Laying vapor barrier films during the construction or repair of the house - the urgent need or unnecessary waste of money? Indeed, you will never see the result of this material. But without it, in any of the so-called roofing pies, external walls and interoaded floors, negative consequences will be immediately noticeable, and they will have to eliminate them for a long time and expensive.

Photo: Legion-Media

Comfortable temperature in the house - 22-24 ° C. While most of the year in the middle lane of Russia, the temperature "overboard" is noticeably lower. Due to the difference in the parameters of cold street and warm home air, the latter always seeks to go out. At the same time, the air contains much more moisture than in cold. An increase in its quantity in the room contributes to cooking, taking a shower, washing and even human breathing. To preserve heat and prevent excessive moisturizing of the insulation and enclosing building structures, vaporizolation films are used. They do not allow moisture to penetrate the warm (heated) premises in the insulation or reduce its amount to a minimum, thereby preventing the wetting of the material and maintaining its working quality. Indeed, even with a minor moisture (per 1-2%), the thermal conductivity of fibrous thermal insulation increases by 20-30%, and therefore, heat losses increase. At the same time, even such a thin defense prevents the formation of condensate and, as a result, the appearance of molds and colonies of fungi on the wooden structures of walls, overlap, roofing houses, as well as corrosion of metal elements, noticeably extended their service life.

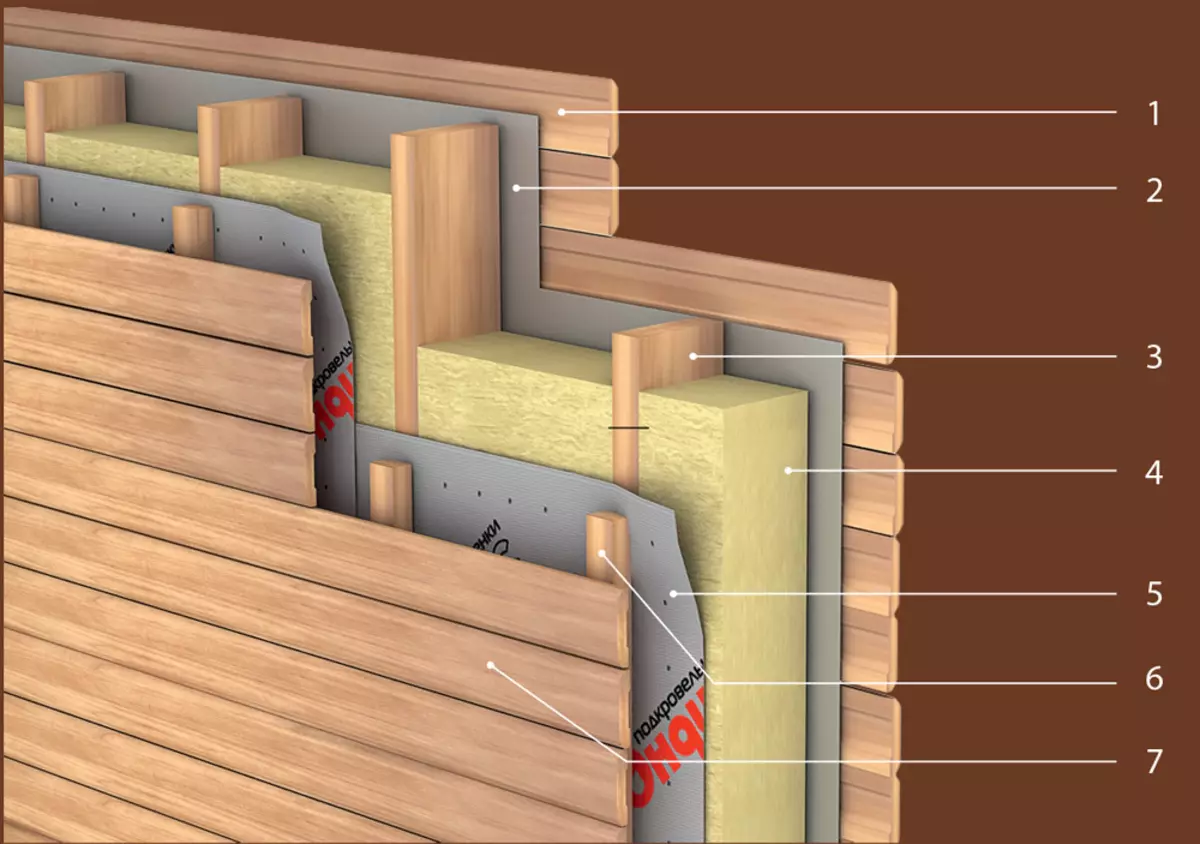

Frame wall insulation scheme: 1 - exterior decoration, fixed on wooden bars; 2 - diffusion membrane; 3 - frame racks; 4 - thermal insulation material; 5 - vapor barrier film; 6 - wooden bars for mounting interior decoration; 7 - decorative material (photo: "Ontutis")

As for visible consequences, it will suffer without steam-protected due to constant moisture inside the walls, the floor or ceiling will suffer. Planks of laminate, parquet or parquet board can be deformed, swell up and, even worse, rot. The reason for this is a condensate accumulating in the ceiling over a cold basement when the temperature difference on the first floor and above the ground. Moisturizing the walls and overlaps of the upper floors will gradually lead to the darkening and detachment of wallpaper, paint swelling, wood trim deformation. Residents of the house may notice that the roof flows, but they will not find holes in the roof, because it is not. And there is moisture, which is assembled in the insulation under the roof and under the action of gravity falls in the form of droplets from the ceiling, imitating damage to the roofing material. However, all these troubles can be avoided if the diffusion membranes, hydro and vaporizolation films in the structures of the building are competent. We will talk about the latter. In the domestic market, these products are represented by many companies, including: "hex", "Ondulin", "Saint-Goben", "Technonol", Dörken, Juta, Rockwool.

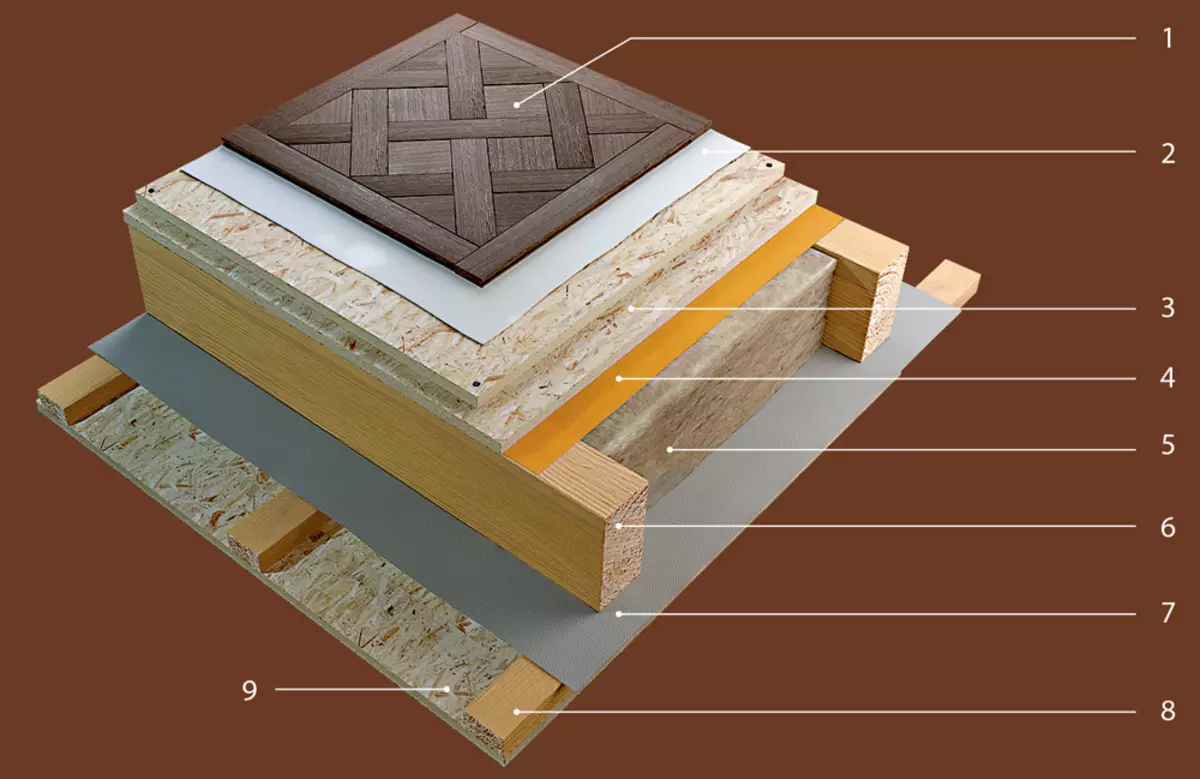

Floor design scheme for lags: 1 - floor covering; 2 - soundproofing substrate; 3 - rough floors; 4 - diffusion membrane; 5 - thermal insulation material; 6 - wooden lags; 7 - vapor barrier film; 8 - Wooden bars for fastening the sheat; 9 - Lower Floor Ceiling

Polyethylene, polypropylene and others ...

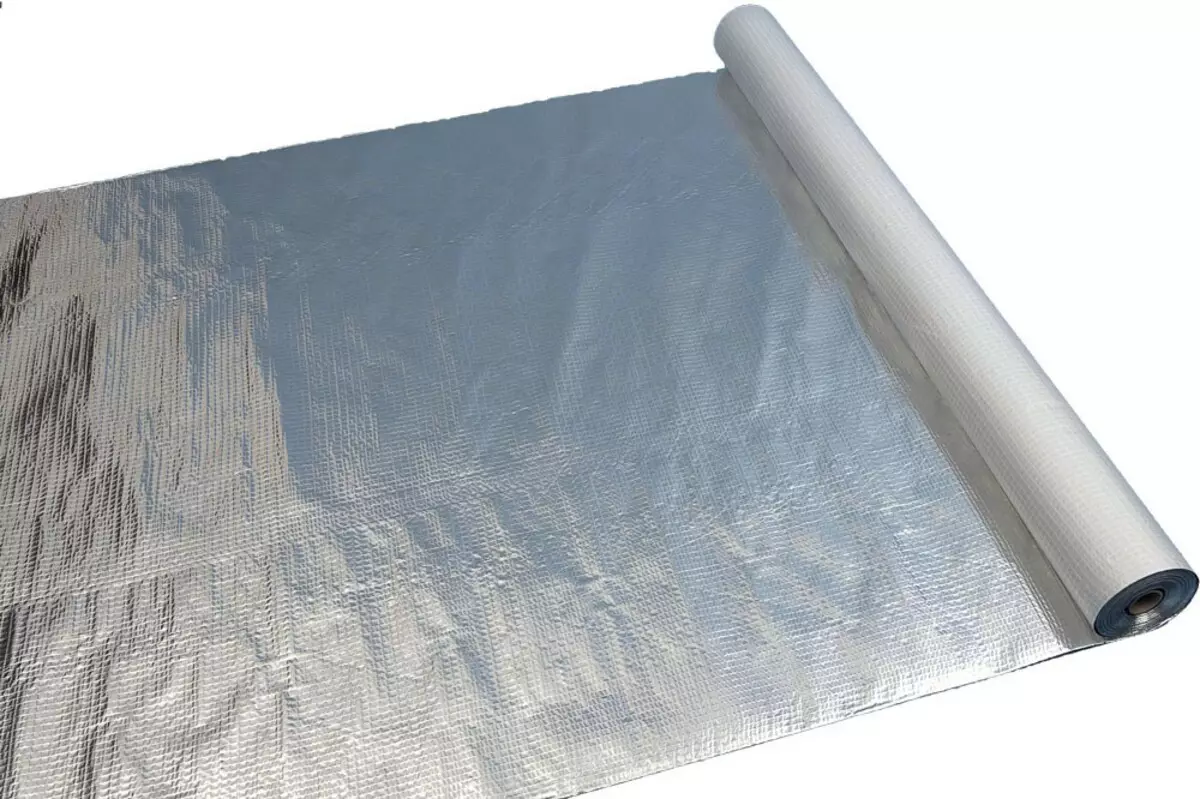

Parosolation films are made from different materials. Polyethylene products are considered budget, but many of them are not durable enough. The most technological reinforced films that are characterized by greater durability.

In products from nonwoven material polypropylene, as a rule, one side is smooth, and the other rough. When installing them, they have a smooth side to the insulation, and rough inside the room. Then, with a decrease in temperature on the street, excessive moisture condenses on the cold surface of the film, but does not flow and does not eat from it, and it is kept between the fibers that form roughness. With increasing temperature, the moisture evaporates, returning to the room.

Regardless of the material, the film must be sufficiently strong and plastic, which is especially important for installation in narrow places. When working, use adhesives and connecting tapes.

Photo: "Saint-Goben"

Inner insulation of walls

The frame is attached to the enclosing wall. Most often it is performed from wooden bars of 50 × 50 mm (the size depends on the thickness of the heat insulation). Broi-racks are installed vertically at a distance of 600 mm (a). Between them lay the plates of the insulating material, so that they fit tightly to the wall, frame and on the junctions to each other (b). The insulation layer impose a vaporizolation film, attaching it to the bars using a construction stapler (B). The canvases of the film are laid with an inlet 10-15 cm. After fastening the seams on the joints and around the perimeter, it is imperative to be sampled by assembly tape. On top of the vaporizolation, the bars are mounted a counterbuilding (1.5-2 cm thick) for its additional fastening and preparation for trimming with a finishing material. At the same time, the gap will help avoid possible moistening of the finish in the case of condensate formation with a sharp increase in air humiditySugar tightness

Photo: "Ondulin". With the onset of cold weather, when we start to pull our home, wet warm air is trying to outward through all sorts of holes in the floor, walls and roof. It is noticeable to extend the service life of the house will help inexpensive, but useful vapor insulation films

The vaporizolation film is mounted on the inside of the enclosing structures, in front of the layer of decorative finish. And in rooms with high humidity and houses for seasonal accommodation (cottages, cabins, etc.) between the inner facing and the layer of vaporizolation, it is desirable to provide a small ventilation gap of 15-25 mm.

The mount is performed in two stages. First, the canvases are mounted, having their flask (at least 10 cm) and fixing the construction stapler. After the end of the process, all the joints are definitely sampled by the mounting ribbon. Real workers often refuse this necessary element, seeking to "save" the customer's funds. However, without scotch, even the highest quality vaporizolation film is not able to protect the roof from the convective moisture and heat transfer, which means that possible damage. After all, through small cracks between the canvases under convective exchange, tens of liters of condensate can be accumulated in the convective metabol.

Photo: "Ondulin". Under the roofs there are canvas diffusion membrane. She misses the pair of water vapor from the premises, but becomes an overwhelming obstacle for droplets condensing on the inside of roofing

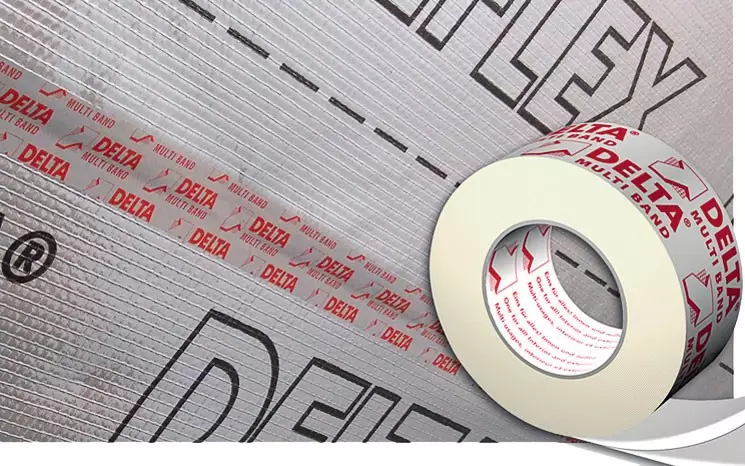

In addition, the cause of a loose docking of the canvas can be not intended for sizing a pair barlasting ribbon from countries of Asia and Eastern Europe or narrow unilateral tapes (50 mm wide and less). Only 100 mm width ribbons provide sufficient area and adhesive strength of the adhesive connection even with not too neat installation and a possible sedimentation of thermal insulation.

Wet air often penetrates through the leakage of the film to the inner and outer walls, floor, furnace and fireplace pipes, ventilation mines. These places forget to compact or perform work incorrectly: do not leave the strain stock of the film on the shrinkage or do not take into account the characteristics of the material. For example, to non-stroke wood and other rough surfaces, insulation is glued with special glue from synthetic rubber or adhesive compositions based on acrylic or polyurethane mixtures.

If everything is done correctly, it remains only to check the actions of electricals: during the laying of wires and installation of electrical installations, they can spoil a qualitatively laid vapor insulation film by cutting it. We hope that this will not happen.

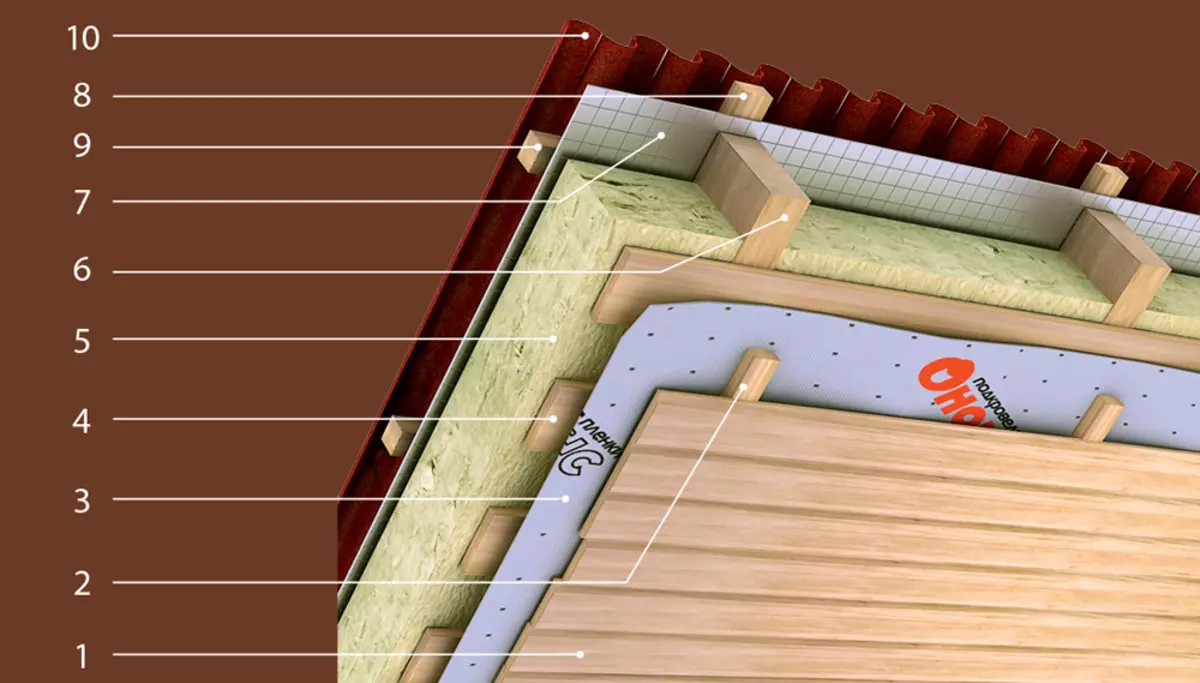

Scheme of roofing cake with insulation: 1 - ceiling finish; 2 - wooden bars; 3 - vaporizolation; 4 - doom; 5 - insulation; 6 - rafters; 7 - diffusion membrane; 8 - Bruks of the Ventzazor; 9 - doom; 10 - Roofing

| Benefits | disadvantages |

|---|---|

Prevents excessive moistening of thermal insulation and, as a result, maintains its heat shielding properties. | It worsens the microclimate in the house due to an increase in air humidity, which contributes to the condensation of moisture on the vapor barrier layer and as a result leads to a damage of finishing materials, especially in the absence of artificial ventilation. |

It prevents the appearance of fungi, mold on wooden elements and corrosion of metal parts of bearing structures. | It has low fire resistance. |

Reduces thermal losses associated with the transfer of warm air through the looseness of the enclosing structures. | |

Works in a wide temperature range from -40 to +80 ° C. | |

Easy mounted. | |

Reduces operating costs. | |

Reduces the likelihood of penetration into residential premises of harmful secretions from fibrous insulation. |

Useful reflection

Photo: CIFRE CERAMICA. Reflective layer films suitable for rooms with normal micro climates and high humidity - bathrooms, bathrooms and kitchens

Special attention should be paid to metallized vapor insulation films. Along with other beneficial properties, they have the ability to reflect the inside of the room to 80% radiant thermal energy. And the higher the energy carriers will cost, the more profitable will be to use reflex (reflective) materials. The latter include: two-layer film with aluminum spraying "Ondutis R thermo" ("Ondulin"); Multilayer film with aluminum layer, protected by a polyester coating of Delta-Reflex and Delta-Reflex Plus, with an integrated self-adhesive tape (both - dörken); Four-layer film "YUTAFOL N AL 170 SPACE" (JUTA) with aluminum layer.

The most important requirement for a vapor barrier layer is its complete tightness, for which it is necessary to carefully glue all the seams, joints and places of insulation adjustment to designs

Reflex vaporizoation manufacturers recommend choosing for rooms with high concentration of water vapor, with high humidity and temperature (bath and sauna); For structures that do not provide sufficient output of vapors into the external space. Some films can be used as a base when arranging warm floors. By the way, the metallized vapor insulation materials are protected from electric and radio emission. It is no coincidence that in Germany, Delta-Reflex film is often used in the construction and reconstruction of kindergartens and schools not only as vapor barrier, but also as protection against the so-called power grid.

Photo: Tulikivi. Reflex films are attached to the bottom of the rafted aluminum spraying inside the room and fix the stapler brackets or nails with a wide hat.

Photo: Juta. Connecting tapes provide a vapor and airproof connection of the films during vertical and horizontal overlap

Photo: Juta. Parosolation reflex films provide one hundred percent protection against the penetration of warm wet air into the insulation and building structures of the house due to practically zero vapor permeability, leaving them dry even in winter

Overcome obstacles

The ability of the film to pass steam is characterized in Europe "equivalent to the diffusion resistance of water vapor" (SD), and in the Russian GOST 25898-2012 "Methods for determining the resistance of vapor-permeal" - actually "piping resistance". For example, SD = 100 m, that is, the ability of the film of this thickness to prevent the diffusion of water vapor is equivalent to the air layer with a thickness of 100 m. And steam-permeal resistance is the difference of partial pressure of water vapor (Pa) in opposite parts of the product with flat-parallel sides, at which 1 m² The square of the film in 1 h passes 1 mg of water vapor, with the equality of air temperature from the opposite sides of the layer. In any case, the higher the same value, the smaller the water vapor passes through the film due to diffusion.Parosolation films

Name | "ONDUTIS R 70" | "Parosolation for roofing, walls, ceiling" | Delta®-Dawi GP | "Izospan with" | "YUTAFOL N 110 Standard" | IsOver VS 80. | "Fillet vapor insulation for a scope roof and walls" |

Manufacturer | "Ondulin" | Rockwool. | Dörken. | "Hexa" | Juta. | Saint-Goben | "TEKHNONIKOL" |

| Material | Polypropylene | Polypropylene | Polyethylene | Polypropylene | Polyethylene | Polypropylene | Polypropylene |

| Break load strips 5 cm, n (along / across) | No less 110/80 | No less 128/80 | 200. | No less 197/119. | 220/190. | 160/110 | 160/120 |

| Vapor permeability g / m² • 24 hours | Not more than 10. | Not more than 19. | 0 | 0 | 0.9 | 0 | five |

| Parry permeation resistance, m² • h • pa / mg | — | 7. | Diffusion resistance couple SD - 100 m | At least 7. | 0 | Coefficient Paropemy Tsacia 0.00005 mg / (m2 • h • pa) | 2.6 |

| Water removal, mm waters. pillar | No less 1000. | No less 1000. | — | No less 1000. | — | No less 1000. | 2000. |

| Width, see | 150. | 160. | 200. | 160. | 150. | 150. | 160. |

| Roll length, m | fifty | 70. | fifty | 43,75 | fifty | fifty | fifty |

| Price, rub. / Steers. | 1 100. | 1 150. | 4,900 | 1 500. | 2,300 | 1 650. | 900. |