Every year, pipes from new polymeric materials appear on the market, and the fittings of the new design appear. All of them are usually convenient, to work with them is a pleasure, with some "cast-iron" not compare! But how do new materials and fittings behave with time?

Photo: shutterstock / fotodom.ru

Pipes made of polymeric materials and metal-plastic are not afraid, let's say rust, and are quite capable of listening to dozens of years with proper handling. However, they have their weaknesses, and if they neglected, it may later be difficult to occur with the pipeline.

Causes of pipe breakthrough

Most of the errors are performed when installing. The most typical includes:

- Use of pipes, fittings and assembly tools of various manufacturers. Even the compliance is not a guarantee in this case. GOST limits only the maximum permissible deviations of the diameter from the thickness of the pipe wall in the largest side.

- An uneven cutting edge of the pipe before mounting the connections.

- The use of unsuitable sealants and adhesive compositions that have a devastating chemical effect on pipes and fittings.

- Pollution of connected surfaces of fittings and pipes.

- Incorrect installation of compounds when mounting rings or threaded adapters are not pulled on to the cut end of the pipe, as well as when the end of the pipes are not up to the fitting.

- The disproportionate need for the effort applied to the manual mounting tool.

- Installation of pipes adjacent to fitting, with deviation from the fitting axis, resulting in bending or torque, transmitted to the fitting.

Main error When installing polymer pipes - non-compliance with the basic setup rules. Be sure to make sure that the pipes and fittings are not exposed to excessive mechanical exposure. If any element of the pipeline has even minor damage, it is better to replace it. Even unpacking the bay pipe is preferably without cutting the packaging with a knife. To avoid damage in places of passage through building structures, it is necessary to lay the pipe in the hyelze from corrugations. If you install pipes in winter, remember that the welding is carried out only at a plus temperature (minimum 5 ° C). And of course, do not forget that the tools and pipes must be clean.

Ivan Hrpunov

Technical specialist of the company "Kashirsky Dvor"

The fixation of polymer pipes must be carried out with the help of special fixing elements, clamps and clips. Photo: Uponor

When installing polymer and metal-plastic pipelines, it is important to protect pipes from mechanical damage. Photo: Uponor

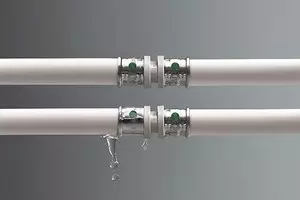

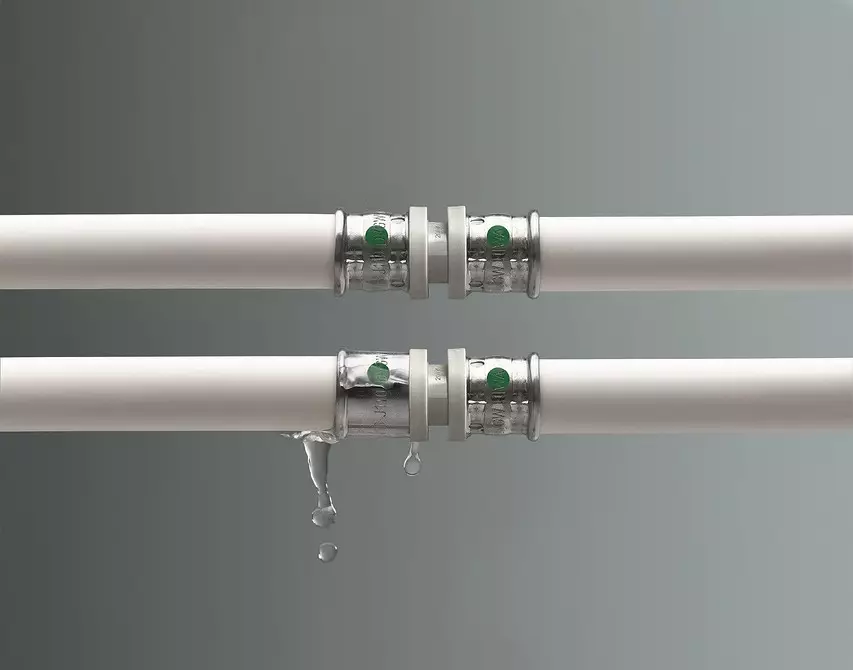

Pipes should not be bent or tensile load; Do not deviate from the fitting axis. Photo: Viega.

Get pipes and during operation. Freezing, exposure to ultraviolet, excess of the maximum allowable pressure during hydraulic tests - all this can be fraught with the output of the pipe output.

How to put pipes

Here recommendations will be the simplest: installers must clearly follow the rules for laying pipes of a type or other type and be neat when working. It is impossible to use excessive force, and when working only use a good tool. Some types of fittings require a special tool that can cost expensive. But you should not refuse it. In the extreme case, the tool can be rented.

Among sufficiently common mistakes can be called the installation of pipes without taking into account their temperature coefficients of linear expansion. In polymeric materials, it is high enough. If, for example, a submarine from the collector to the heating device is in a straight line, and its length exceeds 5 m, then the temperature deformations will be fully transmitted to the attachment node to the heating device. You can avoid this using some simple techniques.

1. Put the supply from the reservoir to the heating device with a turn of 90 °, leaving a straight plot in front of the radiator not more than 1.5 m.

2. Fix the attachment attachment node.

3. Decorate the end of the connecting tubes with the radiator.

With an open gasket of polymer pipelines, temperature elongations should be calculated and compensated by using G-and P-shaped compensators, fixing gutters and fixed supports or use metal-polymer pipelines.

Sergey Bulkin

Head of Technical Support Group Direction "Engineering Systems" of Rehau