The log and the timber is still quite accessible at a price, and therefore the houses from these materials are retained. We decided to consider the nuances of the opening device in the chopped wall, as well as the problem of choosing windows and doors for a wooden building.

Photo: "Bavarian House"

Walls made of logs and timber, in contrast to stone and frame, are subject to significant shrinkage - a decrease in height due to the sealing of interventic seams and wood drying. This fact seems to be well known and should be taken into account when making and assembling a log (in particular - when applying openings). However, it is completely ignored or take into account only formally, that is, compensating structures do not fulfill their task. Usually it happens when the team of professional carpenters is entrusted only the initial, draft stage of work, and to complete construction, the "universal" can be invited or eliminated by their forces. Such a desire to reduce costs is quite understandable, but fraught with sad consequences: the jamming of windows and doors, the appearance of huge slots between the crowns, distorts of walls, etc. However, errors can be avoided if you comply with all the rules of wooden house-building.

Practical advice

When choosing an entrance door, preference should be given to web, lined with HDF-based panels and viniplast, ship plywood or oak rails. Powdering color also reassigns atmospheric effects, but does not provide additional thermal insulation. Vinyl leather and standard finishing of laminated MDF will not transfer and 3 years of street exploitation even if there is a visor.How to solve a shrinkage problem

Log and brusched walls give shrinkage 5-6% (sometimes up to 9%). The walls made of dry glue bar are more stable, but they are saturated by 1-3%. After 3 years, this process is mainly ends, but in the future, quite serious movements occur due to changes in the level of moisture and aging wood.

When applying openings, the problem of shrinkage of wooden houses is solved with the help of a cluster, or sowing, - a rough box of bars, which does not interfere with the vertical movements of the crowns, but at the same time eliminating the possibility of the curvature of the walls. Plumbing boxes are installed at the construction stage either later (in the second case, when assembling a log, the movements are strengthened by one or two continuous crowns). Some firms (for example, Podolsky Doc, Artwinn) take orders for the manufacture of structures from glue timber and oak, including for open-shaped openings - arched, triangular trapezoids. The price of one set of parts starts from 1500 rubles. Mounting will cost approximately the same amount.

Arched structures (and wooden, plastic), flaps with frequent binding, as well as carved platbands and forged lattices produce only to order, and the period of work can be made several months

The cocks are performed by two basic ways, almost equivalent in terms of labor costs, strength and protection against purge.

The first - on the ends of the brawl (bars), forming the sidewalls of the face, the chainsaw form a solid vertical thorns (about 50 mm in height and the same in the width), shoals from bars with a longitudinal groove chosen in them. From above, the jumper is installed (cushion) with a thickness of 40 mm or more (depends on the width of the day).

The second - in the ends of the bricken (BRUSEV) by the chainsaw and the chisel chosen the groove in which the mortgage bar is inserted, and the cant of a thick board is nourished to it; In the presence of milling equipment, you can make a one-piece joint of the T-shaped section.

The "Schip-groove" connection must be performed with a small (5-10 mm) gap under the pass. As a seal, it is impossible to use materials based on mineral fibers, as they are not durable enough and dry worse.

A compensation gap leaves over the sorts, the value of which should be 1.5-2 times more of the calculated shrinkage. The slit is filled with packles or thin boards, wounded by the seal; As a shrink shrink, they will have to knock out one after another.

Often in the platform choose an outdoor quarter, into which the window or door frame is subsequently inserted, and then we are framed by the outside with wide platbands that closing the mounting seam simultaneously, the junction knot to the wall and the upper compensation gap.

Typical errors when appliance

- Violation of the integrity of the bustling and upper strapping crowns.

- Insufficient compensation clearance width over a plug-in box.

- Hard attachment of mortgage bars or shoals to the wall.

- Execution of a casing box of thin boards: When mounting the window or door fastening screws, breaking the racks, stuck in the ends of the wall logs (bars) and interfere with the shrinkage.

- Careless sealing of the joints of the wall with a drop or use for this purpose inappropriate materials, such as Poly Penopleyotylene or mounting foam.

How to choose a window design

If the placade is performed correctly, the standard window structure (up to 1450 × 1450 mm) does not experience excessive pressure from above. Therefore, the frames can be made of wood, metal, relatively soft and flexible plastic (the strength is important in the manufacture of panoramic windows and glazed doors). The foreground is put forward design and comfort.

The heat insulating properties of the window by more than 70% depend on the glass. In a country house, experts recommend setting structures with a reduced heat transfer resistance of 0.65 m² • ° C / W and more - double-chamber, thickness from 32 mm, with an outer low-emission glass filled with inert gas.

When choosing windows, pay attention to the products with three-skater glass packages

Products from the shaped profiles

Wooden designs must be equipped with overlays

Wooden designs should be with aluminum sash

Practical advice

It is better to perform casing boxes of planed and polished bars - larch or oak. Then the loops will not require additional finishes and will correspond to the most stringent canons of wooden architecture.

As for the frames, you can choose one of the three options.

PVC products do not require labor-intensive care, do not freeze and are not blocked. Preference should be given to four- and five-chamber profiles of systems such as SUPREMA (EXPROF), Brilliant-Design (Rehau), Expert (KBE), Softline (VEKA), Premium (Proplex), etc. - they are warmer and hard three-skimmer. Laminated on both sides of the PVC windows will cost 1.5-2 times cheaper than budget wooden (from pine). At the same time, the modern film reliably reproduces the texture of the tree and even has a typical relief. Only when opening the sash, the zone of the fold becomes visible, which in most cases is not laminated. If you do not like these white sites, it is necessary to purchase structures of light-colored light or dark brown profiles (it will be up to about 25% more expensive) or contact the company, the technical equipment of which allows you to laminate folding surfaces (for example, Kaleva).

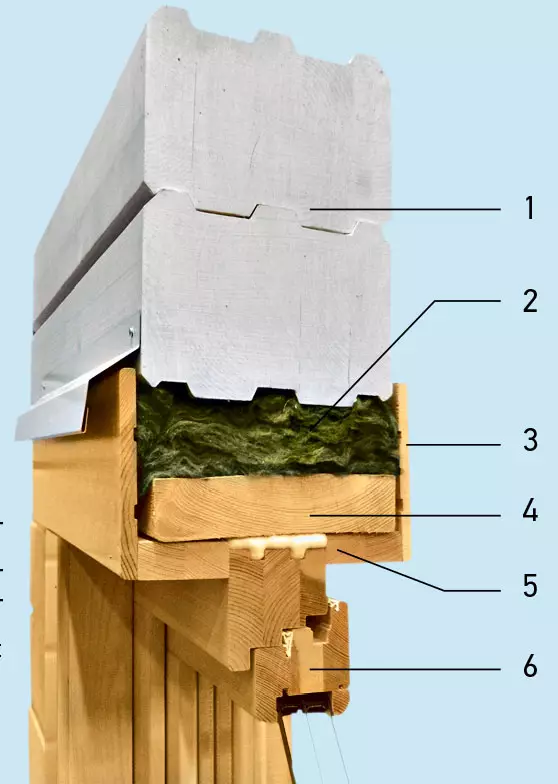

Upper compensating seam device: 1 - wall of glue profiled timber; 2 - papail (50 mm); 3 - platband; 4 - Heat from the board (40 mm); 5 - Silent Reiki; 6 - window block

Wooden frames are resistant to bending loads. In compliance with the production technology and using a high-quality glue bar, the specified geometry of the window block does not change during operation, the sash almost do not savage and only occasionally need adjustment. The wooden frames are stronger than plastic, so suitable for French windows high up to 2.8 m and up to 4 m wide (when the frame enhanced by the frame). But even the best varnishes and paints are not able to protect the tree from the destructive effects of water and ultraviolet radiation. So that the windows do not have to regularly paint, the outer surfaces are protected by overlays of painted aluminum. But such structures refer to premium segment and cost at least 2.5 times more expensive than laminated plastic.

Aluminum frames are the most durable and stable. However, the thermal conductivity of aluminum is hundreds of times higher than the tree or PVC. Therefore, windows for heated premises have to be performed from profiles with a polyamide thermal survey. The designs of the so-called warm aluminum cost 4-6 times more expensive plastic, although inferior to the latter by heat insulating properties.

With proper preparation of openings, plastic windows will serve dozens of years. Small deformations of the frames caused by the shrinkage of the house are possible, but the problem is solved by adjustment

How to choose Material

We are accustomed to the fact that the entrance door must be made of steel, and during the construction of a chopped home are not going to make an exception to this rule. Meanwhile, ordinary metal structures are not able to provide good thermal insulation and is not adapted to operating under the open air.Steel is characterized by a high thermal conductivity (almost 300 times higher than that of the tree), so the inner surfaces of the web and the box in the winter are cooled below the dew point, and condensate appears on them, and sometimes inves. Faster, the castle pocket of the canvas and the zone of the River are faster (especially in the corners and near the loops). In addition, from the lock wells a little blowing, the outer panel often fades or strates, and sometimes they begin to rust metal parts.

However, it is enough to establish a second (inner) wooden door - and you can forget about freezing or draft. Another option is to order a steel door block with multi-layer insulation and double curtains on the locking wells. Ideally, the area of locks and the box (around the perimeter) should be heated by a resistive cable.

By the way, wooden entrance doors are presented on sale, including modern designs made from the engineering array of pine, larch, oak or ash, additionally insulated sheet plug, with an enhanced threshold and powerful loops. But they are usually more expensive than steel.

Protection and decor

In a wooden house, the windows often protect grilles and rolls, but if you decide to strictly stick to architectural canons, then you should order swing shutters with solid or lamellable flaps. Joiner's workshops are able to make solid set of web, decorated in accordance with the northern architectural tradition - volumetric thread and forged lining.

Photo: Vladimir Grigoriev / Burda Media

The summer cottage from the planed vehicle will decorate light lamellable shutters, which, by the way, can be performed not only from the tree, but also from PVC (such products are presented, say, in the range of VEKA). Well, the most durable protective flaps are made of steel. Unlike wooden and plastic, steel parts are inspired not on the window box, but to their own frame from the corner, which must be considered when mounting windows.

Interior doors

For a long time, a classic interior door for the cottage was considered a product from a pine / fir array with a Filöncated design. Such models are inexpensive (injustable canvas with a box costs from 4 thousand rubles.), They are easy to repair with low damage. A number of companies, such as "Plant Horizon", Bis Art and Balwald, produce premium-segment doors from oak and larch, including under the "high" varnish; The price starts from 40 thousand rubles.You can also purchase serial shields with a strapping from the wood array and MDF-trim - they do not succify, almost do not change geometric sizes when enhanced humidity, and they are quite rare. At the same time, the facing - whether it is a veneer or paper-layered plastic - does not spare and is not separated. Applied by leading manufacturers Materials and adhesive compositions of moisture and heat-resistant.

Practical advice

Optimal in terms of price and quality option for the summer veranda - windows from cold solid-dimensional aluminum profiles with single-chamber windows or single chalters. Far parts are usually painted with powder composition in white and brown. Unfortunately, finishing for sublimation technology that allows you to imitate the texture of the tree, much will increase the price of the structures.

At the installation stage

If the wall thickness is 150 mm or more, the windows and the inlet door in the door can be positioned closer to the street or, on the contrary, shifted towards the room. In the first case, it will be easier to mount the outdoor framing, install wide windowsill and a tambourine. In the second - the risk of freezing window and door boxes and fogging of the glass will decrease; This option is preferable for the winter house.

Methods for fastening window and door boxes in a wooden house standard: use either invisible mounting plates, or self-tapping screws and depth. The mounted gap is filled with polyurethane foam, which must be protected from the side of the street with a sealant, and from the inside of the room - a vaporizolation ribbon. Mounting seams are closed with platbands or nicknames.

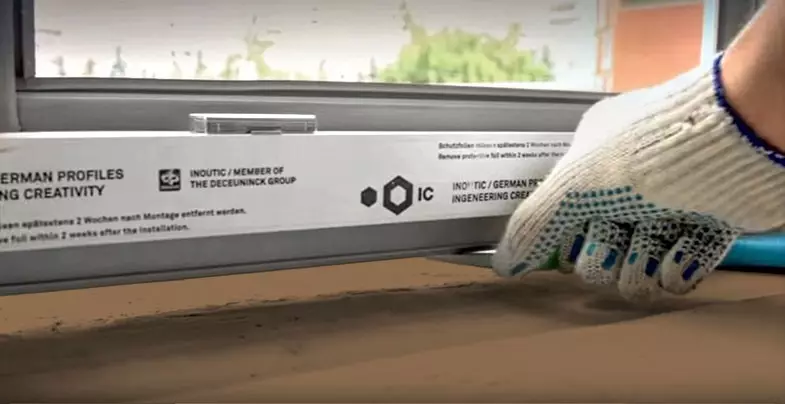

When mounting the window to the box fasten the coaching profile

The design is aligned in the opening with plastic wedges.

Further fixes with screws through the frame

Further fixes with screws through the frame

Then hang out the sash and gate the gap between the wall and the box. Then they screw the cast

Make sure that the workers gave the windowsill barely noticeable (1-3%) bias towards the room, and in the direction of the street - 10-20% in the direction of the street

What to do if the door jammed

Arriving in the spring to the cottage, we sometimes unable to unlock the front door. The reason for this can be a shrinkage of a church or seasonal basement of the foundation. In such a situation, you should not turn the key in the lock using any lever or other tool, because you risk breaking the mechanism. It is better to try to influence the cloth - put on it, lift the mount or, on the contrary, try to squeeze down, continuing to turn the key gently. After you open the door, you will have a little crush the feed holes for the regeneration. And in case of failure, it is better to call a specialist from the service company to avoid major repairs.

Internal doors who scored moisture in the unheated room can be jammed, so they are better to leave them open. If the window does not open, the loop adjustment will help.

On the ends of the BRUSEV form a spike

Then they are made and installed at the place of the shoals and a heap

The joke of the clusades with wall bars seal pacles or other material from plant fibers.

Make and install the glue cluster for figure, only experienced masters are capable of making.

A rough box is tightly driven to the wall to do without platbands; The ends of the login at the same time are sometimes striking.

The massive windows of the oak does not require replacement during the entire service life of the building

In order for the frame of the goat harmonized with window frames, it is not necessary to order these elements in one company.

The cock for the internal door is performed according to the general rules. Door box are fixed using steel plates

The discovery is framed by volunteer and platbands that fully hide the mounting seam.

Mounting seams must be compacted to provide sound insulation