As a rule, the main reason for the troubles occurring with wood, as well as coal and pellet fireplaces and furnaces, "hiding" in the smoke tube. The beginning of the heating season is not far from around the corner, and we decided to find out how to avoid mistakes in the design of the chimney and correct the already admitted.

Today, structures from sandwich modules (steel + insulation) came to replace the brick tubes. In compliance with production and assembly technologies, they provide fire safety and excellent traction. However, sometimes the chimney refuses to work properly. On the forum of IVD.ru website and specialized Internet resources for heating, we chose the descriptions of the symptoms of the most common "diseases" of chimneys. In the formulation of "diagnoses" and the search for "drugs", engineers of production companies and practitioners have helped us.

Photo: Stuv.

The fireplace is badly melting, the firewood is not lit, and the glass of the furnace door is quickly covered with soak, through the holes for the air, the streams of smoke break through.

Photo: jeremias.

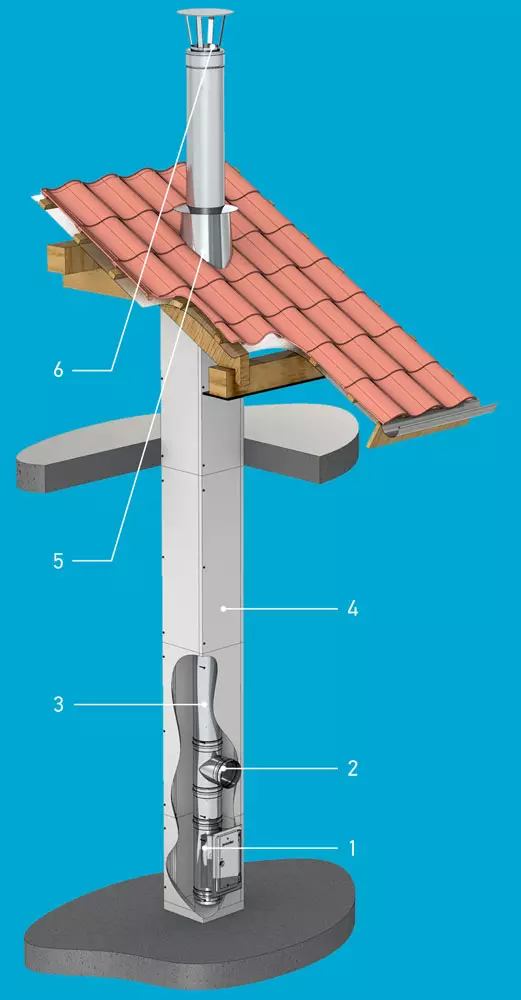

An embodiment of the design of the direct-flow internal chimney of stainless steel: 1 - revision with the drive for condensate; 2 - a tee for connecting to a furnace or a fireplace; 3 - insulated tube; 4 - decorations of GVL or CSP; 5 - passing waterproofing module; 6 - Umbrella Deflector

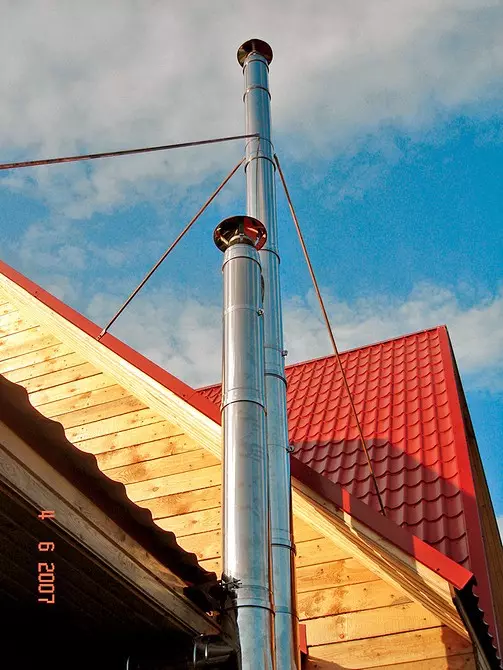

Listed signs of bad thrust. The most common cause is a strong pollution of the chimney. If smoking just built the fireplace, then the source of malfunctions can be chimney of insufficient length (less than 5 m), too much knees, narrowing and extended horizontal sections. In case of insufficient thrust, it is often helped by an increase in the height of the pipe for 1-2 m, and only well insulated modules must be used and attach the increasing to the construction of the building with cable stretch marks or studs so that it is not demolished by the wind. If after that the traction is not normalized, the chimney needs a complete reconstruction - an increase in the diameter and hidden the "highway". Another way is the installation of electrodemost, but it has drawbacks (about devices for improving thrust we will describe separately).

The reason for the bad work of the chimney is most often the errors of designers and installers and only sometimes - manufacturers

As a rule, the fireplace is token normally, but there are large smoke clubs through the air holes.Such a phenomenon is called tipping thrust. It is possible that the chimney is incorrectly derived relative to the skate, and in the area of the head, the air flow currency is periodically directed downward. The probability of tipping the thrust of the wind increases with insufficient insulation of the top of the pipe: smoke has time to cool, the speed of its movement decreases sharply, and the wind gusts easily disrupt the fireplace. The cause of the trouble may be the nozzle-umbrella of an unsuccessful design that creates aerodynamic resistance.

Thermal warming helps solve the problem. If it is impossible to replace the upper modules, you should order a shell (outer casing), the diameter of which will allow you to mount an additional layer of thermal insulation with a thickness of 30-50 mm. It is better to use special insulation from basalt wool, such as Rockwool Fire BAtts (Nellgated). An additional protection against overturning thrust wind can be a vane deflector.

The fireplace consumes a lot of fuel and gives little heat.

The direct-current chimney of the round-section height of more than 6 m is often pulling too much, and slow down the burning is not possible, even completely closing the holes of the holes for air inflows (because the residual gap is always provided). In this case, the efficiency of the device turns out to be very low.

To regulate the thrust you need to install at the outlet of the sewer (alas, you will have to disassemble the entire pipe). In addition, heat-generating or heat accumulating modules in the lower part of the chimney will be useful. The first are equipped with metal ribs and operate on the principle of the radiator, the second two-axis, but the insulation is replaced with a stone crumb or pearlit sand.

Some sequigues are strongly heated, sometimes their temperature exceeds 100 ° C.

Most likely, this problem is caused by local thermal destruction or shrinkage of poor-quality insulation. The probability of disruption of the tightness of the inner pipe is small, but still it is impossible to exclude it. Overheating of the shell is dangerous, especially if there is a barbed design nearby (closer 0.5 m), because the cutting wood is capable of self-propagation at a relatively low temperature. In addition, the deterioration of thermal insulation leads to an increase in the number of smoke condensate: the capacity for it will quickly alter, and if equipment is installed, allowing to merge condensate into the sewer (neutralizer), the consumption of a costly reagent will increase.

Chimney with a similar defect should be replaced. As a temporary measure, it is possible to restrict ourselves to the installation of an additional thermally insioning casing (for example, from GWL, with a filling of stone cotton), but before it is necessary to check the state of the walls of the smoke channel - this service is provided service firms.

Incorrectly chosen deflector nozzle can cause sudden traction disorders and penetration into carbon monoxide residential

Once the pipe was very bad on all over, it was heard to crackle, the smell of a split metal appeared in the rooms. Then everything came to normal, only a galvanized umbrella darkened and began to rust.

Describes classic symptoms of fire fire in the pipe. Chimney from high-quality materials (working channel - stainless steel brand 321, 430 or 439 according to AISI classification, insulation - basalt or ceramic wool) is obliged to withstand such a test. After the incident, it takes some time to follow the gear temperature, and in addition, it is advisable to make a photo of the smoke channel. In general, the fire in the pipe is better not allowed for which it is enough once a year (when using long-burning furnaces - 2 times) clean the chimney.

After a few years of operation, through the joints, especially in the upper part of the chimney, in the attic, the condensation began to leak.

Obviously, the chimney is badly insulated, which causes the intensive formation of condensate, and at the same time incorrectly manufactured and assembled: its elements are oriented by crop down. (It is necessary that the detaching parts of the smoke channel are turned up.) Trying to compact the joints with the furnace sealant in this case it is useless. Chimney can be operated for some time, but, waiting for a warm season, it should be reconstructed.

In the spring, brown flots on the roof were visible, near the pipe.

Most likely, a significant umbrella is to blame, on the cold surfaces of which condensate fell. Even more eating fluid can be formed on the walls of a metal box with a roof arranged for several pipes (chimneys and exhaust). Such a box should be filled with clay almost to pipe sections, and the area of the umbrella is reduced. A little rain and snow harmlessly for chimney and heating equipment, but remove condensate traces almost impossible from the roofs and walls.

More traction

Quite often to adjust errors made in the design of the chimney, use special pipes for the pipe.

Floon deflector Closes the mouth of the chimney from horizontal and vortex air flows. It consists of a moving pin-fixed on the vertical axis, which is equipped with a "plumage", thanks to which the shield is located with a windward side of the pipe. With moderate wind, the deflector stabilizes and strengthens the thrust, much reducing the likelihood of its tipping.

Rotating deflector It is a spherical turbine. Under the influence of wind (regardless of direction), its blades rotate and create a vacuum in the pipe. Such devices have proven their effectiveness as elements of roofing ventilation systems. However, they are almost unsuitable for chimneys, since the pull is worsening cravings, and in winter they can get out, completely overlapping the path to smoke gases, which is extremely dangerous.

Electric Education The simplest design is a pipe nozzle with a fan whose blades rotate directly in the smoke channel. It is desirable that the performance of the device can be adjusted - thus, it will be possible to ensure quick extracts, and then measure the thrust.

The dymosos is reliable, since its moving parts are protected from moisture and sleep (as well as from the effects of caustic substances and high temperatures), economical (power consumption 40-100 W / h) and almost silent. Its main disadvantages are the need for periodic cleaning from resin and soot and the dependence on the power supply. However, the second drawback is easy to overcome by setting the backup source of energy. The smoke is sometimes used as a "medicine" with a bad line, but it is mainly designed for the convenience of using fireplaces with open firebox and island foci.

The deflector developed at the Central Aerohydro-Dynamic Institute (TsAGI) allows you to achieve satisfying thrust at the length of the chimney of only 3-4 m

Traces of condensate on the roof indicate errors when performing a passage node or choosing a ledge. Preferably to eliminate defect

The chimney for the fireplace with the factory fuel is collected from ready-made modules - pipes, knees, tees, adapters, etc. When installing, it is recommended to seal joints with heat-resistant sealant

A single stainless steel module changes color as a result of overheating, which practically does not affect the service life of the structure.

Condensate flutters through the joints of the casing pipes speak about the presence of serious defects

Located near the house, high trees during a strong wind can generate vortex air flows that are capable of tilting cravings for a short time.

Even a high-quality mineral-cotton insulation in sandwich modules is not more than 10 years, because it is exposed to extreme loads that causes fiber destruction.

And the deflector of the TsAGI (a), and the electric smoke (b) will have to shoot when it comes to clean the chimney, so the connection with the pipe should be easily the library

When smoking the chimney, the upper modules must be attached to the roof with durable stretch marks from steel cables or metal studs

Rotary deflector will not improve the work of the fireplace. This device is intended to increase the performance of hoods

Not all designs of vane deflectors are successful: some with sharp gusts work unstable, and in winter are covered with outflow and freeze. Even high-quality fluger needs maintenance - lubrication, cleaning against pollution