We tell about the peculiarities and benefits of electric warm floors, their nuances of their installation and versions presented in the market.

Photo: shutterstock / fotodom.ru

Electric warm floors exist nearly 90 years - about as much as the heating cable, the release of which was launched in 1926 in Norway. Today, they are widely used as a primary or additional heating system in apartments and country houses.

Usually warm floors are fitted with selectively, in those areas where the installation of cabinets, beds and other furniture is not planned, so as not to spend electricity. In addition, overheating is dangerous for the electrical cable itself. Therefore, you need to have a clear plan of premises before laying the system.

The benefits of electrical warm floors a lot. It is simple and reliable equipment capable of ensuring comfortable dwelling heating due to the low-temperature heating mode. They do not have a compact and strongly preheated heat source - it emits the surface of the floor, heated to a temperature of not more than 30 ° C (usually grabs a temperature of 20-25 ° C). This method of heating is more comfortable for a number of reasons:

- There is no risk of burns, possible when using water heating radiators, convectors and similar heaters;

- There are no pronounced convection flows of air that can be perceived as drafts; reduced the content of dust in the air;

- The air temperature is higher near the floor surface; Such a temperature gradient (feet in heat) is preferable from the point of view of the physiology of the human body;

- In the hallway and bathrooms heated floor allows you to quickly dry it.

Thermal film is optimal in the case when quick installation of a warm floor is required. All manipulations can be spent literally for 2 hours: shutterstock / fotodom.ru

How is heating?

Heating elements can be divided into structures with a heating cable and heating elements of another type (film, rod), which are made of a composite material based on carbon fiber. The cable can, in turn, divide into two types: with a resistive and self-regulating cable.In resistive, heat release occurs when the electric current is passed. Such a cable is heated evenly along the entire length of the area connected to the network.

The self-regulating cable is capable of changing the intensity of heat transfer depending on the degree of heating of a particular area. It is beneficial from the point of view of savings (energy consumption is reduced by an average of 20-30%) and very convenient. If some part of the cable cooled, then the chilled area begins to heat intensively. On the contrary, the heated section of the cable reduces heat generation. Such "responsiveness" is achieved due to the very complex structure of the cable. In it, two parallel conductive conductors are separated by a thin layer of a polymer semiconductor, capable of changing the electrical resistance, depending on the change in the temperature of the polymer. Due to this, the self-regulating cable cannot overheat, if the heat transfer is hampered on some of its sites (such a situation may occur if it may leave some heat insulating thing on the floor, such as a towel in the bathroom).

Warm floor options

Currently, there are many varieties of warm floors on the market. The cost of these systems has decreased markedly over the past 10 years, today it averages 2-3 thousand rubles. per square meter. It is proposed both cable in segments or bays and products in the form of ready-made sets, including the temperature sensor and heating control (thermostat for a warm floor).

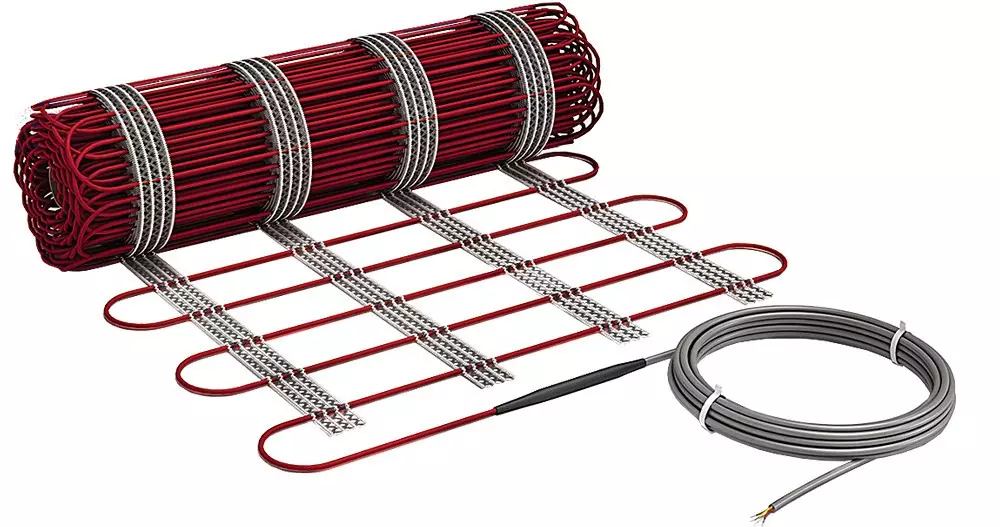

Floors based on cable mats and sections. In them, the cable is mounted on a polymer substrate. Width of mats 80-90 cm, the most popular 50 cm.

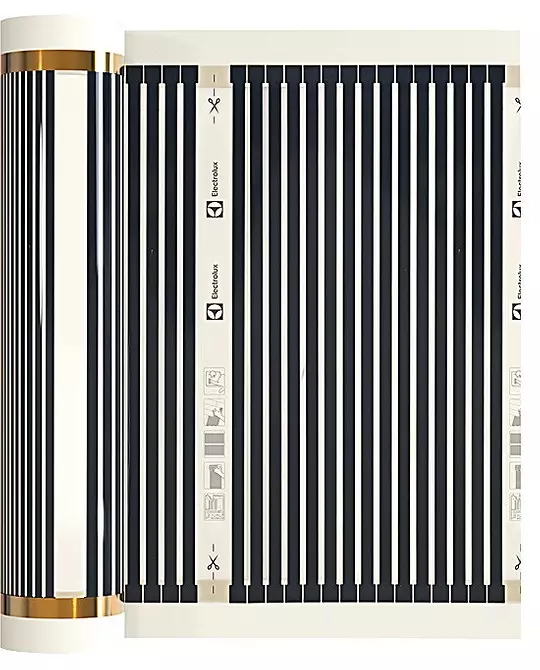

Floors based on self-regulating thermoplary. The sets of 0.5, 0.8 and 1 m wide are manufactured. Conducting elements in the film are made in the form of flat conductors, which is why the thickness of the product is only 0.5 mm and does not affect the height of the floor. Such a film is designed for dry installation without a screed, it can be put under the laminate.

Floors based on carbon rods. This is a new development of Caleo. In them, instead of the cable, a number of parallel-arranged carbon rods connected by conductive residential are used. Such a design, according to manufacturers, is of greater reliability (carbon rods stable to loads, rather than a regular cable or film) and efficiency (compared to resistive cable - by 60%).

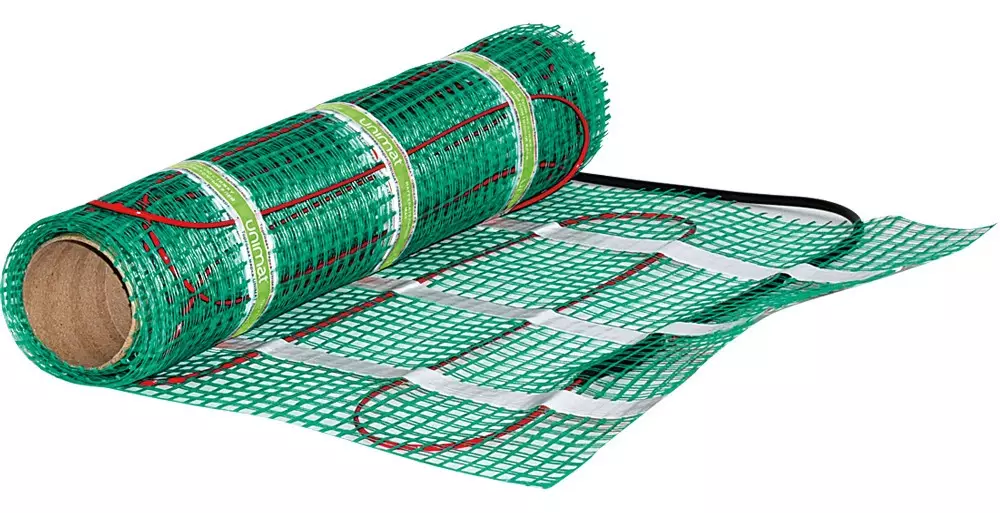

Upper heating mat UNIMAT CORD T (Caleo). Photo: Caleo.

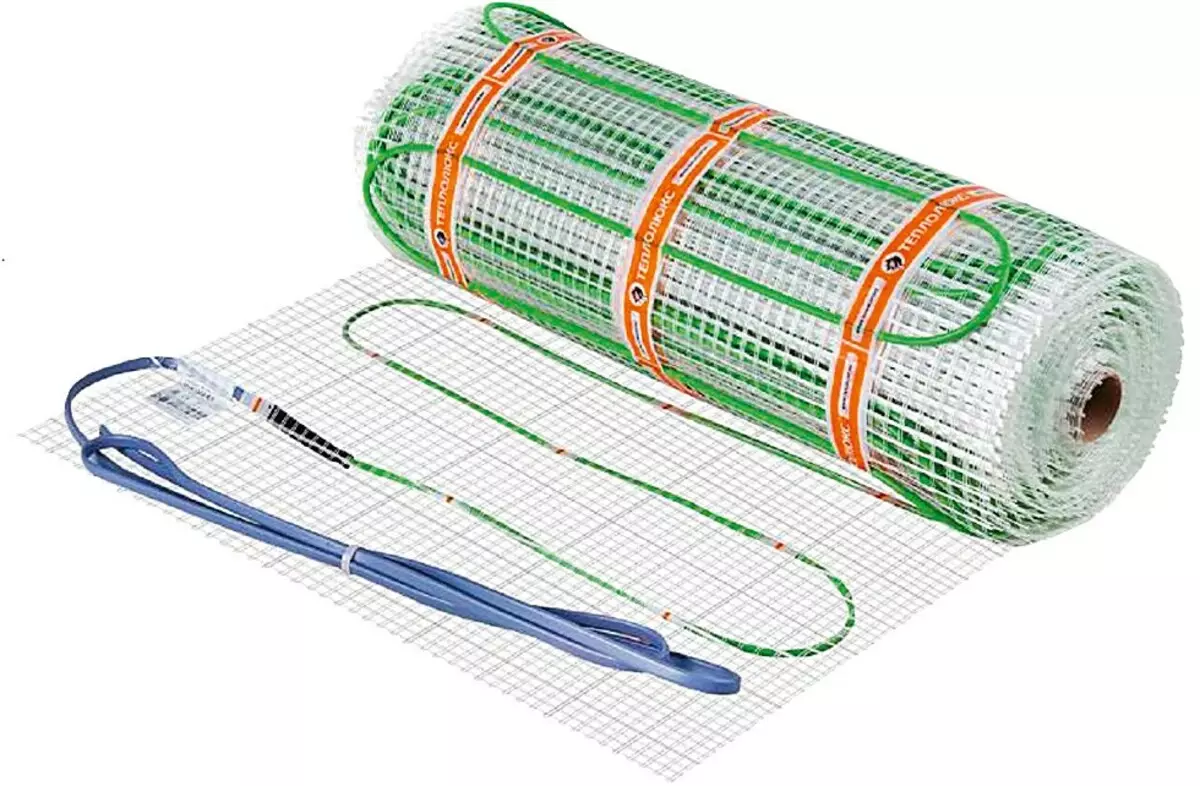

Warm floor "Tronolux Tropix", 1200 W, 8 m2. Photo: Leroy Merlin

Cable floor "Spyheat Wagon". Photo: OBI.

The Caleo Grid Infrared Floor set for 4 m2 area. Photo: Caleo.

Electrolux Thermo Slim film set. Photo: "RUSKLIMAT"

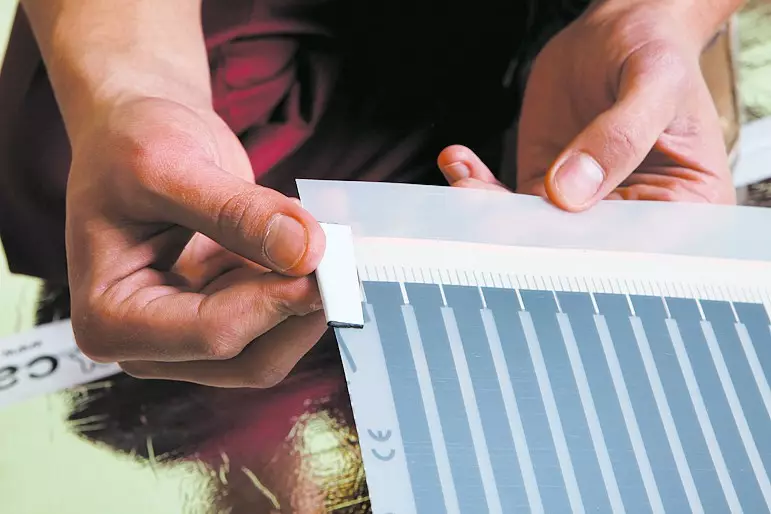

Sections of a film warm floor can be cut off a wide vertical line with a logo. Photo: "RUSKLIMAT"

Sets based on infrared film under flooring. Photo: "RUSKLIMAT"

Sets with heating cable for mounting into a concrete screed. Photo: "RUSKLIMAT"

Cable heating systems make it possible to equip the heating zones of the most whimsical shape. Photo: "RUSKLIMAT"

Thermostators are selected based on the maximum power consumed of the power plant. The temperature regulators are joined to the thermostat, placed on the floor. Photo: "RUSKLIMAT"

An important characteristic of any type of warm floor is its specific power given to 1 m². Domestic systems can vary from 70-80 to 250 W / m². Systems with a capacity of less than 100 W / m² are used, as a rule, for additional heating when mounting directly under the floor covering. Systems with a power of 100-170 W / m² are usually used for additional or main heating (the thickness of the screed, the more powerful system). Systems of greater specific power are used in particularly complex cases, for example, for the main heating of insulated loggias, premises on the first floors, etc.

What type of warm floor choose - depends on the configuration of the room, the tasks set, the selected coating and the installation method. If laying in a screed or tile glue is assumed, choose between cable systems, mats or carbon rods. And when laying a laminate on a solid base, the film warm floor will be a non-alternative option.

5 benefits of electric warm floors

- Easy laying. This applies to ready-made sets with heating mats or film. In some cases, it is not even necessary for the manufacture of a concrete screed, and not a specialist can perform styling.

- The speed of heating. Electric warm floors Even under thick (5 cm), the screed is warmed up to the desired temperature in a few minutes.

- Frost resistance. Electric warm floor is not afraid of low temperatures.

- Safety. Unlike water, electric warm floor during damage will not cause flooding of the underlying rooms.

- Maintainability. Modern equipment allows you to accurately determine the place of damage to the cable or films.

Laying warm floor

Stages of laying electric film warm floor directly under the floor covering

The floor is placed the heat-reflecting material, and the film sheets are so that there is no air gap. Photo: Caleo.

Stripping contacts. Photo: Caleo.

Connecting contacts. Photo: Caleo.

Isolation of connecting contacts. Photo: Caleo.

Disabled compounds are caused by a breakdown of any warm floor. Installation of the temperature sensor. Photo: Caleo.

A protective polyethylene film is placed on the warm floor, and it is possible to immediately lay the floor covering. Photo: Caleo.

When laying a warm floor in a concrete tie or tiled adhesive, it is prohibited to turn on a warm floor to completely drying the screed or glue.

Stages of laying infrared rod warm floor Unimat in a concrete tie

The heat-reflecting material is laid on the clean and even primary floor, and the rod floor set is uniformly unfolded on it. Photo: Caleo.

If necessary, the core floor cut into segments, the cut ends are isolated. Photo: Caleo.

The cable connections wear shrink sleeves and warm to ensure tightness. Photo: Caleo.

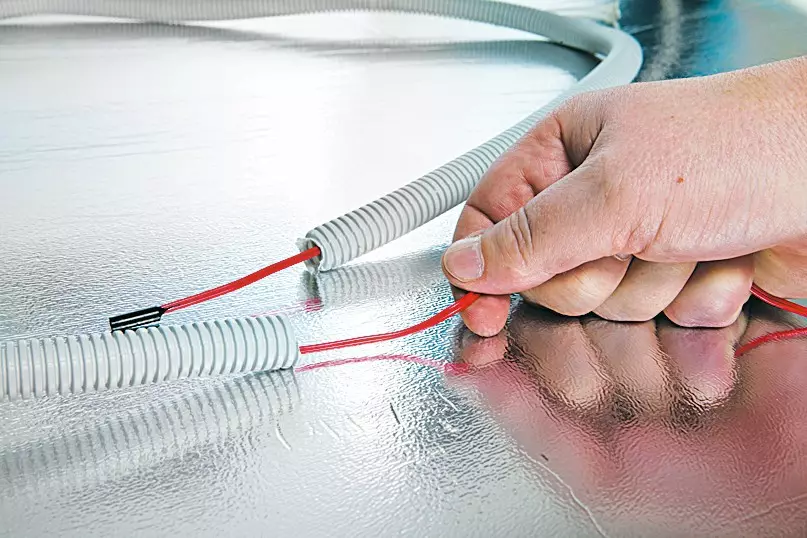

The temperature sensor is installed in the corrugated tube. Photo: Caleo.

The temperature sensor is located in the middle between the rods. Photo: Caleo.

Elevated and fixed mats can be poured concrete. Photo: Caleo.