To use carpentry and carpentry connections, construction requires not only a special tool, but also a considerable experience. Therefore, non-professionals have such compounds most often obtained inactive. The optimal option is to apply new types of metal fasteners.

Photo: Ingo Bartussek / Fotolia.com

Most of the preserved wooden architecture monuments are erected without a single nail, with the help of an ax alone, and this fact still causes admiration. But after centuries, the fasteners used for the construction of wooden houses are made from metal, therefore, therefore it makes no sense to repeat the "feats" of the ancestors. It is easy to build, quickly and reliably. Consider the metal fasteners offered by manufacturers on the example of nodes and elements, which make it possible to significantly simplify and speed up the connection of the floor lag with beams or wooden walls, and at the same time some other operations.

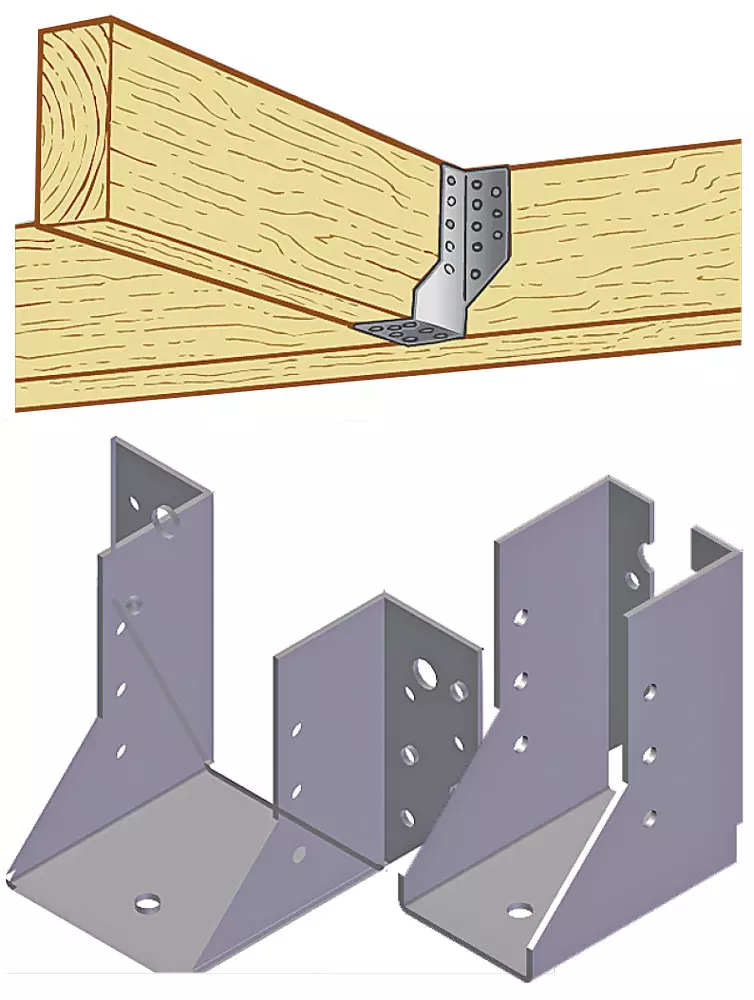

Photo: Essve. The beam shoes are equipped with holes with a diameter of 5 mm (located both on the flange and on weapons) for nails / screws and holes with a diameter of 9 or 11 mm for bolts or coarse screws. On the bottom surface of the flange there is a hole with a diameter of 7 mm for an additional fastening of lags

1. Connecting elements with perforation

Photo: Eurutec. Special elements for performing distributed in wooden housekeeping operations: Adjusting screws for window boxes or dooms (a); tightening self-tapping screw (b); Hobotec selflessness for fastening a massive board, blockchausa or imitation of a bar when wearing a wooden house (B)

If the beams and lags are invisible in the interior, they can be connected using the so-called beam shoes manufactured, for example, Essve. These elements are suitable for fastening the tree not only to the tree, but also to concrete or brickwork (when using the appropriate dowels). They are made mainly of hot-dip galvanized with a thickness of 1.5 or 2 mm, but there are in the market and more expensive products from stainless acid-resistant steel A4. Shoes are available in two versions: with challenges, crushed out or inside. Price: from 50 to 500 rubles. For 1 pc.

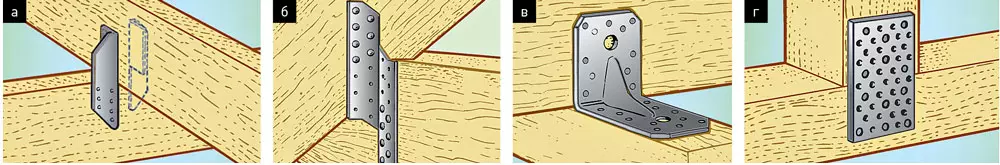

The manufacturer recommends mounting the beam shoes to the connected elements with special anchor screws with a diameter of 5 mm (depending on the load, the latter can be inserted into everything or into some holes), and with a very large load or fixation to the "stone" material also use bolt holes. In addition to the anchor shoes, perforated universal locks (a), rafter mountings (b), corners (B), plates (g), shown in the figure, and so on is presented on the market.

Photo: Essve.

Advantages of anchor screws

Why do the perforated fasteners manufacturers offer to use the anchor screws? What is the latter better than ordinary self-tapping screws or anchor (frant) nails used to fix the beam shoes and other metal perforated elements?Advantages are caused by the features of the design of anchor screws.

First, their flat hat tightly presses the fixed metal element to the wood.

Secondly, the smooth cylindrical part under the screw screw has the same diameter of 5 mm as the holes in perforated metalloelements. It fully fills the hole and therefore completely transfers the load, and also works well on the cut. In addition, thanks to the cone head rest, the screw is better centered.

The usual self-sufficiency does not always transmit the load completely, it works much worse on the cut. Well, the anchor nail cannot be dismantled without destroying the part of the wooden element in which it is drunk.

But the anchor screw is easily twisted and can be wrapped in a wooden element in a new place.

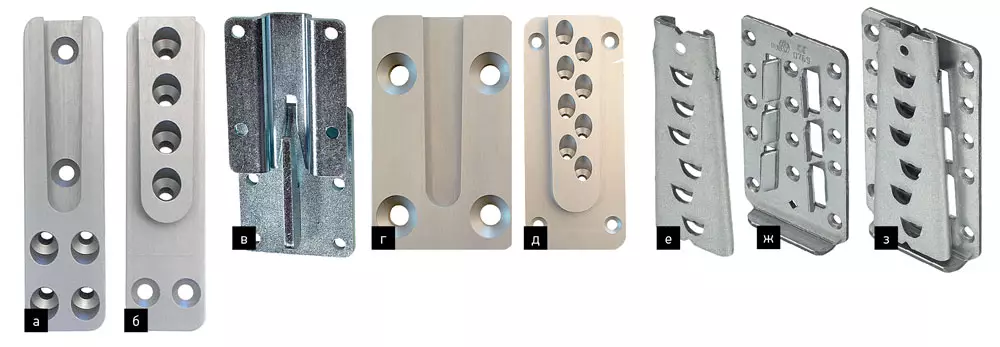

2. Metal Schip-Paz systems

The Nodal Connector "Atlas" is made by the German company Eurotec. The element is made of aluminum and consists of two parts, one of which is equipped with a spike, the second - appropriate groove. They fasten with each other on the principle of "Lastochka Tail", which allows to ensure reliable transmission of vertical and horizontal efforts, perceive efforts when tensile and compression and even bending moments. The compound can be both visible and hidden, for which both metal pieces are combined into pre-erected grooves. The length of the nodal connector "Atlas" - 70-200 mm. Price - 1500-5500 rub. For 1 pc.

The main competitors of Eurotec in the Russian market are the Austrian companies Pitzl and Sherpa Connection Systems, which produce a similar range of connecting elements. The SHERPA system is more known, providing the carrying capacity of compounds from 5 to 280 kN -

Special program for calculations allows you to pick up fasteners for each specific case. Any connector consists of two aluminum parts, which are also fastened by the "Lastochka Tail" principle. The cost of SHERPA elements is from 800 to 12 thousand rubles. For 1 pc.

Photo: BB Stanz-und Umformtechnik, Pitzl. SHERPA connectors (a - d) made from superproof aluminum alloy, and steel elements of BB (E - H) allow you to create not only high-strength and reliable building structures, but also very aesthetic stairs and even furniture

Another Eurotec competitor is the German company STANZ-UUND UMFormTechnik, which has developed a connecting node. It is made of a galvanized sheet steel with a thickness of 4 mm and consists, as well as its aluminum beans, from two parts that are fixed to each other on the principle of "Lastochka Tail". Both halves are attached to wood with self-draws, the number of which depends on the size of the element. BB connectors have a width of 70 mm and a length of 90, 125, 150 and 190 mm. The price is one of the most accessible today: 180-800 rubles. For 1 pc.

Connectors allow in a few minutes to solve the tasks, which in classical construction technologies are required hours and even days.

3. Three-dimensional rails

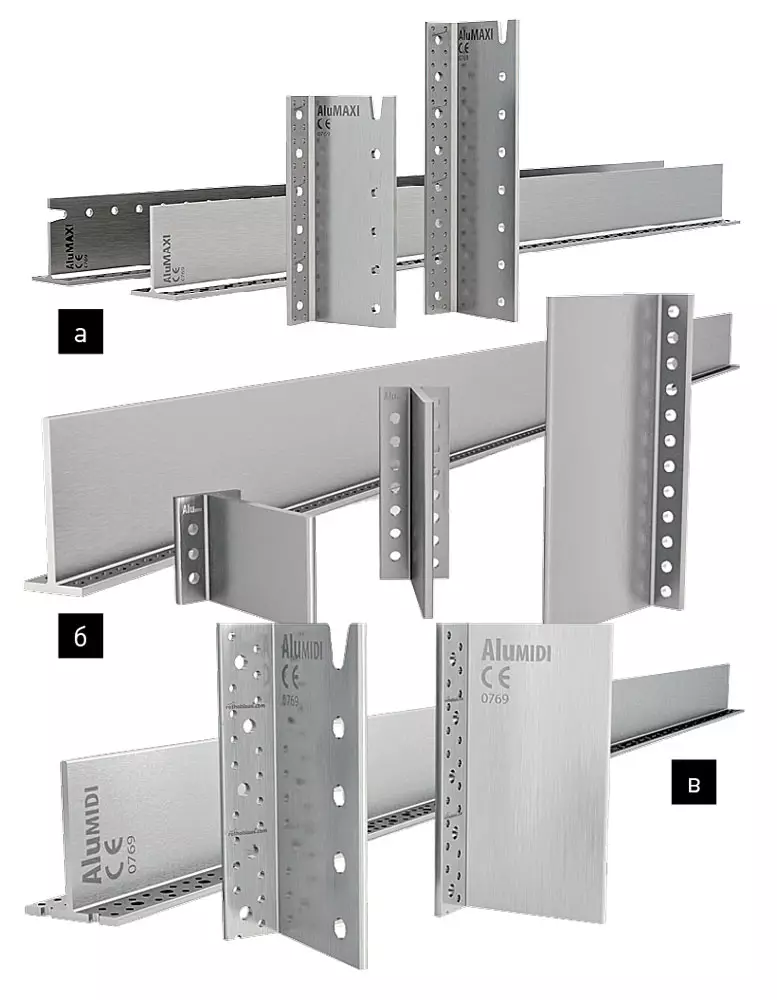

Photo: Rotho Blaas. Three-dimensional perforated aluminum rails for creating secret connections: Alumaxi (a), alumini (b) and Alumidi (B)

The Italian company Rotho Blaas proposes to connect the details located both perpendicular to each other in the same plane and at an angle of vertical, using T-shaped rails, which are made by extrusion from aluminum alloy high strength EN AW-6005A. They are produced in three modifications designed for different levels of loads: ALUMINI, ALUMIDI and ALUMAXI. Each presented rails both with holes at the base and perpendicular to it the shelf and without holes in the shelf. Rakes may have a fixed length (from 80 to 768 mm), and in modifications without holes, rails are available with a length of 2176 mm with cuts every 64 mm, which allows you to make fasteners of any length.

Photo: Rotho Blaas

When installing, the base of the rail is attached to the beam by self-drawing, then a groove of which corresponds to the rack shelf is made on the end to the labia beam. If the latter has perforation holes, then using the shelf as a conductor, the holes are drilled in the lag, they put it on the shelf and insert metal pins into them. If there are no perforations, a lag is put on the shelf and a compound is fixed with a screw with a drill. Price Raking Fasteners: 1230-18 425 rub. For 1 pc.

The connecting system should be selected in accordance with the sizes of the cross sections of the connectable beams, as well as the static and dynamic loads acting on them.

4. Hanging elements like "Yozh"

Photo: Rotho Blaas. Installation of elements "Hedgehog" is simple. In the end of the lags, a deepening is made, into which the connecting element is invested and fixed with screws twisted at an angle. Next, lag through a predetermined hole is attached to the beam with a threaded element screwed into the central hole of the connector

Rotho Blaas Disc connections are a carbon steel washer with galvanic galvania. At the base of the washer, there are drilled holes for self-tapping screws, in the central part - a hole with carvings. In the latter, the stud is screwed, they make it a free end in a pre-drilled hole in the beam and fixed from the opposite side of the beam with a wider washer with a wide wash. The resulting connection is successfully operating both on the shift and extrusion. With a large load in the end of the lags, you can simultaneously install up to three DISX elements with the base diameter of the washer 50, 80 and 120 mm (the diameter of the threaded holes - M12, M16 and M20, respectively). Price: from 4145 to 9044 rubles. For 1 pc. (Screws are included).

An alternative to Disc connectors serve EUROTEC IDEEFIX elements. Fastener is made in the form of a hollow cylinder with an external diameter of 30, 40 or 50 mm made of aluminum alloy. At the bottom of the cylinder there is a hole with M12 thread, M16 or M20. In the upper - cone recess with the screws under the self-tapping screw, drilled at an angle of 45 °. An ideefix element is attached almost the same as the previous connector, but the lag to the beam is fixed not with a pin, but a powerful bolt with a wide hat (included with the kit with the screws). Price - 1500-4500 rub. For 1 pc.

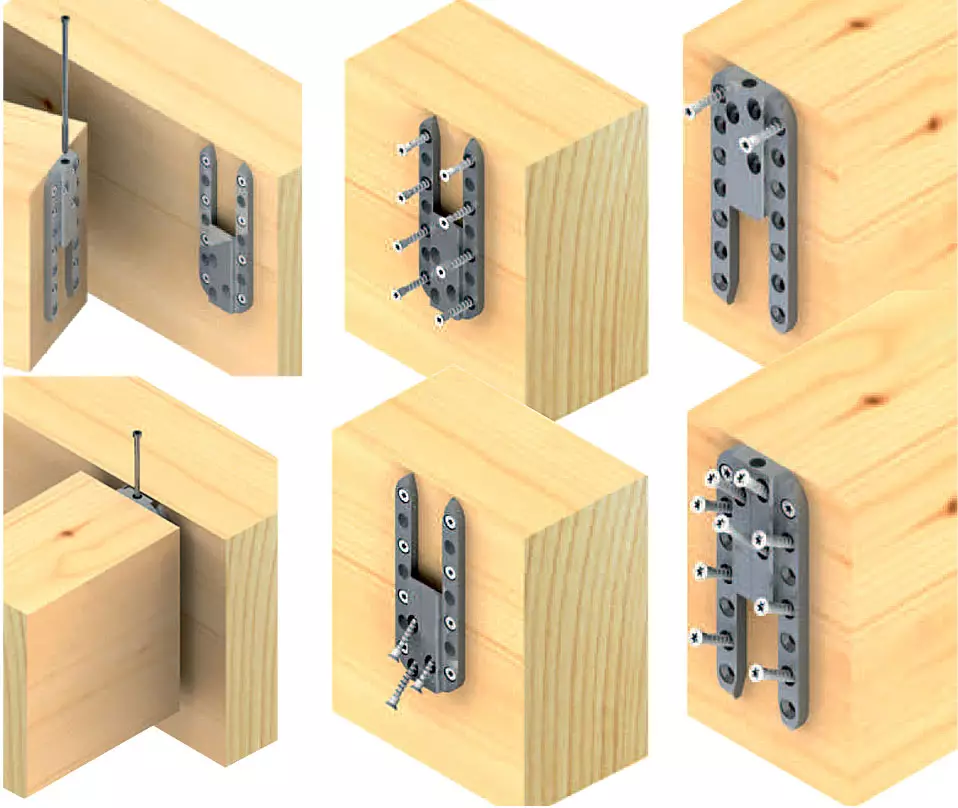

5. Self-tapping screws Konstrux

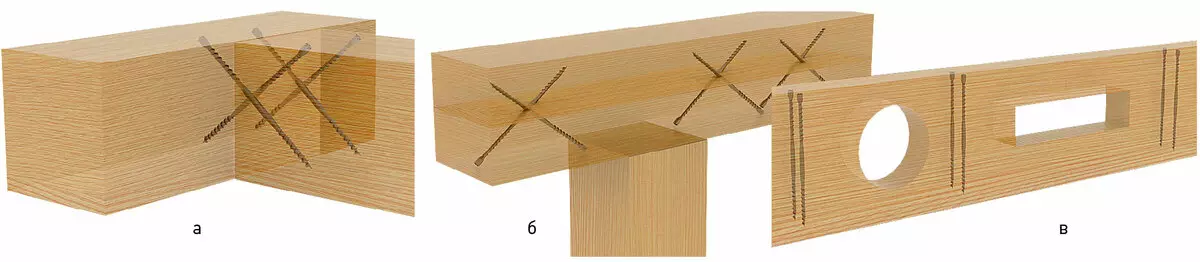

These unusual products allow you to save not only the time required for assembling the node, but also means, because the connecting metal elements are not needed. The self-tapping screws have a complete thread that creates high resistance to pulling out, and is completely twisted into wood at an angle of 30, 45 or 60 °, which radically changes the usual scheme of their work. In this case, the screws operate only for pulling out that it allows them to make a significant part of the efforts acting on the connection. Thus, it is possible to connect the parts at an angle (a), to allocate the elements, reducing their deflection (b), enhance the places of cutouts in beams and lags (c) (see figure below).

Photo: Eurotec. Choose a suitable screw konstrux, element bonding scheme, and also calculate the required number of screws helps a special ECS program, which can be freely downloaded on the site of the manufacturer of self-tapping and large seller

There are self-tapping screws with cylindrical (screw diameter - 6.5; 8 and 10 mm) and counted (screw diameter - 8 or 11.3 mm) head. Length - 65-1000 mm. Price - 20-800 rubles. For 1 pc. For the installation of screws with a length of less than 245 mm, the pre-drilling is not required, but for longer (in order to prevent an entry to the side) it is recommended to drill holes in advance for the samp of the depth to ⅓ from its length.

6. Special self-tapping screws

With the help of the Hobotec self-train, massive boards, blockchas or timber imitation are fixed. The product cap is equipped with milling ribs and is easily comfortable in wood, and the tip is made in the form of a drill. The mill in the middle of the short-length screw increases the diameter of the hole, allowing you to make the fastest element densely. The screws with a diameter of 3.2 mm and a length of 20 to 60 mm are made of conventional steel coated (price - 1100-2200 rubles. For packaging of 500 pcs.) Or stainless steel (price - 3500-7500 rub. Per pack of 500 pcs .).

The tightening selflessness is also equipped with a cutter, but its tip is different - it has a special groove that turns the screw in the tree drill. A flat hat has a large diameter and is equipped with an independent head and a hex sliced. A special wax coating is applied to the self-sufficiency, reducing friction when screwing. Product diameter - 3-12 mm, length - 30-600 mm. Price - from 300 to 5 thousand rubles. For packing out of 500 pcs.

Photo: Eurotec. Self-tapping screw - Flyugel for fastening wooden sheat to a steel base. Equipped with a tip-drill and special "wings" (located above the tip), which expand the hole in the wood and break when the metal drilling. As a result, cutting the thread in metal, the screw is fixed in it, and the wooden element attracts the hat to the metal. Length: 32-125 mm. Price: from 500 to 2500 rubles. For packing out of 500 pcs.

Adjusting self-adjustment is useful, for example, for fastening window and door boxes or a wooden drying to a tree, concrete, brick or metal (an element can be equipped with a drilling tip of two types). Self-tapping screws into the box and the wall or power element behind it. At the same time, the ring cone "spikes" arranged under the head of the screw are firmly fixed in the box (almost like a fishing hook), due to which its position relative to the wall is easily adjusted by further screwing or unscrewing the fastener element. Length - from 60 to 125 mm. Price - from 2000 to 3,500 rubles. For packing out of 500 pcs.

Special tapes make it possible to significantly speed up and facilitate the implementation of those operations that are necessary when creating wooden structures.