Home masters are likely to need expert advice. In this article, you can find the recommendations of Estima Ceramica specialists in laying a porcelain stoneware.

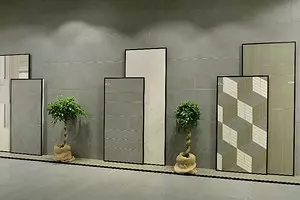

Photo: Estima Ceramica

First of all, you should know that the porcelain tile for walls or floor is a coating that gives the construction design of protective-decorative properties.

The structure of the lined construction includes:

- base;

- glue composition layer;

- Facial coating of porcelain tiles.

Before starting tile work, it is necessary to prepare the basis. A good reason should be durable, dry, degreased. The base should also be released from free particles - dust, sawdust, old peeling paint and other contaminants.

In addition, before starting styling, the tiles should be made in terms of the base. The deviation along the surface plane should not exceed 2 mm by 2 meters.

The next stage is the primer of the base. The primer composition strengthens the base, filling the microdefects. In addition, the priming procedure is performed to normalize the absorption capacity of the base to the adhesive composition. After complete drying, the primer can be processed directly to laying the porcelain tile. But first you need to open the boxes with a tile, decompose it on the floor and think over the laying scheme. This is done if you need to select a tile pattern or when laying a varnotonic material.

Photo: Estima Ceramica

Next, you should decide on the adhesive composition. It is very important here to remember that porcelain stoneware, in contrast to ceramic tiles, is characterized by extremely small absorbent ability. For example, in the porcelain stoneware production of TM Estima®, the water absorption indicator does not exceed 0.07%. It follows from this that, for reliable fixation of the porcelain tile, it is necessary to adhesions with higher adhesion (adhesive ability), as those used when cladding with ceramic tiles. By the way, most of the well-known construction chemistry producers produce universal adhesive compositions, intended for laying both porcelain stoneware and ceramic tiles.

Photo: Estima Ceramica

Estima Ceramica Experts for working with porcelain are recommended enhanced (high adhesive) dry adhesive mixture, which refers to C1 class. The index "C" means "cement", and the indicator "1" indicates that for separation from the base of the 10x10 cm tile format, an effort of at least 50 kg should be applied. Such adhesion is enough to reliably fasten the small and medium-sized porrite.

For lining of the base, large-format porcelain is required adhesive with higher adhesion. To obtain it, it is recommended to mix glue composition related to C1 class, with a latex additive. The resulting "cocktail" has greater elasticity, and its adhesion corresponds to the C2 class. This means that for separation from the base of the tile 10x10 cm, an effort of at least 100 kg will be required.

The process of preparing cement tile glue is not different from obtaining solutions of other dry building mixtures. The contents of the bag is inducing with water (if necessary, a latex additive is introduced into the mixture) and is continuously stirred by an electric door with a mixing nozzle until a homogeneous mass is obtained. Then the solution must be withstanding for 5-10 minutes, the adhesive is ready for use after re-stirring.

Photo: Estima Ceramica

We proceed to apply glue. Works on laying tiles are performed at ambient temperature from +5 ° C to +40 ° C. The adhesive composition is evenly distributed on the surface of the base with a steel spatula. Then the glue layer is leveled with a toothed spatula. This tool generates a uniform thickness of the adhesive layer, not allowing the formation under the tile of emptiness, and removes the excess glue. The size of the spatula tooth is selected depending on the size of the tile. For the tile of small and medium format, a spatula with a height of a teeth is 6 mm. For laying of large-format porcelain stoneware, a spatula with teeth is 12-15 mm.

Another subtlety: when laying a large-format porcelain stoneware to achieve the best result, it is better to apply glue on both the base and on the tile.

After laying the tile there are no more than 40 minutes in order to adjust its position (if required).

Photo: Estima Ceramica

Laying porcelain stoneware: with seam or without a seam?

Currently, it is possible to meet a porcelain stoves made by both ways. At the same time, it is recommended to provide for gaps between tiles. They are needed to reduce deformation loads. Such loads occur during the shrinkage of the base (new home) or in the case of increasing the temperature of the lining itself, for example, when it is heated with solar rays. In addition, the seams provide free migration of water vapor through the base. The width of the seams are chosen on the basis of the tile format.If it is assumed that the base and tile cladding will not be subject to deformation, then it can be limited to minimal gaps. To obtain cladding with seams of 1.75 mm, the floor alignment system is perfect. The system is used to perform high-quality floor lining and wall tiles with a thickness of 3-14 mm.

For the meaningful word "system" hides the simplest and ingenious device. It includes only three plastic parts:

- The base is a disposable rack;

- Cap of reusable;

- Nut-washer, also reusable.

Stand base has:

- threaded part;

- Conductor defining the width of the gap;

- Hat.

Photo: Estima Ceramica

How is the floor alignment system?

After the tile is laid on the glue, the base-rack hat is supplied under it so that the conductor lies tightly to the tile end. Then the adjacent tile is stacked close to the conductor. Next, the cap is put on the rack. It is pressed against the surface of two adjacent tiles with a nut-washer acting as a valve "lamb" water tap.After a complete drying of the tile glue - it will take 24 hours - you need to knock off the cap along with the nut-washer using a rubber image. In this case, the base is broken above the conductor. The conductor itself will remain in the gap between the tiles.

Using this system you can align:

- Linear seam between two adjacent tiles. This technique is used when cladding with large-format porcelain;

- T-shaped seam between three adjacent tiles when performing figure lining;

- Conducting seam between four tiles. This method is applied when cladding in a small tile.

So, the porcelain stoneware is laid. It remains to fill the grinding gaps between the tiles. This operation can be started 24 hours after the end of laying tiles. But before, without waiting for a complete drying of the tiled adhesive, it should be cleaned with its surplus from the seams and remove the remains from the surface of the tile facing.

The selection of grout depends on the type of cladding, the width of the intercutric seams and the operating conditions. The most common grouts on a cement basis. Estima Ceramica experts recommend using precisely cement grouts. These compositions are distinguished by high performance and affordable price. Cement grouts do not fade, resistant to mechanical abrasion and the action of household detergents. Modern producers of dry mixes produce thicker compositions, both for narrow and wide seams.

Photo: Estima Ceramica

Filling the seams, the residues of the grouts are removed using special cleaning products. After that, it remains to wipe the lined surface with a wet woven napkin and ... admire the result of his works.

Recall that Estima Ceramica is the largest domestic manufacturer of ceramic granite. The company's products are well known not only in Russia, but also abroad, exported to more than 50 countries of the world.