What eco-friendly building materials based on wood-based Russian market?

Photo: "Tamak"

The intensive increase in the volume of low-rise house-building caused a significant need for materials, the mass use of which leads to a significant increase in labor productivity, cost reduction, reduction of the work time and improve the characteristics of housing safety.

The reliability and safety of the residential building is largely determined by the properties of materials used for its erection. The most important parameters specifying the safety of the materials themselves can be conventionally divided into four categories: chemical, physical, fire and biological. In order to guarantee the safety of the residential structure - both everyday and extreme situations, each of the materials used should have the highest marks in all categories.

Christmas trees

The maximum set of highest estimates for each of the following safety parameters is made by materials made from a mixture of wood of certain size (serves as a filler) and cement (it is binding and ensures strength) - coils. With their production, aqueous solutions of mineralizing additives (calcium chloride, calcium nitrate, sulfate aluminum, aluminum chloride, liquid glass, etc.), which antiseptic wood, prevent the release of saccharides from its composition and interaction with cement, increase the adhesiveness of binder with wood .The bioscistance of the trees is achieved due to the calculation released from their composition when calciding hydroxide solidification, creating a strongly alkaline medium. All Christmas trees are easy to process: cut, drill, connect nails, etc. In addition, the peculiar texture of their surface provides a good connection with plaster and concrete.

For the convenience of presentation, we divided the materials selected for the review for three groups, which were assigned the following conditional names: opilk concrete, shpobeton and fibrobeton.

Security indicators listed in the review of materials

- Chemical: do not distinguish harmful volatile substances.

- Physical: able to provide thermal comfort in premises at the level of existing standards; not electrified; Have sound insulation properties (capable of absorbing sound).

- Firefighter: are weakly thorough (g1), so-flammable (B1); Do not spread the flame (RP1); have low smoke-forming ability (D1); Low hazard from the point of view of the toxicity of combustion products (T1).

- Biological: biostoyki, not affected by bugs - vertices, homely rodents, etc.

Opilk concrete

The most famous representative of the materials of this group is cement-chipsticks (CSP). The initial material for their preparation is shavings of small and medium fractions and cement.In the production process, the "carpet" of three layers of a chip-cement mixture (in the outer layers - chips shallow fraction, in the internal - larger), which are then pressing are pressed. As a result, plates are obtained with a density of 1100-1400 kg / m³ of the following dimensions: length - 2700, 3200 and 3600 mm, width - 1200 and 1250 mm, thickness - 8, 10, 12, 16, 20, 24, 36 mm.

The products obtained are used to cover the external frame walls (plate thickness - 10-24 mm), covering the frame walls of dry and wet rooms (8-24 mm), cladding columns and riglels (8-16 mm), the collection of flat roofing (12 , 16, 20, 24 mm), washing the attic overlap (12, 16, 20, 24 mm), the base of the base under the floors (20, 24, 36 mm) and as the subcast plates (24, 36 mm). In addition, the CSP can be used in the construction of garages, cellars, street showers, hozbloks, garden tracks, fences (including noise protection), with veneer of ventucleobs, as both removable and non-coordinate formwork when erecting foundations and walls, etc. . When mounting on nails, the plates are pre-selected. Price: from 650 to 2000 rubles. For 1 pc.

Fire hazard of materials and structures

According to one hundred 274.465.001-2013, the fire danger of building materials is characterized by the following properties: flammability (G1-G4); flammability (B1-B3); The ability to spread the flame on the surface (RP1-RP4); smoke-forming ability (D1-D3); Toxicity of combustion products (T1-T4). Building structures are characterized by the limit of fire resistance (its value varies from 15 to 360 min), which is determined by the loss of carrier ability (R), the integrity (E), the heat insulating capacity (I or W) and smokeperiness (s), as well as the GOST fire hazard class 30403-96 (K0-K3).

CSP

Photo: "Tamak". Due to the monolithic structure, the CSP plate successfully opposes moisture, the rays of the Sun, the temperature and biological effects

Fatural tests of the internal CSP-Test wall for strength prove that it can withstand significant loads

The resistance of fire at the CSP slab is such that in the event of a fire, they are able to withstand its effects within an hour

Today, CSPs 8-12 mm are widely used to cover wooden frame structures

Shpobeton

The modern building market offers at once three material belonging to this group: "Arbolit", "Durisol" and "Velox". All of them are 90-95% consisting of a large chip of coniferous species of trees, which has been treated with mineral additives and a fastened portland cement. Between individual "slices" there are air "bags", providing high not only heat, but also soundproofing characteristics of materials (the RW air noise reduction index is within 50-60 dB), which allows them to use them even to build noise protection structures.In addition, due to the porous structure, these materials have sufficiently high air and vapor permeability ("breathe"), which, in theory, provides the same healthy microclimate in the house, as in Wooden. Their undoubted advantage is increased adhesion to plastering compositions, which simplifies the decoration of the walls, reduces its complexity and, consequently, the timing and cost of work. It is also important that the heat capacity of the lump concrete is much more than other light concrete, so the walls folded from it will serve as heat batteries. Private developer Such materials also attract the fact that during installation do not require heavy lifting techniques. Outdoor and interior decoration can be any, but it should not reduce the ability of materials to "breathe."

"Arbolit"

The material is designed and standardized in the 1960s. In the USSR, where more than 100 factories were built. Then he was for a long time forgotten, but today is going through the second birth. "Arbolit" (from Lat. Arbor - "Tree" and Greek. Lithos - "Stone") is essentially a kind of light concrete.

There are three types of "Arbolit": thermal insulation (density - up to 450 kg / m³), structural-thermal insulation (450-600 kg / m³) and structural (600-850 kg / m³). The larger option today enjoys the greatest demand, since it is it used in construction in the form of ready-made large-format blocks, from which carrier walls and partitions of buildings are erected.

The disadvantages of Arbolita include high moisture permeability and reduced moisture resistance, to combat that it is desirable to maintain air humidity in the rooms within 75%, and the outer surfaces of the walls must have a protective finishing layer. In addition, it is necessary to provide good waterproofing of the foundation, sufficient approach of the base of the house above the breakfast and the enlarged departures of the sleeves of the roof. It should be noted that the one-time exposure of water for blocks is not dangerous - they will stand it, but constant wetting is unacceptable.

The process of production of blocks is as follows. Specially selected wood is crushed, then sorted to select particles of a certain value (used sieve with calibrated holes) is dusty, and then it, together with cement, water and chemical additives enters the mixer. The finished "solution" is poured into metal forms and are compacted with vibropress. While the mixture does not fully harde, it is kept in shape and only then take the resulting product. The customer is finished block not earlier than 2 weeks.

Large companies along with 500 × 300 × 200 mm products make "halves" - 500 × 300 × 150 mm, blocks with a "groove" (to create jumpers over the proasters), as well as lightweight blocks (with recesses) for the construction of partitions of the second floor and others. Price of blocks - from 4500 rubles. per 1 m³.

Arbolite blocks are placed almost the same as other large-size blocks. Before mounting the inter-arc overlap, the outer and inner walls are crowned with a monolithic concrete armoomas, which not only levels the level of the walls, but also contributes to the uniform distribution of the load generated by the overlap and overlying building structures, and also provides additional strength and seismic resistance of the house.

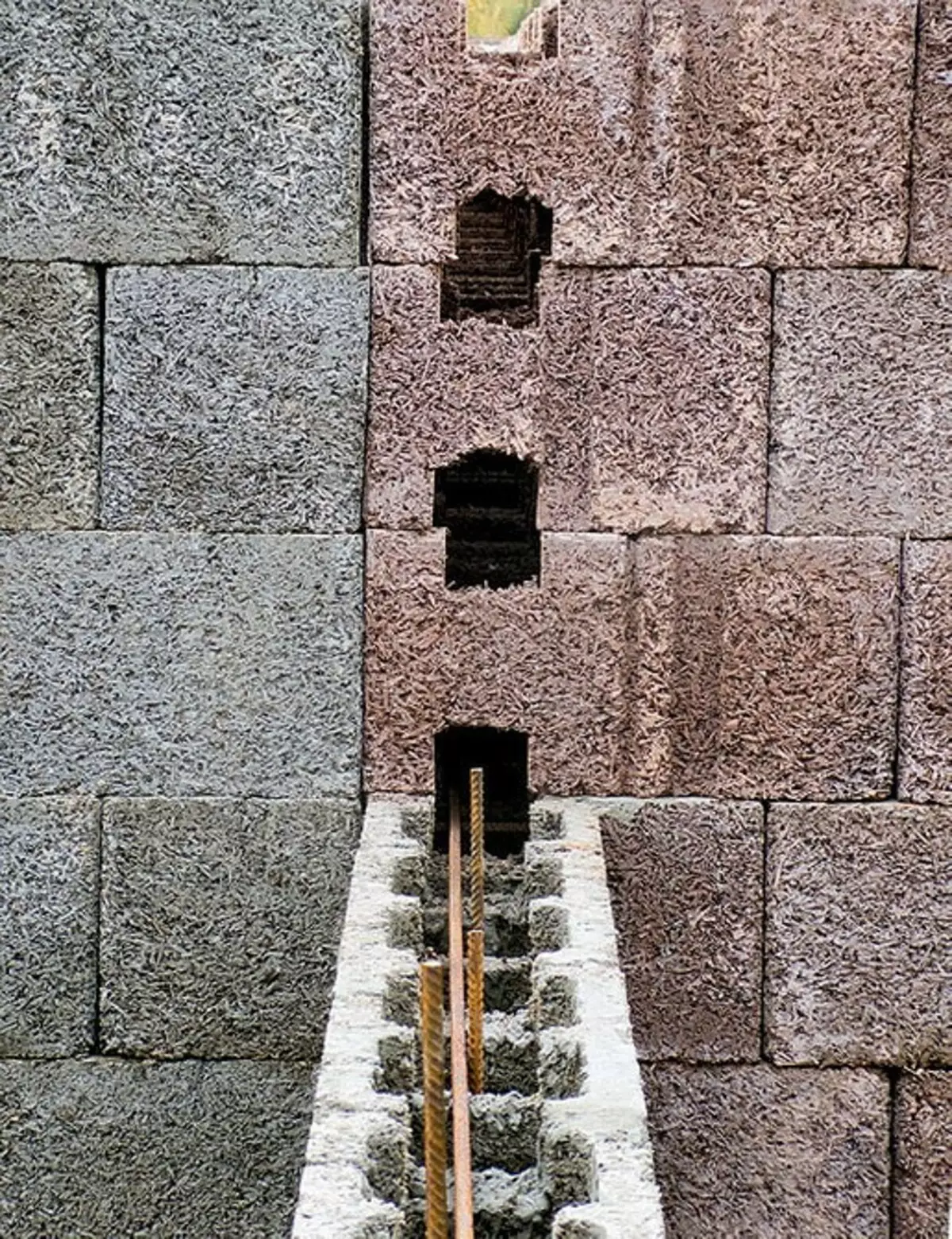

"Arbolit"

Photo: "Arborate". The reduced resistance of the heat transfer of the wall from the "Arbolit" thickness of 30 cm without additional insulation is 3.25 m2 • ° C / W

To enhance the wall structures folded from the "Arbolit" blocks, separate plots of masonry reinforced with steel grid

From "Arbolit" drank even nonsense-dart elements

Preparation for the pouring of the Armopoyas, the Wedding Wall

Dubisol

Dubisol is not only material, but also the original construction technology, which is based on the use of hollow wall blocks made in the factory conditions, playing the role of a non-coordinate formwork. Price: 130-340 rubles. For 1 pc.In the course of the construction of walls, the blocks are set by rows on each other, but without the use of the binder. Mandatory condition - the internal cavities of the blocks of all rows of the walls must coincide vertically, but when laying between adjacent rows, an offset is needed to half a block. At the same time, the recesses existing at the top of the blocks in each row are horizontally put the reinforcement rods, which sprinkle on the length of the flap with a wire cleaner. In the center of rectangular cavities, the blocks are installed vertical fittings (length not more than 1.5-1.8 m), having tied it with a horizontal wire twist (and if necessary, with in advance "flooded" in the foundation by anchors).

Similarly, they laid the second, third and even fourth rows of blocks, putting them on vertical fittings. After that, the vertical cavities formed in the assembled wall are filled with concrete brand B15, B20, B25 or B30. It is poured manually or using concrete pump. The concrete flooded in the cavity is sealing manually (pitching method) or a deep vibrator. Consumption of commercial concrete per 1 m² wall ranges in the range of 0.075-0.125 m³. The following four rows are set and repeated the fill process with concrete (as the wall grows the vertical rods increase). As a result, a monolithic reinforced concrete lattice with powerful vertical carrier pillars associated with more subtle horizontal rusty jumpers arises inside the erected wall structure. The high strength of such a carcass allows you to make it support for overlapping from concrete - prefabricated or monolithic.

Composition of the Durisol system

It includes blocks for the construction of fences carriers of unheated buildings and interior partitions, as well as blocks with polystyrene inserts for the construction of external walls with high heating saving properties - for residential buildings. The series except blocks for the formation of rows includes special angular halves and capable of replacing their universal blocks that are used to perform jumpers over the proof.

Dubisol

Photo: V. Kovalev / Burda Media. From Düsisol blocks, it is possible to make wall structures of non-standard or curvilinear form, such as erker. In this case, the necessary elements are made on the spot

To connect the armature of the outer and inner walls in the side walls of the outer blocks cut the grooves

From offset relative to each other, blocks hold the grooves and ridges available on their end planes, which also perform the role of labyrinth seals

Racing wall structures

"Velox"

A comprehensive technology for the construction of monolithic energy-efficient houses using VELOX sep-cement slabs ("Velox") was patented in Austria back in 1956 and today successfully applies in more than 40 countries of the world, and more recently in Russia.The main element of the "Velox" construction system is 2,000 × 500 mm in size, which are mainly available in two modifications: single-layer plates thick 25, 35, 50 and 75 mm used for the formwork device of external and internal walls; Two-layer heat-insulating plates made of single-layer (35 mm) by sticking polystyrene foam (PPP) with a thickness of 150 mm, which allows you to build wall structures with a reduced heat transfer resistance at RO = 4.37 (m2 • ℃) / W. There are plates with an increased up to 200 mm layer of PPS. Plate price: 300-1200 rub. For 1 pc.

The system also includes: ceiling plates (200 × 500 × 25 mm); boxes (2000 × 380 × 170-260 mm, height depends on the length of the span) for the manufacture of lightweight ribbed monolithic floors; single and double-sided mounting metal ties 320 and 480 mm long, providing a predetermined distance between the walls of the outer and inner formwork of one row connecting the plates of different rows in height; Spatial frames - trigons used mainly in the power ribs of monolithic overlap.

From these basic elements in compliance with certain rules and erected both small and multi-storey buildings. Mounting begins with one of the external corners of the building, while the plates at the junction fasten the nails with a length of 100 mm, which are driven at different angles. Then, the plates that form the outer and the inner wall of the first row formwork are consistently dragged, connecting them in pairwise screed.

As a result, straight and angular sections of walls are gradually emitted, with the projected projects provided for in the project (their "ends" with end plates with a thickness of 75 mm). Having finished the installation of the formwork of the outer walls, proceed to the creation of "shells" for carrying inner walls and partitions. When the installation of the first row throughout the area of the house is fully completed, inside the formwork in the places provided by the project, vertical fittings (trigons) are installed and the concrete of the brand is not lower than M200 (manually or concrete pump). Next, the following ranges of formwork are assembled, shifting vertical stakes of plates in adjacent rows at least 250 mm.

The technology of the construction of walls is organically complements the original method of facilitating the facilitated ribbed monolithic floors. The basis of the latter - concrete beams reinforced by steel trigones and 120 mm wide and height from 185 mm to 275 mm, located in a step of 620 mm and the components of the monolith with concrete walls.

"Velox"

Photo: "ECOTOMOSTROY". Plates "Velox" fasten with each other nails driven at an angle

The predetermined distance between the outer and the inner walls of the formwork provide metal ties

Trigons are also used for vertical reinforcement, which significantly reduces steel consumption

When building ribbed monolithic floors of solid flooring, they make a thickness of 25-35 mm from the plates "Velox"

Fibrobeton

It is also called fibrololite - it is a natural slab material produced from fine chips (length - 250-500 mm, width - 1-4 mm, obtained on special machines and often referred to wood wool), portland cement and water. In the production of wood fiber, treated with a solution of liquid glass, is mixed with cement and water, and then under a pressure of 0.5 MPa by ribbon pressing method, products are treated with ferry and dried. Standard products - plates with a length of 2400 and 3000 mm, a width of 600-1200 mm and a thickness of 30 to 150 mm. They have low bending strength (from 0.4 to 1.2 MPa) and flexibility, but at a sufficiently low density (from 300 to 1050 kg / m³) have good thermal conductivity indicators (0.10-0.15 W / (m • ° C) and sound insulation characteristics. Today, fibrolite plates of companies such as Celenit (Italy), Green Board (Russia), Träullit (Sweden), etc., are presented on the Russian market, TRÄULLIT (Sweden), etc. In accordance with the areas of use, all products can be divided into structural, Acoustic and designer.Structures. The scope of their use in building structures is determined by the density, which is divided into low (200-500 kg / m³), medium (500-800 kg / m³) and high (more than 800 kg / m³). As an example, consider the plates of the Green Board system.

Plates with a density of 250 kg / m³ (GB1, thickness - 100 mm) and 300 kg / m³ (GB1, thickness - 50 mm) are used for heat and sound insulation, noise absorption, thermo- and hydraulaging of the microclimate of the premises. An increase in density up to 450 kg / m³ (GB450, thickness - 25 mm) allows the use of material for similar purposes, as well as to use as a non-coordinate formwork and plating frame walls that perceive limited loads. Products with an average density of 600 kg / m³ (GB600, thickness - 14, 25, 35 and 50 mm) and 700 kg / m³ (GB2, thickness - 25 and 35 mm) perform the functions of the non-coordinate formwork in monolithic structures from light and heavy concrete; They are used for the outer and inner skin of the walls of frame buildings, partitions, as well as ceiling bodies. Finally, the plate is a density of 950 kg / m³ (GB3, thickness - 10 and 12 mm) and 1050 kg / m³ (GB1050, thickness - 10, 12, 18, 22 mm) serve as a sheatting of insulated frame walls (instead of OSP-plates) Used in the manufacture of sandwich panels (based on PPS or GB1 plates), as well as the structures of rafting-beam systems (instead of OSP-plates).

The cost of the structural plates of Russian production varies from 290 to 1200 rubles. For 1 pc. Italian and Swedish products will cost about 1.5 times more expensive. Tile has a number of shades of five main colors - sky symbols, clouds, wood, land and sea. Designer tiles are presented by the products of the Swedish company Baux (enters the Träullit group). They have different shapes and colors, which allows the decorative panels of almost any size from the purchased finished elements.

In addition, the tiles have good sound-absorbing properties, able to absorb and empty (depending on the air condition) and accumulate thermal energy. The mass of products is about 14 kg / m². They can be mounted on the wall or ceiling in two ways. At the first surface, the surface is pre-tight with thin metal sheets, and on the back of the tile, magnets are fixed - in this case, it is possible to change old or damaged panels to new ones, as well as change the panel pattern as often often. The second method involves sticking to the surface.

This year, the production of designer tile has mastered the Russian Green Board. The price of products of domestic production - from 1 thousand rubles. For 1 m². Swedish are somewhat more expensive - from 2 thousand rubles. For 1 m².

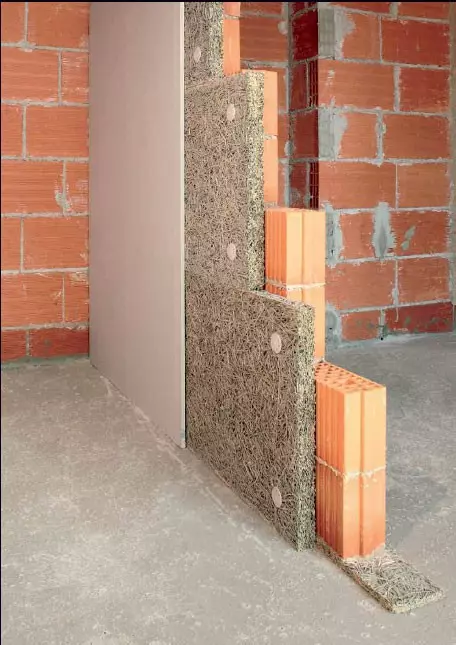

Fibrolite construction

Photo: Selenit. In brick buildings with a monolithic reinforced frame, fibrolite structural plates are used to insulate the so-called cold bridges.

High density plates with a thickness of 10 to 22 mm are successfully used as an outer sheatting of external and internal frame walls and partitions

Medium density plates are suitable for soundproofing brick partitions

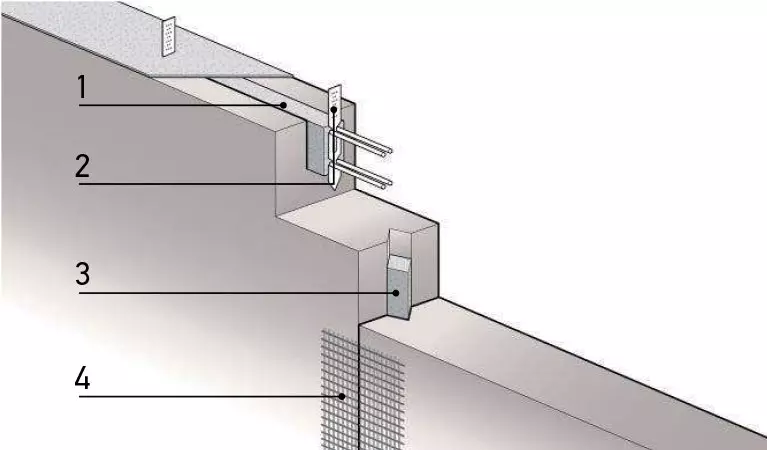

Panels for walls

Scheme of creating in the grooves of panels of a carrier monolithic reinforced concrete frame

The position on the upper end of the panels is stacked by the reinforcement and concrete poured - the carrier beam of the frame (1) is formed; The grooves on the vertical joint of the panels create a duty for casting a support column of the frame (2); steel plate for fixing the arma- tours (3); Reinforcing grid on the junction of panels

Most recently, TRÄULLIT developed a system of production of full-size monolithic wall panels from a mixture of wood wool and cement (fibrolite) and the construction of residential buildings from them. These light panels have a length of up to 6 m, a height of 2.7-3 m and a thickness of 25 to 50 cm (depends on local climatic conditions - the resistance of the heat transfer RO may vary from 3.29 to 6.58 (m² • K) / W). Products are made on an automated line (which provides constant quality and high factory readiness), where window and door loops are immediately cut into them, as well as the necessary grooves for mounting or laying communications. From the factory on the construction site of the panel are transported in a vertical position.

The heat accumulating ability of the panels - 250 kJ / m² • K. The fire resistance indicator of the wall - Rei 360 (during tests, the wall panel was subjected to a continuous effect of a flame with a temperature of 1200 ° C for 6 hours - from the opposite side of the wall, the temperature was only 45 ° C). Due to the low weight (the density of products - 300-350 kg / m³), a lightweight foundation can be used under the walls of such panels.

The house assembly technology is characterized by simplicity, low consideration and low cost. Moreover, in the collected design of the panel (their compression strength is only 27 kN / m), there is practically no load. It takes on a power reinforced concrete frame consisting of columns and beams, the formwork for which are horizontal and vertical grooves on the ends of the wall panels. So in the joints of the two wall panels vertically, square cavities are formed by a cross section of 70 × 70 mm. In the upper part of each product there is a U-shaped deepening with a cross section of 100 × 160 mm, which allows for the formation of a solid "ring" groove under the perimeter of the walls under the beam.

FiBroit for panel construction

Photo: Träullit. Window loops are cut out in the panels, the grooves are made under the electrical wiring and the draft shuttering is made.

The process of erection of walls from structural fibrolite plates of factory manufacturer is characterized by simplicity and high speeds combined with low labor intensity and cost

Steel plates fix the position of the reinforcement in the top sinus panel

After installation on the foundation (on a layer of cement mortar), the panels are pressed. Vertical cavities and horizontal grooves are placed steel reinforcement, and then poured concrete (if the building has a multi-storey, then the columns in the joints of the panels are drawn through all the floors from the foundation to the top carrier beam). In order to keep the reinforcement in horizontal grooves at a distance from fibrolite, special metal plates with a thickness of 3 mm with a sweep tip, which drives into the body of the panel. To the same plates, the beams of overlapping or rafters are fixed. When finishing the walls are plastered.

The advantages of the new technology - in the design of the walls there are no bridges of cold, structures are durable, racks for mold and rot, have a small weight and not exposed to shrinkage. On average, in an hour of a brigade of installers (at least three people), it can, with the help of a crane, install two wall panels, so the construction is carried out very quickly. The cost of the panels necessary for the installation of external walls of the typical one-storey house with a total area of about 100 m², in Sweden is about 12-15 thousand euros. In Russia, the panel is still coming from abroad (the domestic plant for their production is still designed) and therefore costs much more expensive - about 1.5-2.0 million rubles. For the same kit.

Fibrolyt for design

Photo: Träullit. Designer tile Baux Träullit can have a round, hex, square, rectangular, rhombic and triangular shape. At the same time, products of different forms are selected in size so that they are easily combined in a single figure

Acoustic plates

Designed to correct the acoustic medium in the premises to which increased soundproofing requirements are imposed: sports halls, home theaters, etc. Plates are used to cover the walls and create sound-absorbing partitions, in stationary sound-absorbing suspended ceilings or in additional screens. For these purposes, it is proposed to use plates with a density of 450 and 600 kg / m³ and a thickness of from 14 to 25 mm. The price of Russian products produces from 600 to 1200 rubles. For 1 pc. Italian will cost approximately 1.5 times more expensive. Some separately stand acoustic stoves that can be applied for the design finish of the premises. They are available on the basis of conventional or white cement and painted in various colors (according to the catalog), and also supplied with edges with a chape-stepped fold, etc. Cost: domestic - from 1000 rubles. For 1 m2, imported - 1300-2000 rubles. for 1 m2.

Photo: Troldtekt.