The choice of the foundation type for a low-rise building depends on many factors associated with the structure of the soil on the site and the architecture of the building. Universal design does not exist, but closer to it is a monolithic unlucky plate, which is suitable for almost any soil. We tell how to establish such a foundation correctly.

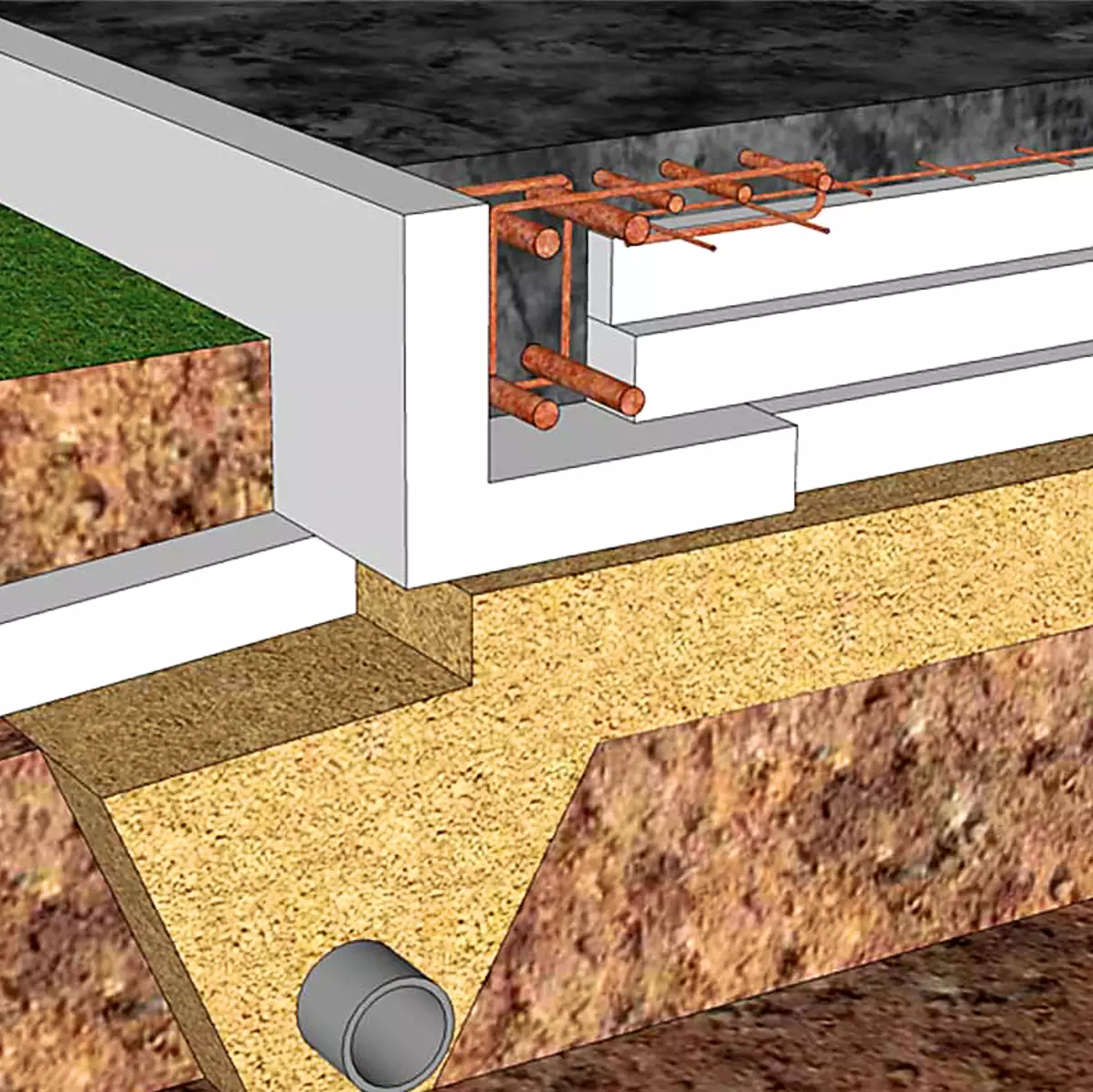

Photo: shutterstock / fotodom.ru

The slab foundation provides a uniform distribution of the load from the building to the ground throughout the area of construction, that is, it is potentially stable than the tape and pile foundation. Such a base is optimal on weakly infant and movable soils, including the most problematic - dust and or etched sands, disices and peatlands. On the stove you can build as heavy houses with block-brick walls, and light framework facilities. But to avoid unnecessary costs, the foundation needs to be adapted to specific geasels and construction tasks.

Photo: Stonehut.

Types of slab foundation

There are several main varieties of slaughter foundation, each of which has its own specifics of application, its pros and cons.Simple floating slab foundation

It is a smooth and smooth monolithic reinforced concrete plate, sprinkled in a formwork on top of a pillow of sandbrevia with a thickness of 30-40 cm (the latter falling asleep into the place of the removed fertile layer). Such a design is simple and reliable, but has a serious disadvantage - a very large consumption of concrete. The fact is that the loads acting on the foundation are unevenly distributed: and frosty powder forces, and the pressure of the building walls are focused mainly at the edge of the plate. To prevent the deformation and cracking of monolith, it has to increase its thickness throughout the area; During the construction of a two-three-storey brick building, the required foundation thickness can reach 400-500 mm. Another minus is the possibility of small seasonal plates of plates that threaten damage to underground communications.

The platform for the construction of the slab foundation is aligned by level. Then pour a layer of sand with a thickness of 10-20 cm. Photo: Stonehut (3)

And rubble - not less than 20 cm

To eliminate small irregularities, you can put on top of one more layer of sand, undermining geotextiles under it, and start assembling insulation

Ordrous floating foundation

Such a stove with a small (up to 200 mm) of the total thickness has high strength, as it is amplified with ribbies, which can be located both from below, and from above and have a different configuration. If the construction is small, enough protrusions under the external and inner walls, but additional rigidity jumpers are often required, and sometimes it is advisable to place the ribs in the form of rectangular "cells" on the entire area of the plate (such a method simplifies the mounting of the beam overlap). Operation from above performs the function of the base and protects the walls from wetting, but requires more time; In addition, the design is less rigid, since the connection of the plates and the roother is provided in the main embodiment of the reinforcement.

Speed up construction work and save on formwork will allow special blocks of L-A-shaped section, glued from the sheets of extruded polystyrene foam. Photo: L-Block

Warm Swedish Plate.

Its main feature is that concrete is poured over a layer of moisture-proof insulation - sheets of extruded polystyrene foam with compressive strength of 0.25 or 0.5 MPa (depending on the calculated load). Due to this, the ground under the foundation does not freeze and frosty powered forces do not act on the design. The Swedish cooker has lower fins (in the insulation layer it is easy to form grooves for ribbon ribs), serves as a draft floor and, as a rule, is equipped with a water heating system used for heating the entire building. And since concrete monolith has significant thermal inertia, then in the house it is easier to maintain a constant temperature - both in winter and in the summer.

From these blocks lay the "border" around the perimeter of the future plate. Photo: L-Block

Warm plate (UCH)

| Benefits | disadvantages |

|---|---|

| Prevents frosty grounding of soil and thus much reduces the risk of cracking in the walls of cellular concrete. | In areas with uneven relief requires large-scale earthworks (the pile foundation is more profitable). |

| Provides a large area of support for the soil, which means the minimum and uniform, without distortion, the sediment of the building. | It does not allow to arrange a basement or cellar in the house. |

| With characteristic of most of the territory of the Russian Federation, the depth of freezing (1.4-1.6 m) allows to reduce the consumption of concrete by 30-50% compared with a blunt tape. | Poor suitable for seasonal home. In this case, it is more economical by a non-fledging (slab or tape) foundation. |

| Does not require the use of expensive finished metal and railway structures and powerful earthy, drill and scoring techniques. | The fill of concrete should be carried out in a short time, which means it is not to do without an expensive factory concrete. Delivery delay by more than 12 hours will sharply reduce the strength of the plate. |

| It is equipped with a warm floor, which is recognized as the most comfortable heating system. |

When the base of the base of the joints of the plates of EPPS places the rotary and sealed (as a rule - polyurethane glue). For lower fins, there are depth 20 cc. 20 cm. On the rest of the area, the plate should have a thickness of at least 10 cm. Photo: Tehtonolikol

Today, the Swedish stove is considered one of the optimal foundations for a low-rise building. It is widely used in the construction of buildings from cellular blocks, as well as "skewers" - especially on problem soils, where the behavior of the floating ribbon is difficult. Perhaps the only minus of the Swedish plate is a relatively low base. With spring melting, the walls may suffer from moisture. Partly overcome this drawback will help the thick, raised sandbreaker pillow.

Frames Röber rigs are performed separately and lowered in the groove, and a single-level grille for the entire plate knit "at the place". Photo: Tehtonol

To make the fittings in the thickness of concrete, sometimes plastic stands are used. Photo: "IPS"

The frame knit steel wire (while it is convenient to use a special gun). Photo: Tjep.

Or weld. Photo: Vladimir Grigoriev / Burda Media

The thickness of the heat-insulating layer in the construction of the UCP should be from 200 to 400 mm. We recommend using for insulation of the foundation plate extrusion polystyrene foam Carbon ECO Sp, which has low thermal conductivity and water absorption, high strength and biostability; It fully retains its properties in the ground for at least 50 years. The installation of thermal insulation is carried out in several stages: the angular elements from EPPS are first collected, then in the resulting "box" from sheets of polystyrene and stroof ribs according to the project's working documentation. After that, the additional layers of thermal insulation are placed; At the same time, the recesses for the ribbon ribbies are formed. Useful option for a slab foundation is a warmed germination that shifts the freezing zone down and away from the base. Thus, the entire design of the building receives additional protection against frosty powder. Since the ground under the foundation does not freeze, optimal conditions are also created for the functioning of the drainage system.

Valeria Lychits

Technical specialist of Technonol Company

Construction of slab foundation

The construction of a slab foundation consists of several stages, at the end of each of which the quality of work performed should be carried out. We will not describe the whole process in detail, but I will answer key questions that the participants of the IVD.ru forum are often asked.

Pipes of warm sex should be resistant to damage, as in the installation process they are subjected to mechanical effects. The optimal option is made of cross-linked polyethylene PE-XA. Photo: Stonehut (2)

How to calculate the thickness of the plate and the cross section of the reinforcement?

It should be guided by the standards (SP 50.101.2004 and SP 63.13330.2012). A simpler way implies the use of finished projects that have all major construction firms. To check the calculations and compare options, it is worthwhile to use special computer programs, such as Foundation, Gipro or WinBase.

On the "classic" swedish plate, you can immediately build the walls by putting under the first crown (or a number of masonry) two layers of rolled waterproofing. Photo: Stonehut.

Do you need drainage around and under the stove of the foundation?

On swampy and flooded areas, it is extremely desirable. In this case, the function of the drainage layer performs a beech of the rubble of a large fraction (20-70 mm). The system will be more efficient if the tubular drain is thicker (their optimal step is 1.5-2 m). Drain is also needed around the perimeter of the slab or scene. Water should be discharged into a drainage well or a downward relief; At groundwater level of less than 1 m from the surface, it is advisable to use the automatic pumping system by the pump. The presence of drainage will reduce the risk of ground freezing under the house, will extend the service life of the foundation and reduce the risk of cracking of the scene.The plate is poured under the whole house, including a porch and terrace (veranda). If you add these elements later, the likelihood of the formation of overcasts and cracks at the junction of the walls is greater.

How to pave communications?

Watering and sewer pipes, as well as an electrical cable (if its underground input) is paved when the cushion device is provided. They are protected from possible damage to the EPPS layer or turn into several layers of waterproofing material. In principle, it is possible to connect to communications and after the end of construction - through a used insulated box.

But sometimes the monolithic or masonry base is built. Photo: "Foundation 47"

Is it possible to build a slab foundation in the cold season?

This is possible, but is associated with increasing costs and risk of declining design.

Concrete with winter modifying additives by 25-40% more expensive than usual, and the construction of a heated dome, without which it is not possible to do in heavy frost, will cost 30-100 thousand rubles. In winter, earthworks are very difficult, and all other tasks are complicated by cold and lack of light-time.

The breakfast is poured over the draining pillow and reinforce the road grid. Photo: Izba de luxe

Is it possible to build a slab foundation from homemade concrete?

Only for a small building of economic purposes. If we are talking about the house, then this method is excluded, because when pouring the concrete with small portions, it is not possible to avoid numerous "cold" seams that will catastrophically reduce the stiffness of the plate and its resistance to the formation of cracks. When the finished concrete is delivered, the break between the arrivals of the car must be 3-4 hours.

There is advisable to perform a length of 1-1.5 m with fragments with a length of 1-1.5 m to avoid cracking. Photo: Izba de luxe

Is it possible to lay the floor covering directly to the surface of the Swedish plate?

Yes, as a rule, it is possible to do without a leveling screed. In the extreme case, the thin layer of the self-dependent mixture is fed. Note that it is desirable to lay coatings on a Swedish slab, well-conducting heat, such as a porrite or stone tile, a special laminate.

On open terraces over the plates, an atmospheric coating with an anti-slip surface is placed, for example, a porcelain tile or clinker tile, a terrace board of larch or a composite. Photo: shutterstock / fotodom.ru

3 myth on reinforcement

- The reinforcement should be knit, not welded, as welding adversely affects the strength of the metal. In fact, it concerns only alloyed reinforcement, which is practically not practically used in individual construction. Knitting fittings easier and cheaper than and explains the popularity of this method of installation.

- You can knit fittings anything and optionally tightly, since the connections are necessary only for the mounting positioning of the framework of the frame. Meanwhile, according to construction regulations, the rods must be pulled up to each other during the viscous and cruciform connections. Fallows (their length is 40 reinforcement diameters) should be born with steel wire in several places.

- The diameter of the reinforcement is not important if the required reinforcement coefficient is observed (the ratio of the area of the reinforcement cross section to the cross-sectional area of the concrete structure). In fact, the use of thin reinforcement (8 mm) increases the complexity of installation and complicates the quality control of the work performed.

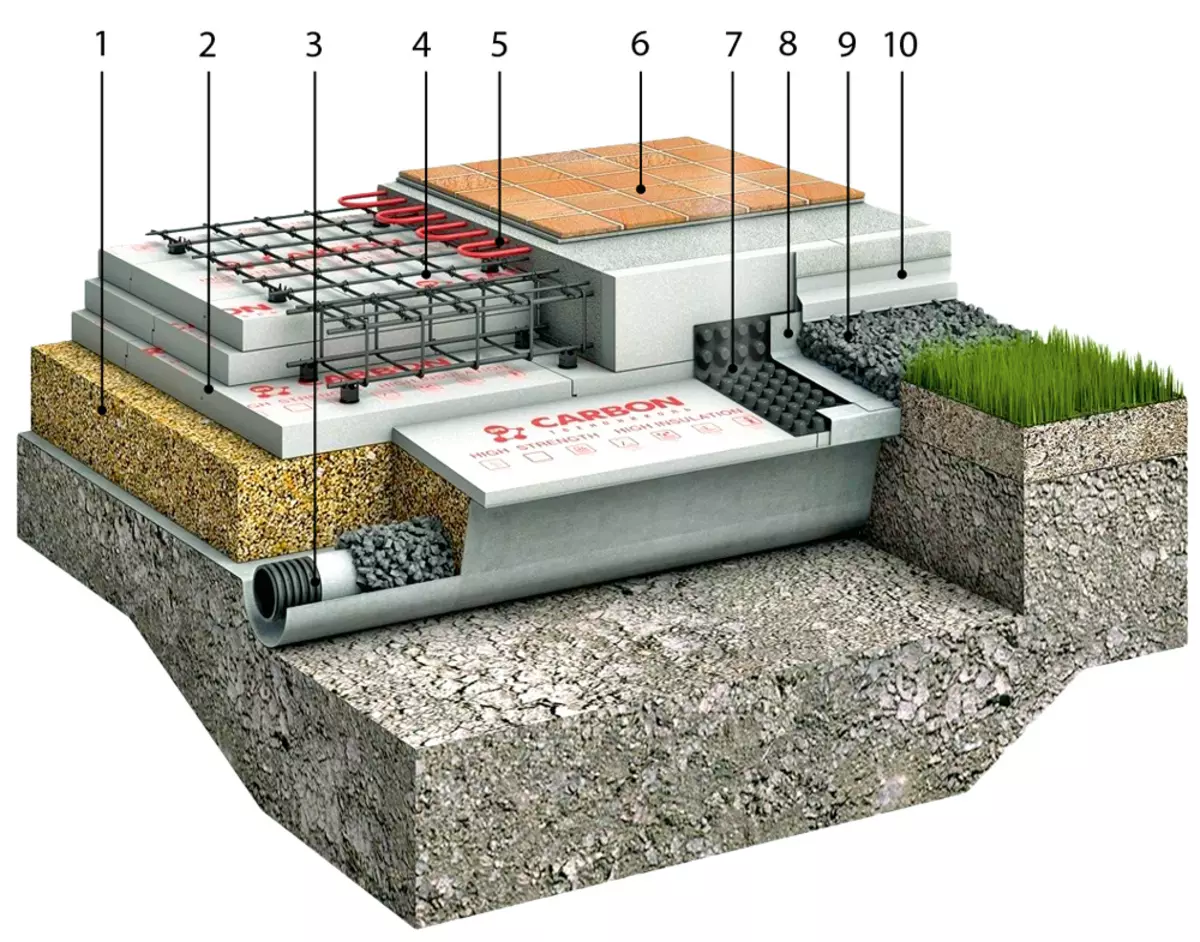

Option design of insulated slab foundation

1 - Pescograbviy-naya pillow; 2 - insulation (Epps plates); 3 - drainage pipe; 4 - reinforcement frame; 5 - pipes for a warm floor system; 6 - floor covering (tile); 7 - drainage membrane; 8 - filter layer (geotextile); 9 - gravel frustration; 10 - moisture resistant finish. Photo: Tehtonol

The floor heating system is tested in two stages. After mounting the pipeline and to the pouring of the concrete slab, the integrity of the pipes are tested by fluid pressure exceeding the working 1.5 times. The duration of the test is 3 hours. As an exception, with the impossibility of hydraulic testing (for example, due to frost), a compressed air test is allowed. When pouring concrete pipes should be filled with a cold coolant and be under pressure (working or testing). After the set of concrete, the necessary strength is the thermal test, which lasts seven days. At first, for three days, the system should circulate the coolant heated to 20-25 ° C. Then the maximum operating temperature is set, which is supported for four days. During this period, the uniformity of the warm-up of all circuits is checked with a contact thermometer.

Sergey Bulkin

Rehau expert

Enlarged calculation of the cost of construction of an insulated slab basement with an area of 80 m2

Name of works | number | Cost, rub. |

Geodesic breakdown | Set | 12,000 |

Earthwork, device pillow | 32 m3 | 16 800. |

Drainage devices | Set | 18 000 |

Wiring of water and sewer pipes | Set | 14 500. |

Installation of formwork, insulation, reinforcement frame | Set | 32 000 |

Installation of pipes for a warm floor | 380 pog. M. | 34 200. |

Concreting, vibratetonization | Set | 26 000 |

| Total | 153 500. | |

Applied materials on the section | ||

Sand | 16 m3. | 14 500. |

Crushed stone granitis | 8 m3 | 16 000 |

Edged board | 1.5 m3 | 3500. |

Pipes (PVC and Polypropylene) | Set | 22 000 |

Armature (rod 12 mm and grid 8 mm) | 1.1 T. | 32 000 |

Epps CARBON ECO SP 1180 × 580 × 100 | 235 pcs. | 79 900. |

Strip and fastening materials | 7 500. | |

Concrete M300 | 13 m3. | 44 200. |

| Total | 219 600. | |

| TOTAL | 373 100. |