Frame walls are perfectly protected from the cold and at the same time little weigh. In addition, customers attract a variety of finished projects, an acceptable price and high construction speed. That's just what technology to give preference?

The frame house can be erected in different ways. Classical technology (it is customary to call it Finnish) is to assemble the skeleton of the building from the boards (timber), the trim and insulation of walls directly at the construction site. Another option involves the purchase of a set of details of factory readiness - open frame panels or warmed panels. Finally, you can buy a house from the volume modules.

Plotting blockhaus

Let's talk about the peculiarities, pros and cons of the most common types of sander (leaving the graded buildings behind the frame, which will be dedicated to a separate article), but before we bring together a briefly on the fact that they are united - wall structures.

Touching facade board

The cheapest and at the same time the universal (for any soil) the foundation of the skeleton house - the pile-screw. On dry areas, you can pour a floating tape. For the floor heating device optimal "Swedish" stove

Construction of frame walls

In a frame building, the main power loads perceive firmly connected with each other with a friend of the rack and riglels from durable material - most often a tree. As a rule, it helps the solid outer covering (from oriented-chip, cement-chipboard, plywood, etc.), which increases the spatial rigidity of the house box and the bearing ability of the walls. And the thermal insulation corresponds to the air or gas-filled material, which is placed in the frames of the frame - the intervals between the racks and the rigels.

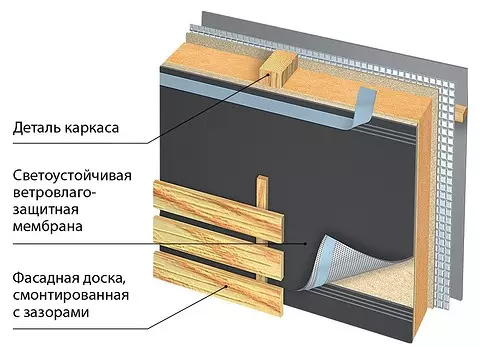

The covering of a block chamber or a facade board does not provide efficient windscreen protection, therefore, under the finishing material, a special rolled material or a plate / panel with puzzle connections should be placed

If fibrous minerals are used, as well as wood insulation, then for their protection against moisture there is not enough sheet sheathing - it is necessary to additionally insulate the material from room air and atmospheric precipitation with special films and membranes.

From the inside the frame walls are usually trimmed with drywall sheets, and then paint, cover with decorative plaster or are covered with wallpaper. Outside, on top of a sheet of plating, they can be separated by wooden, plastic or composite panels, plastering on the grid, sack the facade wallpaper, lining with tiles or not too heavy sawdow (sandstone, sewer thick up to 25 mm thick).

Houses from sip-panels often hand over to the customer without decoration. At the same time, it is for a long time to postpone facade work, because even the highest quality OSPs are not designed for long resistance to atmospheric influences

Competently constructed frame walls practically do not give shrinkage and are not blocked. The house quickly sleeps and well keeps heat (especially if you install windows with energy-saving glass windows). In this case, the performed frame wall is less suffering from the transition through zero than a stone or log.

Now - about the disadvantages. Such walls almost do not have thermal inertia: rooms quickly get out through open windows or doors, and the deseparable fireplace is able to turn the living room into the steam room. But the most significant minus is that the skeleton wall is not able to take extra moisture from room air. Therefore, in such a house it is difficult to do without a modern ventilation system, the price of which will be at least 350 thousand rubles. (At the same time, it is necessary to provide a place for the laying of Ventkanalov).

Sometimes installed solid (height in two floors) angular racks that increase the strength of the frame

Wide beam overlaps in bars strapping is not allowed - you need to use brackets

In the corners, the framework is strengthened by bodies

Build according to the rules

The frame house-building in Russia is regulated by the joint venture (Code of Rules) 31-105-2002. This is a detailed and quite relevant standard containing the description of the parts and components of the building, engineering systems and the defining procedure for the production of work from the foundation before finishing. Several outdated only items relating to the choice of materials: a lot of new products appeared on the market. The document is based on European practice and does not affect the construction scope of sip panels and modules.

The frame frame is collected as the sip panels are installed in a vertical position, sealing the joints of polyurethane foam

Sometimes the construction site is covered with an awning of film

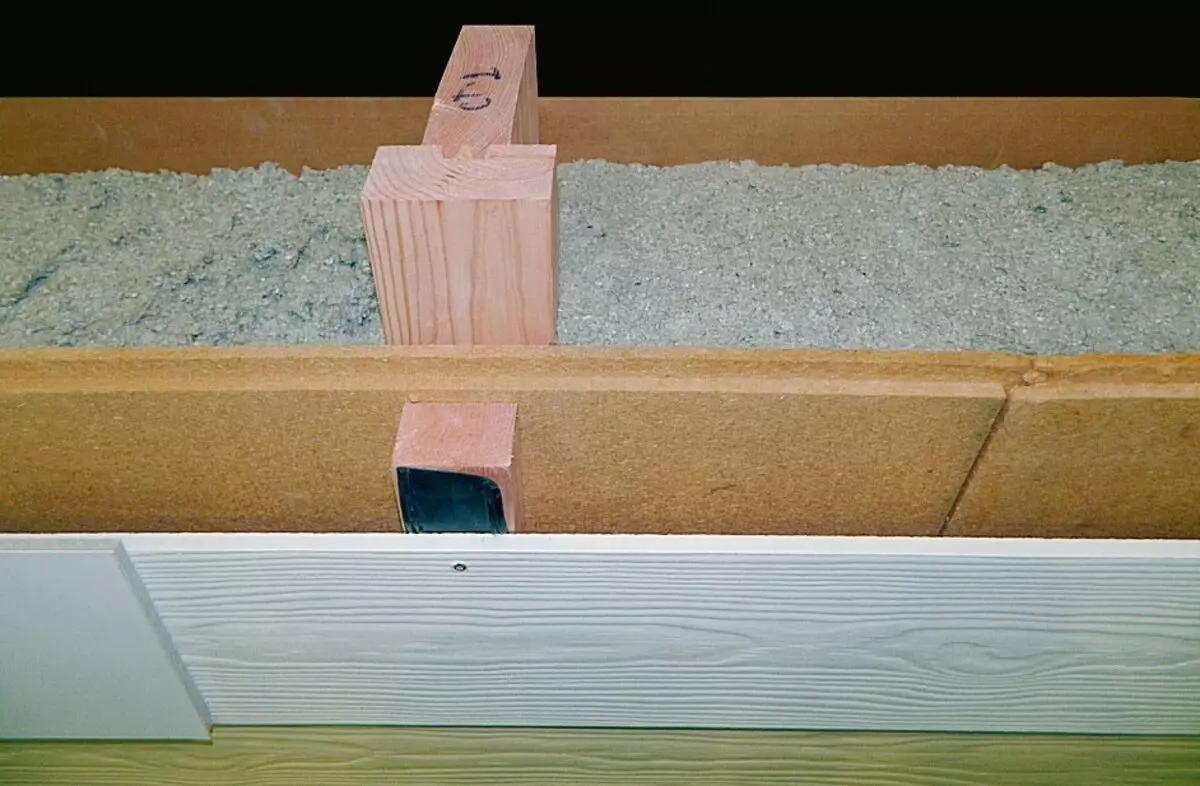

Options for the design of frame walls: with the skin of soft wood-fibrous plates, filling with a vermiculite and composite siding finish

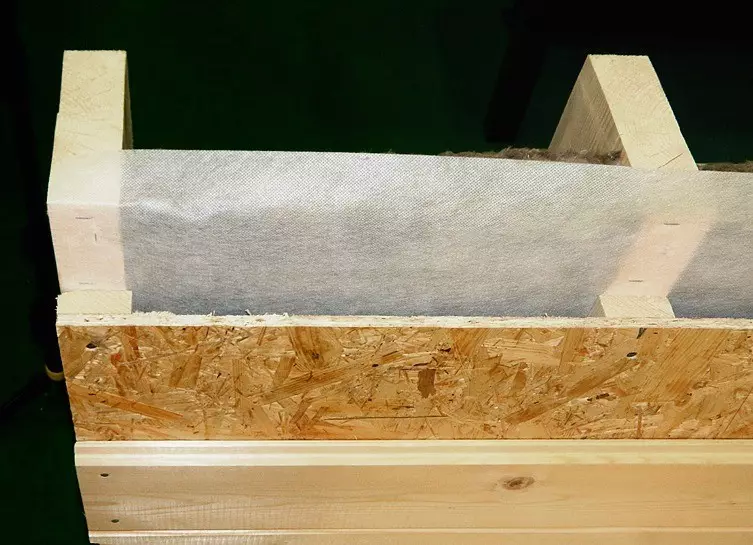

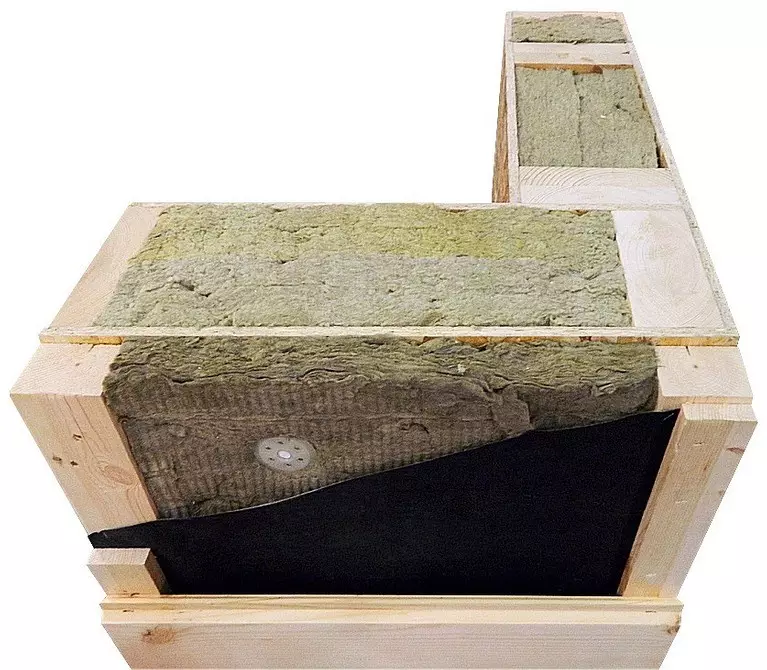

With OSP cover, filling with mineral wool and triggery. In any similar sandwich, an imprisonment is required between windband and the following (located closer to the street) layer

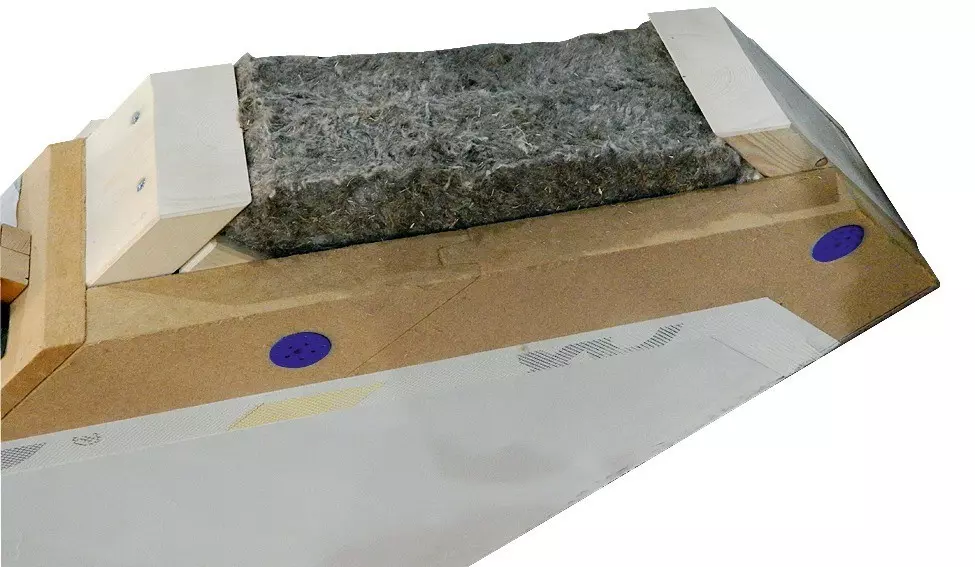

Walls with two-layer insulation for energy efficient buildings: mineral wool and linen cotton

And soft fiberboard with hydrophobic priesto

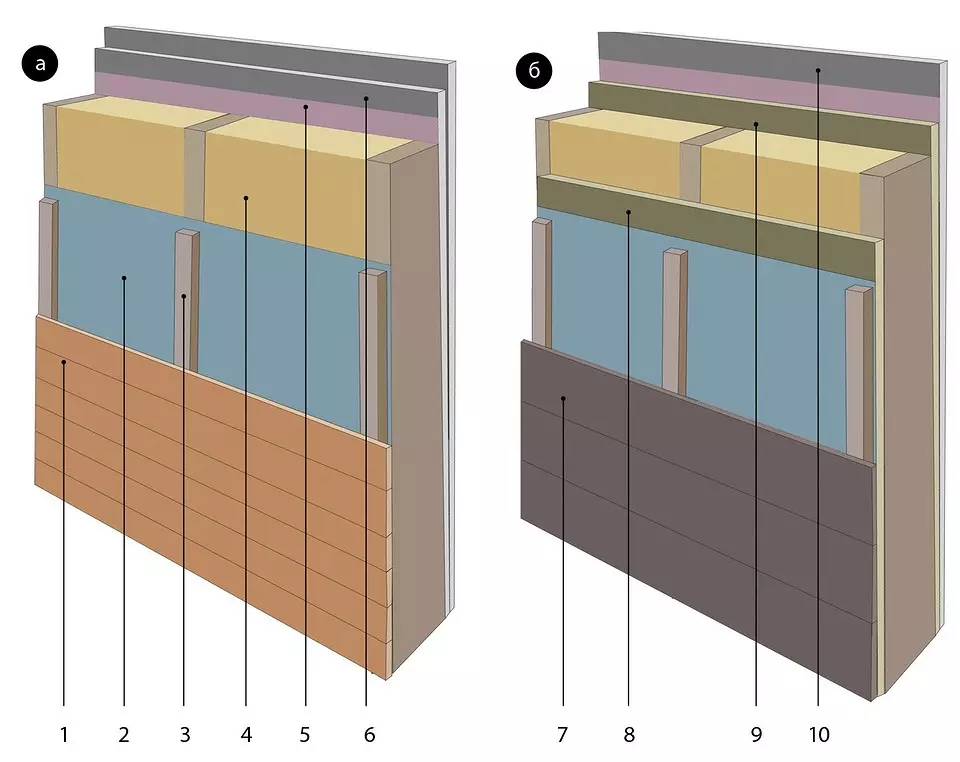

Wall designs: without an outer sheet cover (s), with sheet sheel (b)

1 - pinned facade board with a thickness of at least 25 mm; 2 - windproof vapor-permeable membrane; 3 - doom; 4 - mineral wool or other insulation; 5 - vapor barrier film; 6 - plasterboard sheets 12.5 mm (two layers); 7 - vinyl siding or other thin layer finish; 8 - OSP-3 plates with a thickness of 12 mm; 9 - Plate of OSP clacs emissions E 0.5 or plywood with a thickness of 10 mm; 10 - GKL or GBL thickness 12.5 mm (one layer)

Construction technologies: Finnish skewers and sip-panel houses

The heat insulating properties of the walls and the features of the microclimate in the skewer almost do not depend on the construction technology. What does it affect? First of all, the speed of the process and the cost of 1 m2 of the area of the house. In addition, the requirements for the technical equipment of the contractor. Finally, your choice will almost certainly affect the planning and architectural look of the building.Finnish classic

This method allows to do without lifting technology and a large number of workers. And it is not necessary to contact the construction company - you can buy or order a project and hire the brigade of masters from two or three people. With the right organization of the process, the house box with an area of 120-150 m2 with windows and outer decoration will be completed for 3 months.

The simplicity of the form of modular buildings is compensated by the use of trendy color solutions, modern finishing materials and large-format glazing

We will briefly describe the construction of a classic carcass. After the construction of the foundation and liner of communications, the beam overlap of the first floor with draft floors is mounted. Further on this site, in a horizontal position, the framework of walls and partitions of the first floor are harvested, which are then raised, fasten and tied on top of the timber. Then an interoaded overlap (with a support for the upper strapping) and the framework of the walls of the second floor or the rapid roof design.

The cross-section of the framework elements is chosen so as to ensure the strength of the structure and effective insulation (the required thickness of the mineral wool layer is 150-400 mm, depending on the climatic conditions and requirements for heat resistant).

The assembled skeleton of the building is coated with sheet material (usually OSP-3 plates with a thickness of 12-15 mm), cover the roof, after which the frame cells are filled with insulation. Today, out of competition, mineral wool mats, but nothing prevents other materials, such as cellulose cotton wool or polyurethane foam. In the process of insulation, engineering networks are mounted. Then the walls are tightened outside the wind aggravation (unless special windproof panels with a polymer impregnation were used for the plating), and from the inside - vapor insulation, which is pressed with a gentleman. Conduct finishing work.

When designing a classic sander, you can choose any architectural style, arrange erkers and arches, balconies and loggias (although, of course, these elements will increase the cost of construction). But the height of the building should be limited to two floors, and the most economical and reliable option is one above-ground floor and residential attic.

The heat insulating capacity and service life of the walls of such a house depends mainly on the quality of the performance of work, which will have to be carefully monitored - independently either with the help of hired specialists. But also, taking into account their services, the cost of 1 m2 of the total area of the house without taking into account engineering equipment and decoration will be no more than 16 thousand rubles.

Panel principle

Kits of small shield houses could be purchased at the very beginning of the country's summer of the 90s. last century. The walls were collected from the so-called open panels - frame frame elements of approximately 1.2 × 2.5 m with an outer lining from the wall paneling, plywood, CSP, etc. This allowed to quickly bring the construction under the roof, and then hesitate to insulate the walls and go to Interior decoration. Today, some firms also implement the frame-shield principle using the open panels of large dimensions (2.5 × 2.7 m or more) with different options for the outer decoration.

Separate companies offer houses from insulated framework wall elements of their own development, such as filled with mineral wool and soft fiberboard ("Martin House"). However, the Canadian construction technology from sip-panels won great popularity.

The traditional sip-panel consists of two OSP-3 plates, between which a sheet of polystyrene is located. Not so long ago, a new type of product of non-combustible glass edges and a high density mineral wool core appeared on the market. In both cases, the parts of the panel glue each other under the press of polyurethane glue. Sip panels produce different thickness; For overlappings and roofs under the conditions of the middle strip of Russia, the material is optimal with a thickness of 224 mm, for the outer walls - 174 mm, for interior partitions - 124 mm.

Building technology provides for the installation of a hidden frame from boards, racks and riggers of which are inserted into the edges of the panels. Shakes with frame parts are sealed with polyurethane foam.

At the factory, the modules are separated from the inside and outside

Collect a rafter design and a doom, but the roof insulation and the laying of roofing are carried out after the assembly of the Domakarkas modular house is performed with a large margin of strength so that the design can withstand loading, transportation and unloading

Often use double beams and reinforced connections

When assembling at home, a sealing tape from an elastic material is fastened with a sealing tape from an elastic material, such as Polynestenylene. Then the modules are solid and tighten with screws.

Sip-panels of standard (2.8 / 2.5 × 1.25 m) and non-standard sizes are sold by manufacturers, and yet independent construction is somewhat difficult, since the assembly process requires specific experience. More often at home on Canadian technology, they are ordered in firms offering several typical projects to choose from.

This method of construction is somewhat reliable than the classic, as the firm gives a guarantee for up to 5 years to materials and work. At the same time, it is obliged to eliminate the detected defects for free, for example, purging or wetting walls. However, the cost of "Canadian" houses is usually higher than "Finnish" - from 19 thousand rubles. For 1 m2 without finishing and engineering systems.

The wall frame is allowed to collect only from high-grade chamber drying wood. It is more correct to use calibrated boards and bars, products from a glue massif or combined 2-ways (wood + OSP)

Wall design with wooden plankin decoration

Steel frame

The frame of a low-rise building can be assembled not only from the tree, but also from steel thin-walled profiles (usually p- and s-shaped sections). Such products are offered by Atekhum, Salves, Kingspan, etc. The main advantages of the LSTK (light steel thin-walled structures) are high assembly rate and geometry accuracy. As a rule, the frame is delivered to the object fully prepared for installation: the profiles are cut in size and marked according to the design documentation, the holes for fasteners are drilled. Steel products are reliably protected from corrosion by hot galvanizing. Unlike bars and boards, they do not crack and do not block.

However, the steel framework, taking into account assembly work, will cost at least 70% more expensive than wood. In addition, steel profiles, even with a minimally permissible wall thickness (0.7 mm) and perforation, slowing the heat transfer, are cold bridges. To avoid condensate formation in the thickness of the structure, the walls have to additionally insulate the thermopanels based on extrusion polystyrene foam, mounted inserted on the frame.

Features of the order of the modular house

With a volume-modular technology, major construction operations, including finishing and installation of engineering networks, are carried out in the covered shop. Finished modules (usually two, rarely three or four) are brought on cargo platforms and lowered with a faucet on the pre-erected foundation. Then they are splitting, sealing joints, and connect the house to the main communications.

In our market, modular houses represent the company "House-Ark", "Dubld", the experimental design plant of volume modules No. 1, Woodel, etc., the production time is usually from a month to two.

By ordering a modular building, you save a lot of time and get rid of all troubles for buying materials, search for workers and control the quality of construction. However, they will have to accept the humble choice of design solutions, small size of the premises and the specific architectural modulists. Most of the houses are rectangular in terms of, often with a single-sided roof, tiny eaves or without them without them. As a rule, in the house one floor (but often there are residential mezzanine), and its total area almost never exceeds 100 m2. The cost is fully finished to accommodate modular chalet - 31-38 thousand rubles. for 1 m2.

To reduce the risk of forming the bridges of cold, you can perform a frame with two rows of racks and riggers, offset relative to each other, and two-layer insulation, but this will increase the cost of building the house by about 20%

To reduce the height of the modules (otherwise they are not transported under the bridges and lines of power) without losing the height of the rooms, the ceilings in the house make inclined, as in the attic, while the roof is well insulated