What wall materials and structures will suhold heat and humidity? What oven is better to purchase? How to ensure the flow of water? We answer these and other common questions about the construction of a traditional bath.

As a rule, for the traditional bath, a separate building is erected (if you equip the steam room in the house, then not to avoid increasing humidity in the neighboring rooms). First of all, you should decide on the dimensions and layout of the future bath.

Photo: "Factory Project"

Calculation of area and volume

When warming up the pair and montage of the smoke, do not do without aluminum adhesive tape and special heat-resistant sealants. Photo: Hobby, Klebe

We have already managed to get used to crawl cabins, but should not be guided by their dimensions during the construction of a traditional bath. In the steam room, there should be enough space for regiments, furnaces with a tank, acerry, cool water capacities; At the same time, it is necessary that on the room it was possible to move freely, not at risk of burning about the Kamenka.

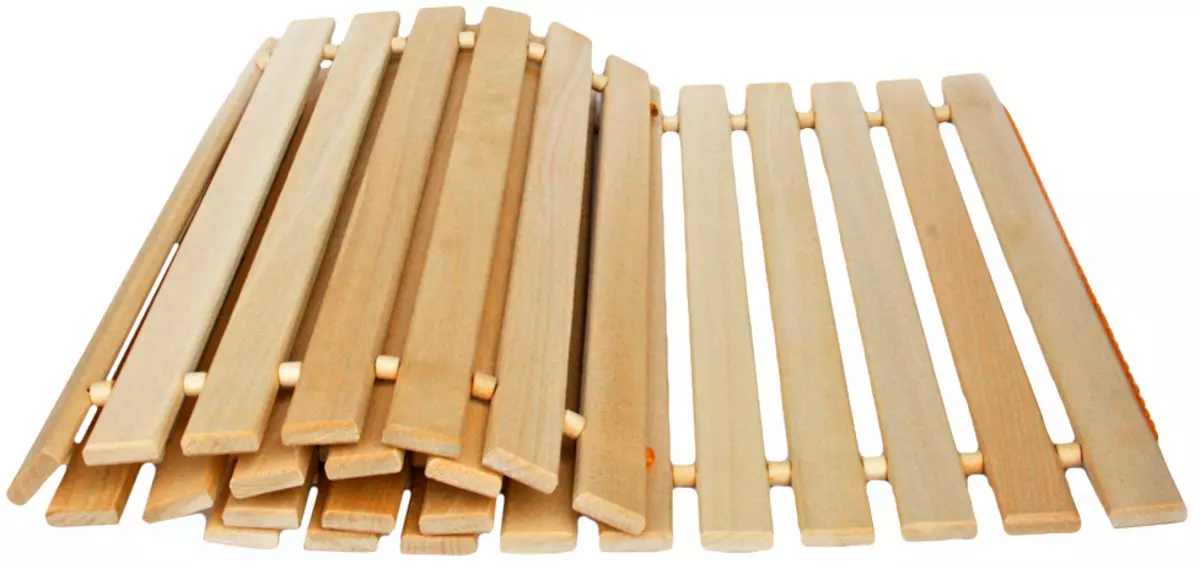

Flooring. Photo: "95 °"

When calculating the area and volume, the steam plans follow the rule: 3-4 m2 or 7-8 m3 per person. The ceiling should be mounted at 210-230 cm from the floor - with a greater height, it is difficult to achieve a comfortable microclimate (in the zone of the lower regiments it will be cool).

Photo: Klafs.

Lamp. Photo: "95 °"

The shelves are built into one or two tiers, while the lower is located at 90-110 cm from the floor, and the upper one is 50-70 cm above. Their width should be about 60 cm, and the length is at least 160 cm; Between the upper level and ceiling, you must leave a distance of at least 110 cm.

Without a pre-banner can not do. It is believed that in the area it should exceed the steam room for at least one and a half times, because in this room it is necessary to place a table for tea drinking, shop, a small woodcarce, wardrobes for clothes, linen and dishes, as well as shelves for bath accessories.

When buying a finished bath, you get rid of troubles on the organization of the construction process and the purchase of equipment, as well as the troubling expectation of the object. Photo: "House-Ark"

In modern projects, it often provides for a small entrance tambour and bathroom - such a layout allows much to increase the level of "bunny comfort", but will require additional costs. Put the area for shower and hallway at the expense of the steam and the pre-banker should not.

Photo: "Wooden Workshop"

Turnkey solutions

Kupper from cedar boards can be purchased for 60-120 thousand rubles. Such a capacity requires attention and care: It is desirable to process it once a year to its protective compositions from the outside and as possible to be wrapped with water from the inside. Photo: "King Cedar"

Today, there are ready-made frame baths with all internal equipments. The design will deliver to you on the site on the truck and turn the crane. With a modular scheme, when the bath is collected on the spot from the steam and pre-bankers, the dimensions of the building can reach 2.3 × 5.8 m. The best option of the foundation under it is screw piles. At the bath from the plant a lot of advantages - this is the unusual appearance of facades, and thoughtful ergonomics of premises, and the exquisite interior design, over which professionals worked, however, the cost of such structures today is quite high - from 40 thousand rubles. For 1 m2 of the total area.

Bath is better to place in the depths of the site. Next to her are appropriate a recreation area and a prefabricated or landing pool or a wooden font, which will provide hardware bathing.

"Wild" log house with a delicate roof is perfectly combined with the concept of a traditional bath, but imposes special requirements for the landscape. Photo: "Sibsrub"

Walling

Nowadays, most often buy team logs Bat from a log with a diameter of 180-260 mm or a bar of 100/150 × 100/150 mm. The sets of the rounded log and glue bar will cost 2-2.5 times more expensive than normal, but these materials provide a simpler sealing of interventic seams and also do not need to be finished.

Ideally, the walls of the bath must have both heat-insulating, and heat accumulating ability so that in the steam room for a long time the required temperature (45-55 ° C) remained and did not have to drown the furnace during washing - the hard heat from the walls of the Kamenka is by no means useful. From this point of view, you should choose a timing by a cross section of at least 150 × 150 mm or a log diameter of 240 mm; Ideally, it is necessary to use a larch well carrying moisture.

Photo: Helo.

However, in practice, the material of a smaller cross section usually choose and insulate the walls from the inside (how to do it, we will tell further). The point here is not so much in saving, how much in the modern rhythm of life, which requires that the steam room warms up for 2 hours, and this is possible only if you can install a layer of effective thermal insulation on the inside of the fence.

Shelves and flooring is easy to make on site. For frames, it is better to use a pine or larch, and for the skin - a lime, Osin or Oak Abashi. More complex designs with hidden fasteners can be ordered in a carpentry workshop or purchased ready. Photo: Helo.

Walls under warming and decoration can be erected from bricks, as well as building blocks. This, by the way, does not contradict the tradition - in the south of Russia, for centuries, the baths were built from Saman and local limestone.

The best material for the interior decoration of the bath is lining from aspen and linden, as well as alder and Canadian cedar. The wood of these breeds is not "crying" resin when heated.

It is quite acceptable to apply the framework technology - in this case, to fill the shields, it is necessary to use stained wool slabs that have stability of the shape and almost susceptible to thermal destruction.

If you warm the walls, the ceiling and the floor of the bath and install a powerful furnace, the steam room can be operated both in traditional and in suchogeneous mode.

We emphasize that the partition between the parillery and the pre-tribades should also have thermal insulating ability. It can be erected from the same material as the outer walls, or make a frame.

Photo: Klafs.

The choice of foundation depends on the type of soil, wall material and the configuration of the construction. If the bath is small and the design of the fencing ensures uniform load on the base, on sandy, sandbreaker and debris soils are allowed to use fine-gulled poles; For moderately bunched spoes and loam (at groundwater level more than 1.5 m from the surface), a floating tape of monolithic reinforced concrete is suitable. If the construction has a complex configuration, and the soils on the section are bunched and weakly mixed, it is necessary to choose a pile-screened or slab foundation.

Photo: "95 °"

Bath insulation

When the walls of the walls are insulated in the brusade or log bath, use a moving vertical inches, to which horizontally nourishes the plates of the sheath, handling the gaps from the floor and the ceiling to compensate for the shrinkage. In the stone and skeleton bath, the shrinkage is not required.

For the root, only high-grade (with a minimum number of bitch) pine bruises cross section of 50 × 50 or 50 × 40 mm are suitable, which should be arranged in 50-60 cm increments.

For insulation, conventional and foil plates from mineral wool should be applied, such as Light Batts and Sauna Batts (Rockwool), Extra (Paroc), "Classic Plus" (ISOVER). To ensure the rapid heating of the room, the minvati layer is sufficient 50-80 mm thick.

When installing thermal insulation, mineral wool slabs should be protected from moisture. Usually for this purpose serves foil paper. Another option is to buy insulation with a protective layer. Photo: Rockwool.

To protect the insulation from the steamed moisture, and at the same time to reflect the inside of the room with radiant heat, and the insulation is tightened with a vapor insulation material - aluminum foil or foil paper. The last on reflective ability is inferior to foil, but exceeds the last strength, so it is easier to work with it.

It is important to achieve maximum impermeability of the vaporizolation layer. For this, the foil strip is mounted with a totaling of 70-100 mm, sealing joints and holes from fasteners with aluminum scotch. When using foil heaters, it is enough to smoke the joints of the plates.

You should not try to provide vapor barrier with a bitumen-based rolled materials, as they emit an unpleasant odor for a long time. And polyethylene and polypropylene films will not withstand heating.

On the floor, the total thickness of the mineral wool insulation should be at least 100 mm; Plates are located between carrier beams on the draft rut from boards or moisture-resistant sheet material (for example, CSP). The ceiling is required to insulate the layer of minvati with a thickness of 150 mm.

Luminaires in the steam room must be moisture-proof. In addition, they should be closed with retained screens to accidentally not break and do not burn about hot glass. LED devices are impossible to be installed: they are not enough heat-resistant. Photo: shutterstock / fotodom.ru

Engineering equipment

In the bath necessarily arrange the supply and exhaust ventilation. The generally accepted diameter of the channels and valves is 100 mm. The length of the vertical exhaust pipe is 3 m. The wiring is conducted under the trim in the PVC-sleeve with a heat-resistant cable with the WPC marking, PVKV or RKGM. All chains must be grounded and automatically protected.

Photo: "Bankov"

Floor floor

In a traditional bath, water flows through the gaps between the floorboards either by the bundled horror. A much higher level of comfort provides modern drain floor. With its device over the beam of the overlap (the space between which is filled with insulation), it is filling a solid level base, for example, of two layers of waterproof plywood or hydrophobized chipboard on the boarding board. This basis is necessary to give a bias to the location of the catchment. Next lace out the ceramic tiles and mount at the bottom point of the floor ladder, which is attached to the sewer tube.

On top of the tile floor, board pavements made in such a way as to level the slope to the ladder. Mostki must consist of small fragments so that they can be easily removed - it is easier to maintain purity in the steam room.

Photo: Sun Sauna

Choosing a furnace

Taimyr 2017 oven is the first bath oven "Thermophore", working on natural or liquefied gas (from 19 thousand rubles). Photo: "Thermophore"

The Kamenka for the Russian bath is chosen from the calculation of 0.7-1.4 kW of thermal power by 1 m3 of the volume of the wage (depending on the thickness of the insulation layer and the planned battery use time - mostly in summer or year-round). The furnace must be wood, since most of the electric units will not withstand specific operating conditions - they will fail. The most accessible option is a factory steel furnace with convection casing. Models with ceramic talco chlorite facing have greater inertia, but also cost 3-4 times more expensive.

In the absence of hot water, it will be worthwhile to the water tank, the volume of which should be chosen from the calculation of 5-8 liters per person (water in the tank is brought to almost boil, and it is diluted with cold in the tub). Note that many Russian furnaces produce in two versions - with a tank and without it; The first is 2.5-3 thousand rubles. more expensive.

Pangoline furnace with ceramic facing, reminiscent of the scales, emits soft heat, gives a "light" pairs and does not cool down (from 70 thousand rubles). Photo: "Thermophore"

Model "Geyser Mikra 2017" with a two-stage vaporization system suitable for a traditional bath, so

And for sauna (from 12 thousand rubles.) Photo: "Thermophore"

The heat exchanger embedded in the furnace will provide hot water shower, but this solution is suitable only for the summer bath, and it will have to drain water from the system.

The closed stone laying and the water supply valve to the stones will give more "light" pairs. And the fuel channel will drive the oven from the pre-banner, where it is not difficult to find a place for firewood and furnaces.

To mount the chimney, passage modules will be required, providing thermal insulation of overlap parts. The shield for the furnace is usually made of heat-treated wood. Photo: "Bankov"

The glass door of the furnace does not hurt: the view of the open flame will help to create a cozy atmosphere in a pre-banker or a steam room. It will be necessary to wash the glass regularly, but today products based on acids appeared on sale, which easily cope with Soch.

Photo: Tulikivi.

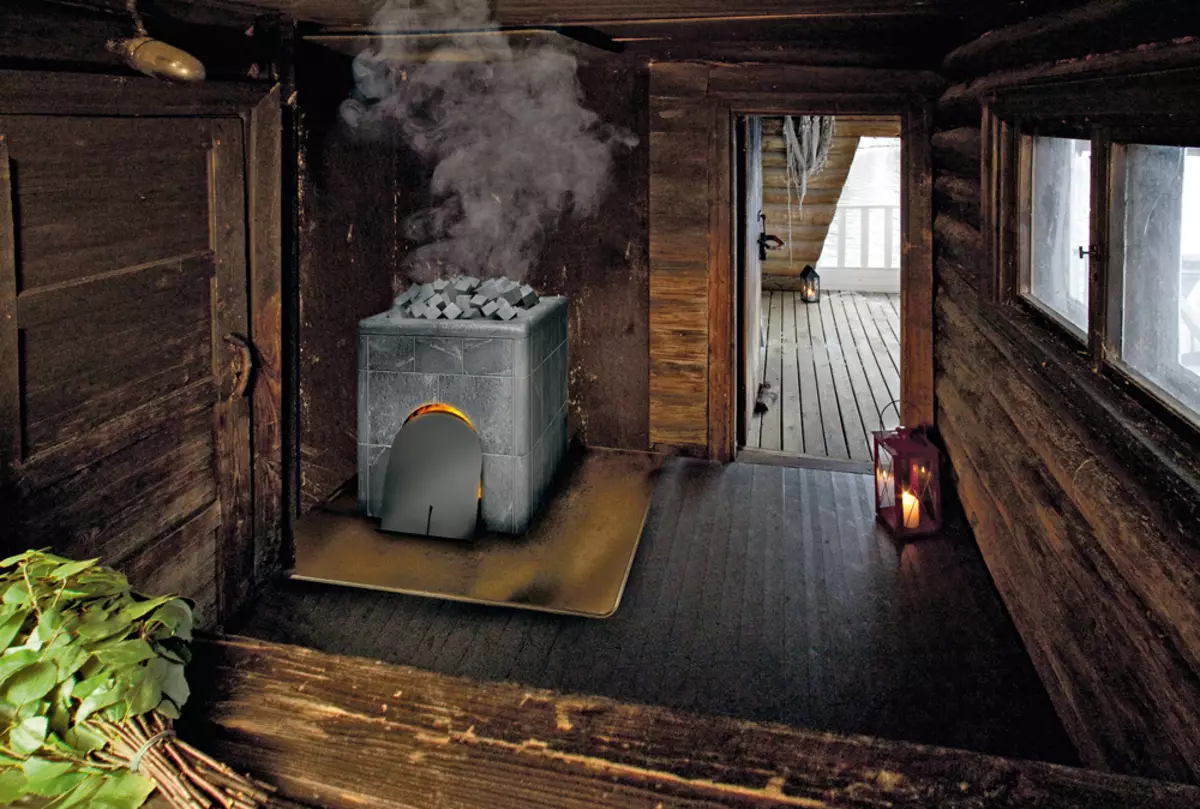

Sterile soot

It would seem that the bath in black long ago turned into a legend of old years. Meanwhile, the interest in it is preserved, and not at all theoretical - such baths continue to build. However, in the modern version there is a chimney, but a little smoke passes through the stone laying and enters the room. Due to this, a bitter smell of child is reigns in the steam room, and all surfaces are effectively sterilized by carbon oxide. Before starting to steam, such a bath must be used about half an hour and once a few years have changed the wigged inner finish.