A short northern summer requires the dachas of the efficiency in solving the tasks of the life support of cottages, including water supply. If nearby is a well or, for example, a lake with clean water, then the pumping station will allow you to regulate the problem in almost one day.

Self-priming pumping installations are completely ready-to-use devices that do not require complex settings before commissioning and do not create special problems with connectivity. Usually they consist of three main nodes - self-priming pump, hydroaccumulator and control automation. A similar design is much more convenient than a single pump, since the tank and pressure switch allow you to optimize the work, reduce the load and increase the duration of the device and connected to it. Additional advantages of pumping installations - compactness and simplicity of installation. If necessary, they can be easily dismantled.

Photo: Kärcher.

Focus on details

Of all the design types of pumps (centrifugal, ejector, axial, screw, vibration, rotary, etc.) for domestic water supply are used mainly centrifugal, characterized by simplicity and high efficiency. Their working body is a rotating wheel with blades that report the kinetic energy to the flow of water. Centrifugal pumps are usually designed only for the pumping of clean water without sand and sludge, but the gearboxes or particles of scale can still get into the mechanism. Therefore, the service life of the technique largely depends on the material from which the impeller is manufactured.

Thus, stainless steel products are distinguished by durability, but also cost more than wheels from wear-resistant plastic, often used in household models. The pump housings can also be made from different materials: plastic, stainless steel, cast iron. On average, plastic products cost inexpensively and, importantly, have a low noise level. Steel - usually the most expensive and noisy, but also the most reliable. Cast iron enclosures on the same indicators occupy an intermediate position. It is worth noting that the ejector-type pumps used are less sensitive to the presence of contamination and air in water.

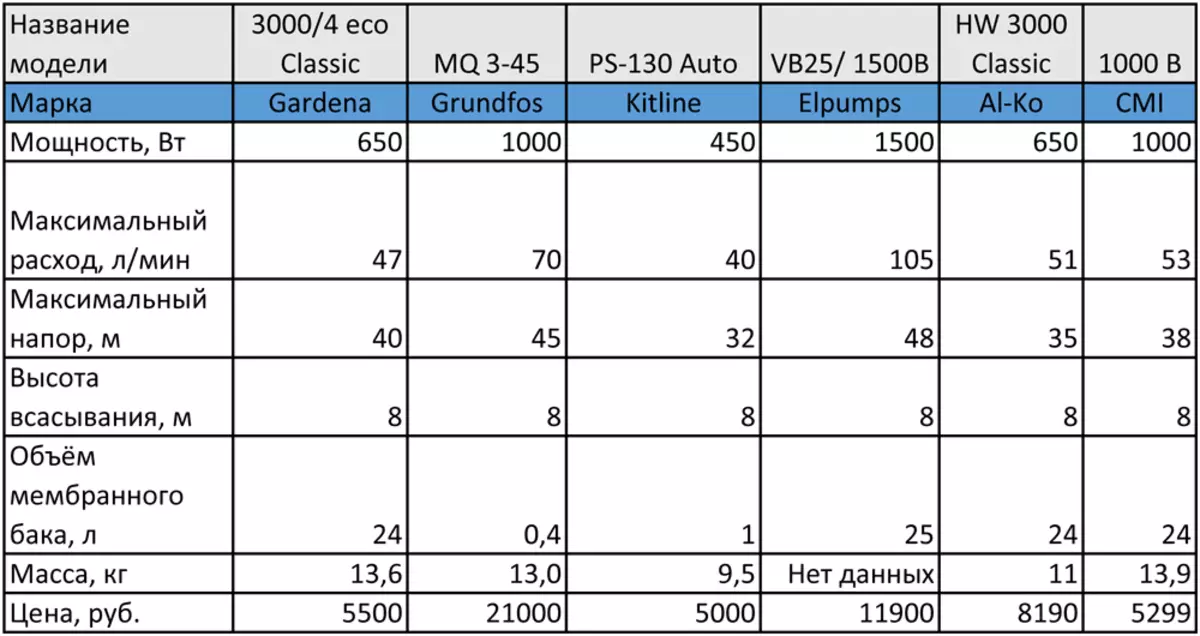

Asynchronous rotary engines, which are usually equipped with centrifugal pumps, are often produced in a "lightweight" version, with aluminum winding. This modification is cheaper, but, as a rule, the aluminum winding is less durable than copper. In addition, the copper winding engines are more economical and serve longer. With short-term inclusions, this difference is imperceptible, but in the mode of operation close to the round-the-clock, of course, you need an engine and a pump of increased reliability.

Each pump has the following physical characteristics: the pressure generated by it (height on which the device can raise water), flow or supply (water volume, pumpable per unit of time). It is important to remember that for pumps of any type and design of the pressure and consumption are in the inverse dependence: the higher the pressure, the less expense, and vice versa. This parameter is expressed graphically as a curve of the dependence of the flow rate. The curve must be specified in the product documentation.

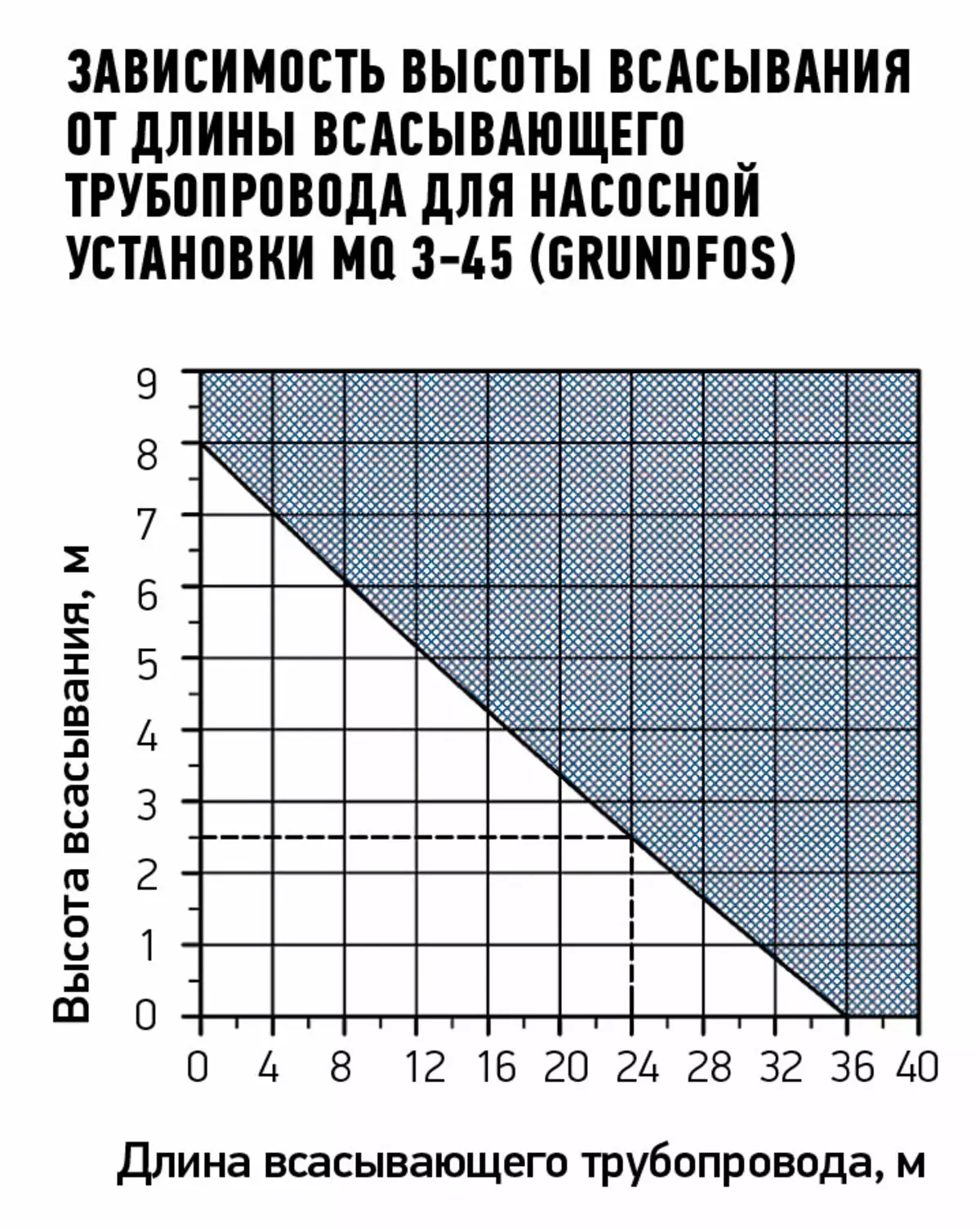

The self-priming pump is also characterized by the height of suction - the distance vertically from the level of the water mirror in the source to the inlet pipe of the pump. This value can reach 7-9 m. Not only the depth of water lifting, but also the maximum distance (horizontally) to place the pumping station depends. Hydraulic calculation of pressure loss in the suction water supply is sufficiently complicated, therefore usually use absorption diagrams. The larger the length of the horizontal portion of the suction water supply, the smaller the depth with which the pump is capable of lifting water. So, when installing directly above the source of water, the Grundfos MQ 3-45 automatic pump can raise water from a depth of 8 m. A while removing horizontally from the point of water intake, by 24 m, the depth of water lifting decreases to 2.5 m.

The membrane tank, or a hydroaccumulator, is a hermetic container separated into two parts by an elastic partition (membrane) and the pump connected to the output highway, which, in turn, is connected to the water supply. One part of the tank is filled with water, under pressure the elastic partition is deformed. When the pressure drops in the membrane plumbing, it is rectified by water from the hydroaccumulator. Thus, it is possible to avoid sharp pressure jumps in the system (hydraulic shocks) dangerous to the technique. In addition, a fluid supply is created in the hydroaccumulator, and therefore there is no need to turn on the pump provided that you spend less water than the useful volume of the tank. Usually this value does not exceed half of the total volume, therefore, let's say, with a 16-liter tank, you can roll out from the water supply system 8 liters of water. There is enough such a quantity to open and clear the water in the kitchen several times - wash the plate, dial the kettle, and the pump will not turn on. And the less often it turns on and off (ideally no more than 10-20 times a day), the longer will last.

What volume of the membrane tank is considered optimal? You can say "the more, the better", but to the known limits. Practice shows that the most convenient hydroaccumulator is designed for 16 or 24 liters. However, from the traditional membrane tank, it is possible to refuse if the pump engine is equipped with an electronic switching relay and a smooth starter automation that allows you to drastically reduce the volume (up to 0.5-1 l). It is such a tank (0.3 l) that the pump station MQ (Grundfos) is equipped, which is rightly considered one of the most compact. However, there are now other solutions, for example, AUPS-226 models ("pumps plus equipment"), PS-130 AUTO (Kitline) with a tank 2 liters appeared on the market.

The main difference between pumping stations from pumps - the first has equipment that allows them to work without constant control by the owners

Managing Automatics

In the simplest case, it means a mechanical (spring) pressure switch, which includes and turns off the pump at a certain pressure range on the network. Advanced pumps are equipped with an electronic relay with a duct sensor, which is considered more reliable and, as mentioned above, allows you to get rid of a bulky hydroaccumulator. Also in the package can include automatics of a protective disconnection when overheating of the pump, voltage drops on the network, the protection system from dry stroke. Otherwise, you will have to buy the necessary components yourself. Much depends on the nature of the work and quality of the power grid.For example, when the home network is equipped with a complex of special devices, then additional "personal" pump protection against voltage drops may not be needed. On protection against dry stroke (it will cost 3-5 thousand rubles.) You can save if the process of functioning the pump is constantly monitored. But with long autonomous work, of course, it is better not to risk.

From additional equipment, you must mention the check valve that prevents emptying of the water supply when the pump is turned off. The check valve is often included or acquired separately. It is installed on the entrance nozzle of the pump. Also, a coarse filter is mounted at the entrance, which prevents sacred insoluble particles into the pump. The system is usually equipped with a built-in pressure gauge, which greatly facilitates control of the pump.

All self-priming pumping stations must be installed on a horizontal base, the maximum bias should not exceed 6-7 °

Photo: Gardena.

The advantages of the pump station 3000/4 Eco Classic (GARDENA) (a) include a convenient water filling system (b), the presence of a built-in filter (B) and an economical mode (g)

Operation and service

Household self-priming pumping stations are usually designed to pump pure non-rigs (up to 35-40 ° C) water, so do not use them, let's say, as drainage installations. If during operation it is supposed to often transfer the pump (for example, from home to the garden and back), then it is better to choose a model convenient for transportation, not very massive and with the corresponding handles.

To bring the pump to action, it is necessary to pour into it a certain amount (4-5 liters) of water. The same may be required with a long break in the equipment. In addition, you need to adjust the pressure relay settings if this parameter in the plumbing differs from standard values (the inclusion pressure is 1.5 atm, the shutdown pressure is 3 atm). When the relay is mechanical, you should remove the protective casing and, rotating the adjusting nuts of the springs, manually set the necessary parameters.

In the electronic relay, the adjustment is made using the control panel.

The pumping station can be installed both indoors and outside - the equipment is unpretentious and usually has the degree of equipment protection not lower than IP x4. It is recommended only to use a canopy to protect against rain and direct sunlight. For winter conservation from the device, it is necessary to drain all the water. It is desirable that in the pump design of the pump, a special drainage, as in Gardena models. In this case, the emptying of the pump will not be difficult and you will not have to use spanners or some other devices - it is enough to unscrew the cork with your hands.

Pump superficial centrifugal with a plastic case "Jumbo 60/35 P" ("Dzhelex") and a pumping station "Jumbo 60/35 P-24" on its base

Pump installation MQ 3-45 (Grundfos) is one of the most compact, so it can be placed on a limited space at home and on the street

The pump station Hydrojet JPB 5/24 (Grundfos) (b) is equipped with a silent engine, as well as a membrane tank, designed for 24 liters

AL-KO HW 4000 FCS COMFORT Pump Station

AL-KO HW 3000 CLASSIC Pump Station

VB25 / 1500B pumping station (ELPumps)

Pump station 1000 B (CMI)

Kitline pumping station: model from the Aujet S series

Kitline pumping station: compact device PS-130 AUTO