Ukudalwa kwamafomu ama-bizarre ngosizo lwamashidi agobile futhi aphukile epulangwe: Shintsha ngesimo seshidi le-plasterboard nokufakwa kophahla nokhokhiswa kophahla kanye ne-arched izinhlaka.

Ithempulethi, lapho unganikeza khona i-plapeta board ngendlela oyifunayo, i-wizard ngayinye yenza ngendlela yayo kusuka ezintweni eziyinhloko (Plywood, chipboard, eyomile ye-IT.p.) ngokukhulu kuka-8-15 mm. I-radius yethempulethi kufanele ibe incane kancane kune-radius yobuso obuhle, futhi ithempulethi selivele selivele futhi / noma lifushane, ishidi lokugoba lebhodi yokugoba.

Ukugoba kwenziwa lula ngokumangazayo. Kuphela ngaphambi kwalokhu kuyadingeka ukuthola ukuthi yiluphi uhlangothi lwe-workpiece lapho kugoba kuzocindezelwa. Lapho-ke, kulolu hlangothi, kwi-billet yenza uchungechunge lwama-punctures ku-10-20 mm ukukhuphuka nokujula okucishe kube yingxenye yesithathu yobukhulu beshidi noma okuthe xaxa. Ungazisebenzisa nge-shill, kepha ochwepheshe basebenzisa i-roller yenaliti ekhethekile. Okulandelayo, le ndawo inamanzi ngamanzi ngesiponji noma ibhulashi. Ukucutshungulwa kufanele kwenziwe kaningi ngaphambi kokugcwala umnyombo we-plaster ngamanzi (kuyeka ukunwetshwa cishe ngehora). Ukuze usebenze kahle futhi awuzange uthole olunye uhlangothi lweshidi (kulokhu, lapho uguquguquka, amakhefu amakhadibhodi aluhlaza kungenzeka), okungekho kufakwa kufakwe ohlangothini lwamapulangwe noma ama-gasket enjoloba. Lapho-ke i-workpiece ifakwe ngokucophelela kusifanekiso esivumelanayo ngokuhambisana ne-usewwall yayo bese ugoba kahle kuyo.

Esikhundleni esigoqikayo, umsebenzi we-workpiece uhleliwe futhi wesokunxele ukumiswa. Isibonelo, ingavinjelwa amahlandla ambalwa ngeribhoni elinamathelayo bese ususa ithempulethi kusuka kwisifanekiso esisetshenziselwa iphepha elilandelayo. Isikhathi sokomiswa kokomiswa kwesisebenzi sisuka ku-12 kuye ku-22.

Ngokwenziwa kwezinto ze-curvilinear nge-radius encane ye-curvature, enye indlela isetshenziswa kusuka ku-100 to400mm. Umnyombo wayo umi ngokulandelayo. Ngasohlangothini oluhlanekezelwa khona (ubuso bungeza egumbini) le-workpiepe yokugaya uchungechunge lwama-grooves abunjiwe, imigqa ehambisanayo yokugoba. Ukujula, ububanzi nesinyathelo se-grooves kuncike ekutheni kudingeka yini umsakazo we-curvature ukuthola. Uma uncipha igxathu ye-grooves kunale ebanzi futhi ujule (kuze kube ngamakhadibhodi ohlangothini olungaphambili), kunobubanzi futhi obugobeke kahle kakhulu. By the way, ama-grooves angenziwa emncane endaweni engenazikhala esebenzisa i-chisel. I-billet iphinde yahlanzwa ngokuphelele othulini futhi ifakwe kuphethini elilungiselelwe ngaphambili. Ngasikhathi sinye, iyagoba, futhi ukugcina ukwakheka okusha kwama-grooves asetshenzisiwe. Okuhle kakhulu kulokhu kulungele i-Spachure "Uniflot". Ngemuva kokomisa i-putty, ingabe isiqeshana singafakwa endaweni.

Dala izindawo ezingenayo neziphukile ezinikeza amathuba angeziwe ekwakhekeni kwezinto zokuhlobisa ezingaphakathi noma ezifihlane nobunjiniyela bezokuxhumana, akulukhuni uma ngabe ishidi le-plasterboard linqunywe ngekhadibhodi ngakolunye uhlangothi lwekhadi (Kepha amakhadibhodi awathinti !!!) Kulezo zindawo lapho kunesidingo khona ukwenza ikhefu.

Ishidi elincane le-radius eliguquguqukayo le-plasterboard

| Isimo seqabunga | URadius ugoba ngokuqina kweshidi, mm | ||

|---|---|---|---|

| 6.5 | 9.5 | 12.5 | |

| -Manzi | 3300. | 3500. | 31000. |

| -Omile | 31000. | 32000. | 32750. |

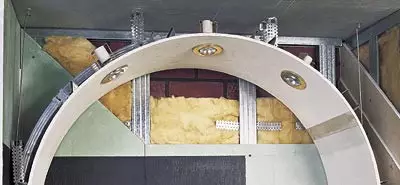

Ukufakwa kwezinhlaka zophahla kanye ne-arched

Izici eziphambili zalezi zinhlaka yilezi ezibizwa ngokuthi yi-PPILS: Izinhlobo zophahla ze-PP (60mm ububanzi kanye nokuphakama 27mm) nohlobo lwe-arched lwe-radii curvature ehlukahlukene. Amashalofu amaphrofayli anjalo angalujikelwa ngaphakathi nangaphandle, okukuvumela ukuthi unikeze izakhi zophahla lwe-convex kanye nokwakheka komkhonze. Uma wehlulekile ukukhetha amaphrofayili asetshenzisiwe enziwe ngomumo, khona-ke amafomu afanele angenziwa kalula wedwa. Ngale njongo, ukusikeka okwenziwe yi-V kwenziwa emashalofini ephrofayli eqondile bese uyigoba. Uhlaka lwamaphrofayili lubekwe ophahleni kuze kube yilapho ishidi eligobile linamathiselwe. Amaphrofayili ahlukene abunjiwe noma amafreyimu anamathele ophahleni nge-dowel noma amiswe okwesikhashana ekumisweni okuqondile okubizwa ngokuthi ngokuqondile (amabakaki abalulekile) Ukwandisa ubude bokumiswa okujwayelekile, ungafaka i-STED ekhethekile eyengeziwe. Ukunyakaza kwama-dowels kuya ngesimo, indawo kanye nesisindo sesakhiwo esimisiwe, kepha akufanele kudlule i-80cm. Lapho ufaka ku-skeleton kakhulu, ishidi eligobile lihlelwe kuqala kusetshenziswa ukuma okubunjiwe okufakwe ophahleni oluphakathi kophahla lwamapulangwe kanye phansi. Lapho-ke ishidi linamathele kumaphrofayili ezinhlama usebenzisa izikulufo zokuzishaya, ezisukela maphakathi neshidi futhi kancane kancane ziphendukele emaphethelweni. Izikulufa kufanele zifakwe kwi-perpendicular e-perpendicular ebusweni beshidi bese zingena kwiphrofayili yensimbi ekujuleni okungenani kwe-10mm, nakwibha yokhuni, ngokujula okungenani okungama-20mm. Amakhanda ezinhlaka asuswa ngo-0.5-1 mm eshidini le-drywall, bese efaka isicelo.

Amahlaya amashidi e-plasterboard kufanele abe kumaphrofayili ethwala noma imigoqo. Lapho kungenzeki, imivimbo yensimbi enobukhulu be-0.5-0.6 mm nobubanzi obungu-100 mm bubekwa emalungeni kusuka ohlangothini olubuyela emuva kwamashidi. Okulandelayo, ama-seams enziwa ngokusho kobuchwepheshe obujwayelekile, futhi uma kunesidingo, khona-ke ukuswakama kobuso bonke.