Over time, the contact of the electrical conductors begins to deteriorate. We understand why this happens.

Shutterstock / fotodom.ru.

Wireless inspection clamp products: Celiane series (Legrand). Photo: Legrand.

You can learn about problems with wiring or wiring products in many signs. For example, periodically starts to work the RCO. More often the usual light bulbs in the chandelier. Finally, the fails of the excessive heating of the wiring and wiring products in places of poor contact of current conductors and the characteristic smell of burning plastic are evidenced.

Wireless wireless clamp products: Unica series (Schneider Electric). Photo: Schneider Electric

Why is the contact of the wires with time deteriorates (cases of mechanical damage of conductors and electrical installation products we will not consider). This is usually true for one of the following reasons.

Socket 16 A with grounding plate, SL series, with non-free clips (JUNG). Photo: jung

Causes of contact of contact

Conductors were interconnected with violation of technology. In particular, their twist is not allowed to the "pigtail", as sometimes there are negotiators of amateurs. For switching of wires in PUE, only a twist is allowed, enhanced by soldering, welding, crimping sleeve or so-called CIZ connecting cap. In the domestic conditions, it is easier and more reliable to use connecting feedback (spring) terminals. They are easy to install and dismantle even a novice, and the connection they provide quite reliable.

Photo: shutterstock / fotodom.ru

Socket 16 A, Series A, Champagne Color, With Cavigated Clamps (JUNG). Photo: jung

Screw connections in places connecting wires to electrical products weakened. This is the problem of all screw connections, no matter how tightly they screw them. The fact is that the metal of wired veins, heating, is deformed over time. Therefore, all screw connections in outlets and switches must be tightened once every 2-3 years. Alas, almost no one is engaged in such prevention.

When tightening the screw terminals of electrical installation products, do not overdo it to damage them; For switches and electronic devices, tightening torque from 0.5 to 0.6 nm, for outlets at 16 A - 0.8 nm.

In modern rules of electrical installation products, contacts are often manufactured from special materials. For example, in a series of electricians Unica (Schneider Electric), internal circuit breakers contain a large percentage of technical silver, which reduces the transition resistance, the contact becomes less susceptible to oxidation. This leads to less heating and improving the quality of the use of mechanisms. Therefore, with regular problems with heating, the switch makes sense to replace old models to new ones.

As the most effective solution to this "screw problem", it was proposed at all to abandon compounds of this type. In the outlets and switches of the new design use of non-centered clamps. They fix the conductor reliably, and the connection does not weaken over time, it is not necessary to twist it or somehow servicing in a different way. It is not surprising that the wiring products with the eventless clamps are already among many companies: there are similar rules in the Assortment ABB, Jung, Legrand, Schneider Electric and other well-known manufacturers.

Difficulties with aluminum?

Socket with insidious clips Legrand, Celiane series. Photo: Legrand.

The use of aluminum conductors (this is mainly an old wiring; now, as a rule, the wires and cables on the basis of copper are laid) has its own characteristics that need to be considered. The coefficient of thermal expansion of aluminum is greater than that of other metals (steel, copper, brass, etc.), which inevitably creates the efforts of the connecting compounds when heated. Clips to attach aluminum conductors should be made of aluminum or aluminum alloy or contain extension compensation devices, such as spring washers. When attaching aluminum conductors, it is recommended to pull the screw clamps in a few days. In addition, during operation, it is recommended to periodically check the tightening of screws.

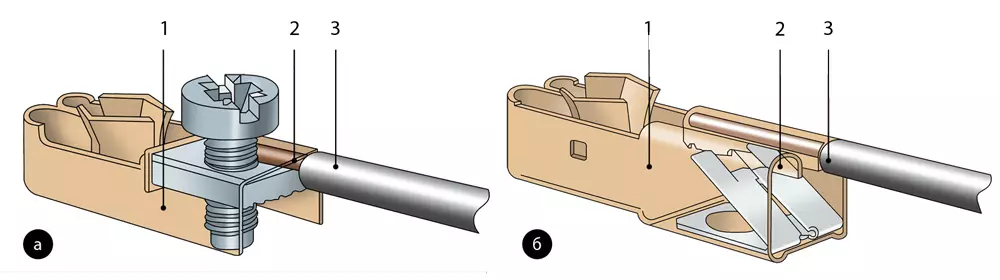

Constructive diagram of screw and case-free clips used in electrical installation

Double screw clamp (a): 1 - socket socket; 2 - Terminal Plank; 3 - wireless clamp wire (b): 1 - socket socket; 2 - spring; 3 - wire