Excess moisture in the bathrooms and kitchens is often the cause of premature destruction of decorative decorations, carrying structures, and is also fraught with leaks and bays of neighboring apartments. Avoiding these problems will help competently made waterproofing wet zones.

Photo: shutterstock / fotodom.ru

How to protect wet zones from excess moisture

In the bathrooms and kitchens, the concentration of water vapor in the air is much higher than in other rooms of the apartment, which is due to the use of large volumes of hot water. On the walls near the baths and the shells periodically enter the jet of water. On other surfaces, condensate often settles, which we notice when fogging mirrors and windows. Yes, and the floor is often wet. Therefore, even waterproof cladding from ceramic tiles or plastic panels cannot guarantee one hundred percent protection against moisture penetration. As a result, the colonies of fungi and mold are formed on raw surfaces. Gradually begins to determine the finish, and over time, even enclosing structures.

Waterproofing walls and floors will avoid the negative consequences of high humidity in the premises of apartments and houses. Let's talk about the most convenient in the use of finished polymer waterproofing compositions.

It is the most convenient to use for this purpose the coating materials: bitumen mastic, cement mixtures, two-component cement-polymer and ready-made polymer compositions. The latter are most technologically designed not only for non-deformable bases (concrete, foam and aerated concrete, brick, cement, cement-sand and cement-lime, gypsum, from PGP), but also for complex, deforming (GCL, GVL, CML, CSP , OSB, Wooden).

By the way, the maternity owners can use waterproofing and in residential premises of the apartment. Then the risk of the bay of neighbors in emergency situations or during the device was a wet screed, entailing considerable expenses, will be minimized. In this case, instead of polymer mixtures, it is better to choose more democratic in the price of a cement-based mixture, for example Hydrostop (Bergauf), UE. 20 kg - 578 rubles, "Hydroplast" (UNIS), UE. 20 kg - 670 rubles.

Ready waterproofing formulations are easier than others to use. To apply them, it is not necessary to have special skills. These materials are most effective in bathrooms and kitchens, but they can not be used in rooms with very high humidity and constant capillary moisture sacrum (for example, in basements). In this case, it is worth choosing traditional rolled waterproofing. It is worth warming from a common mistake when, after using the finished composition, the negligent workers suddenly remember that they needed something to finish, drill, stamp, etc. These actions, as well as the drop in tools can disrupt the integrity of the protective layer. Therefore, in the room, the surface of which is covered with a thin waterproofing layer, one should not carry out any additional work, except for mounting the facing.

Ivan Hrpunov

Technical specialist of the company "Kashirsky Dvor"

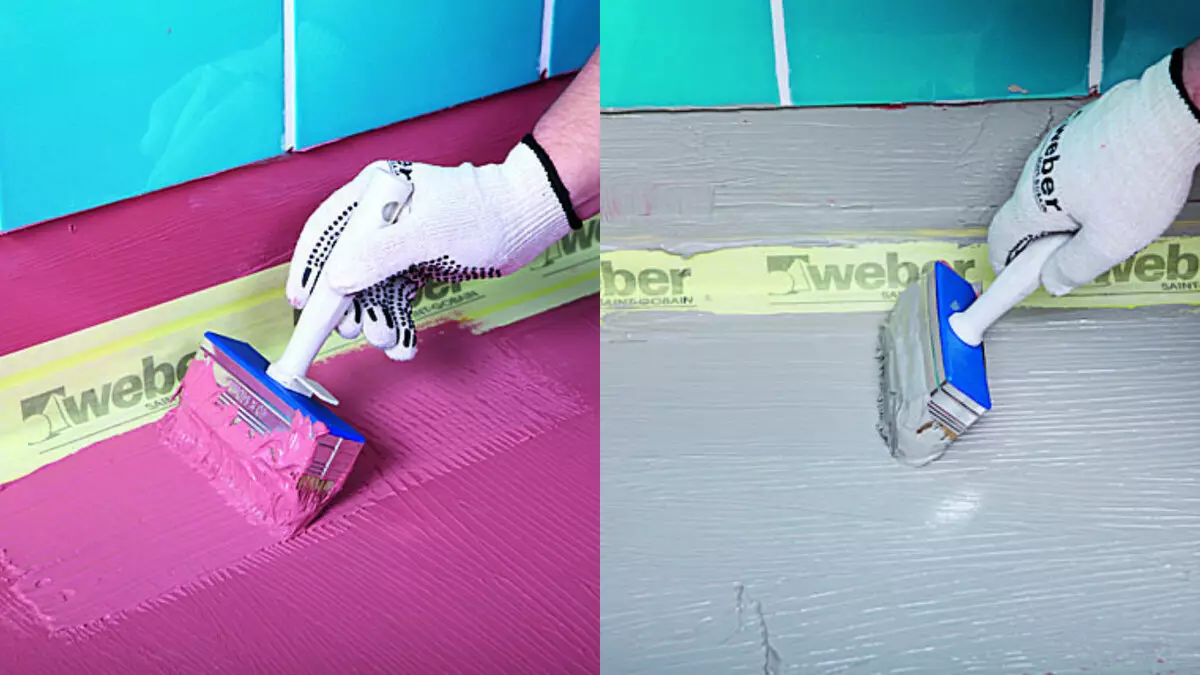

The waterproofing composition of Weber.tec 822 ("Saint-Goben") produce gray and pink colors. At first, the base is covered with a mass of pink color, and after drying it (after 2-4 h) - gray. The contrast between the layers helps not to make skips and better control the uniformity of application. Photo: "Saint-Goben"

Benefits of waterproofing compositions

Polymer waterproofing compositions are ready for use are aqueous dispersion based on synthetic resins that do not contain solvents. Unlike dry mixtures, it does not need time and additional efforts for their preparation. And unscrupulous workers cannot worsen the properties of the compositions, changing the ratio of the source materials recommended by the manufacturer. (Of course, if it does not come to mind to add something into the plastic mass.)Finished waterproofing is applied with brush, roller, spatula, and sometimes the sprayer is evenly without spaces. After hardening, a thin (0.5-1 mm) is formed, a durable, vapor-permeable layer, which reliably protects the base from the negative effects of water. When choosing the composition is worth paying attention to the range of operating temperatures. Some materials can only be applied in heated rooms. Others do not lose properties on balconies, in garages, in wet areas of seasonal houses. As for the conditions for the application of waterproofing, at this time and within 2 days after the end of operation, the temperature of the base and air should be at least 5 ° C and not more than 30 ° C. It should be remembered that low air temperature increases the drying time of the composition, high - reduces. For example, a two-millimeter layer of the MAPEGUM WPS (MAPEI) liquid membrane at 23 ° C completely dries in 5 hours, and at 5 ° C - for 12 hours.

PROS | MINUSES |

| Have a high adhesion to the grounds from different materials, including wood, GKL, GVL, etc. | It is expensive. |

They have good elasticity and are suitable for complex, deformable grounds. | Some formulations have a limited area of application, as a rule, they cannot be used in unheated premises, with the arrangement of bowls, etc. |

Economical. | |

Convenient for applying. | |

Have high thixotropy, they are well idle both horizontal and vertical surfaces. | |

Quickly dry. | |

Eco-friendly, harmless in work and operation. | |

Most permissible to apply on heating screed. | |

Quickly gain strength, reduce the time of repair work. |

Preparation of surfaces for waterproofing work

Waterproofing work before laying ceramic tiles start with surface preparation. If necessary, substances remove substances that weaken the adhesion of the composition to the base: fat, dust, old coating. Orthodox and cracks on the walls and half align. The first - moisture-proof plaster, the second - self-leveling bulk mixture. After that, the composition recommended by the manufacturer of waterproofing is grounded, taking into account the type of base. For weakly and moderately absorbing - one, for hard absorbing - others.

Typically, waterproofing covers all planes of walls and floor. However, it is permissible to apply a solid layer on the floor with a wall at the wall (at a height of 10 cm) around the perimeter and in the area of so-called wet zones: a bathroom, shower, sinks. After pre-calculating the total area of these sites, it will be possible to purchase a smaller waterproofing packaging.

Note that, due to the long viability of waterproofing in the bucket, you can work as much as you need. The remaining material should be used for several months (of course, if it was stored in a hermetically closed original packaging at a temperature recommended by the manufacturer) and do not worry that it will lose work properties.

How to keep seat tightness

The joints of horizontal and vertical surfaces, including from two heterogeneous materials, such as concrete floor and walls from GLC, are called conditionally moving. Due to the difference in the expansion of materials in these places, cracks are often formed, instilling with water. In order for the waterproofing layer to power the load on the gap, the internal and external angles, the walls of the wall / wall, the wall / floor, the places of the seams and the joints of the base surfaces are sampled by a special elastic ribbon. It is a grid of polyester with a waterproof coating of a thermoplastic elastomer, which is stretched with the discrepancy between the structures and is compressed after their return to the place, while maintaining the tightness of the joints.

Ribbons waterproofing size 0.12 × 10 m: Litoband R10 (Litokol) (1 pc. - 1404 rub.) Photo: Litokol; Knauf Flakendichtband (1 pc. - 985 rub.) (Upstairs on the right). Photo: Knauf; Weber.tec 828 DB 75 ("Saint-Goben") (1 pc. - 1100 rub.). Photo: Saint-Goben (below left); Dichtband DB 70 (Murexin) (1 pc. - 2014 rub.), Photo: Murexin; .

Photo: Knauf.

Photo: "Saint-Goben"

Photo: "Best"

Photo: Henkel

Photo: Mapei.

Photo: Litokol

Photo: Murexin.

Characteristics of finished waterproofing compositions

Mark. | Flakelandicht | Weber.tec 822. | "Akvaskrin N64 " | Ceresit Cl 51. | Mapegum WPS. | Hidroflex. | Flüssigfolie 1ks. |

|---|---|---|---|---|---|---|---|

Manufacturer | Knauff | Saint-Goben | "Best" | Henkel | Mapei. | Litokol | Murexin. |

Consumption for 1 mm layer thickness, kg / m. | 0.7-1,4. | 1,2 | 0.4-0.7 | 1,4. | 1.5 | 2,3. | 1.5 |

Drying time before laying tiles no less, h | 12 | 24. | 12 | sixteen | 12-24 (four to five days for non-subsurrent bases) | 24. | 24. |

Permissible working temperature, ° C | From -20 up +80. | From -35 up +70. | From +5. up to +40. | From +5 to +30 | From -30 to +100 | From -30 up to +100 | From 0 to +70 |

Storage time of unborn packaging, month. | eighteen | 12 | 24. | 12 | 24. | 24. | 12 |

Packaging, kg. | five | eight | 4.5 | five | five | five | 7. |

price, rub. | 1302. | 2050. | 1111. | 1199. | 1412. | 2231. | 1306. |

Learn more about building materials on our website.