To connect the items to one piece, sometimes it is not necessary to invent a bike - it is enough to apply epoxy glue. Let's talk about his types, properties and competent use.

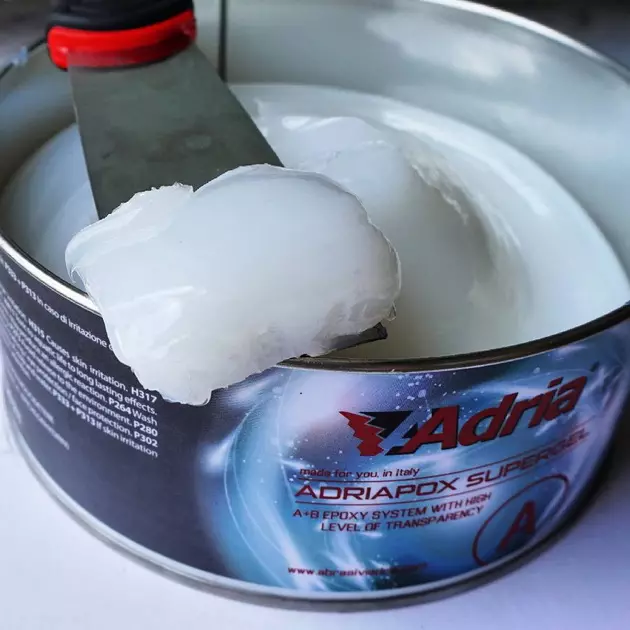

Photo: Instagram abrind

Composition of epoxy glue

Epoxy is considered universal. It further connects surfaces from various materials. The main element of the adhesive mass is epoxy resin. It can penetrately penetrately inside the glued surfaces, which ensures a solid and durable connection. Glue is a composition of epoxy resin and auxiliary components. Their characteristics are presented in the table.| Share matter from the mass of dry resin | Substance | Properties | |

|---|---|---|---|

| Hardeners | up to 15% | Polyamines, aminoamides, hardeners-modifiers from polymers, etc. | Change the condition of the substance from the gel into solid, determine the strength of the connection |

| Solvents | 3-5% | Kcelol, various alcohols or acetone | Increase glue solidification rate |

| Fillers | from 50 to 300% | Powder (metal oxide, aluminum, silica), special fabrics, glass or carbon fibers | Determine the characteristics of the material, can operate hardeners and / or stabilizers |

| Plasticizers | up to 30% | Phosphoric or phttalic acid esters | Determine the physical and mechanical characteristics of the mixture |

The range of epoxy adhesives is very wide, they have described ingredients in different proportions and combinations.

Properties and scope of epoxy adhesives

The frozen glue forms a non-shock, resistant to oils, alkalis and solvents. Epoxy is characterized by high adhesion to various bases, it easily transfers sharp temperature differences in the range from -20 to +250 s is not an electrical conductor. Seam is elastic, it can be grinding, painting, varnishing and drilled. It is possible to add additional components to the main recipe, which gives the composition of new properties.

Thanks to these properties, the material is widely in demand in many industries:

- Mechanical engineering. Production of abrasive tools, technical equipment, etc.

- Aircraft and cosmonautics. Solar-powered production, installation of heat protection, internal and external, assembly of aircraft.

- Building. Assembling bridge structures from reinforced concrete, three-layer building panels and much more.

- Short and automotive industry. Assembly of fiberglass enclosures, fixing parts from heterogeneous materials, installation of high-loaded nodes, etc.

Photo: Instagram Madewithdots

Pros and cons of epoxy glue

Adhesive mixtures based on epoxy resins are diverse, but they all have common advantages:

- Resistance to the effects of aggressive chemicals, among which oils, gasoline, non-concentrated acids and alkali. Detergents and other household chemicals do not destroy the seam.

- Heat resistance. Turn the temperature rise to +250 C.

- Elasticity. Small displacements of glued fragments, drilling and grinding of the seam are possible.

- Full waterproof.

- Good adhesion with various materials, including plastics, wood, cement, plasterboard, etc.

- Sustainability of the shrinkage and the formation of cracks.

Epoxy and some disadvantages that need to be taken into account before applying them. The mixture cannot be selected for working with nickel, polyethylene, zinc, silicone, chrome and teflon. It is forbidden to glue such compositions objects that come into contact with products. Another minus is a high hardened speed, so it should work very quickly and accurately. Otherwise, it will be impossible to correct possible flaws.

Photo: Instagram Aviora_Sekunda_Aktobe

Two-component and single-component glue

The adhesive composition is produced in two forms, each of them is a full-fledged material.One-component composition

Ready to use the mixture is produced in the packaging of a small volume. Due to the fact that a hardener has already been introduced into the mass, the adhesive begins to stick immediately after opening the packaging. For this reason, the material is not used to work with large volumes, but it is well suited for small repair, seamless sealing, etc.

Photo: Instagram Mechtairealnost

Two-component mixture

There are two containers in the package. One with a composite composition, the other with the hardener. Before working, they need to be connected, strictly observing the proportion that the manufacturer indicates the instructions. The advantage of two-component material is that it can be mixed as needed to obtain a composition for large amounts of work.

Photo: instagram hmstudio_com_ua

Epoxy-based glue

The range of material is very wide, so the compositions are classified by such signs:Consistency

The adhesive mixtures are made in the form of liquid or plastic mass resembling clay. In the first version, it is a gel that is very convenient to apply on glued fragments. The plastic mass is quite dense, fushed into hermetic tubes. Before work, it is removed, lightly wetted with water and thoroughly knead hands. After that, it can be applied to the base.

Photo: Instagram Autoshop_camaro_kemerovo

Method of curing

Based on the type of hardeners, the compositions are divided into three groups that differ from the recommended solidification temperature.

- Without heating. The solution becomes solid at a temperature of order of +20 C. On the structuring of the composition takes a fairly long time, more than 72 hours, heat treatment is recommended to accelerate this process.

- Modified compositions with solidification temperature from +60 to +120 C. differ in increased resistance to organic-type solvents and shock viscosity.

- Heavy-duty hot curing mixtures. For solidification, the temperature is required from +140 to +300 C. heat-resistant, have high electrical insulating characteristics.

Photo: Instagram avtomobilni_magazin

Glue consumption and curing time

The adhesive consumption depends on the thickness of the layer, which it is applied and on the base material. So, porous surfaces, such as concrete or wood, significantly increase material consumption. On average, one square meter takes about 1100 g of glue, provided that the layer thickness is not higher than 1 mm.

The curing rate depends on the composition of the composition and ambient temperature. It is not recommended to work with the material in the cold. The optimal temperature is from +10 to +30 C. To speed up the process of solidification of seam glue, you can warm up. On average, the curing of liquid adhesives of EDP leaves about two hours and about a day per full polymerization. Cold welding is hardening much faster - in just 10-20 minutes.

Photo: Instagram Nail_anzhelika78

Universal or specialized glue

The scope of adhesives based on epoxy is very wide. They are used in the production of ships, airplanes, cars and construction. Frames in everyday life are in demand. With their help repair furniture, equipment, decor items, outdoor and wall coverings and more. Epoxy seal various engineering communications, it is used for the manufacture of souvenirs, jewelry, crafts and many others.Universal formulations or specialized materials are chosen for use in everyday life. Such varieties of epoxy glue are most in demand.

"Moment" from Henkel

Two epoxy layers are produced. One-component "epoxylin" and "super epoxy" consisting of two components. For convenience of mixing the latter is produced packaged in two syringe. These are universal compositions forming a durable seam, which, after curing, can be grinding, painted and even drill.

Photo: Instagram Kantstovary_perm

Cold welding

Specialized mixtures for repair of objects from various metals. Possess increased strength, high curing speed. More often produced as a plastic mass, but I can be in liquid form. Products are represented by different brands under the names "Pokilipol", "Epoxy-titan", "Epoxy-Metal".Adhesive EDP

It is so abbreviated called epoxy-diane material with polyethylene polyamine. Refers to universal adhesives, works with various bases: tree, leather, concrete, stone, ceramics, rubber, etc. Acquires stated strength within 24 hours after applying. Released with different companies under the brands of EPD, Khimkontakt-epoxy, Epoox Universal.

Epoxy glue can be prepared independently at home. How to do it, shown in the video material.

Instructions for using epoxy glue

For high-quality gluing parts, it is necessary to accurately comply with the manufacturer's recommendations. In general terms, such an instruction looks like this.- Preparation of the foundation. It is impeded by sandpaper, cleared of contamination and dust, degreases. Solvents are used at home for degreasing.

- Preparation of adhesive composition. One-component mixtures do not need to be prepared. Two-component mixed. The first epoxy is extruded in the container, then the hardener. The proportions must be accurately observed. Then the ingredients are thoroughly mixed.

- Bonding details. The composition is neatly applied to one of the surfaces connected. The second is superimposed on the right place and grudges tightly. In this position, the details are fixed for 7-10 minutes, after which it remains to wait a few hours so that the adhesive composition has gained the necessary strength.

Useful tips on storing and removing glue

The manufacturer recommends storing the composition in a dry place in a vertical position. The integrity of the package should not be broken, otherwise the air will fall inside, which will worsen the quality of the adhesive. Store the composition only at room temperature. Packed epoxy is stored from a year to three years, but its properties deteriorate over time.

Working with glue involves the use of protective funds, since it is very difficult to wash it. While the composition is still liquid, you can wash off with soapy water or acetone if the glue is already beginning to polymerize. The frozen epoxide is very difficult to delete, you can try such methods:

- Heating with iron or hairdryer. Under the influence of high temperatures, glue softened and easier to remove it.

- Freezing by refrigerant. After such treatment, the composition is made fragile and digs from the surface.

- Application of solvents. The glue is wetted by aniline, toluene, ethyl alcohol, etc. After some time, score stain.

Photo: Instagram KAMINDUSTRY.RU

Precautions

The composition of the adhesive mixture includes substances with a sharp smell, some of them are toxic. For this reason, it is necessary to carry out all work with epoxy only in a well-ventilated room. It is advisable to protect the respiratory organs mask. People prone to allergic reactions, it is recommended to wear gloves to prevent the substance from entering the skin.

If the solution still got on it, it is necessary to wash it off as quickly as possible with soapy water. If only pure water is used when entering mucous. If irritation appeared, you should urgently visit the doctor. For mixing glue, it is forbidden to use the dishes in which food will be stored or prepared.