubuhle betshe lemvelo futhi ihlanganisa kahle nezinye izinhlobo zezingubo, yandisa iphalethi likapende nokwenziwa. Isetshenziswa njenge-facade ne-wansior yokumboza amakamelo amahhovisi. Endlini kungcono ukuyisebenzisa ihlukanise noma ezindaweni ezincane, ezintweni eziyinkimbinkimbi zezakhiwo zodonga: ukuvuleka, ama-niches, ama-prorrusion, amabhokisi, ama-racks.

Ukumboza ngemifino yokusanhlamvu exubile. Ukwethulwa kwenani elincane lama-granule amakhulu kunqwaba yamatshe amahle anwebise amakhono okuhlobisa ama-coatings. Imvamisa, basetshenziswa nge-ironing, nalabo abanokunye okuthe xaxa - i-roller noma indlela yokufafaza.

Umphumela oyinhloko ukulingiswa kwetshe "Susarin". Inkululeko enkulu kunazo zonke yokudala inika indlela yokubusheleleka ingaphezulu ngosizo lwepulasitiki. Kulokhu, okusanhlamvu okukhulu kugoqwa eceleni kwesisekelo, kwakha i-groove. Ukuhlukahluka kwabo, ubukhulu kanye nobukhulu bungatholwa yimiphumela ehlukahlukene. Uhlobo lokunyakaza kwamathuluzi lungaqondile, isiyingi noma se-wavy. Ubude besikhathi phakathi kokusebenza kwezinto ezibonakalayo kanye nokuqondanisa kwalo, ubukhulu bengqimba, ukugxila nobukhulu bohlamvu olukhulu, konke kuthinta amandla okugcina, ukuhlinzeka amandla okugcina itshe lemvelo. Ngemifanekiso, sasebenzisa ngqo i-visolcalcethin brand coating nge-limescale filler.

Ukumboza ngemifino engashintshile kahle. I-punching filler ezingutsheni ezinjalo isetshenziswa i-quartz crumb ehlelekile, isihlabathi se-quartz noma i-lime. Bakhuphule amandla emishini, ngakho-ke kuvame ukusetshenziselwa ukuqeda ama-facade. Zisetshenziswa yi-pneumatic sprayer, ububanzi be-nozzle bungabukwa. Ushintsho ekucindezelweni nasekuhambeni komoya luvumela ukutholakala okuphezulu ngokukhululeka okuhlukile, okufana no-wavy noma uhlobo "ijazi loboya".

Ukumboza nge-fineger filler. Lezi zimbozo zenziwa ikakhulukazi ngemisebenzi yokuhlobisa. Izincwadi zivusa futhi zaziwe yibo bonke "udaka lwaseVenetian". Ama-fillers amahle, ngokuvamile asuselwa ku-lime, kanye nemibala ikuvumela ukuthi udale ama-nuances anemibala emihle kakhulu. Uma zisetshenziswa izingqimba eziningana ze-lesile (esobala), ngamunye wazo angaba nombala wazo, umphumela obonakalayo wokujula kokudweba kwenzeka. Ngakho thola ukulingiswa kokuhlanganiswa kwemabula. Faka isicelo kubo nge-spatula eguquguqukayo, nokuvumelana okuthe xaxa, i-tampon, isiponji, i-roller.

Ungasilungiselela kanjani isisekelo

Ingaphezulu le-coating elibhalwe phansi lisetshenziswa ngalo, kufanele lisome, lihlanzeke, uma kungenzeka, bushelelezi futhi kungashintshi. Konke okunekhono eliphendulayo lamanzi, noma okungakwazi ukugcina isisindo sokuhlanganiswa okusetshenzisiwe, ngokwesibonelo, ukungcola, uthuli, amafutha, ama-oyela, amabala athambekele noma ukudonsa, kufanele kususwe ( ukuxubha insimbi noma i-sandpaper). Izindawo zensimbi zihlanzwa ngokugqwala futhi zimboze kabili upende we-Alkyd wethoni ehambisanayo.

Izici ezinkulu, izimfihlo ze-wiring zidinga ukucija. Ukuqhekeka okubukhali kanye namaphutha okungewona angewona umgomo awedluli ukujula kwamanani amabili obukhulu bengqimba esetshenzisiwe.

Lapho-ke ingaphezulu kufanele lihlanganiswe ne-primer kwisisekelo se-acrylic ngezwi lokuhlanganiswa. Kufanele kwenziwe uma isisekelo sidonsa kakhulu amanzi, njengodaka, ama-gross, amadala, ama-plasters adala. Kuyinto efanelekile ukusebenzisa inhlabathi enconywe ngumenzi. Ukumboza ngama-granule ahlanganisiwe okusanhlamvu, isisekelo kufanele senziwe kakhudlwana ngisho nokwenza lula ukweqa izinhlayiya ezinkulu futhi uthole igridi ye-fishir yama-grooves.

Kuthu, izindonga ezindala zavalwa nge-platerictiveboard, ezakha kakhulu ubunzima bokulungiselela okwengeziwe kwesisekelo. Bapenda izikulufa zeCoat Screw Screws futhi zihlanganiswe kahle amalunga (ikakhulukazi ama-angular) esebenzisa ibhandeji lokwakha kanye ne-tutty stucco engeziwe. Lapho-ke izindonga zambozwa, zomiswe, zaphonswa nge-sandpaper futhi zimbozwe ngenhlabathi i-ACQ.

Lapho usebenza ngezimbali ezinjalo, kunolwazi oluncane lomsebenzi wokupenda, kuyadingeka ukukhombisa ukunambitheka okumnandi nokubuciko. Kungani ungazami ukwehlukanisa ngendlela entsha okungenani ucezu lodonga olufanele, ngokwesibonelo, ephasishi?

Iseluleko Sethu

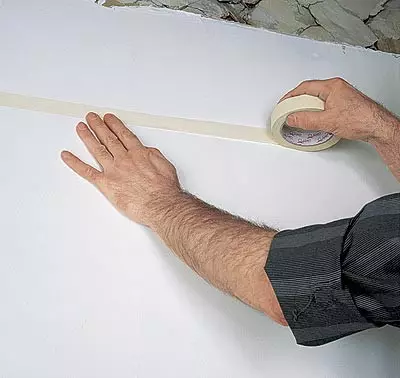

Okuqukethwe kokunye ukuguquguquka kwe-pasty kusetshenziswa ngensimbi ironing, kusukela phezulu kodonga, njengokungathi kuvuka phansi kuya phezulu. Ngemuva kwalokho ungqimba olubushelelezi lusatshalaliswa ngesisekelo sokuhamba kwesiphambano. Faka isicelo se-coating kungcono kusuka ekhoneni kuya e-angle yodonga. Ingaphezulu elikhulu lingahlukaniswa ngezindawo ezisendaweni ezungeze i-5m2 esebenzisa itheyiphu ekhuphukayo. Lapho iqondanisa, kufanele icindezelwe ngokuqinile ebusheleleke, bayibambe nge-angle ephansi (kuze kufike ku-20) odongeni lodonga.Indawo oqale ngayo kufanele ihlukaniswe ngokuphelele. Uma kunesidingo, abantu abaningana bahola umsebenzi. Uma ngasizathu sikela umsebenzi kufanele uphazanyiswe, onqenqemeni lwendawo ecubunguliwe uvikelekile ekumisweni ngeribhoni ekhuphukayo. Kuyadingeka ukususa kuze kube yilapho impahla yomile ngokuphelele.

Ukumboza kusuka kuma-granules ahlelwe kahle we-cream ukhilimu-like noma ukuguquguquka okuthe xaxa okungaphezulu kungafakwa nge-pneumatic spreyer (umfutho womoya 0.2-0.7 MPA, ukugeleza komoya kuya ku-16 l / s, ububanzi bomgodi we-nozzle from 4 to7mm). Fafaza kwenziwa ukunyakaza okusheshayo ngokuhamba kusuka phezulu kuya phansi bese kwesobunxele kuye kwesokudla, kudlule. I-Sprinkler kufanele igcinwe i-perpendicular ibe yibanga elisekude lama-30-50 cm. Ukuthola usizo oluncane lobuso futhi kunciphise ukusetshenziswa kokuqukethwe, kunconyelwe ukukhulisa ukusetshenziswa komoya futhi kunciphise ukucindezela. Ukuthola impumuzo ye- "fur coat" noma "i-lamb", udinga ukunciphisa ukusetshenziswa komoya futhi wandise ingcindezi. Ukuqeda izikhala, ungenza ukudlula kwesibili, kepha hhayi ngaphambi kwamahora angu-1-1.

Ungakhohlwa ukugeza wonke amathuluzi ekugcineni komsebenzi.

Amathuluzi adingekayo

I-Spatula, i-FUAR roller, ibhulashi le-floss, i-roulette, izinga noma i-twine, umbusi omude, ipensela, insimbi kanye neplastiki yepulasitiki, ukupenda iplastiki, i-sandpaper, ipulasitiki.

| Cindezela ngokucophelela i-pendaphthalic koqweqwe lawo amahembe okuqinisa amapuleti we-plasterboard. |

| Ukuthunga emalungeni amapuleti nasemakhoneni, ku-PRCRIBTT, yomile nobufakazi nge-bandage yokwakha ye-PVA glue glue. |

| Ngosuku olulandelayo, ngemuva kokujikisa ezingxenyeni ezimbili kanye nokugaya i-sandpaper, zisule izindonga ngendwangu eyomile, zinqume umngcele ongaphezulu we-coating ophahleni) bese uguqula itheyiphu yephepha eliveziwe ngokwayo. |

| Inani elifunekayo lomhlabathi we-acq we-prymer, elinqunywe ngesilinganiso se-0.05 l / m2, uthele esitsheni sepulasitiki, engeza amahlandla ama-5 amanzi futhi ashukunyiswa kahle ngesandla. |

| Faka inhlabathi nge-fur roller ngokulinganayo ibe ungqimba olulodwa kuzo zonke izindonga. Inhlabathi yomisa amahora 1.5-2. |

| Cwilisa i-vieroquartz pre-coating (viero) esekelwe kwi-quartz eqoshiwe, ehambelana nethoni ekhethiwe, ngokususelwa ku-flow rate ka-0.2 kg / m2, bese uyisebenzisa ngamanzi esilinganiso esingu-1: 1. Faka isicelo nge-roller, uma kungenzeka ngokulinganayo. |

| Imiphetho yezindonga emakhoneni, phansi nophahla, isola i-brush-flert. |

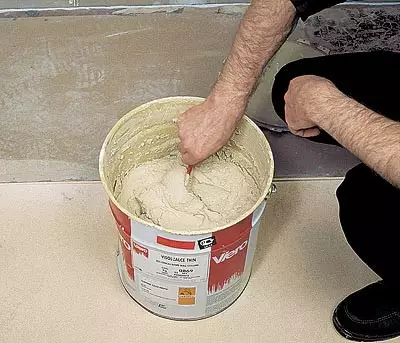

| Ngemuva kwamahora amathathu, lapho i-vieroquartz yangaphambi kokuhlangana izokoma, ivule imbiza yensimbi ngenhlanganisela eyisisekelo ye-visolcalce futhi uyixube kahle ekuguqukeni kwe-pasty. Ungakhohlwa ukuxuba ngezikhathi ezithile okuqukethwe nakwinqubo yokusebenza. |

| Izinto zokwakha nge-spatula endizeni esebenzayo yezingxenye zensimbi ezixakile ezingenasisekelo ze-150-200cm3. |

| Faka isicelo se-coating ekuqaleni kokuhamba-up, bese usheshisa ukunyakaza okwenziwe ngobushelelezi. Zama ubukhulu bengqimba ukwenza usayizi wama-granule amakhulu. Ngakho-ke, amboze uzungu lwe-1.5-2m2. |

| Ngemuva kwemizuzu engama-20-30, lapho impahla esesigabeni esetshenzisiwe iqala ukusunduza (shintsha kancane umbala), qala ukuyivuza ngombala wepulasitiki othambile ngokushintshana ngokushintshana okuphezulu nokushintshana. Bukela ukuthi indawo esebenzayo yethuluzi ayimile, singayima kancane ngamanzi. |

| Uma, uma kuqondaniswe, ingxenye yodonga inenhlokweni encane, thayipha impahla embalwa epulasitiki gladlon bese iyamemeza kuleli sayithi. |

| Ngemuva kokuqeda okugcwele kodonga olulodwa, qala ukucubungula eduze. Gijimisa ukuhlanganiswa ngokunyakaza kusuka ku-angle ngaphakathi kwendawo engaphezulu. |

Abahleli babonga ukuqina kwe-moscow "crete" enikezwe izinto zokwakha nosizo ekuqhubeni izithombe.