Dry collection ties are widely used both when repairing apartments and country construction. Let's talk about the benefits and disadvantages of the dry screed, as well as the nuances of the installation that affect its properties and durability.

Photo: Knauf.

As a rule, clean gear can not be treated directly to the overlap. The latter is rarely quite even for this, and besides, it can be badly isolate sound and warm. To correct these disadvantages, a rough layer is needed, a popular variety of which is dry screed.

You can make a tie of this type in the apartment in two or three days (two installers for a working shift are assembled on average 30-40 m2 of the floor), and the labor costs are almost independent of the layer thickness. It does not require drying, combined with most flooring, perfectly isolates heat and noise - both shock and air. Dry screed allows you to save money and indispensable if you need to significantly raise the floor level or smooth out big irregularities.

Photo: Quick-Step

Construction standards (in particular, SP 29.13330.2011) Recommend to apply it in cases where it is necessary to avoid wet processes and speed up the production of work. But for the screed to cope with his task and did not require repair a few years later, it is necessary to choose the right materials and prevent marriage when installing.

Tasks and solutions

Dry screed can serve various purposes, depending on which its components are selected.Alignment of overlapping and raising floor level

With this task perfectly copes the "classic" design. Its bottom layer is performed from a special ceramzitic backfill, and the upper - from durable sheets on a plaster or cement basis (most often GVLV with a thickness of 10 mm), which laid at least two layers. The easiest way is in installing special elements of the floor Knauf with a mounting folding 50 mm width. The minimum thickness of the flowing screed is 40 mm, and the maximum is 100 mm. This type of draft floor is suitable for both plane and beam overlaps (monolithic, prefab, wooden with pavement, etc.).

Improved overlap characteristics

Keramzit fishing makes it possible to eliminate significant irregularities and the level of base levels, provides additional thermal insulation and satisfactory protection against air and shock noise. However, if it is necessary to significantly improve the heat insulating ability of the overlap (as, for example, in apartments on the first floor) or provide additional sound insulation of 10 dB and more (let's say, in the room of a home theater or studio for music), other solutions and materials are applied.

Suppose the overlap does not have significant level drops, but only small irregularities. Then they are smoothed by the plate, and then fit the effective heat and sound insulation material - mineral wool plates of high density (Rockwool Flor Batts, Paroc SSB 1 or their analogs) or the sheets of extruded polystyrene foam; The thickness of this layer is usually 30-50 mm. On top, GVLV or other sheet material are fond.

Photo: Classen.

If the overlapping deviates from the horizontal or there is a ledge, mounted a multilayer design, consisting (bottom-up) from backfill, laying sheets, heat-and-and-fluent mats and two layers of GVL. Instead of elements of the floor and dry-fiber sheets during the installation of the heat-sounding screed, the Faneur, chipboard and other wood-based plates are sometimes used, but only if we are talking about the permanent otap of the apartment or cottage. Before installation, any leafy materials need to withstand in the room at least three days.

Creating a base for tile

Dry screed has another one, a rather specific scope of application - preparation of the board for laying ceramic coatings (in a bathroom, hallway, a cuisine of a country house). In such cases, a good service will serve hydrophobized chipboard, cement-based plates and a FSF plywood with a thickness of at least 10 mm. They are mounted using screws and / or adhesive without a substrate (heat and soundproofing layers in wooden floors usually have between beams).Installation of soundproofing tie

Passed in the thickness of the dry communication screed (pipes and cables) are required to be protected from damage using boxes and housings.

To avoid transmission of vibrations from the screed walls and on the contrary, the "border" from the narrow bands of the noise absorbing material is placed around the perimeter of the room. Photo: Rockwool.

Mats from stone fiber tightly customize to each other, cutting in size with a witty knife. Photo: Rockwool.

Phaneru laid into two layers, observing the disintegration of the joints and bonding the sheets of screws. Photo: Rockwool.

Flooring is mounted with indented walls, and then build up "border" to the height of the entire floor cake. Photo: Rockwool.

Typical errors when mounting dry screed

- The absence of a vaporizolation substrate - over time, the materials of the draft floor will raise moisture, and the fungus will be treated in its thicker, which will reduce the service life of the structure and will adversely affect the microclimate indoors.

- The use of unsuitable backfills, such as large-scale clay gravel or sand with an admixture of clay, is the likelihood of uneven shrinkage.

- The absence of compensation tape along the walls - with moisturizing the upper layer can be taken.

- Careless putty joints when using soft floor coatings - lines of lines of sheets will be well noticeable.

Montage dry tie

The dry screed device is proceeded after laying water, heating and sewer pipes, if they should be hidden under the project under the gender. Works are carried out in several stages.Preparation of the foundation

Before starting work, the overlap is cleaned of garbage, and the slots and joints of the slabs close the repair mixture on a cement basis. Next, it is necessary to take care of the isolation of the draft floor from vapors penetrating from the following premises. To do this, overlapping the bands of the polyethylene film, providing them with no less than 15 cm.

Structural Noise Protection

This task is solved using the edge ribbon from foamed polyethylene or technical cork (tape thickness of at least 10 mm). It is allowed along the walls around the perimeter of the room. Another ribbon feature is to compensate for the extension of the top layer of the screed when the humidity changes.

Photo: Quick-Step

The advantages of complete systems, which represents the company KNAUF, is that they are present everything you need for assembling design, and the components are ideally compatible, and the installation is clearly regulated. The substrate and the edge tape are provided, the optimal fraction of claying gravel is selected.

The system of OP 131 "Vega" in combination with a stove of overlapping 140-200 mm thick has characteristics, significantly exceeding the requirements of construction norms (air noise isolation indexes RW - 52-57 dB, index of the LNW shock noise level - 56-60 dB). In this case, the mass of 1 m2 screed with a thickness of 50 mm is only about 40 kg / m2.

Denis Izhutov

Product manager of the company "Knauf Gyps"

Determining the level of the screed

With a "folding" of the zero level, they come from the minimally permissible local screed thickness, which is 40 mm - both for a conventional flowing design and for the heat-sounding. With the help of a laser leveling on the walls, marks are applied and lay beacons from rails or metal profiles. When determining the design level of the floor, a shrinkage should be taken into account, which depends on the thickness and quality of aligning backfill. To reduce the possibility of such changes, the backfill is desirable to compact with a special hand roller.Laying the main layers

Bulk material is spilled by the lighthouses by the rule, and then in two layers (necessarily with the disintegration of the joints) put moisture-resistant sheets, gluing layers of mastic and fasten them with screws. If soft materials (carpet, PVC tile) are used for the floor covering of the floor, the joints of G Clap with a gypsum-polymer putty. Under the thin-layer commercial linoleum requires additionally alignment of the screed with a solid layer of solution.

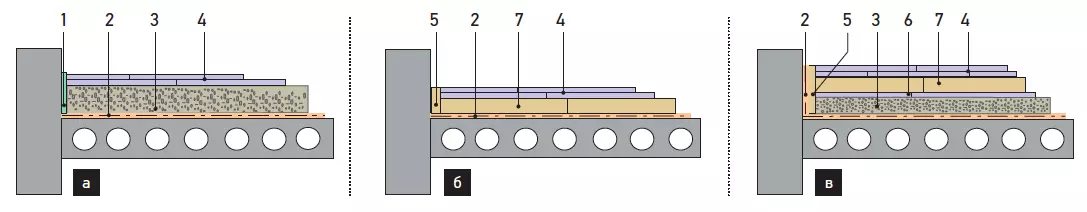

Dry screed design options

"Classical" leveling (a), heat-violating (b), leveling and heat-violating (B). 1. The edge tape of polyethylene foam is 3-5 mm thick. 2. Polyethylene film 3. Flipping from calibrated clay gravel. 4. Moisture-resistant gypsum fiber sheets with a thickness of 12.5 mm, laid in two layers and fastened by self-drawing and adhesive mastic. 5. Noise absorbing high-density mat from mineral wool with a thickness of 20 mm. 6. The separation layer of GVLV is 12.5 mm thick. 7. Mat from mineral wool with a thickness of 30-50 mm. Visualization: Vladimir Grigoriev / Burda Media

| Pluses dry tie | Minuses dry tie |

|---|---|

High erection rate and the opportunity almost immediately (after 24 hours) to be flattened. | The screed with backfill is poorly tolerance; When it is used in the bathrooms, waterproofing is required (for example, coating). |

| The possibility without a significant increase in labor costs to eliminate significant level differences. | Filing screed cannot be operated in rooms with vibration loads on the floor. |

| A small mass that allows you to use the design in houses with weak floors. | Installation of heating elements (both water and electric) in the thickness of the basement of the floor requires non-standard structural solutions. |

| The lack of wet processes and, accordingly, the risk of leaks in the apartment below. | |

| The possibility of laying communications in the thickness of the backfill. | |

| High maintainability compared to concrete tie. | |

| Good heat and soundproofing indicators. |

Montage of the dry screed "Vega" (OP 131)

When installing a dry screed, first of all, the overlap is tightened with polyethylene film. Photo: Knauf.

Then the self-adhesive edge ribbon is fixed to the walls. Photo: Knauf.

Next, clamzite gravel falls asleep and smash it with a special rule with supporting straps and bubble levels. Photo: Knauf.

Finally mounted floor elements. Photo: Knauf.

And put the coating. Photo: Knauf.