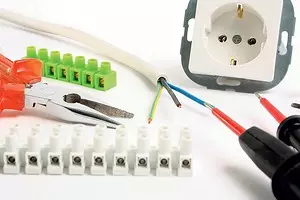

Most of us have to sometimes resort to the help of an electrician that optimizes homemade wiring or eliminating fault. As a rule, it is required to connect the conductive conductors of wires and cables. In this, it would seem, a simple procedure have its own subtleties that should be remembered.

Fontanis / Fotolia.com.

The connection of the conductive livers is a responsible event. After all, with negligent or wrong work, contact will be unreliable, and the wiring in this place will begin to warm up. During heating, the metal is deformed, why contact may be disturbed. This situation will at best lead to the failure of wiring and technology. In the worst possible fire.

Photo: joserpizarro / fotolia.com. When choosing one or another connection method, it should be remembered that the repair may have to be conducted in adverse conditions (lack of space, an uncomfortable location of the connection area, etc.). In this situation, modern commuting (terminals, caps) are usually much more convenient than soldering, and even more so welding

How should the electrician act? "The rules of the electrical installation device" say: "... Connection, branch and termination of wires of wires and cables should be made using crimping, welding, soldering or sections in accordance with the applicable instructions approved in the prescribed manner." This list does not have a "twist", the most popular method of connection. It is believed that this method is not reliable. Today it is not recommended to use a "pure twist" - it should be enhanced by soldering, welding, crimping sleeve or a CES connective cap. Each method has certain advantages.

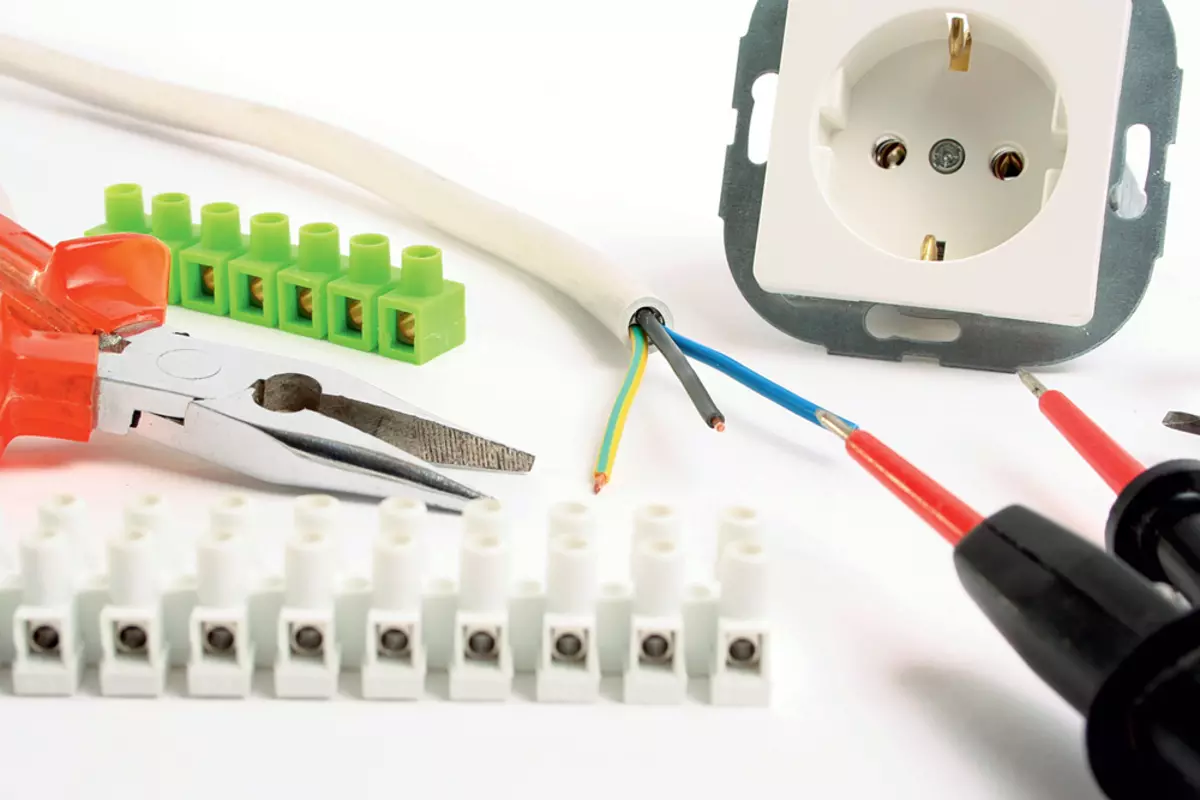

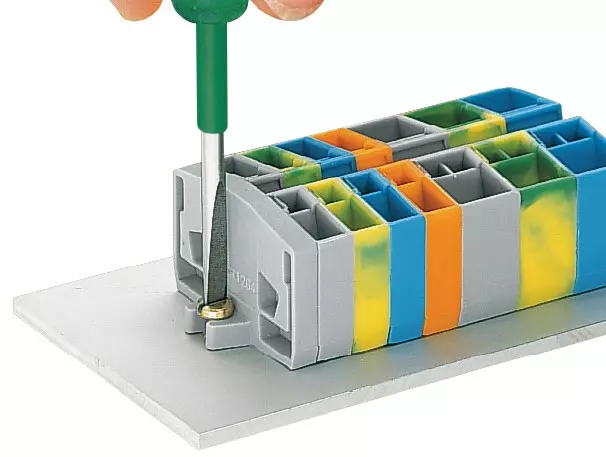

Photo: Boris Bezheus / Burda Media. Wire switching devices: Pads with screw terminals

Soldering, welding

Perhaps the most reliable options. But perform a high-quality soldering, and even more so welding, only a specialist using the appropriate equipment can. Therefore, it is best to leave these ways to installers professionals.

Photo: Boris Bezheus / Burda Media. Connecting caps SIZ velocked on twisted veins

Pressing Gilsoy

In this case, the special tool is also required - press clamps. Cheap models will cost 1-2 thousand rubles. Learning how to handle it is much easier than, say, with the welding machine. At the same time, the crimping provides a high quality connection. It is only important to gently twist the veins and pick up the slide of the suitable diameter so that it fits tightly to the wires, and did not hang on them. Pressing is optimal for connecting stranded cables.Sizes connecting caps

They wear on twisted veins and with a little effort come on them (thread is provided within the products). Caps SIZ are widely used, as they do not need an additional tool for their installation. They differ in the diameter of the beam lived, which is calculated. Cap PPE should pick up very carefully, otherwise it will hold badly.

Terminals

When using them, each lived inserted into a separate groove. This option, in particular, allows you to switch aluminum and copper conductors that should not be contacted directly with each other. There are many varieties of pads, the simplest are screw, where they lived with a tightened screw. The lack of screw connections - they must be regularly (let's say, once a year) pull up to compensate for the flow of metal conductor. Therefore, spring terminals are considered to be more perfect, in which the spring technology does not allow the contact to weak. Spring terminals are designed and manufactured by Wago. Connections of this type do not need maintenance, as the materials and design of the terminals provide high-quality contact between the latter and conductors for many years.Comparative characteristics of aluminum and copper wires

- The aluminum wire allows a smaller current load with the same cross section.

- Aluminum wire has a smaller plasticity and it breaks easier.

- Aluminum is oxidized in air, and over time, the film film worsens the contact of the wires. To prevent oxidation, you should eliminate air access to the metal. For this purpose, special heat shrink tubes are applied to the connected wires, or a special electrically conductive paste, which is applied to the connection.

- Metals have the ability to gradually deform under the influence of load (fluidity), so the screw connections weaken over time. Aluminum, this unpleasant property is expressed much stronger.

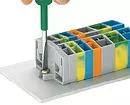

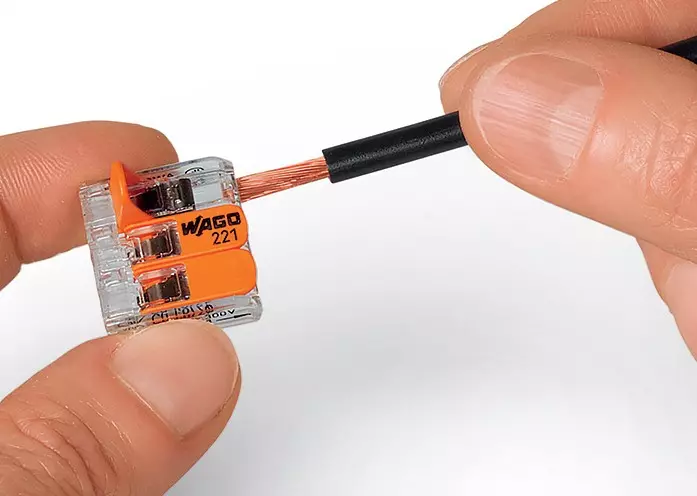

Photo: Wago. Compact two-, three-time and five-wire terminals of the series 221 (WAGO) are suitable for any types of conductors and can be used in a limited space.

The transparent case allows you to see whether the wires are connected correctly.

Compact modular terminals 264 (WAGO) to connect a large number of conductors (over five poles) of any types, cross section to 2.5 mm² and maximum load 24 A