Many owners of country houses will be seen by the furnaces, boilers and fireplaces - and therefore, without chimney, do not do. We tell about modern species of ceramic pipes, nuances of their operation and installation.

Photo: Schiedel

The new generation of Wolfshöher brand W3 is designed for installation inside frame, concrete or brick casing. Photo: Wolfshöher Tonwerke

Brick chimneys today are infrequently built: too hard to find a good master and suitable material. Systems from finished elements (modules) are much more in demand, allowing you to collect the smoke "highway" in one or two days. For many years, pipes made of steel and ceramics compete on the market. For the first, it is usually a guarantee of no more than 10 years, and on the second - up to 30 years (while the real service life of ceramic pipes exceeds 50 years). Indeed, pottery is more resistant to the effects of high temperatures and caustic smoke condensate, however cost 2.5-3 times more expensive than steel and moreover, extremely demanding on the quality of installation. Such a significant increase in costs justifies itself only with the responsible approach to the selection of the system and strict compliance with the rules for assembling the structure.

The outer chimney is preferable from the point of view of fire safety and saving space, however requires better insulation and protection against atmospheric influences /

The consoles and brackets for the outer chimney should be attached to the supporting structures of the building, and not to the facade trim. Photo: Schiedel

Types of ceramic chimney

Sound-wired products of the Kerastar system are equipped with a stainless steel casing plant. Photo: Schiedel

Ceramic chimneys are represented on the Russian market for Ecoton, Effe2, Schiedel, Tona and Wolfshöher Tonwerke. Ecoton, Schiedel and Tona offer complete insulated systems such as Sandwich. Wolfshöher Tonwerke produces only chammed pipes and glue for them - both are used by small manufacturers and assembly firms. The EFFE2 products are positioned by a mansion, from which we will start a review.

Chimney from ceramic modules

Chimney from ceramic modules (EFFE2 ULTRA, EFFE2 DOMUS). It consists of elements of a complex cross section - with internal and outer walls and radial jumpers. The working channel can be round (diameter 120-300 mm), oval or rectangular; The external cross section of the pipe is only rectangular.

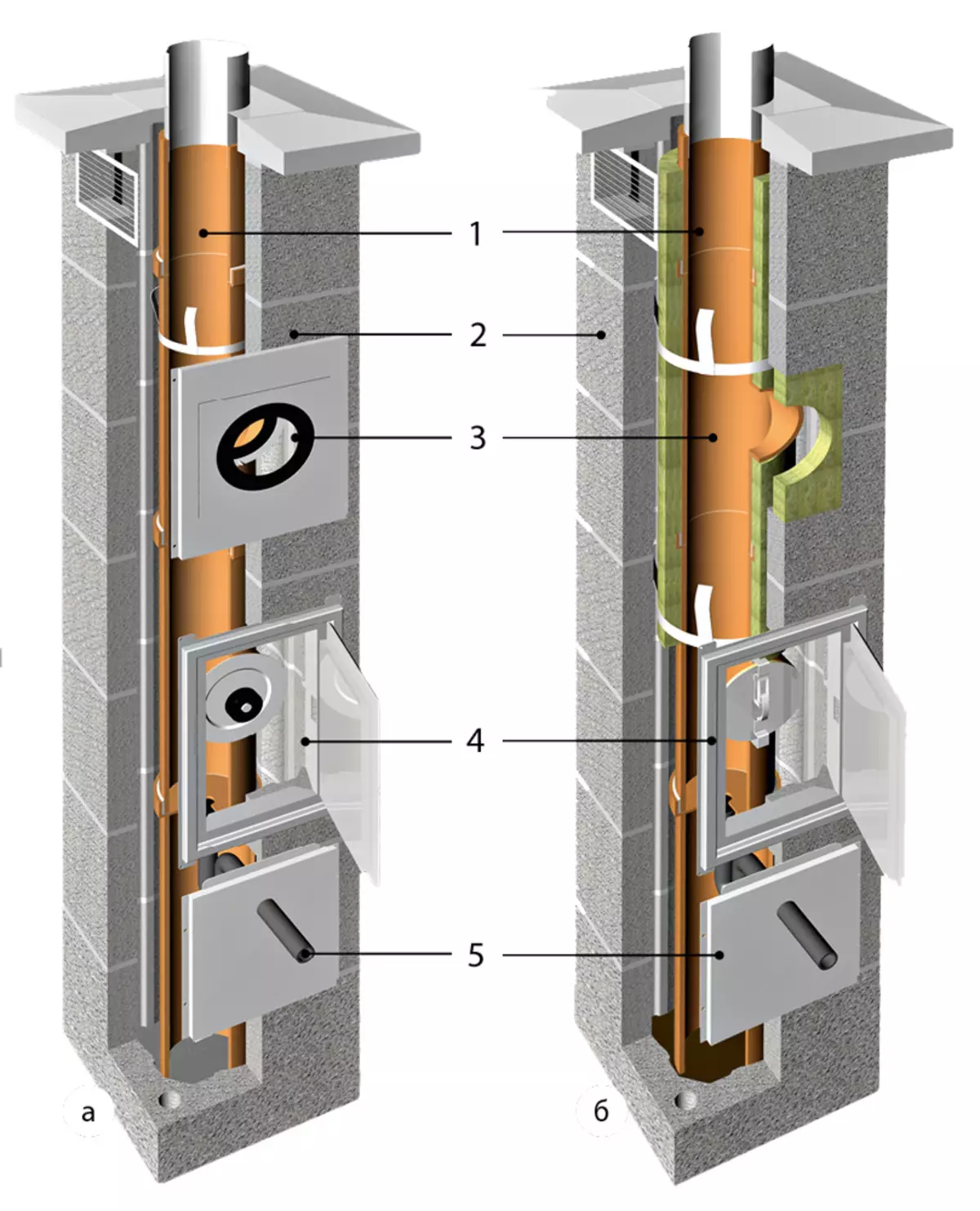

The TONA TEC LAS system is designed for high chimneal pressure and is designed for heat generators and boilers, which use liquid and gaseous fuel. The insulated Tona Tec Plus system (b) is suitable for boilers, furnaces and fireplaces operating on any type of fuel. The main elements of chimneys: 1 - working channel; 2 - concrete casing; 3 - connection module; 4 - revision; 5 - condensate receiver. Photo: Tona.

A small mass of the design (about 27 kg / mb. M with a channel diameter 140 mm) allows you to do without a foundation; There is also no suction mounting (with a support for a brick or block oven) or installation on the wall console.

The main minus of the chimney from all-ceramic modules is associated with the insufficient for Russian conditions with thermal insulation of the inner channel and, as a result, the abundant formation of a large amount of condensate, especially if equipment with low flue gases (durable burning furnace, condensing boiler). It is necessary to purchase an additional thermal insulation casing made of pressed stone wool under shuttering or independently assemble a warming box (for example, from dry-fiber sheets with a filling of basalt cotton). Another problem is in a relatively low structure strength: it must be located inside the predetermined mine, to be brick or enhance steel corners.

Pros and cons of ceramic modular chimney

| Benefits | disadvantages |

|---|---|

| Stands to moisture and acids, compatible with equipment running on gaseous, liquid and hard fuel. | Required to the quality of installation. Pipes are fairly fragile and with incorrect and negligent assembly can crack. |

Withstands the short-term effect of the temperature above 1000 ° C (fire soot in the pipe). | Models with concrete casing need a solid base (usually own foundation). |

Helps to minimize the amount of smoke condensate; Compatible with devices for collecting and removing condensate. | The complexity of repair and replacement. A partial or complete dismantling of such a chimney in a lounge is difficult. |

Eliminates the possibility of leakage of flue gases to the room, some systems are capable of operating at overpressure of gases (gas components). | |

Two-channel systems provide ventilation and allow you to organize air supply for combustion. |

Chimney with concrete casing

The chimney with a concrete casing (for example, Ecoton S-Block, Schiedel Uni, Tona TEC) is a three-layer "sandwich": an internal ceramic pipe is wounded with thermal insulation material and enclosed in a shell of volatile ceramzite-concrete blocks. The casing not only performs a protective and decorative function, but also gives the design stability. Such chimney can only be indigenous: it is installed next to the heating unit on a general or separate foundation.

The thickness of the pipe walls in different manufacturers varies from 4 to 6 mm; This parameter does not affect the operational characteristics of the structure, however, products with thin walls require greater caution during transportation and assembly. The accuracy of the manufacture of fields, which affects the consumption of mounting solution and the tightness of the compounds.

As thermal insulation, ordinary flexible mattes from stone wool can be used or ready-made "shells" from the same material, but higher density. The second preferred in terms of durability and ease of installation, but cost 40% more expensive.

In concrete elements of the casing, holes must be provided for vertical reinforcement rods that ensure the strength of the masonry. When installing outside the building, the casing should be plastered and painted with facade paint.

In the upper part, the chimney is warmed especially carefully, using clay gravel clay (its advantage - low water absorption) or ready-made cohesives from mineral wool. Photo: "Red roofs"

Chimney with metal casing

Chimney with a metal casing (for example, Schiedel Kerastar) is all the same warm "sandwich", but intended for wall mounting. It is able to withstand outdoor operation and does not need a finish (the outer pipe is made of polished stainless steel). Another advantage of such systems is the possibility of assembling the chimney of a complex configuration, crawling rafters and other obstacles (due to the presence of taps 15, 30 and 60 °).

The shell above the roof is made of reinforced concrete or sheet steel imitating brickwork; The umbrella is made of steel or copper. Photo: "Red roofs"

Installation of chimney

The main complexity of the ceramic chimney is due to the fact that the design always includes steel elements - the inlet nozzle, the cleaning door, and sometimes even the Sewber, the mounting brackets to the walls and clamps. Since steel has a higher thermal expansion coefficient than ceramics, compounds should be performed with a 2-5 mm gap, using asbestos cord or elastic heat-resistant sealant (Fischer DFS GR, Penosil 1500 ° C, etc.).

Tiered furnaces and fireplaces are often equipped with an oven ceramic chimney, which not only serves as an interior decoration, but also allows you to more effectively use heat from the device. Photo: godin.

Pottery pipes are glued with special silicate glue. At the same time, it is necessary to carefully remove the surplus of the working solution, especially from the inner surface of the channel, which should be perfectly smooth, otherwise the pipe will be quickly clogged with soot. Modules of concrete casing are placed on cement glue. Since the height of the elements is small, it is necessary to constantly control the verticality of the chimney using a plumb or laser level.

The fire prevention indentation from the inner walls of the pipe to unprotected wooden structures should be at least 500 mm; to the insulating screen closed (minvat + steel) - 380 mm.

Finally, it is very important to choose correctly and gently install a headband consisting of a coating plate (usually concrete) and a metal-deflector metallic umbrella. The stove must herdict the gap between the working channel and the casing. After all, if the insulation at the top of the pipe will ignore, the thrust will deteriorate sharply (it is possible even to roll over) and the amount of condensate will increase. Incorrectly made deflector can also cause problems with the burden. In this regard, it is better to purchase a headband from the producer of the chimney, even if it costs more expensive in the scene or ordered in a third-party workshop.

When laying a chimney from ceramic modules, you can collect a frame cover. Its base is performed from steel galvanized profiles. Photo: "Driving power"

For the skin, a non-combustible leaf material is used (gramifications class), such as glass-cemer sheets

When walking overlaps, safe indents from wooden beams and flooring are observed.

Pipe gloves are decorated with a ceramic coating plate on which a steel umbrella deflector is mounted

Cost of ceramic chimney systems

System name | Effe2 Ultra. | Ecoton S-Block | Tona Tec. | Schiedel Uni. | Schiedel kerastar |

| A type | From all-tempered modules | Heated, with concrete casing | Heated, with concrete casing | Heated, with concrete casing | Heated, with stainless steel casing |

price, rub. | From 3800 (excluding additional insulation) | From 7300. | From 11,000 | From 10 200. | From 13,000 |