Floor coatings from the wood array are beautiful, durable and maintainable. However, create a foundation for a wooden coating in the apartment - the task is not simple. We tell how to cope with it.

Photo: Kährs.

Modern glues for parquet and a massive board are universal: they allow you to lay the coating both on Panero and on the concrete. Photo: kiilto.

Overlapping from precast concrete slabs in high-rise buildings is very easy to prepare for laying laminate or rolled materials - for this it is simply necessary to align it with a cement-sand tie. But the piece parquet and a massive board are much more capricious: they are prone to the charge and create a significant tightening load on the fastener and the adhesive layer. With air humidity drops in the apartment, wooden elements change the dimensions, as a result of which bloated and cracks are formed. And if the concrete base ignores (as a result of leakage or failure in the work of the general ventilation), the tree will start rotting. To overcome these shortcomings helps a properly performed flooring.

Photo: Parketoff

Label

Material is applied using an adhesive gun or a toothed spatula. Photo: "Delta"

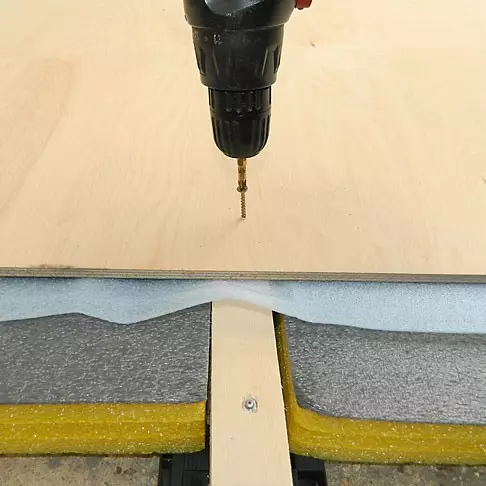

Quickly create a smooth and durable base for the board or parquet floor allow lags. Usually they are made from antiseptic coniferous bars and reliably, with a step of no more than 1.5 m attaching to the slab overlapping with screws with a diameter of 4.5 mm or metal dowel-nails. To level the level drops, use lining from non-zagging materials (for example, plastic) fixed by mastic.

The floorboards from the engineering and heat-treated array with the lock compound is allowed to lay the floating method (without fastening to the base) to the cork substrate.

When the floor is found on the lags it is desirable to use special fastenings with a vibrational rubber insert. At the same time, for air noise isolation, the space between lags should be filled with mineral wool or clay. Photo: "Soundgard"

Before mounting the lag, the entire floor area needs to be treated with cement-polymer waterproofing. In addition, experts recommend to fill the space between lags with clay gravel, and over to unwell a vapor barrier film, so that the moisture from the lower room does not penetrate the floorboard. If it is necessary to significantly improve the sound and thermal insulation characteristics of the overlap, the ceramzite should be replaced with mineral wool plates.

Photo: Templa

The massive board with a thickness of 35 mm, in principle, can be attached directly to the lags with a cross section of 50 × 70 mm and more laid in a step of 600 mm using a hidden edge fastener. However, more often in the apartments are used more subtle (up to 30 mm) coatings of solid solid and valuable wood solids. In this case, do not do without a solid supporting "base", which is performed from two layers of plywood with a total thickness of 16-20 mm. Parquet dies or tipped boards are fixed to plywood nails (with a special pistol) and polyvinila acetate or polyurethane glue.

Note that between the sheets of plywood, it is necessary to leave compensation gaps of 3-5 mm wide, and around the perimeter of the room - 8-10 mm.

Phaneur before the installation should be kept in the room for five to seven days, and after stacking to polish to remove small waves, interfering with raking parquet.

Metal threaded spires make it easy to adjust the position of the lag in height and set them for one level, but eaten up to 20 mm ceilings height. Photo: "Support-77"

Lagged black floor weekly, extremely demanding for the qualifications of workers and also steals at least 70 mm of room height. However, it has a small mass, which means it does not create a large additional burden on the overlap. In addition, lags allow you to quickly eliminate significant level drops (the value of the latter does not affect the consumption of the material) and immediately begin the installation of the finite coating, and not wait a few weeks, as in the case of a concrete tie. Finally, the essential plus of the lag shaft is that its main elements react to moisture fluctuations in about the same way as wooden coating. Due to this, significant internal stresses occur in the design.

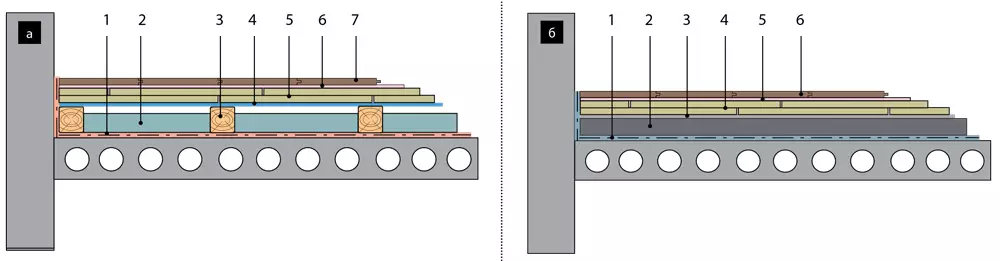

Base options for parquet: Lagged floor (s) and screed with plywood flooring (b)

Visualization: Vladimir Grigoriev / Burda Media

A: 1 - coating cement-polymer waterproofing; 2 - claying frustration; 3 - lag; 4 - vapor barrier film; 5 - plywood (two layers of a total thickness of 20 mm); 6 - polyurethane glue for parquet; 7 - parquet;

B: 1 - rubber hydraulic insulating membrane; 2 - cement-sand screed with the addition of fibrovolock; 3 - polymer mounting glue; 4 - plywood (two layers of a total thickness of 16 mm); 5 - Polyurethane glue for parquet; 6 - parquet.

How to adjust the lag

For a long time, the factory sets of floor bases from regulated lag or adjustable plywood were popular. The adjustment in them was provided by hollow plastic threaded sleeves, through which the mounting to the overlap was carried out. However, the load on these nodes is very large, and the designs often turned out to be unreliable due to the poor quality of plastic. Metal threaded studs are more durable, but they are more difficult to fix it with concrete. Plastic wedges are convenient and durable. They are cheaper than bushings and studs, can be located with any step, and it is no harder to "tune" them.

The draft floor is obliged to withstand high static and dynamic loads and be perfectly smooth: even minor tubercles and pits interfere with walking and cause premature coverage. Photo: Kährs.

Lagged black floor device

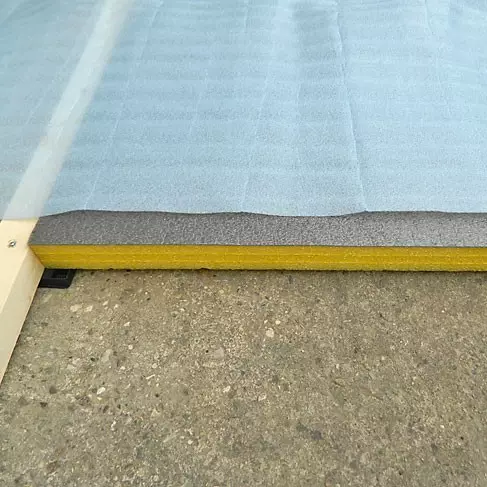

Wooden lags were horizontally using double plastic wedges capable of withstanding the load up to 1.5 TCs. Photo: Vladimir Grigoriev / Burda Media

The position of the lag was tested by a bubble level.

Next, through the bars and wedges drilled holes in the slab overlap

And attached the details of the dowel-nails of 80 mm long

After that, they laid the thermal-and-fluent mats between the lags, and then shown the entire area of the floor by vapor insulation film

Whose joints of whose stained scotch. In completion, the sheets of plywood mounted, using screws with a blended cap for this, which screwed up 25-30 cm in increments

Without unnecessary details

Modern wooden floor coverings - a multi-layered engineering board and dry parquet dies with compensation propuls - are slightly boxed, so they can be laid on the cement-sand tie. True, for this, its compression strength should reach 15 MPa (150 kgf / cm2), and the tensile strength of the upper leveling layer is 3.5 MPa. And it is very important that the residual moisture content (mass moisture) of concrete was no more than 3.5%. The screed survey is carried out according to the methods of SNiP, and it can be entrusted by a specialist in installing a parquet, or a construction expert.

Perforated cork substrate extinguishes shock noise and springs when walking. Photo: "Parquet Hall"

Concrete base is preferably polished, dust and primed. When the soil is completely dry, it can be started to lay the flooring, pre-apply a thick (3-5 mm) layer of elastic elastic mastic on a polymer basis, for example Berger Bond M1 (Berger-seidle), Pavi-COL P25 (ADESIV) or PUK-446 P ( Stauf).

However, the installation on a solid layer of elastic elastic mastic is more reliable. Photo: "Parquet Hall"

For lag, conventional one-piece sections of 50 × 50 or 50 × 70 mm are suitable. However, it is important to choose high-grade products without large bitch, surveys and other defects

There is another solution designed for apartments with low ceilings, where it is necessary to lay an ordinary parquet or massive board. The overlap is equalized by a high-strength bulk mixture (layer thickness 10-30 mm) or suit thin (up to 40 mm) reinforced tie of the cement-sand mixture, and then with the help of polymer glue and dowel-nails, the sheets of waterproof plywood thickness are 12-15 mm thick. Note that the strength and humidity of the screed in this case impose no less strict requirements than when laying the parquet on concrete. The plywood layer will cost 1200-1400 rubles. For 1 m² (material + work), but it will not give the flooring to be swallowed.

Typical errors in the preparation of the base for a massive board and parquet

- The device of floating patterns of rough floors, for example, from mineral wool mats and puzzle chipboard.

- The use of lag from low-grade wood and linings made of soft material, unreliable fastening of the lag. Over time, the floor begins to creak and see.

- The lack of compensatory gaps between plywood sheets and the perimeter of the room. With increasing humidity, the floor can take place in places.

- Insufficient strength of the screed and its bad clutch with overlapping. Hyded, boards are quite capable of tearing the leveling layer from the stove.

- High residual moisture screed. Most likely, finishing flooring will have to fully disassemble, and usually the reuse of the flooring is impossible.

Photo: Empiri.