Along with the usual and gluing bar, the modernized versions of wooden walls with higher heat transfer resistance are increasingly used in the construction of individual houses. In the article, we will tell about such technologies, consider their pros and cons.

Photo: shutterstock / fotodom.ru

Modern wooden house perfectly fit into the natural landscape, decorate the street of the cottage suburbs or a small antique Russian city. It symbolizes the "ecological trend" and traditional measured lifestyle. It is not surprising that the demand for such houses is constantly growing.

Here are just the walls of the massive timber or the "reasonable" thickness of the thickness in the middle band of Russia do not significantly reach the requirements of modern regulatory standards. According to the joint venture 50.13330.2012, the walls of residential buildings on the latitudes of Moscow must have a heat transfer resistance (R) of about 3.2 m² • ° C / W. But R brusade wall with a thickness of 150 mm (log - 220 mm) is only 1.0-1.1 m² • ° C / W. The cost of heating an ordinary wooden house is too large. The desire to reduce them led to the emergence of a multilayer bar and combined wall structures.

Wide eaves protect wooden walls from moisture. Photo: Naturi.

Thermobrus.

This material offered by Malener House, Herobloshrus, Woodlock, etc., is approximately as much as the glue bar from the pine massif - 18-20 thousand rubles. For 1 m3. As a rule, it has a three-layer design: the external lamellas (plates) with a thickness of 35-45 mm are made of a staircase dried in the chamber, and a "middle" - from a polymer cellular insulation with a density of 45-60 kg / m3 (extruded polystyrene foam, polyurethane foam, polysocyanurate) .

The ends of the thermobrus are sometimes painted, but it is more correct to first remove the insulation from the releases and glue the wooden dies into its place. Photo: "Angarsk House"

Depending on the type of insulation, production technologies are distinguished and the production technologies: billets from solid (for example, polystyrene) foams glue with boards under the press, and the polyurethane foam is used in liquid form, filling the space between the slats, which are pre-fastened with wooden jumpers. In the first case, there are no bridges of the cold, but in the second the stronger of the bar and its storage resistance is ensured. Some firms (for example, the Angarsk House) make a five- and six-layer timber, alternating boards and EPPS, which increases the strength (carrying ability) of the walls and facilitates the installation of doors and windows.

The tightness of the interventional compound of the thermobrus is achieved by milling the longitudinal lock, the profile of which captures and insulation, and wooden plates. Sometimes seams are additionally compressed by polyethylene or fibrous ribbons. Photo: "Thermobrus"

The crowns are solidified with studs or copper. Photo: Holz House

And the angular compounds and the rearness are performed by ringing in Poledev. Photo: Vladimir Grigoriev / Burda Media

With a thickness of 150 mm, the walls of the thermobrus have heat transfer resistance (R) from 2.9 to 3.2 m2 • ° C / W. The bar choose longitudinal grooves and ridges, thanks to which the interventional connection is well protected from purge. Theoretically, it can be not sealing it, but usually builders when assembling a house are paved between the crowns of polyethylene, flange and polyester ribbon. When using polyethylene, it is important that the tape is inserted only in the layer of the insulation and did not enter the junction between the plates, contributing to the accumulation of moisture in the tree. Vertical stability of low (up to 3 m) walls from the thermobrus (as from other types of insulated timber) is achieved mainly due to angular and longitudinal thickening compounds.

Polyurethane tape. Photo: Vladimir Grigoriev / Burda Media

The number of coppieres or tightening studs, which you have to drill holes in wooden plains and / or jumpers, try to minimize, often having vertical fastening only in the corners, near the openings and in narrow simplests. Considering the accuracy of the geometry and the low probability of barrage, it is permissible. With the construction of the walls of the two-storey house, the screed should be placed with a standard pitch of 1.5-2 m.

The thermobrus is easier and much warmer than traditional lumber, but maintain a comfortable level of humidity in the house built of it is more difficult. The fact is that the high density heaters used have a closure structure and poorly misses couples. Sometimes the normal air exchange can only be provided with the help of forced ventilation, but two-three natural hoods and ventilation through windows usually grabs.

Window and doorways need casing, which are mounted before filling the walls insulation. Photo: Yeti Architects

As for the durability of the thermobrus, there are no full data on this account, it can only be noted that the stated service life of the insulation used without changing properties is more than 50 years.

As a rule, the bar is insulated with foam plants. Photo: "Angarsk House"

Less often - cork agglomerate and other materials. Photo: "Promstroyles"

Sometimes empties are left blank and blend cellulose cotton wool in them. Photo: Logeco.

Batch Bar Logeco.

The material is a hollow variety of thermobrus: the cavities between the boards are filled with vapor-permeable fibrous insulation (mineral or pulp wool) in the construction process. In this case, the inner space of the bar is separated by the longitudinal partitions, and the transverse wooden bonds between them are located in a checker order, which avoids the appearance of cold bridges. Wooden elements of timber not only glued, but for greater strength are connected by transverse brackets. During the construction between the crowns, a traditional flask and fibrous synthetic seal is paved.

Details of the household complex, as a rule, do not need fit and firmly adjacent to each other, but as a result of uneven shrinkage, the gaps may increase. Photo: Yeti Architects

Double "mini-timber"

The essence of this technology is that between the two relatively thin (usually thickness of 45 mm) of the walls of a dry tipped board built on the principle of the cut (with a compound in the corners of the word inwards), placed a layer of thermal insulation, as a rule - a stadst cellulose wool.

Collect the walls of a double "mini-bar" more difficult than an ordinary timber or a rounded log, as you need to produce more operations. Photo: Homgart.

According to the cost of a wall of a double "mini-bar" with a thickness of 200 mm (R ≈ 3.8 m2 • ° C / W) are close to the walls of a solid glue bar with a thickness of 150 mm. The box of the house needs only painting and theoretically must give a minimum shrinkage - no more than 3% of the height. But due to the difference in the surrounding conditions, indoor and street wooden walls are seated unevenly. Moreover, at the end of the main shrinkage in the cold season with a functioning heating, the inner layer dries, while the outdoor swells from rains and fogs. At the same time, the difference in humidity of the material can reach 40%, and in the amount of 7%. Since in the corners internal and outer boards are rigidly connected to each other, the first "hang" on the second, as a result of which the slots are formed on the inner surfaces, and during the length of the walls more than 6 m and the height of more than 3 m, local dockens of the house of the house are possible.

Facade of the building helps shaped eaves and borders. Photo: Naturi.

The problem solves the sliding angular connection "Lastochka's tail", which allows the walls to "live" independently of each other, but increases the cost of the house box at least 15%. Another way to increase the strength of the walls and prevent the insulation of the insulation - the replacement of the board with a thickness of 45 × 100/120 mm for a ram 70 × 140/180 mm with a double and higher tongue. Such walls are reliable and look more product, but it will cost 60-80% more expensive.

When erecting a house from a double "mini-bar", inter-wallet seams are desirable to seal a tape from polyurethane foam; You can also use a ram with a high double tongue. The "mini-timber" needs only in painting, but the coating should be renewed once every 5-7 years, otherwise the walls will begin to breed and rot. Photo: 101 DOM

Single "mini-timber"

This simple and reliable construction is essentially one of the options for facade insulation. The basis of the wall is a frame of a dry armor with a cross section of 50/70 × 120/140/180 mm. It is covered with vapor insulation outside it, and then mounted a moving gear of 50 × 100 or 50 × 150 mm bars depending on the required thickness of the insulation (mineral wool slabs). The insulation is closed with hydraulic protection, and then the house is squeezed by imitation of the bar (you can use other options for the facade board, as well as composite and vinyl siding). Corners decorated with wooden linings that protect the insulation from moisture and give the house a finished look.

To avoid the risk of uneven shrinkage, the walls from the "mini-bar" it is desirable to build no higher than 3 m; Preferred projects with attic or semi-gang floor. Photo: Yeti Architects

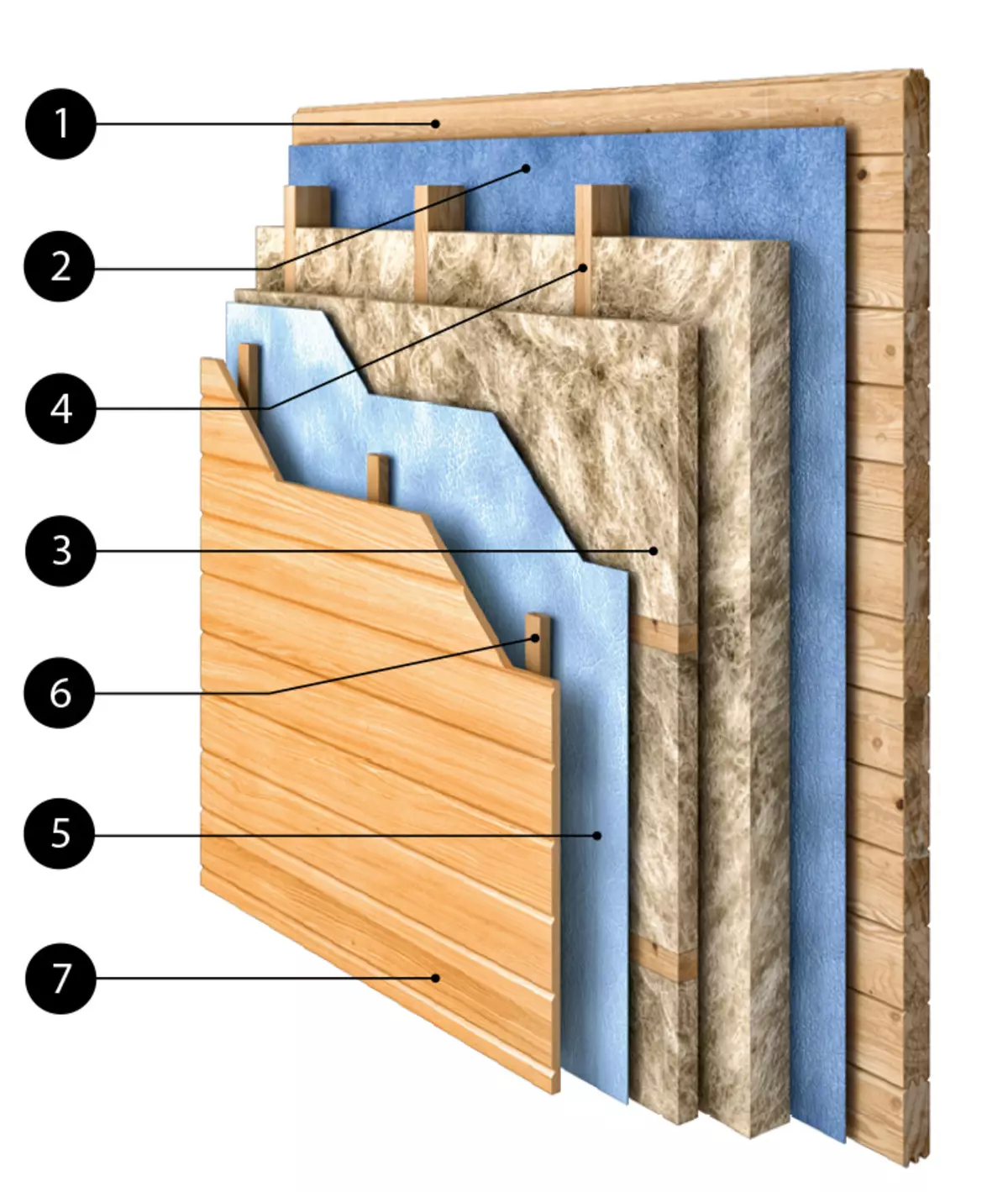

Device fence based on a single "mini-bar"

1 - timber; 2 - vaporizolation; 3 - insulation; 4 - frame; 5 - windband; 6 - doom; 7 - imitation of timber. Photo: Homgart.

In the design of walls from the "mini-bar", vapor insulation and windproof materials are not used. The wall gives moisture outdoor air, and a comfortable microclimate is preserved in the premises

Weak spots

Problem sections of walls from any insulated timber - these are loosen and corners. In the corners you need to close the insulation and decorate the ends of thin boards. When ordering a household complex, the necessary parts should go into the bar, additionally put the proton plugs or sliding nicks. Sometimes masking structures have to make it yourself. It is more difficult to arrange the proof. Some builders ignore the shrinkage of the walls and hardly fix the draft boxes, without leaving them compensation gaps above them. This is a rough mistake, especially since it is easy to make and install a traditional cluster. To do this, it is necessary to remove part of the insulation along the ends of the walls and insert the sliding rails into its place, and to nourish them the black box boards. Above the upper jumper of the latter, it is necessary to leave the insulated fibrous material the clearance of about 4% of the height of the day.

During the construction of a warmed bar, the speed of work and the proper storage of the household complex is very important. The worsen boards begins to lead, the crowns are poorly paid, it is possible to break the parts on the adhesive seam or insulation

Thanks to the lock and puzzle compounds, the wall of the vertical timber has high strength and is not blown away. Photo: Naturi.

Warming postfactum

If the house from the bar is already built, but it turned out to be too cold, he had to warm it. From the point of view of comfortability of the dwelling, it is preferable to external insulation, which is easier to maintain a constant temperature in the rooms (due to the thermal inertia of the bar). The most common insulation design is described in the section on a single "mini-bar". Use for outer insulation materials with a closed cellular structure (for example, an EPPS or PPU plates) is undesirable, as this may lead to the overcoat of the brusade wall by condensate from the room. If the house is covered with brick or it must be adapted for short-term winter visits, the walls are insulated from the inside. In this case, it is important to protect the insulation and the wood layer of vaporizolation.

Wooden walls, including dry lumber, still give a shrinkage that you need to consider when building roofs, frame partitions, installation of backups and framents of openings

Photo: 101 DOM

Unusual orientation

In the story about the new designs of the bar walls, it is impossible not to mention the construction technology from the vertical bar (Austrian brand Naturi).

Actually, the elements from which such a house is erected is difficult to call the bar, rather, these are profiles of complex section, made by milling from solid dry timber. Profiles are installed vertically and fixed due to the guide pins and curly locking. Meblent gaskets as well as insulating films and membranes when assembling the house box are not used. It does not need it in the trim: the outer elements have a smooth surface and are associated with the wall and the same castle compound. The wall of the vertical timber does not give a shrinkage, can withstand heavy loads from overlaps and roofs and allows an extra moisture to leave the room. Due to the presence of closed air chambers, it is somewhat surpassed by the heat insulating capacity of the construction of the glue bar (according to the manufacturer's application, the fencing with a thickness of 200 mm has a heat transfer resistance of 2.05 m2 • ° C / W).

To avoid the need to adjust the pillars supporting the balcony, the latter is best built on consoles. Photo: "Angarsk House"

This technology is associated with high energy and timber costs (up to 50% of wood volume goes into chips and sawdust) and refers to the category of elite: the conditional cubic meter of the vertical bar costs 35-40 thousand rubles. (For 1 m2 walls will have to pay at least 7 thousand rubles.).