If in one project skillfully connect the traditional Russian and Italian architecture with new technologies, it will be possible to create modern houses of the most unusual form. For example, similar to the aircraft.

The Russian construction company in collaboration with Italian architects in a short time has built its first energy-saving frame-panel house A + in the suburbs. The construction technology, they developed together, designed the housing of the Italian company Santilli Ingegneria, the Russian company APRIVIRIALBERO, on the newly opened factory of wooden houses in the Chekhovsky district of the Moscow region, manufactured a complete set of panels and wooden elements for the building, and then elevated it under the control of Italian architects. In the article we will talk about the implementation of this project.

Photo: "APRIORIALBERO"

Choosing a project

The works of the talented Italian architect Vincenzo Santili liked many domestic companies that acquired its projects, and then realized, without considerably with local operating conditions. Have you been satisfied with customers with the heat-saving ability of structures designed by Italian standards? We will default about it. Let's just say that the design and architecture really satisfied them. The buildings were unusual and even somewhat unusual for the Russian market for private houses.

APRIORIALBERO company decided not to follow this path, but to agree on the development of projects adapted for operation in the context of the Russian winter. The Italians gladly perceived this idea. The new requirements have mastered the requirements for themselves, studied the standards and designed a series of energy-efficient houses A +.

The structure of the outer wall: the outer cover of 20 mm, the OSP plate 15 mm, the insulation (eco) is 240 mm, the OSP plate is 15 mm, the drywall is 12 mm. The reduced heat transfer resistance R0 = 5.9 m² · ° C / W, which corresponds to the category A +

According to Vincenzo Santilli, for the project under consideration, he took the house typical for Russia with an attic, replacing a full-fledged second floor, but at the same time he lowered the roof "wings". As a result, the two-story building is only the central part of the building, and all the adjacent rooms adjacent to it have an increased height of the ceilings. And the ceilings of the premises located both in the central part of the house, so

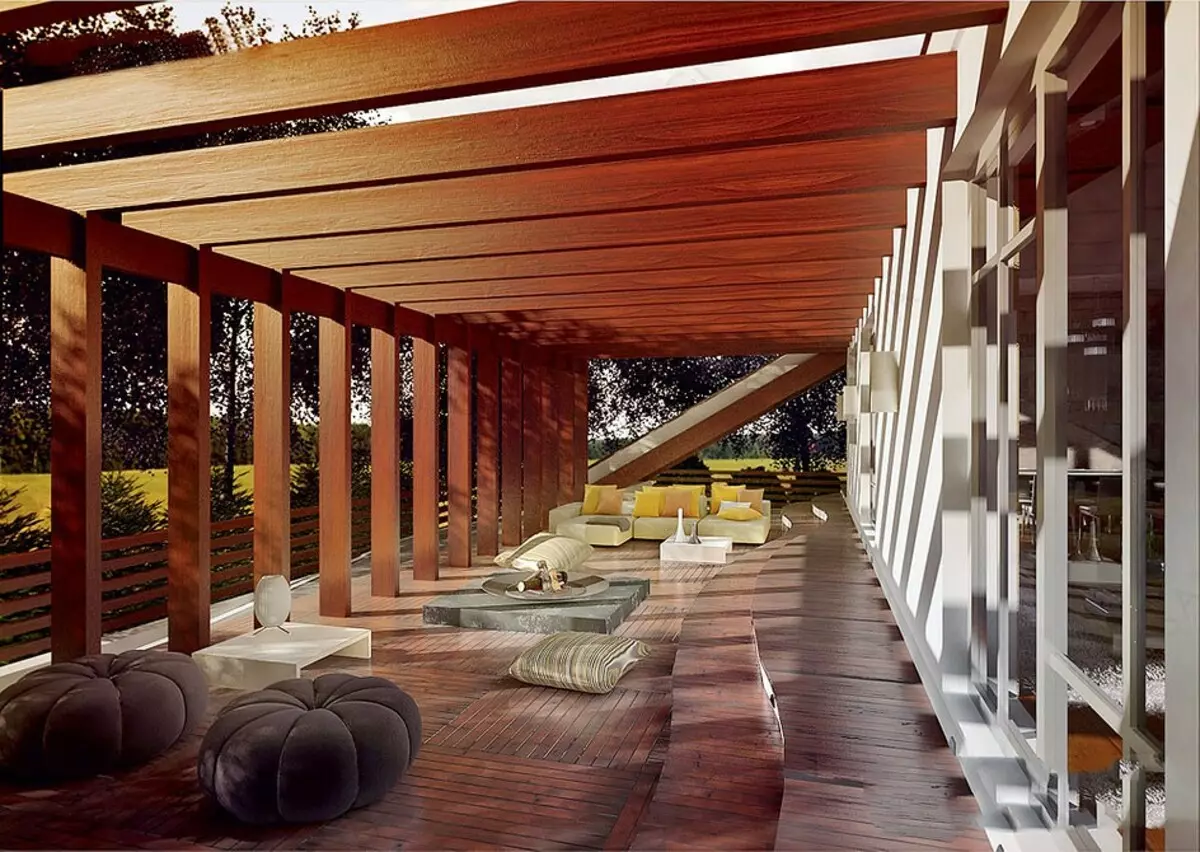

And under the "wings", not straight, and bevelled, which should create a feeling of space, light and air. Outside the house under the "wings" there are pergolas, which is typical for Italian, but atypically for Russian architecture. However, nothing bothers the customer instead of one of them to arrange, for example, a canopy for the car, and instead of the second - the terrace or a veranda usual for Russia. It is only necessary to voice these wishes before the project is started, and then the necessary changes will be made in the working drawings.

Frame from high quality glue bar religible made of boards

Design frame panels

All panels used to assemble houses have a frame of glue wood, which is trimmed with OSP-plates (OSB-3) with a thickness of 15 mm from two sides. At the same time, for the manufacture of overlapping panels, external walls and roofs, a timber is used by a cross section of 240 × 120 mm for panels of the inner walls - 120 × 80 mm. The step of the racks in any case is 600 mm. In the inner cover of all cavities (formed between the racks and beams of the frame) of the finished panel, the holes with a diameter of 80 mm are cut. Through them, cavities by planning are filled with insulation - an eco-tailed (50 kg / m3 density for panels of the inner walls and 80 kg / m3 of all others). Then, the carved fragment is returned to the holes and the resulting gap scotch is riveted.The cavities in which cables will be laid, are filled with insulation already at the construction site.

Foundation of the house

According to a predetermined geo-survey, under the house there is a layer of very dense loam, without clay lenses, which eliminates the exhaustion (the soil is saturated only from the surface and then dries quickly). In such a soil, it is extremely unwanted to plunge the foundation. Therefore, it was decided to build a belt monolithic small-breeding foundation. The width of the concrete reinforced ribbons was 400 mm, the height of the base is 1200 mm. Because of the small slope of the site, one side of the foundation lies almost on the ground surface, the opposite is blown into the ground by about 800 mm.

In places stipulated by the project, there are concrete stands between the ribbons - they will serve as additional supporting platforms for wooden beams, which will be based frame slabs. Their main purpose is to prevent the inevitable (over time) the deflection of wooden beams of overlapping.

Special hydraulic jack makes it easy to move items when installing

Special tool

When installing the house often there is a need to move the frame panels or tightly pull each other. Using for these purposes a sledgehammer, you can damage expensive and exactly fitted under the size of the framework of the panels, so in this case the builders used a device that is essentially a hydraulic jack. Supports for its sites during operation served trimming of the glue bar attached to the framework of the panels.Ground overlap

It was used to the surface of concrete tapes of the foundation, a waterproofing tape was used, and then laid the reference timber with a cross section of 240 × 100 mm. The bar was thoroughly leveled with wooden pads, and then attached an anchor bolt to concrete ribbons. The alignment operation is quite a time tool and occupied almost two business days, but as a result, it was possible to remove the surface of the bar on which the panel of the outer walls will be taken, almost "in zero" (the height difference around the perimeter did not exceed 2 mm), which not only facilitated, but also Significantly accelerated the installation of the Domocompute panels - he was spent in ten days.

When installing the basement, the original scheme proposed by Italian architects was used, in which the floor panels of the first floor do not rely on the foundation tape from above. Supported by the cylinder beams with a cross section of 240 × 140 mm, attached by powerful anchor bolts to ribbons from the inside, as well as dual beams, which are laid along the midline of the flaps (further rely on intermediate concrete stands). With this scheme, the vibration arising from the operation of the overlap is not transmitted to the walls.

The floor panels with a thickness of 240 mm attached to the beams of overlapping by self-draws with a length of 400 mm, twisted at an angle of 45 ° towards each other (step 300 mm). It should be noted that this method was bonded, or more precisely, the wall panels were stacked.

The front facade of the house was chosen by boards painted in a dark tone, and supplemented with copper decorative elements. The balcony was installed parapet from tempered glass

Secrets of Montaja

The building complex panels are presented in detail in detail in the photos, so we comment on the most interesting moments remaining "for the scenes".

Let's start with the material from which the framework of the panels is manufactured. Today, many house-building companies are trying to independently perform all technological processes: produce a glue bar, they will be profiled and build at home from it. APRIORIALBERO did not take on the production of the glue bar for the manufacture of the frame and the power elements of the roof support design. Her specialists appealed to one of the best Russian producers of glue wood - a plant "Sokolsky dock". Why exactly to them? First, wood for a plant manufactured by a plant is harvested in certified forests allocated for industrial logging, with strict compliance with technology and subsequent reforestation, which is confirmed by the international FSC certificate. Secondly, a thorough compliance with the manufacturing technology was confirmed by the MPA certificate issued by the European Center in Stuttgart. Therefore, "APRIORIALBERO" boldly purchases the glittering beams of a large cross section from this manufacturer, which, if necessary, cut into thinner elements.

It is also worth noting that in the manufacture of panels, the insulation (eco) is not fascinated by all cavities formed by the frame: the empty remain those in which electrical cables will be laid. After the installation is completed into such cavities through the cut-off holes, the electrocabilities placed in a non-combustible corrugation were tightened. And only after the completion of these works and inspection of the system's performance, the insulation is blown.

The next moment. The unscrupulousness of the joints of all the compounds of the elements without exception is ensured by the use of psyl tape glued into two rows, as well as sizing special scotch. Immediately after the end of the installation, the join's household complex is sinking from the inside of the building, and after 2-3 weeks - outside (joints should dry).

Finally, it should be mentioned that all the strength elements of the house design are made with a one-hour, or even a double safety margin. Moreover, for their manufacture, it took almost 130 m3 of glue wood. It is possible that this approach will seem wasteful. But Italian designers and Russian builders do not doubt his correctness. They believe that such a powerful frame system does not deliver the operational problems to the owners of the house, and therefore give the assembled construction of 20 years warranty. In the extreme case, the house will have to perform only cosmetic repairs.

Secret aluminum brackets greatly simplify the connection of the elements

New fastener system

Recently emerged complementary brackets manufactured, for example, by the Italian company Rothoblaas, allow you to facilitate the connection of wooden elements both at a right angle, and under the tilt from the vertical. The bracket is a T-shaped element from high-strength aluminum alloy made by extrusion. The thickness and width of its shelves are chosen depending on the magnitude of the parts and the required connection strength. The length of the bracket can be fixed, although there is an opportunity to make brackets of any length, cutting off part of the "Reiki" with a length of 2.2 m. To create a connection, short perforated shelves are fastened with self-proof to run. At the end, the beams fasten with it make the height, the width and depth of which correspond to the long shelf of the bracket (does not have perforations). Then the beam is put on the groove on the bracket and is fixed with self-draws or studs with a drilling tip (the fastener step is set by the template).Turnkey house

It is necessary to explain that the declared 20-year warranty is given only on the condition that the construction company will take on the execution of a complex of work.

It includes:

- design;

- Foundation;

- manufacture of structural details;

- assembly of the house on the foundation on time from 6 to 18 days;

- installation of windows and doors;

- Device of engineering systems (water supply, heating, sewage, electrician, low-rise) within the contour of the house ready for connecting

to external networks;

- complete interior decoration, including wall and floor coverings,

as well as kitchen furniture with built-in home appliances (it is possible to make furniture for the whole house);

- Exterior finish at home.

Engineering and finishing works take up to 2 months after the construction of the box at home. And on them, the customer receives a guarantee of 18 months. Such an approach is very popular both in Europe and in America, but so far, unfortunately, is atypical for Russia.

Build houses need to be high quality, as personally for themselves. And then there will be no problems, and every year to live in such a house everything will be more pleasant.

The foundation of the house - a ribbon fine-gulled

For its device, a trench of a depth of 300-800 mm was dugged (the site has a bias), the bottom of which constructed the sand-gravel mixture (layer 200 mm), and then placed in advance the elements of the metal frame and installed the formwork in them.

Mixed from concrete brand M400 Foundation tapes rose above the level of soil at 600-800 mm. To prevent the evaporation of moisture from concrete, freshly tapes covered with polyethylene film

When, after 4 days, the concrete scored approximately 25% of the design strength, the polyethylene film was removed, and then dismantled and removed from trenche a wooden formwork

Support for overlap panels serve beams with a cross section 240 × 140 mm

The beams had at such a height so that the surface of the floor panels laid on them was on the same level with the top of the foundation ribbons.

To the flooring flooring attached a segment of a segment of a segment of 120 × 100 cm to which panels of the interior walls will be relying

Before installing panels in the grooves on the strapping bars, two ribbon pips pasted

Installation of wall panels began with the corner of the house and immediately dashed in the external walls internal. Panels temporarily attached to the overlap of the outlines, and then tightened with self-draws

At the bottom of the wall panels, the OSP-slabs are extended for a frame per 100 mm - when installing, they tightly wrap the strapping bar. The connection is fixed by self-drawing

In the central part of the house on the collected walls of the first floor, the panels of the block-lathe thickness of 200 mm were laid. They were attached to the walls twisted at the angle of self-draws, the step of which was 300 mm

Over the front of the walls of the walls of the first floor, glue beams were installed with a cross section of 320 × 160 mm, attaching them to a frame of panels with self-draws with a length of 420 mm

On the collected intergenerational overlap, the panels of the walls of the second floor were installed, and then in the grooves made in the manufacture of wall panels, put the beams of the runs. The section of the beams is 420 × 240 mm, they are made of glue wood

After the end of the rank installation, the builders mounted inclined beams on the side of the side facades at home, attaching them to the top end to the extreme run, and the bottom - to the foundation ribbons

240 mm thick roof panels began to lay down from the bottom from the foundation to the roof. Windproofing was installed on the collected slurry and pressed it by the rails

The slats attached to the slats, the slave was attached from OSP-slabs, a ventilated clearance appeared under it

The angle of inclination of the roof is only 30 ° degrees, so the installation of roofing has begun from a solid waterproofing carpet device

A soft bitumen roofing was glued to a waterproofing carpet, the petals of which are like a wooden drank. In future pergolas, located on both sides of the house, created flooring from a foliage board

Since the house is located far from the gas and highways, it was decided to gasify it autonomously. For the implementation of the intention, the tank for liquefied gas was purchased and mounted with a capacity of 5 m3. For the heating season it will come, Xia fill out only once

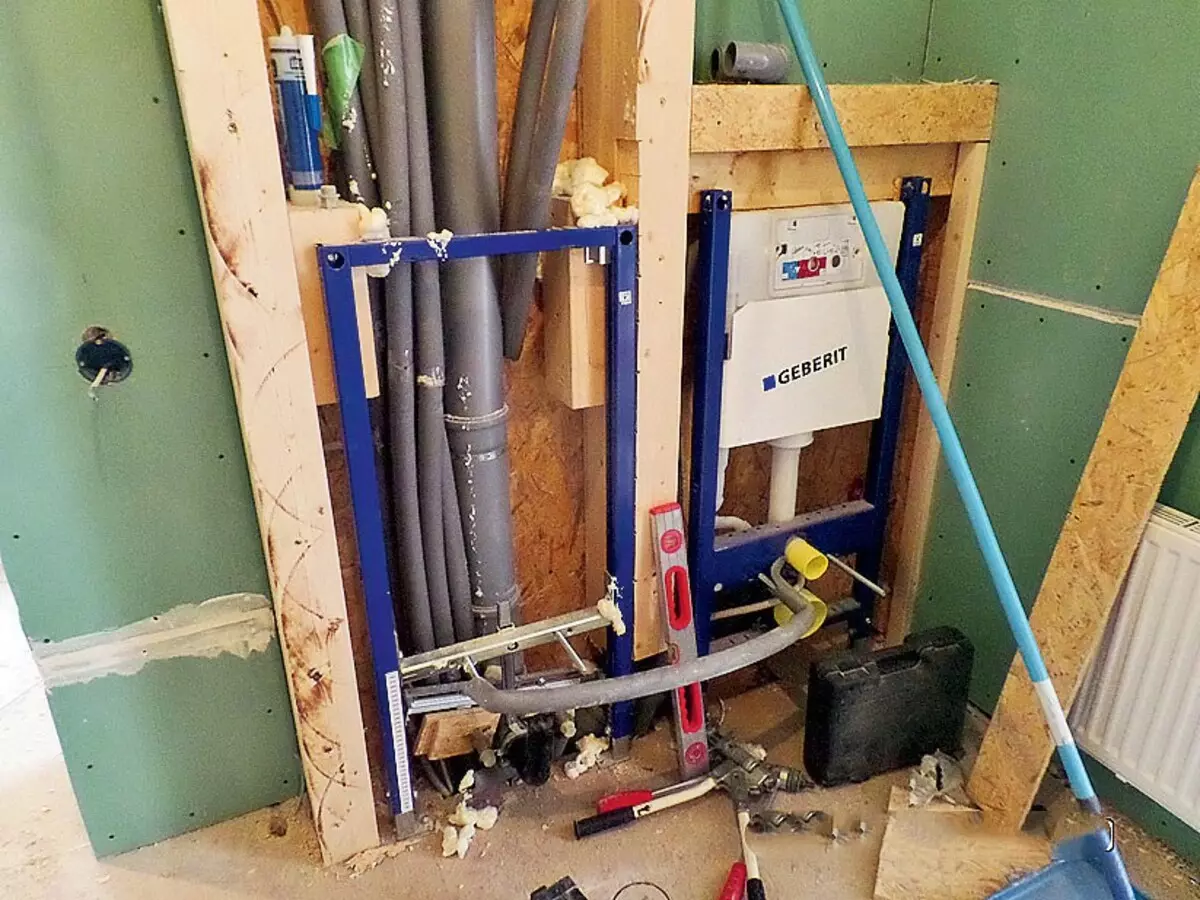

In order not to disturb the integrity of the panels, the tubes of communications and ventilations were packed in special weigls located in the bathrooms

Electrocabilities, on the contrary, laid inside the panels, placing them in a non-flammable corrugation. All cables converge to one shield

When the panel is internal finishing, they were tested with plasterboard sheets, which were splashing and covered with dispersion paint

Wooden elements visible in the interior, as well as wooden energy-saving windows and doors were painted in a dark tone, contrasting with the color of the walls. Floors separated by parquet board

Building roof editions were powered by a colored clapboard

Usefully treated with a protective composition of a gluing bar, with both side facades to the house attached spacious pergolas

In the middle lane of Russia, such an element as pergola is still quite rare

Most likely, over time, the owners will fall around both pergole curly plants, and then both empty "extensions" will certainly become a favorite place of rest of the whole family

Employed calculation of the cost of building a house box (including inner finish) with a useful area of 244 m² *

| Name of works | number | Cost, rub. |

|---|---|---|

| Foundation, Walls, Partitions, Overlap, Roofing | ||

Earthworks and a device of a belt small-breeding railway foundation | set | 412,000 |

Production and installation of a home complex | set | 2 693 640. |

Device Roof Set. | set | 275,000 |

Installation of windows and doors | set | 184,000 |

Interior decoration and intestine staircase | set | 1 464 500. |

Floor coating device (parquet, tile) | set | 167,000 |

Finishing facades, coloring, antiseptation | set | 432 700. |

Engineering Communications, Gazagolder, Septic | set | 375,000 |

Installation of electricians, including the elements of the Smart Home system | set | 952 300. |

| TOTAL | 6 042 595. | |

| Applied materials on the section | ||

Glue bar | set | 2,760,000 |

OSB-3 plates with a thickness of 15 mm | set | 723,000 |

Interior decoration materials, including parquet and tiles | set | 692 940. |

Energy saving windows and doors with double-glazed windows | set | 1 131 620. |

Entrance and interroom doors | set | 340,000 |

Facade Finishing Materials | set | 899 160. |

Materials for installation of engineering communications, including Gazagolder and Septic | set | 1 526 780. |

Materials for the foundation device | set | 790 600. |

Materials for mounting electricians, including the elements of the "Smart Home" system | set | 16 449. |

Metal-raised (used bent tempered glass) Parapets balconies | set | 314 000 |

| TOTAL | 10 839 540. | |

| TOTAL | 17 795 680. |

* Calculation performed without traffic expenditures.