Not only traditional building materials can be used to build a house. We will tell about gas blocks and foam blocks, compare their main characteristics.

Building It begins with the selection of the material from which the construction will be erected. It is optimal that it is durable, durable, with good insulating characteristics. All these properties have a cellular concrete. We will analyze What is the difference between the gasoblock from foam block The most sought-after from his varieties.

Features of cellular concretees

Traditionally, houses are built of wood, bricks, stone. Each of them has advantages that improve the quality of construction. Modern technologies have made it possible to create a composition in which all these advantages have successfully united. The cellular mass is used to erect internal and bearing walls, partitions, insulation, etc.

The determining point is the density of the product and its porosity. The more pores, the lower the density and, accordingly, strength. High porosity compositions refer to the category of thermal insulation. More dense are designed to build supporting structures. In any case, the cellular mixture distinguishes:

- Environmental Safety.

- Good heat and sound insulation.

- Sufficient strength.

- Easy processing.

- Fire safety.

The name of the cellular concrete is hiding a whole group of materials similar to the structure, but differing properties. The most sought-after foam and aerated concrete concrete, which are manufactured by different technologies. Specialists Recommend to use them to build low-rise buildings.

What is Penoble

This is the name of the construction module made by foaming the concrete mix. The production technology is quite simple:

- The mixture consisting of water, portland cement, sand and fibrovolock is mixed in a concrete mixer with the blades of the inclined type.

- A foaming agent is added to the solution, after which the kneading continues.

- Ready composition is bottled in forms.

- It is left until complete drying in vivo. Sometimes an autoclave is used, in this case, higher quality products are obtained.

The simplicity of manufacturing foam material allows you to make it literally at the construction site. What looks like Similar production can be seen online. However, it is almost impossible to achieve uniform density in such conditions.

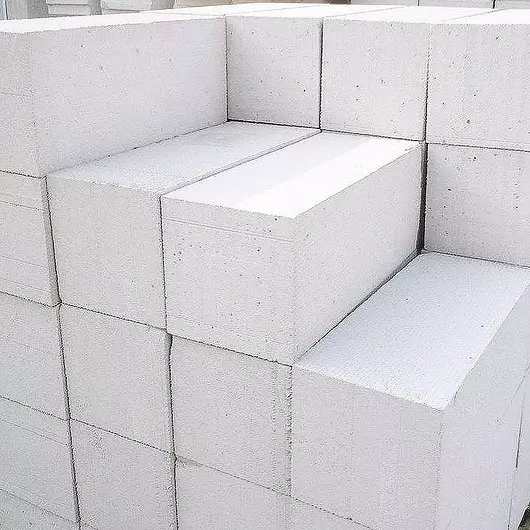

Air bubbles are chaotic moving inside the solution. Therefore, the porosity of foam concrete will be varied not only within the party, but also within one block, but it is worth it cheaper other varieties. Get acquainted with its characteristics:

- A small weight that removes a significant load with the foundation and facilitates installation.

- Low thermal conductivity. The wall from the standard in size of the details retains heat as well as the brick partition with a thickness of 0.7-0.8 m.

- Sufficient strength. Depends on the density of the module, but in any case lower than the brick or concrete. Nevertheless, a number of models can be used with additional reinforcement when building buildings not higher than three floors.

- Moisture resistance. Pores U. Foam block Closed, making it non-hygroscopic. If you get into the water, it will swim, not absorbing the liquid for seven days.

- Fire resistance. Does not support combustion that is not toxiced under the influence of the flame.

- Good Frost resistance. The material retains its properties at low temperatures.

Significant disadvantages include inhomogeneous density. The geometry of the block often depends on the manufacturer. Handicrafts may have significant deviations, which makes it seriously difficult.

All about gas block

Module production technology in comparison Foam concrete is minor at first glance. However, it is they determining the difference in their characteristics. Aerated concrete is manufactured as:

- A gas-generating substance is added to the mixture of portland cement, sand, fiber fiber and water. Most often it is an aluminum pasta. After stirring, a chemical reaction begins, which is accompanied by gas release.

- The solution is declined in forms so that they are filled only in part.

- Within two hours, the mixture is increased in volume, after which the extra mass is cleaned.

- Products are sent to the autoclave for drying.

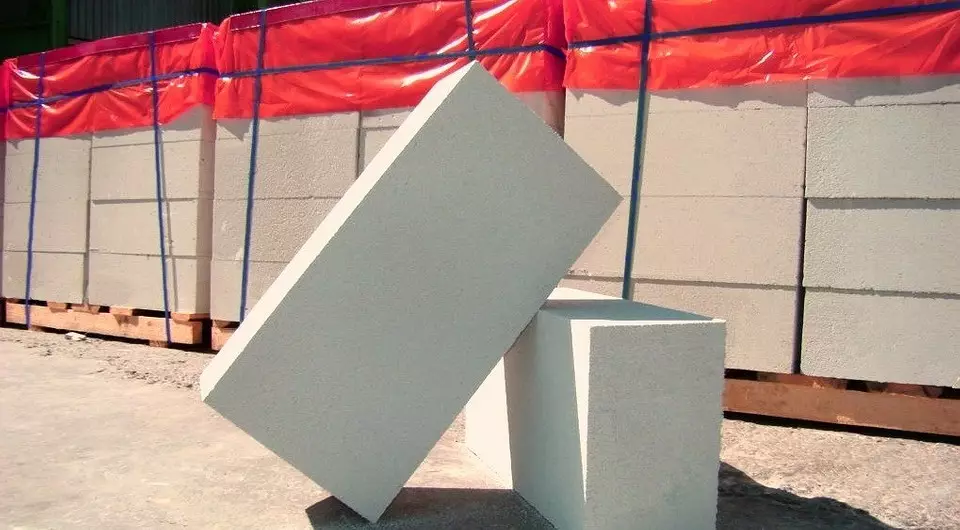

As a result, it turns out a homogeneous composition Gasoblock , almost perfect geometry. Given certain difficulties in manufacturing technology, it cannot be done by handicraft.

We list the main properties of the module:

- Low weight, which is about a third of the brick of the same volume.

- Low thermal conductivity. The air prisoner is a good insulator. The material accumulates heat, as a result of heating costs at home Reduce about a third.

- Ecology. Gas blocks are completely safe. Used in the process of production toxic aluminum paste dissolves without a residue.

- Easy processing. Modules easily Amenable to any cutting tool. They can be cut, drilled, etc.

- Frost resistance. It is estimated at least 25 cycles, subject to construction rules.

- Fire safety. The product is not lit, can withstand the direct impact of the flame of about 3-7 hours.

The main disadvantage of aerated concrete is considered hygroscopicity. Unlike From the foamed analogue, its pores are open, it quickly absorbs water. For this reason, effective waterproofing is mandatory.

Gas chamber and foam block: what's the difference

It may seem that these varieties of cellular concrete have a set of almost the same properties. but difference It is between them and it is essential. Conduct a comparison on the most significant characteristics.Geometry module

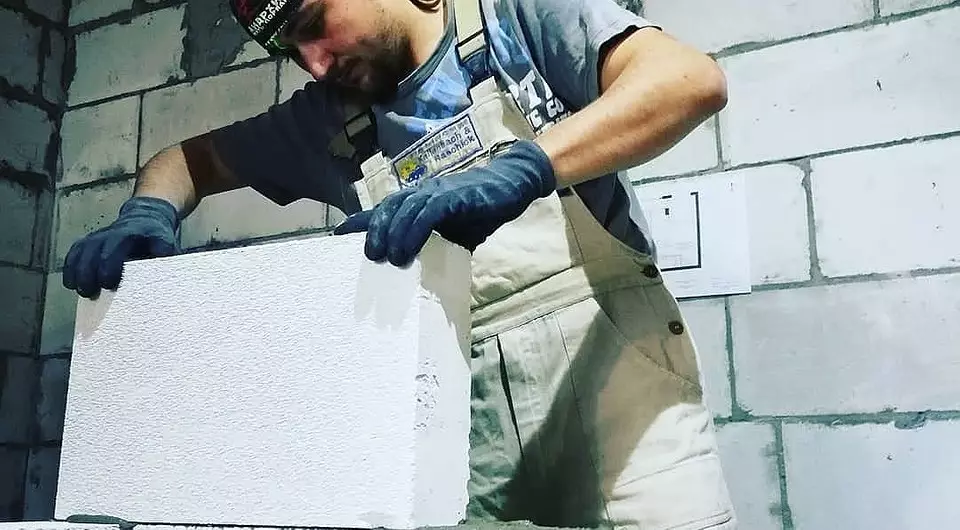

What it is better, the easier it is to keep laying. So, smooth designs can be mounted using a special glue. The seam thickness is only 2-3 mm, which allows you to completely get rid of cold bridges. At the same time, the speed of working with geometrically correct elements is much higher. The costs of decoration are reduced, since the alignment is not required. Foam blocks for this indicator noticeably Different . The error of their sides is 3 mm and above, gasoblocks it is not more than 1 mm.

Insulating properties

Both varieties are filled with air bubbles, but their number is not equally. A more porous is aerated concrete, therefore, it preserves heat better and dries noise. However, the differences are small. In both cases, construction and insulating models are produced. The latter are designed to insulate buildings from more "cold" materials, for example, Slagoblok.

Gigroscopic

The foamed concrete is absolutely nonregroscopic, from it you can build Without special protection against humidity. The open structure of gas modules makes them vulnerable to moisture. They are fast enough to soak water, which worsens their operational properties. Therefore, a mandatory additional waterproofing of the design is necessary.Strength

Characteristics depends on the density of modules and the method of their production. Strong Total products from aerated concrete, past processing in the autoclave. They are allowed to use when the houses are erected to 3 floors for the installation of internal, carrier and external walls. When filling out the framework, the product is set without restrictions. Foam concrete has less strength, so project Construction should provide compulsory reinforcement of structures.

Weight

Both variants are a cellular concrete, based on which it can be assumed that their mass is about the same. So there is really. However, a little Heavy Foam blocks. Due to the low weight, it became possible to produce parts significantly large than, for example, standard brick, sizes. This significantly speeds up the styling process, since the unit of the area accounts for fewer elements.Durability

Calculated life time Both compositions are at least one hundred years. It was not yet possible to check this experimentally, because they appeared only in the second half of the last century. However, it is necessary to understand that this will be possible only under the condition of competent construction and further proper operation of the structure.

Foamclock or Gasoblock: What is more profitable for construction

Doubt is that the building from cellular concrete will be much more economical brick, no longer arises. But the disputes continue about which of his varieties is better suitable for individual construction. There is not all uniquely and Opinions divided. The fact that, with other things being equal, foam concrete will cost cheaper. This is associated with the low cost of its manufacture. However, the total cost of construction may be more significant.

The geometrically correct gas unit can be put on special glue. Thickness strong The seam is only 2-3 mm, so the consumption of expensive composition will be minimal. While the foamed module most often has significant irregularities, as a result of which it can be placed only on the cement solution. To obtain reliable seams, the latter will need a lot, which will increase the cost of expenses.

Additional reinforcement of foam concrete, which is required when erecting any buildings, even small bath , also turns into some amount. The next cost is finishing. Aerated concrete with its almost perfect geometry in alignment does not need. Foam concrete must be at least plastering. As a result, it turns out that initially the cheaper material gives a markedly greater cost estimate. It is worth considering when choosing.

However, it is necessary to take into account another aspect, namely the experience of installers. Professionals easily cope with laying aerated concrete on glue. It is more difficult than masonry on cement and requires certain skills. Therefore, novice builders work better with foam concrete. In this case, you need to choose only high-quality material.

We disassembled Differences of foam block from gas block . They are quite a lot and they are significant. But at the same time, both types of cellular concrete are in demand because they allow you to build a durable and warm house quickly and without extra costs.