Silandisa ngobuhlakani bokwenziwa nokuklanywa, ukubalwa kwezobuchwepheshe komthwalo, ukulungiswa kwesiza kanye nenqubo yokufaka.

Ngesikhathi sokulungiswa, kwesinye isikhathi kunezinteli ezanele noma uhlaka lwezinkuni ezenziwe ngezemishini, ukugoqa isandla se-ambulensi. Ngomsebenzi omkhulu, kuzodingeka ukwakhiwa okungadingeki ukuthi kudingeke ukuhlelwa kabusha kusuka endaweni kuya endaweni, isikhathi ngasinye lapho ngifuna ipulatifomu efanelekile. Kuzolingana nabantu abaningana, izinto ezidingekayo namathuluzi. Uhlaka lwensimbi lwamapayipi alulula nje kuphela futhi luphephile kunokufika phansi kusuka ebhodini. Isixazululo esinjalo sikuvumela ukuthi wonge isikhathi, esivame ukusetshenziswa ekuhlelweni kabusha kwezitebhisi kusuka kwelinye iphuzu kuya kwelinye, ukuthutha izinto zokwakha kuya phezulu, ama-vain azama ukwandisa ukuhamba komsebenzi. Ukwakhiwa kwehlathi kwehlathi kungenziwa ngokuzimela. Ngalokhu sho ku-athikili.

Konke mayelana nokuqopha ukuswayipha

Izinto zokwakha kanye nezici zezakhi- Izikhali nenzinye izinto

- Yimaphi amapayipi enziwa

- Idivayisi yohlaka

Imiyalo yokufaka

- Khetha imodeli

- Ukulungiselela isiza

- Imiyalo yokufaka

Ukufakwa kuma-facade of shalond

- Ukucaciswa kobuchwepheshe

- Ukufundisa

Izinto zokwakha nezici

Kuyinto elula kakhulu ukusebenzisa isethi yezingxenye eziqediwe. Akhiqizwa kucatshangelwa amazinga obuchwepheshe aqinisekisa ukuphepha esikhungweni. Ngaphambi kokuqoqa ukwakha amahlathi ensimbi, kufanele uhlole uhlu kwimiyalo, noma ngabe zonke izingxenye zikhona.

Izikhali nenzinye izinto

- Ama-racks mpo athatha umthwalo omkhulu. Zifakwe epulatifomu kanti ezinye izinto zihlelwe kuzo.

- Ama-struts ahlela ngokuvundlile noma ngokuqondile. Zihlanganisa ama-racks ndawonye futhi zinikeze uhlelo lokuqina.

- Ama-jumpers lapho isitezi esigcwele khona. Ububanzi bokufika phansi ngokwesilinganiso bungu-1-3 m. Ukuphakama kwethayi kuncike ekutheni umsebenzi wenziwa kuphi. Njengomthetho, lilingana no-1.8 -2 m.

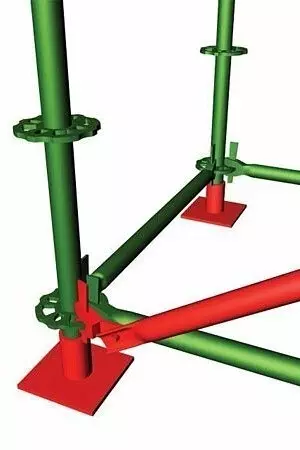

- Izitobha ziyadingeka ukuthi ukwakheka kumiswe ngokuthembekile emhlabathini futhi akuhambanga.

- Izitebhisi ongakhuphuka ngazo phezulu kwezikhungo.

- Ikhuphuka ixhumanisa zonke izinto phakathi kwazo.

Ukuqinisekisa ukuwela ngokwakho, amathuluzi nezinto zokwakha, kusuka ngaphandle, welula igridi yangaphambili. Uma isando singena kwigebe phakathi kwegridi nepayipi elivundlile, ngeke likwazi ukulimaza noma ngubani. Indwangu ye-mesh futhi ivikela naseLangeni, nomoya nasemvuleni. Kuyinto elula kakhulu ukusebenzisana nayo. Ukudonswa kwemali kuphela ukuthi kubambezela uthuli esikhaleni esingaphakathi. Lapho ugaya ingaphezulu le-facade noma usebenza ngezingoma ezinobuthi, kungcono ukuyikhipha noma usebenzise i-respirator.

Izinto zokwakha amapayipi

- Izingxenye ze-Aluminium zinamandla aphansi. Ziyahluka ngesisindo esincane, ngakho-ke zivame ukusetshenziswa kakhulu lapho zilungisa izakhiwo eziphansi. Izinhlelo ezinjalo azibizi, kepha zinethonya elinamandla. Izinto ezaphukile nezinensundu azinakulungiswa. Lapho kwephuka, zibuyise nge-New.

- Izinto ezenziwe ngensimbi zihlala isikhathi eside kakhulu. Banesisindo esibalulekile, kepha bahlangene njenge-compact njengezinhlelo ze-aluminium. Babiza kakhulu, ngakho-ke kungcono ukuqasha. Insimbi ye-Galvanized i-rack ethe xaxa emathonyeni angaphandle, kepha ngamandla ahlukile kwejwayelekile.

Ukusongoza icebo

Izinhlelo ziyehluka ngendlela yokunamathisela ama-racks nama-spacers.

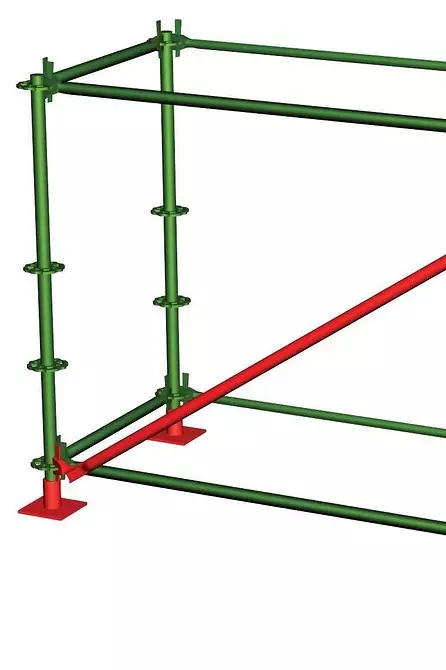

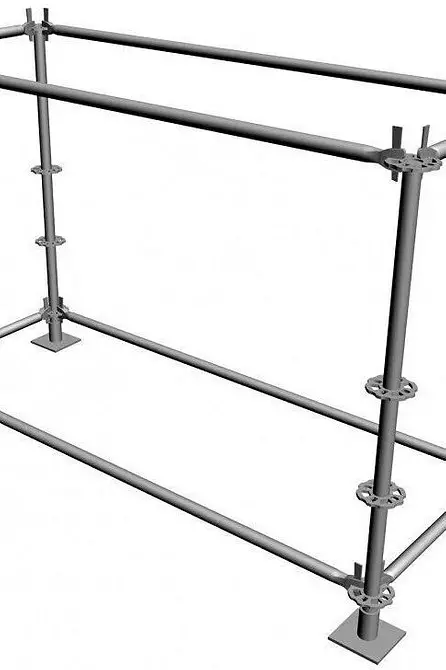

- Uhlaka - luqukethe ozimele bezicaba ezihlanganisiwe ezixhumeke ngama-jumpers avundlile ne-diagonal. Bakha izigaba ezihlelwe ngama-Locks wefulegi. Ama-rack aphezulu aphezulu aphezulu afakwa engaphansi. Amahlathi anjalo alungele kuphela ama-facade abushelelezi.

- I-PIN - Ukufakwa kwenziwa kusetshenziswa izimbobo ezingxenyeni ezivundlile nezikhonkwane - ku mpo.

- I-Wedge - I-Docking ethembekile inikezela ama-Flangese - izindiza ezinezimbobo ze-bolt, kanye nabanini. Ilungele noma yiziphi izinto, ngoba ziyakwazi ukushintsha i-angle, ivumelane nokukhululeka okuyinkimbinkimbi kodonga kanye neplatifomu engalingani.

- Ama-Clamps - Ukuxhumeka kwenzeka ngezinsimbi ezisontekile. Bayimpumputhe futhi bayimpumputhe.

Ngezindlu zangasese eziphansi kakhulu kungcono ukusebenzisa izinhlelo zozimele. Kulula ukuhlangana futhi ube nesisindo esincane kunazo zonke. Zisetshenziswa ngaphakathi nangaphandle kwesakhiwo.

Ukufaka ukufakwa kohlaka

Ukukhetha amapharamitha wezobuchwepheshe

- Ububanzi bepayipi bungu-30 mm.

- Ubukhulu odongeni - 1.5 mm.

- Umkhawulo womthwalo - 600 kg.

Amamodeli wasekhaya anelebula le-LRSP-30, LRSP-200, njll. Inombolo enamadijithi amabili ekugcineni isho ukuphakama okuphezulu ngamamitha, amadijithi amathathu - umthwalo omkhulu ovunyelwe ngamakhilogremu. Imodeli ene-LRSP-30 Brand ilungele indlu yangasese ephansi. Ukuphakama kwayo okuphezulu kungama-30 m. Isitoko esinjalo kufanele sanele ngisho nasezindaweni eziphakeme kakhulu.

Osayizi besigaba esisodwa

- Ukuphakama - 2 m.

- Ubude - kusuka ku-2 kuye ku-3 m.

- Ububanzi - 1 m.

Izinhlobo zokusekelwa

- Akulawulwa kwi-groove yensimbi.

- Iyashintshwa - nge-screw mechanism evumela ukuthi baphakamise futhi bashiye.

Izinhlobo zemikhiqizo enelebula LRSP-30

Imikhiqizo enelebula LRSP-30 ayihlali inedivayisi efanayo. Ziyahlukahluka kulezi zici ezilandelayo.- Ama-jumpers phakathi kwamafreyimu yi-diagonal futhi mpo. I-Diagonal idala ukuxhumana okuqinile kakhulu phakathi kwezinto.

- Ukufaka e-facade, kubakaki besikhathi esisodwa kufakwe kuma-dowels noma kusetshenziswe kabusha. Zilungisiwe kuma-anchors angasuswa odongeni.

- Phansi kwenziwa kusuka emabhodini noma ezingxenyeni zensimbi ezihlanganisiwe ezenzelwe imithwalo esindayo.

Ukulungiselela isiza

Ukuqinisekisa ukuthi ukwakheka akuvukile, udinga ukulungisa kahle isisekelo. Inhlabathi kufanele ichithwe futhi ihlatshwe amandla. Kungcono ukuthi uhlele ama-racks endaweni eqinile noma ukubeka isisekelweni kubo. Kulokhu, kuzodingeka ukuthi usebenzise ngokunenzuzo ukuze uzuze ukuqina, ukulungisa isikhundla semilenze.

Emhlabathini omanzi wenza imichilo yokudonsa kusuka ezitini eziphukile nezinye izinto lapho amanzi ezongena khona emhlabathini. Ukuze inhlabathi ingagezwa, bahlela imisele yokudonsa amanzi. Kufanele zibe khona kude nama-racks. Akudingekile ukuqinisa izindonga, kepha kungcono ukuwavalela ngamashidi e-tin noma nge-slate, noma ugcwale ngemfucumfucu.

Umsebenzi okhuphukayo

Kuyadingeka ukwakha imichilo ngokwemiyalo. Imodeli ngayinye inezimpawu zayo. Ukuchitha umsebenzi kahle, udinga ukulandela kahle izincomo futhi ungazami ukuthuthukisa ubuchwepheshe obukhona.

Ukufakwa kuqala kusuka ekhoneni lesakhiwo. Inhlabathi ihlanganiswe yizicathulo ezinokuphakama okungama-4 cm nokuhlubula esihlahleni. Isikhundla sabo kufanele sibe ngokuqondile. Isinyathelo silawulwa ngokuqinile imiyalo. Ukusetha kahle izicathulo nama-gaskets, sebenzisa izinga lokwakha. Ukuxhaswa kutholakala ngaphezulu. Bese ulungisa izindlela zokulungisa uma zinjalo. Isikhundla sezesekeli kufanele sifane, ngaphandle kwalokho uhlaka luzosetshenziswa. Ekuphakameni kwamamitha ambalwa, ngisho nokunyakaza okuncane kubonakala kakhulu. Kuyingozi ukusebenza ezimeni ezinjalo.

Amafreyimu we-Flat Welded afakwa ezicathulweni. Zitholakala ngokufana futhi zixhunywe ngama-jumpers avundlile ne-diagonal. Ikhwalithi yomsebenzi ihlolwe kusetshenziswa izinga lokwakha.

Lapho i-tier yokuqala isilungile, ihlelwe odongeni amahange noma ama-dowels. Ukusuka ngaphezulu kwe-REGLELS - izingxenye ezivundlile ezenza iqhaza lezizathu zokugcwala.

Lapho-ke izitebhisi eziholela ku-tier yesibili zinamathiselwe. Floored on the riglels. Amabhodi aqinile, ukuze abe phakathi kwawo akukho zikhala. I-coating kufanele iqine, ngaphandle kwalokho amathuluzi azowela esitokisini. Akufanele isebenzise phansi kwensimbi, ngoba iyadingeka kuphela ngemithwalo ebalulekile. Ngobukhulu obuphansi, amabhodi avunwa kanye ne-allen futhi aqinise ukuze angalawa lapho ehamba. Ukuqonda ukuthi kudingeka okungakanani okudingekayo, udinga ukwazi ubude nobubanzi bohlaka. Amanye amamodeli ane uthango lwe-board.

Isikimu sokusongela isikimu sinikezela ngamathuba okudala ama-tiers amaningana. Uma uhlela ukudala isitezi sesithathu, udinga ukufaka isitebhisi sesibili bese wenza i-hatch emgodini phansi ukuze ukhuphuke ngenhla. Ama-diagonal jumpers aphansi nangaphansi phansi anamathiselwe kwi-oda lokuhlola, akha i-rhombus ehlukaniswe ngesigamu se-swelep.

Ukufakwa kwamahlathi ama-facades wejaloki eliyinkimbinkimbi

Kuma-facades ayinkimbinkimbi, iphini, ama-clamp kanye nezinhlelo ze-wedge kufanelekile. Izikhonkwane zikhulu kakhulu ngesiza sangasese. Ukufakwa kwe-Clamp kuthatha isikhathi esiningi, ngakho-ke kungcono ukusebenzisa ama-Wedges. Amakhompiyutha abo akuvumela ukuthi ushintshe i-angle yemininingwane, eyenza sikwazi ukuthola izigaba ezinzima ukufinyelela ezingxenyeni ze-facade.Ukucaciswa kobuchwepheshe

- Ukuphakama kwesigaba esisodwa kungu-2 m.

- Ubude - kusuka ku-2 kuye ku-3 m.

- Ububanzi - kusuka ku-1 kuye ku-3 m. Ngendlu yezwe, kwanele ku-1 m.

Umthwalo uhlukahluka ngokuya ngemodeli nokuguqulwa kwawo. Umkhawulo womkhawulo ungama-500 kg / m2.

Inqubo yokufaka

Ukulungiselela ingaphezulu kwesisekelo kwenziwa ngesimiso esifanayo nangamahlathi azimele. Isayithi kufanele libushelelezi futhi, uma kungenzeka liqinile.

Izendlalelo zokhuni ezinqamule zifakwe emhlabathini ngaphansi kombhangqwana ngamunye weseluleko. Izithende zakwamanye amazwe zingafakwa noma zilawulwe. Amafreyimu amile afakwa kuwo. Isikhundla sabo sihlolwe ngezinga. Kufanele kube mpo ngokuqondile.

Ema-racks ebusweni kukhona ama-flanges - ama-flendicular kuwo izindiza ezinezimbobo ezikhuphukayo. Ama-jumpers we-Longitudinal futhi aguqukayo ahlelwe ngama-flanges asebenzisa izingidi ze-wedge - i-wedge ingena emgodini futhi iboshwe ngendlela yokukhiya.

Lapho uhlaka selukulungele, ama-rigleels anamathiselwe ngaphezulu, izitebhisi ezihlangenwe nakho nezinsika. Amamodeli amaningi afaka izitimela ezifakiwe.

Ngaphambi kokuqoqa ukuswayipha, udinga ukuhlola imiyalo. Imininingwane yomhlangano ingahluka kumamodeli ahlukile.