In balconies, terraces, facades, floors in the fields of intensive operation from interlocking seams, elevated tightness and mechanical strength are required. Provide their additives for the grouting compositions that we will describe in more detail.

Photo: Alcalagres.

Polymer additive MAPEI FUGOLASTIC for suture aggregates of the Keracolor FF or GG (MAPEI) (UE. 1/5 L - 329/1090 rub.). Photo: Mapei.

Total compounds that fill interputer seams are needed to seal cladding, protection against moisture, dirt and extension of service life. Most often in this capacity use cement grouts. Their composition includes cement, mineral fillers, pigments and modifying chemical additives. Thanks to the latter, the grouting mixtures are able to acquire very useful additional properties.

Plasticizer -Dabling Latex for Solid Mixtures Axton (Leroy Merlin) (UE. 0.6 L - 152 rub.). Photo: Leroy Merlin

For example, porcelain stoneware, clinker or ceramic tile, laid on the street or over the "warm floor" system, are experiencing temperature differences, sometimes very significant. In the pools of pools, cladding is subjected to high mechanical and dynamic loads. In both cases, the rapid composition should have increased strength and elasticity. Therefore, manufacturers of dry mixtures advise or use products that include latex in dry form, or shove dry mixture not with water, but a special liquid latex. In the domestic market, these polymer supplements offer many companies: Axton (Leroy Merlin), DS-99 (ISOMAT), IDRostuk-M (Litokol), Fugolastic (Mapei).

Suts with less moisture absorption and porosity is easier to clean with water. Photo: Mapei.

The solution obtained from the cement mixture was a secured latex additive, has elevated elasticity and adhesion to the side surfaces of ceramic elements, which is extremely important when installing cladding for deformable bases and other problem surfaces. After hardening, the passenger aggregate acquires excellent water repellent qualities and the ability to absorb vibrations between the facing material and the base, while maintaining the integrity of the seams and prevents the penetration and development of colonies of fungi, mold and other microorganisms.

After the rest of the dry thunder mixture with a liquid latex additive, its color does not change, white divorces are not formed on the surface of the seams with a solution with a solution.

The elasticity of the Water Latex Fugaflex Eco (Kerakoll) for mineral suture aggregates, which are used on the walls of walls and floors, inside and outside (pack 1/5 kg - 942/2785 rub.). Photo: kerakoll.

Cement grout with a polymer additive has increased adhesion (clutch strength) to ceramic elements. However, this obvious dignity may cause some difficulties when cleaning tiles with a microporous or rough surface, as well as with a high absorbent ability. In these cases, it is desirable to pre-test the grout on a small segment of the facing. In addition, manufacturers of dry mixtures do not recommend applying monster compositions of dark or contrasting colors on a light ceramic tile.

Suture grouts with polymer additives are applied on cladding:

- facades, balconies, terraces;

- bases subject to deformation loads due to atmospheric effects, including sudden temperature drops, with elevated operational loads, vibrations, etc.

- pools;

- when restoring old, damaged or poor-quality filled seams between ceramic tiles;

- Heated floors;

- floors and walls on highly deformable bases (wood, plywood, gkl, etc.)

Filling of interputric seams

Making sure that the glue under the ceramic tiled drying, the seams are cleaned throughout the depth of glue, dust, dirt. Photo: shutterstock / fotodom.ru

The surface of the tile and seams is washed with clean water using a foam sponge and leave up to dry

Taking into account the special conditions of operation, a dry cement grout mixture is mixed with a polymer additive (without adding water)

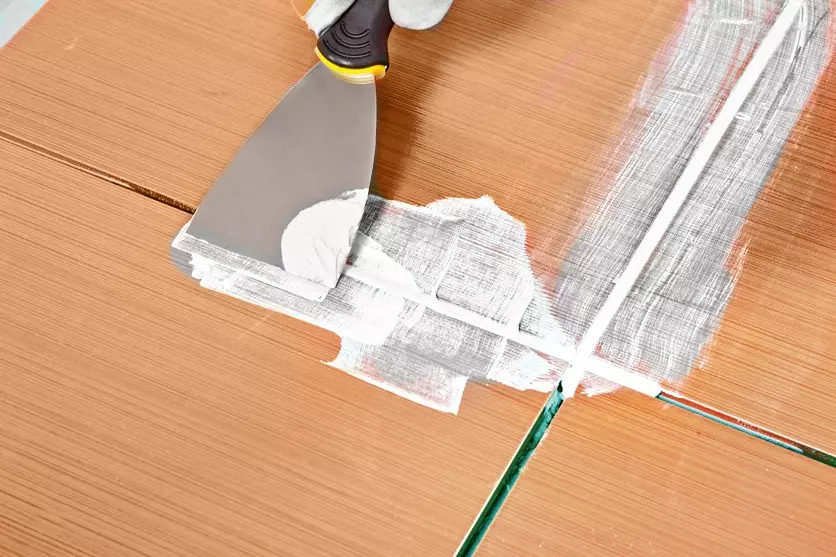

The finished composition of the metal or rubber spatula is rubbed in cladding seams

When the grout thickens, but does not cure finally (after 10-15 minutes), the treated surface is burned with a wet sponge

The raised rapid solution from the tile is removed with a soft cloth no later than 8 hours after filling the seams