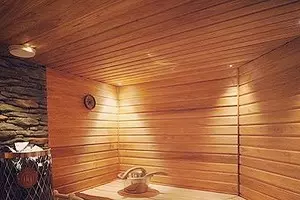

In the cold roof bath requires a mandatory ceiling insulation. We will analyze the four best ways.

Cold roof is not intended to hold heat, so it will be very uncomfortable in the bath with such a roof. How to insulate the ceiling in the bath So as not to encounter such a problem? We'll figure out.

Why insulate the ceiling overlap in the bath

If the roof is cold in the building, it means that it is not insulated. The underproductive space from the street separates only a layer of waterproofing and roof elements. This gives certain advantages:

- small weight design;

- saving funds for the purchase of building materials and installation;

- lack of land in cold.

But there are also disadvantages. The largest of them is heat leakage. And as a result, the need to damn the room is much more intense. If the cold roof is covered by the bath, the situation is exacerbated by the presence of wet heated air. It rises to a laptile ceiling, cools and forms a rich condensate, which spoils construction structures and dripped on people inside.

The presence of condensate on the floors and the ceiling is extremely undesirable. Moisture penetrates inside the design and starts its destruction. Depending on the type of coating, it takes place at different speeds, but always fast enough. Dangerous fungus and mold appear. The only way to solve all the problems is to make thermal insulation ceiling overlap.

Insulation ceiling bath

Method of competent insulationUnder insulation, it is assumed to lay a layer of insulating material that will keep indoors heat. However, only the insulation layer in the bath is not enough. He will not be able to fulfill its task because it is impregnated with moisture and deteriorate. In order for insulation to light for a long time, three layers of insulating materials are required.

Layer №1: vaporizolation

The main task of this layer is to prevent evaporation from entering insulation. All the pairs rising from the preheated room should be held. For this layer, materials such as pergamine or roofing materials can be used for this layer. Or more modern geosynthetic coatings, various membranes and thermophol. Well, if the coating is fooled, then it can also shield heat, returning it to the room.

Insulation ceiling bath

Layer number 2: Heat insulation

The second layer of insulating cake must be delayed warm, not passing it out. Here can be used a variety of materials. Which to choose will tell the budget and your own construction skills. It is important that the insulation is as easy as possible (then it will not create an excessive load on the design resistant to the effects of moisture) and non-combustible, if possible, simple and convenient in the installation.

Layer of vaporizolation

Layer No. 3: Waterproofing

For insulation, there is not enough protection from water only from the side of the room. Another barrier requires, but already on the side of the roof. From there, water can also penetrate. Therefore, on top of the heat insulator, a layer of waterproofing is necessarily placed. This is a film or membrane. It is optimal that one side of the material is completely moisture-proof, and the other passed steam. Thus, the insulation will be able to "breathe" and the water will not fall into it.

An important nuance. If the sauna is built without a attic, the insulation is made only from the inside. If the attic is present, the thermal insulation can fit both from the inside of the room and outside. A crucial role will play the material here, which will be insulated. For example, slab and rolled coatings can be stacked in any way, but bulk or bulk only outside.

Warming dry eco-art

What to insulate the ceiling bath: the best options

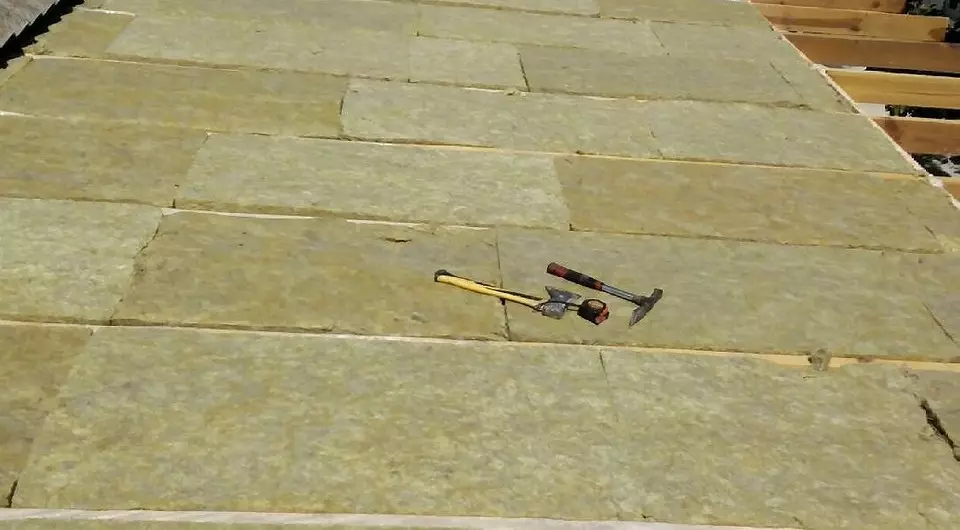

For thermal insulation, you can use different materials. Consider the most sought-after decisions.Mineral wool

General name for group of insulation with similar properties. For thermal insulation ceiling overlap can be used:

- Glass gamble, which is made of glass fibers.

- Slotovat, produced from slags of blast furnaces.

- Stone cotton wool is made of melt rocks.

Mineral wool

Their general advantages include low thermal conductivity, good resistance to temperature differences and fire resistance. The average service life of materials is 40-50 years, which is due to high resistance to rotting and reproduction of pathogenic microflora. The main disadvantages are considered to be the loss of insulating properties, even with insignificant wetting and fragility of fibers, which leads to severe dust.

Comparative characteristics of mineral wats are presented in the table

| Variety | Coefficient of thermal conductivity | Fiber Length, mm | The possibility of burning |

|---|---|---|---|

| Glasswater | 0.042. | 15-50 | Absent |

| Shagkovat | 0.04. | sixteen | Sintered at high temperatures |

| Stone Vata. | 0,046. | sixteen | Absent |

Wadth insulation are produced in the form of plates and rolls. The first are more comfortable in laying. Some manufacturers produce foil coatings, which is very convenient because the metallized layer reflects the thermal rays and delays evaporation.

Ceramzit of various fractions

Environmentally friendly insulation, produced in the form of clay granules of various sizes. The advantages of the material are considered:

- Low thermal conductivity;

- fire resistance;

- immunity to high humidity;

- Resistance to mold and fungi damage.

Granules of Ceramzita

Of flaws Keramzita It should be noted the need for backfilling a sufficiently high layer of insulation, which can lead to an increase in overlap weight. In addition, the upper layer of granules is able to absorb water, especially if technology has been violated during the production process. Wet material loses its isolation characteristics and dries very long. Therefore, the presence of hydro and vaporizolation is necessary.

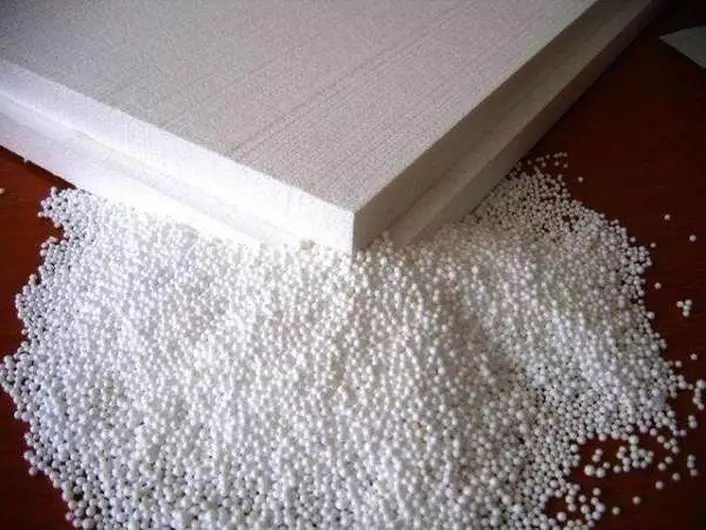

Polyfoam and expanded polystyrene

Produced in the form of plates of various thickness. Polyfoam is a gas-filled material with low thermal conductivity. Polystyrene foam is its more dense variety. The advantages of insulators include:

- high thermal insulation characteristics;

- low weight;

- low water absorption, especially in polystyrene foam;

- resistance to reproduction of mold and fungus;

- Budget value.

Insulation foam

The main disadvantage of the material is the destruction under the influence of elevated temperatures. The insulator is quickly flammed and burns, highlighting extremely toxic substances. It is worth thinking about it, choosing this insulation for a bath.

Ekwata.

Fully eco-friendly cellulose-based insulation, impregnated with sodium tetrabrate and boric acid. The advantages of using the material are considered:

- low heat thermal conductivity;

- resistance to temperature differences;

- low weight;

- long service life;

- Almost complete resistance to insect damage, microorganisms, fungi.

Of the disadvantages it is worth noting the complexity of the installation. If it is produced by the so-called "wet" way, and this happens most often, the use of special equipment is required.

Equata from cellulose

This is not all covers that are used for insulation. Sometimes eco-friendly materials are chosen as an insulator, dozens of years with success used by domestic masters. it Clay with sawdust Or with leaves. The composition of the mixture may vary. In various proportions, chips, cement, peat, chernozem, straw, etc. are added.

How to insulate the bath ceiling do it yourself

Insulation of the ceiling of the floor type

The floor ceiling is used in rooms of a small area. Its main difference is the lack of support beams. The ceiling boards are stacked directly on the top of the wall. This greatly simplifies and heshes the installation, but also gives some limitations. The design is not designed for a large mass, so the insulation layer should be easy.

Warming of floor ceiling

The laying of thermal insulation is carried out in this way:

- We are placed and fix the ceiling planks. If it is assumed that the insulation layer will be high and need free space, boards are secure below the upper edge of the walls. Either over the ceiling, you nail small sides around the perimeter.

- We carry out vaporizolation. We lay the selected material on the boards on the side of the attic . If the coating is fooled, the metallized side must be laid down. The strips put with the allen at least 10 cm. The seams and joints necessarily fix the scotch.

- Mount the heat insulation. The laying method depends on the type of insulation. Plates are placed one near another jack, the rolled material is rapped by strips. The laying is made tight, the distance between the particle fragments should not be.

- We put waterproofing. Film, membrane or reference material type rolled by strips. We put the panels with an overlay in 10 or 15 cm and be sure to cross all the resulting joints and seams.

Warming of floor ceiling

Ready heat insulation is covered with boards or plywood sheets.

Insulation of a stitched ceiling

The design of this type is more durable and reliable. It assumes the presence of support beams that are stacked on the walls. The ceiling is laid down to these beams, from where it appears. From above - the floor of the attic room is attached if it is planned. Thanks to such a design Insulation for a bath on the ceiling Maybe anyone. True, its laying technology can be somewhat different.

Insulation of a stitched ceiling

We will analyze it on an example with a mineral wool.

- On the side of the roofing side of the roof lay waterproofing. Fresh film to wood stapler. The bands are putting the mustache, overlapping one different one by 10 or 15 cm. The joints gently sample scotch.

- We put on top of insulation sheets of plywood or boards. The resulting flooring can be used as an attic floor.

- From the side of the room we laid the insulation, placing it between the beams. The number of layers varies, but in any case, one will not be enough. We put the insulator so that the joints of the first layer overlap the strips of the material in the second.

- Mount the vapor barrier. Film strips or membrane Crow so that they come to the walls. We deploy the coating of the "breathable" side down and fix it to the beams. We do it very carefully so that there are no breaks.

- On top of the finished heat insulation perpendicularly to the beams by mounting the rails to which we lay the ceiling.

Laying insulation

If it is required to lay a bulk insulation, for example, clay, eco-water, etc., other technology is used. In this case, first to beams are fed by the draft ceiling. Its cracks are sealed, stealing steamplasia. The insulation is then falling asleep, waterproofing is mounted. The decorative ceiling coating is mounted on top of the draft ceiling.

Warming panel ceiling

To perform quality Warming ceiling in a bath with a cold roof You can use panels. These are peculiar modules within which the insulation is located. Of these, the ceiling is emerging. This is more laborious than everyone else, the way.

Insulation ceiling bath

Works starting with the manufacture of modules - panels:

- From the boards, you knock off the shield whose size should correspond to the future module. From the inside you feed the homes that will perform in the role of sides.

- In the resulting box we put vaporizolation. We lay it out on the sides and the bottom of the strips with the allen. Shakes are sizing. Film the film by the stapler.

- We are placing thermal insulation. You can take any, but better to choose a heater with minimal weight. Panels with a clayjit or a mixture of sawdust with cement will be heavy, which will make their installation significantly.

- Top plays waterproofing. Stripes are put on a mustache, the joints are sampled. Next lay down the boards. They will become an attic floor.

Heat ceiling

The panel prepared in this way remains upstairs and put in place. The sealer is necessarily stacked between them. It may be jute, trimming minvats or a mixture of sawdust and cement. It is advisable for the whole boards under the panel, which will become a ceiling indoor. Similarly, they come from the attic, flooring floor boards on top of the panels.

How to insulate the ceiling in the bath: folk method

This method is widely used by masters and gives a good result. To begin with the ceiling. It should be durable to withstand a fairly heavy weight of the insulation. Practice shows that the best option in this case is a board-sorton, laid across the room. If the size of the room requires, to enhance the design from the inside, the boards are perpendicular to the board.

Sawdust for insulation

Further work is carried out as follows:

- We lay waterproofing from the roof. If required, put the film with an adhesive of 10 or 15 cm, we sink joints. At the edges, we leave a scope so that the insulation came on the walls by 20 cm.

- I fall asleep sawdust with a layer of 15 cm. Do not forget well tamper. In recommendations the better to insulate the ceiling in the bath from above They often indicate chips, but it is difficult to compact, so their layer should be higher.

- We are placed in a layer of clay that protects the sawdust from fire and increase the life of the heat insulator. There will be enough layer with a height of 10 cm.

The clay pillow is covered with boards or sheets of plywood.

Another option of such insulation is presented in the video.

In the bath with a cold roof, the ceiling insulation is necessary. It will give the opportunity to significantly reduce the cost of heating and will prolong the service life of the construction. It is only important to choose the correct insulation and competently carry out all the work.