Ngesikhathi kwakhiwa indlu yezitini noma amabhlokhi, kugcizelelwa okungaphansi kokhonkolo kanye nezitezi zokunye. Silandisa ngezinhlobo zezakhiwo nokuthi ungawakha kanjani ukunqwabelana ngaphandle kwamaphutha.

Izitezi zikakhonkolo eziqinisiwe zingcono zithola umsindo futhi cishe azithathi hlangothi kuma-vibrations ngokuqhathaniswa nemishini yokhuni. Bahlala isikhathi eside kakhulu, bamelana nomthwalo kusuka ekuhlukanisweni kwama-masonry, izitebhisi, ifenisha enkulu, esiza ikhambi lemisebenzi yokuhlela. Kunamaphutha, okokuqala kwako konke okuhlobene nesidingo sokuheha imishini enamandla nenani elibalulekile labasebenzi, ukuqasha amadivayisi akhethekile nemishini. Izitezi zikakhonkolo eziqinisiwe zivame ukudinga ukuqondanisa okwengeziwe, kwesinye isikhathi ukufakwa futhi cishe kubiza amadizayini amaningi asuselwa kumishayo yokhuni.

Ukuze ungagcini ngokweqile futhi ungagcini ekulimaleni kwekhwalithi, okokuqala, izinzuzo nezinzuzo zobuchwepheshe obuhlukahlukene bokwakhiwa kwalezo zinqwalisweni kufanele zitholakale.

Ukugqashuka kwe-slab okwenziwe ngaphambili

Ngokwakhiwa kwezindlu eziphansi, kuqediwe ama-slabs okuqaqanjelwa kusetshenziswa ikakhulukazi izinhlobo ezintathu: I-PC (enezinto eziyindilinga), i-PB (amapuleti amapuleti amaningi) kanye ne-SFO (ipuleti floor lightweight). Amapuleti we-PC ne-PB akhishwa ngobukhulu obungama-220 mm, kanti owesibili abonakala nge-geometry enembile kakhudlwana kanye nekhwalithi ephezulu kakhulu (bahlaselwa ngokugaya okunzima). Amapuleti pho, ukushuba kuka-160 mm, kubhekwa njengokufanele ekwakhiweni kwangasese, njengoba izindonga kanye nesisekelo sezilayishelwa kancane, zenza lula ukufakwa konqenqemeni kwendawo eyeqile futhi ngasikhathi sinye, ngamandla (ikhono lenethiwekhi) , kuphela okuphansi okuphansi kwezinhlobo ze-PC namapuleti e-PB. Izitshalo zinikezela ngemikhiqizo yenqwaba yamasayizi, yize ama-slabs ajwayelekile kakhulu 100, 120, 150 cm ububanzi, ubude bawo buyehluka kusuka ku-2.4 kuye ku-9 m nge-10 cm ukukhuphuka (kepha lokhu akusho ukuthi inani le-9 m lingaba ivinjiwe ngaphandle kokusekelwa okwengeziwe).

Ububanzi beplatifomu yereferensi yamapuleti ezindongeni zezitini kufanele okungenani kube yi-100 mm. Lapho kukhuphuka, ama-slabs abekwe engxenyeni yesisombululo. Uma kungekho zimboni zefektri kuma-voids, izimbobo kufanele zibe uphawu emakhanda amapuleti.

Ezindlini zamabhulokhi akhanyayo (ukhonkolo we-foam, ama-polystyrene ama-bonts, i-arststyrene, i-ceramic) yokubona umthwalo ovela ku-monolithic W / B BELT 200 mm ububanzi kanye nokuphakama kwe-100-150 mm.

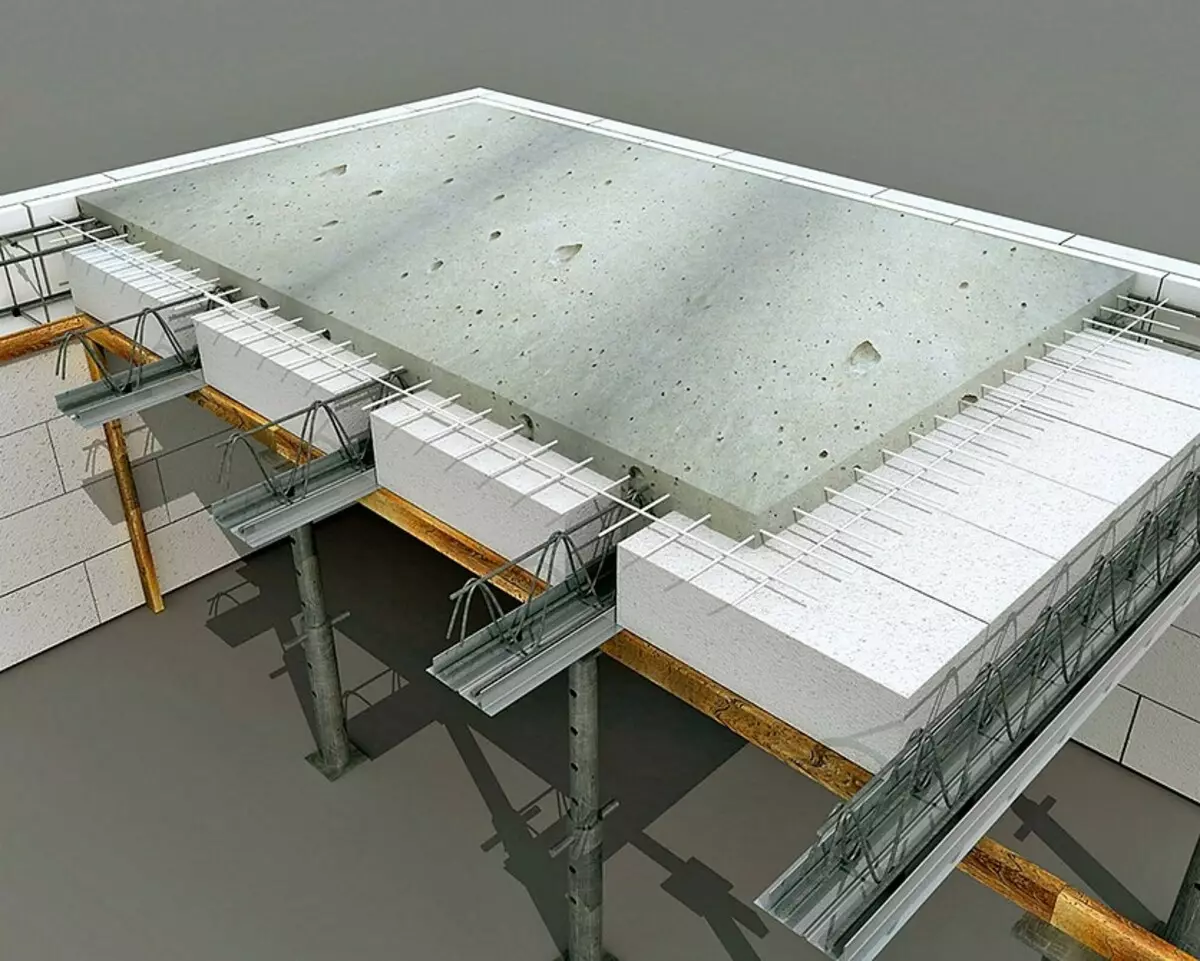

Ngedivayisi, ukunyakaza ku-monolithic noma iqoqo-monolithic sweplap kufakwa yifombi yemiphetho futhi kuthuthukise ifreyimu yokuqinisa

Izinzuzo eziphambili zokugqekeza ezivela kumapuleti aqediwe - Ijubane lokufaka eliphakeme, amathuba okukhiqizwa komsebenzi ebusika (emazingeni okushisa awekho ngaphansi kwezimpawu zamandla ezindawo, izinqubo zokukhiqiza ezilawulwa ngokuqondile futhi kubhekwe ngokucophelela.

Ngakolunye uhlangothi, usayizi ohleliwe wama-slabs ngandlela thile afaka umsebenzi womqambi, futhi ukwakheka kwawo okungunxande kuyaphoqelelwa ukuba alahle izixazululo zokwakha ezingezona ezijwayelekile (izindonga zeRadius, ama-polygonal erkers, njll.). Ukushayela okunzima: Kufanele uguqukele ekusikeni kwedayimane okubizayo, i-Mountal ilayisha amaRigols. Ekugcineni, uzodinga ukuqasha i-crane bese ufaka usizo lwabafakeli abanolwazi ukuvikela amaphutha lapho bebeka amapuleti. Amapuleti PNTO ngokulethwa azobiza cishe ama-ruble angu-1700. Okwe-1 m2, kanye nezindleko zokufakwa kwazo - kusuka kuma-ruble angama-3500. Ngemuva kwesitofu.

Iningi lamapuleti efektri linama-grooves anqenqemeni okwenza kube lula ukuhlanganisa okuhlanganisiwe

I-Monolithic Slab Overlap

Lo mklamo uguqulwa kalula kwifomu lesakhiwo futhi akhiwe ngaphandle kokusebenzisa i-crane. Ngokuqina, kwedlula iqembu, ngakho-ke umsindo womoya uhlukanisa okungcono futhi uvimbela ukuvuza (okuyinto endlini yezwe kuyenzeka futhi kusongeli imiphumela emibi kakhulu kunasefulethini ledolobha).

Lapho uklama i-monolithic slab, kuqondiswa amazinga - SP 52-101-2-2003, SP 52-117-2008 ne-SP 63.133330.2012. Esigabeni sokuqala, kuzodingeka ukuthi kwakhiwe ifomu elenzelwe i-plywood, ngowesifazane noma kwezinye izihlangu ngokusekelwa emishameni nasema-racks. Amafomu angatholakali avela phansi ochwepheshe azosheshisa ukwakha, kepha ngokuzayo kuzokwenza kube nzima ukuqeda uphahla.

Ngemuva kokuhlangana kabusha kwefomu kuyo yonke indawo egqamile, uhlaka lwezinga ezimbili kusuka ekuqinisweni okunobubanzi obungu-10 mm nge-coeffrement ebaliwe yokuqinisa i-welding.

Amapuleti we-Prerast kusuka kukhonkolo oqinisiwe okukhanyayo ayivamile kakhulu. Ukubuya Okusemqoka kungukumelana komswakama okuphansi

Inqubo yokuthulula ukhonkolo kumele yenziwe njengesikhathi esifushane, i-BOSSIng ingxube yefekthri ngokulethwa kwemoto. Ukulungiswa okuzimele kukakhonkolo akwamukeleki, ngoba ngasikhathi sinye sokungagweme ukugwema ama-saims amaningi "abandayo", azoncipha kakhulu amandla e-slab. Kuyinto engathandeki kakhulu ukwakha i-monolithic sweplap ngesikhathi sokubanda, ngoba kungenxa yokwandisa izindleko futhi kukhuphukile ngokwehla kokwethenjwa kwesakhiwo. Okwanamuhla, intengo yedivaysi engu-1 m2 ye-monolithic W / W igcwele ngobukhulu bama-200 mm (umsebenzi kanye nezinto zokwakha ngaphandle okuqediwe) kungama-ruble ayizinkulungwane ezinhlanu.

Izigaba eziphambili zokuqothuka kwe-monolithic

Phezu kwezihlangu zamafomu lisakazeka ukugcwala amanzi agoqwe futhi kufakwe ifreyimu yokuqinisa, ukugoba induku ngocingo. Ukhonkolo wokuthengisa ogcwele. Amafomu asuswa ezinsukwini ezingama-20 lapho ukhonkolo ethola ama-80% amandla.

Waqoqa ukugcwala kwe-monolithic

Lobu buchwepheshe obaziwayo kunguqulo entsha elungele ukwakhiwa okuphansi kunikezwa namuhla kusuka uMark, uTeriva nase-Ytong. Umnyombo wayo ukuthi okokuqala ukuchitheka kuncipha imishayo yamathambo efektri yokukhiqiza efekthri. Phakathi kwemishayo (ngokusekelwa kwamashelufu abo aseceleni) ubeka phansi okuqinile kusuka emabhulokini amaphaphu. Lo mklamo usebenza njengefokulo engeyona eyenziwe, ngaphezulu kwawo akhwela i-mesh kusuka ekuqinisweni. Ngemuva kwalokho wathela ingxube ekhonkolo nge-filler efihla kahle; Ubukhulu besendlalelo ngaphezulu kwamabhulokhi kufanele kube ngu-50-70 mm. Kungcono ukusebenzisa ukhonkolo wezimpahla, noma kunjalo, kuvunyelwe ukulungiselela ingxube ngokwabo, into esemqoka ukuvikela imishayo "ebandayo" lapho imishayo ekhona.Ubuchwepheshe obuqoqiwe-monolithic benza ukuthi kwenzeke ngaphandle kwemishini yokuphakamisa enamandla (yokuphakamisa imishayo, isisindo sawo angeqi okungu-120 kg, ungasebenzisa ama-winches we-manual) kanye ne-Shieldforkwork) kanye nangaphezulu - ukonga isikhathi nemali ku ivumelanisa idivaysi eswidi. Izindleko zemishayo namabhulokhi cishe ama-ruble angama-1,400. Okwe-1 m2, futhi ukugcwala okuqediwe kuzobiza cishe ama-ruble angama-4500. nge-1 m2).

Izigaba eziphambili zomhlangano kanye ne-monolithic sclap

Okokuqala, kukhuliswe ezindongeni futhi kufakwe kuzimele zokuqinisa isikhundla zephrojekthi zokuqinisa imishayo. Ngokulandelayo, babeka amabhlokhi kakhonkolo akhanyayo, futhi ngaphezulu kwawo - igridi yokuqinisa. Imishayo kufanele icindezelwe ngama-racks, ngaphandle kwalokho bangakhubazeka. Wathela ukuhlanganiswa kokhonkolo.

Ukufakwa kwe-Monolithic Sweplap kuzothuthukisa umsebenzi wamafomu ngama-racks aguqukayo. Kuliqiniso, izindleko zokuqashwa kwazo ziphakeme impela - kusuka kuma-ruble ayi-1600. Okwe-50 sq. M ngosuku

Ungaqinisa kanjani izimbobo nama-loops

Izingcezu zezitebhisi, ama-hatches, indle kanye namapayimitha okuhambisa umoya, ama-chimneys kufanele anikezwe lapho aklama futhi enza ukugoqa ngesikhathi sokufakwa. Ngokusho kwamazinga wokwakha, izimbobo zosayizi abalulekile (ezinamabala noma ububanzi obungama-300 mm noma ngaphezulu) kumapuleti e-monolithic kufanele asungulwe ngokuqiniswa kwesiphambano okuphelele kwesigaba sokusebenza, okudingekayo ngokubala ipuleti njengeliqinile.

Nge-Plate Claublehouse, kuyinto efiselekayo ukusebenzisa amapuleti akhethekile ngezimbobo (alos, azishintshwa kahle izakhiwo eziphansi) noma zinikeze amakholomu okusekelana kanye / noma ukulayisha imishayo. Ngaphandle kokuqiniswa nokuqinisekiswa okunjalo, ukubalwa kuvunyelwe ukwenza izimbobo kuphela ngaphakathi kwebanga ukusuka kumbambo owodwa weribhoni uye kwelinye (ezitsheni eziyize awukwazi ukunciphisa izingxenye eziqinile).

Kanjani ukwenza ama-butts ngaphandle kwemifantu

Ukugula okudumile kwezakhiwo eziphakeme zephaneli - imifantu ophahleni ophahleni lwamapuleti okuqoqa okuqoqiwe, kwenzeka zombili lapho ukwakhiwa kwesakhiwo kanye nenqubo yokusebenza kwayo. Le nkathazo awwenzeki njalo ukugwema ilungelo. Kepha ungazama. Isihluthulelo sempumelelo sizosebenzisa amapuleti asezingeni eliphakeme ngethamo lokuthwala, ukuvezwa okuqaphelayo kwesayithi lesethenjwa kanye nokusatshalaliswa komfaniswano womthwalo onqenqemeni

Ngokuqondene nokuhlangana kokubopha kwamapuleti, kubalulekile ukusebenzisa izinto ezisezingeni eliphakeme futhi ungashiyi ubuze obuphazamiseka ngokungafanele ukufakwa komsindo womoya. Imvamisa, uphawu lwe-tubular lufakwa ezansi komthungo (ngokomthetho, i-polyurethane Foam ingasetshenziswa), bese kuthi indawo yesixazululo sesimende-sandy ayiphansi kune-M250, ephekwe kahle ngesisekelo sokuqina usimende ongavikeli amanzi.

Izikhala zobubanzi ezingaphezu kuka-25 zenziwa besebenzisa ubuchwepheshe be-monolithic casting besebenzisa umsebenzi osuswayo noma osatshiswayo kanye nokuqiniswa okuphoqelekile.