Modern systems of heating in country houses are distinguished by the complexity and length of pipelines, so the coolant is not able to circulate on them alone. For efficient heat exchange, special pumps are required - circulating

Photo: Legion-Media

In water heating systems, water (or rather, the heat carrier fluid) moves along a closed contour. From the device where heating occurs (for example, in a gas boiler heat exchanger), it comes to where he transfers the heat in the room - into radiators or, say, the pipes of a warm floor. Then the coolant returns back to the boiler.

Circulation pump with a "wet" rotor Grundfos alpha3, the case is made of cast iron. Photo: Grundfos.

The coolant can move under the action of its own severity (that is, gravity forces). Imagine a boiler and radiator in the form of two communicating vessels. A fold of a colder and heavy liquid in the radiator gradually displaces the hot and lightweight liquid from the boiler heater. This method of moving the coolant is called gravitational. His main advantage is simplicity.

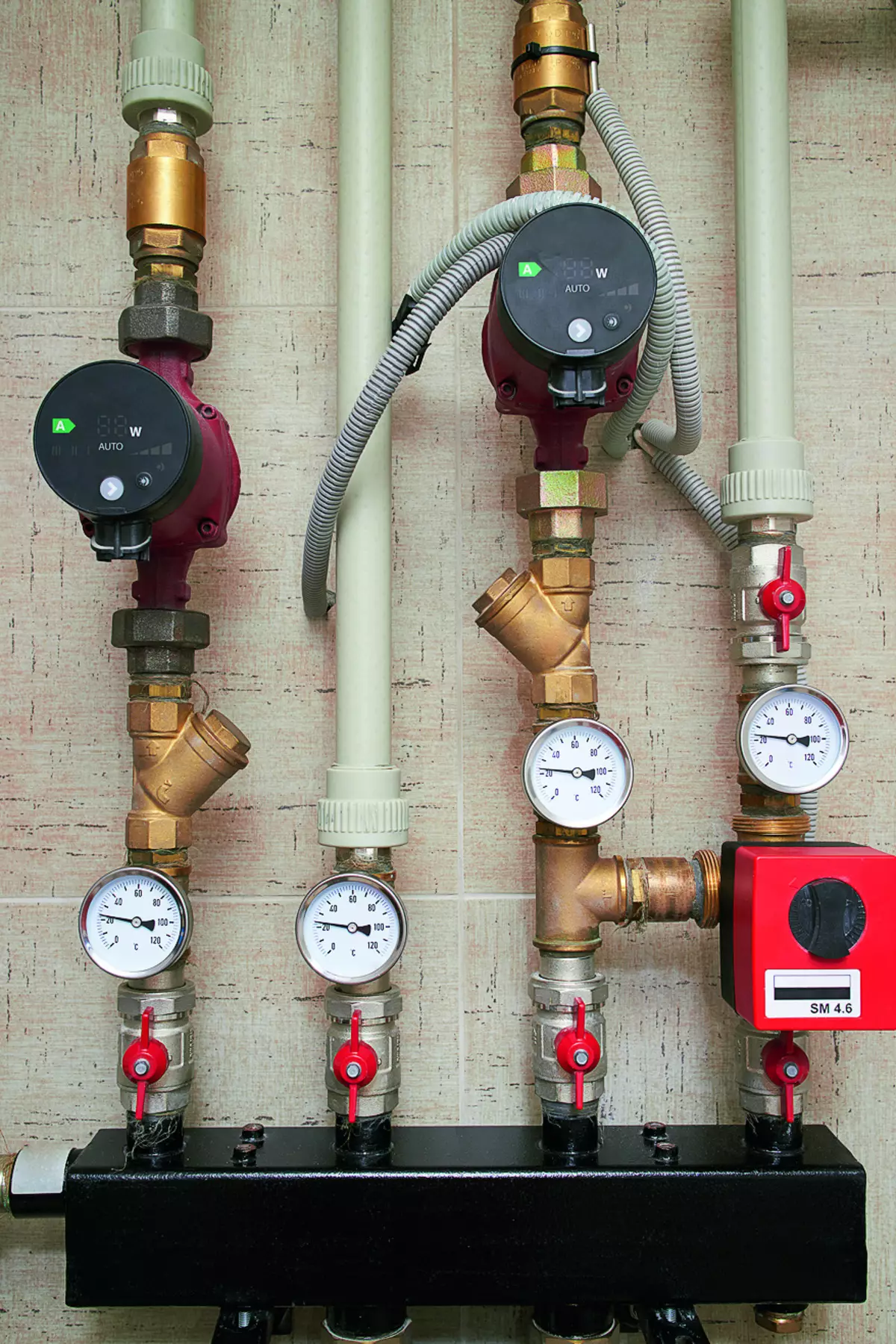

Photo: Aleksey stemmer / fotolia.com

But in practice, it is not always possible to resort to the gravitational method. It is not suitable for high-length pipelines (over 30 m), moreover, limits their geometry (large diameter pipes are required, laid with a strictly defined bias). Therefore, today is often used by a system with forced circulation of the coolant by means of a circulation pump.

Circulation pump "Belamin" BRS 32 / 4G (consumption up to 2.8 m3 / h). Photo: Boris Bezel / Burda Media

When installing the circulation pump, the engine shaft must be located strictly horizontally; Otherwise, the efficiency of work will be reduced, while the pump may overheat

Such design pumps are slightly different from drainage or well models. Equipment, as a rule, does not require a large pressure or high performance. But the pumps should be extremely reliable and durable, because the cycle of their work does not last hours or a day, and several months - that is, as much as the heating season continues. In addition, circulating pumps should be well transferred to constant heating (the temperature of the coolant can reach 80 ° C and higher), as well as contact with chemically aggressive compounds included in the coolant.

Additional equipment requirements are economy (even a small electric motor for six months of continuous operation is able to burn a lot of electricity) and the minimum noise level when working. So any circulation pump, despite the seeming simplicity of the design, is a rather complicated and high-tech unit.

Among the circulation pumps presented on the circulation pump market are the most popular products of Grundfos, Dab, Wilo, Unipump, they are competing cheaper products of domestic producers - "whirlwind", "Jelax", "Kalibr", as well as Chinese-made technician.

Some seven times

When choosing circulation pumps, oriented to the parameters used for all devices that pump fluids - the required pressure and submission (consumption). Feed is the amount of fluid pumped per unit of time. The pressure is called the increment of fluid pressure, created by the pump operation. The supply and pressure is calculated during the hydraulic calculation of the heating system.Household circulation pumps are not distinguished by high performance - consumption averages 2-4 m3 / h, pressure - from 4 to 8 m. As for geometric sizes, they are unified. The pumps differ in the diameter of the connected pipes (household from 0.5 to 1.5 inches) and the mounting length (the distance between the ends of the pipes for connected pipes).

The standard mounting length in most models is 180 mm, but "shortened" variants are also available, for example 130 or 160 mm. This characteristic is usually (but not always) indicated in the articula of the model. However, with the transition to metal-plastic and polymer pipes, it is largely losing relevance. All circulation pumps are divided into two types: with Šmochem <and Šsukhim <rotor. In general, the first type equipment is used. In such devices, the electric motor is lubricated and cooled with a fluid moved.

This design is characterized by compactness and simplicity, but its efficiency (approximately 50%) is lower than that of the console type pumps with ŠChim <rotor (80%). Almost all models of circulation pumps are capable of pumping very hot (up to 110 ° C) fluid. But with cold water there may be problems. After all, most models are designed for fluid temperature not lower than 10 ° C. Therefore, if in the winter you plan to turn off heating and then run it, choose models capable of pumping "non-freezing" with a temperature from -25 ° C (for example, Grundfos UPS 32-60 180) or at least from -10 ° C (say, Wilo Star-RS 30/6 or similar).

How to save 20% fuel? Balancing of radiators of the two-pipe heating system means the optimal distribution of the coolant flows in them. If it is not done, the pump will work with elevated wear and energy consumption, in the adjacent boiler room will be hot, and in the rest of the rooms it is cold. A competently established system saves up to 20% of the cost of fuel and electricity. The usual setup of equipment in balancing the heating systems caused difficulties even from professionals, but now this work is under the power of every specialist in the installation of equipment and homeowner. It is enough to install a new Alpha3 pump with Alpha Reader communication module, download the Smartphone or tablet Grundfos Go Balance application and follow a simple step-by-step instruction. Thus, the balancing of the heating system in the house of about 200 m² takes only about an hour.

Ekaterina Semenova, Engineer Department of Equipment for Private Houses

Grundfos.

Efficiency is exceeded

The main advantage of modern models of circulation pumps is economy. This property is especially noticeable when using intelligent heating systems, which require the performance of the pump, depending on the load of the system, weather on the street, time of day and a number of other variable factors. Most circulating pumps support several rotor rotation rates (usually three). Electronic control systems help reduce or increase speed depending on the needs of heating.

Thus, the WILO-STRATOS PICO-SMARTHOME circulation pump is equipped with a Dynamic Adapt control function (dynamic parameter of the operating point in the partial loading zone of the pump), which reduces the electricity consumption and the energy efficiency of the system is reduced. Convenient control using a home computer, a tablet or smartphone allows real-time control of energy consumption in real time, and in case of malfunction, the system informs the equipment owner.

Intelligent management systems are also used in Grundfos models. The Comfort series has the AUTOADAPT function, with which the pump for 2 weeks tracks the needs of homeowing at water consumption and adapts to them. Compared to conventional pumps operating at one speed, such equipment can reduce costs by 96%. Moreover, the savings of thermal energy can be up to 48%.

Today, the Grundfos series Alpha3 series is considered advanced. They provide three fixed rotational speeds, three modes of maintaining a constant pressure drop, three modes of proportional to regulation of the pressure drop, as well as the functions of the automatic transition to night mode and summer spending. In addition, Alpha3 pumps make it possible to carry out professional hydraulic balancing of a two-pipe heating system.

Do not forget about noise

If the circulation pump is supposed to be installed in a residential building, for example, near the bedrooms, then when selecting equipment, be sure to pay attention to the noise level created by it when working. After all, in night silence, even weak sounds can be annoyingly unpleasant, which, by the way, is well known to manufacturers. That is why most models of circulating pumps for domestic use are distinguished by low noise levels, approximately 45 dB.

Nevertheless, noise during the operation of some devices reaches about 65 dB. When installing such pumps, you may have to provide for effective noise protection.

Photo: SegenVitaly / Fotolia.com

It is important to choose the right mode.

Modern circulating pumps with electronic speed adjustment are capable of supporting several different modes of operation. Thus, users of the GRUNDFOS series of the Alpha2 L series have the opportunity to choose one of the three options:Proportional pressure mode

The pump pressure is reduced by reducing the coolant consumption, thereby minimizes hydraulic noise in pipelines. This option is optimal when placing equipment near residential rooms.

Permanent pressure mode

The pump provides constant pressure regardless of the flow of the coolant. Such a regime is recommended to use in the "warm floor" systems and in two-pipe systems with rarely changing coolant consumption.Mode with constant rotation frequency

Such a mode provides high pump efficiency.

Characteristics of circulating pumps

| Model | Alt 32 / 6-180 | "Circul 25-40" | BRS 32 / 4G | UPC 25-40 | STAR-RS 25/4 | UPS 25-40 180. |

|---|---|---|---|---|---|---|

| Mark. | Altstream | "Dzhelex" | Belamin | Unipump | Wilo. | Grundfos. |

| Consumption, m3 / h | 3,3. | 3. | 2.8. | 3.7. | 3. | 2.72 |

| Head, M. | 6. | four | four | four | four | four |

| Noise level, dB | There is no data | 65. | There is no data | There is no data | There is no data | 35. |

| Power, W | 93. | 65. | 72. | 62. | 68. | 45. |

| Diameter of the connector, inches | 2. | one | 1.25 | 1.5 | one | 1.5 |

| price, rub. | 3300. | 3400. | 3500. | 3900. | 5900. | 6400. |

Pump Installation Recommendations

Before or after the boiler?

The circulation pump should be installed on the return highway. In this case, the pump will constantly contact with less hot fluid, which is favorable for long equipment eternity. In addition, if the pump serves water into the boiler, and does not pump it, then the likelihood of vacuum formation and boiler overheating is reduced.Do I need to arrange bypass for the coolant?

It is advisable to make a distribution (bypass), as it allows the coolant to circulate even when the pump is disconnected due to the malfunction or absence of electricity on the network. Of course, the movement of the sickness will not be effective enough, but in the case of any state of emergency, this option is still better than simple in work.

Do I need protection from dirt?

The circulation pump is poorly to enter the contact of small solid particles, so the mesh filter is installed at the input.

Installation of the pump is simplified due to the standard distance between the ends of the inlet and outlet nozzles. Photo: Grundfos.

Alpha Reader communication module is used to balancing the hydraulic system. It is installed on the device case without additional connection, the data is transmitted via Wi-Fi. Photo: Grundfos.

Model BIRAL M 15-1 (consumption up to 8 m3 / h). Photo: Boris Bezel / Burda Media