In Naberezhnye Chelny, the construction of an energy efficient home was completed, which consumes energy by 78.5% less than it is necessary on the standards operating at the time of its construction. Built for life in harmony with nature, house got the name Natural Balance

In Naberezhnye Chelny, the construction of an energy efficient home was completed, which consumes energy by 78.5% less than it is necessary on the standards operating at the time of its construction. Built for life in harmony with nature, house got the name Natural Balance

Build a "folk" house

Rockwool experts, analyzing both their own rich experience in the construction of high-energy-efficient houses and the experience of their construction by other companies, came to disappointing conclusion: in Russia, it is still quite low rates for energy carriers in the near future, there are no high demand for ultra-modern passive, and those More than active houses with all their architectural and technical bells, and most importantly, with their huge cost, which can reach up to 30 million rubles. Even with a decrease in the price of them, 2 times the picture is unlikely to change significantly. Avoid if the cost of an average energy efficient home will be like Europe and America - no more than 30% higher than the value of the house of the usual and at the same time will not exceed 7-8 million rubles. (that is, it will be about a quarter of the sum above), then the demand for such buildings from Russian consumers may be very substantial.

|

|

|

1-3. The "support" of the house serves a small-breeding ribbon monolithic reinforced foundation with a width of 40cm, the base of which is at a depth of about 70-80cm (1). Along the concrete tapes posted the first, leveling red brick series, which was covered with a layer of waterproofing. The reinforcement grid (2) was installed on it. Then, using red and gray facing brick, built the base house with a height of 60cm (3). From above, a second layer of waterproofing was laid on it.

|

|

4, 5. The walls of the house lay out of aerated concrete blocks with a size of 600x250x400mm, fastening them with cement-sandy solution (4). When overlapping window and door openings, concrete jumpers were used. Walls the walls of the first floor of the "belt" of a brick, which, when creating the overlap, has become a support for the ends of hollow concrete slabs (5).

To verify the correctness of this assumption, Rockwool decided to build a highly energy efficient residential house of medium-sized (total area - 186m2), so to speak, with the usual for the European part of the country and from those who have become familiar to many Russians of amateur-concrete blocks. The technical equipment of such a house should be strictly within the limits needed to ensure sufficiently comfortable living conditions, so as not to cause a significant increase in its total value. Father, as the conceived "House for Life" was erected, called Natural Balance, and which as a result managed to achieve the authors of the idea, we will tell in this article. It is also necessary to specify that the editors sets out ideas and opinions of the authors of this project in the form in which they were represented.

Effective insulation

Speple Protection

With a modern approach to the rationing of heat shields, it is proposed to consider the building as a closed energy system and limit its power consumption as a whole, and not only by reducing losses through enclosing structures. To achieve a given power consumption without a dangerous reduction in the comfort of the microclimate, additional requirements are also introduced: the temperature of not only air inside the house is stipulated - optimal (+19 ... + 20 s) and the minimum allowable (+ 17c), but also the internal surfaces of all its enclosing structures. With a systematic approach, the mainly laid in thermal calculations is the value of the proportion of thermal energy for heating, normalized for each class of energy efficiency of the building (in accordance with SNiP 23-02-2003 there are only five of them and they are denoted by letters A, B, C, D, E ). Such an approach, according to experts, is more correct, as simply obliges the designer to meet the requirements for energy consumption to increase the heat insulating ability of the enclosing building structures.Hearth roofing and floors

The conditions for the developers were valid for the developers so that the projector house corresponded to the class of energy efficiency A. To achieve this, they developed technical solutions to increase the heat-saving ability of walls, floors and roofs. The Natural Balance is installed energy-saving windows with a five-chamber profile with a thickness of 76mm and double-chamber windows with low-emission coating on the inner glass filled with inert gas (heat transfer resistance R = 0.79 mc / W). Moreover, most windows are oriented to the south, which allows the most of the use of natural lighting and capture the heat inclusive with solar radiation. The entrance to the house is equipped with a vestibule, which also reduces heat loss.

|

|

|

6-8. For the manufacture of rafting legs used boards with a cross section of 200x50 mm. The tops of the rafter were poured pairwise, and then the pairs were tied up with a skate beam (6). The lower ends of the rafter is based on Mauerlat, attached to the walls of anchors (7). Parosolation was laid to the rafters and plates of the insulation of a total thickness of 200 mm (8) were laid on it.

|

|

|

9. The insulation laid between the rafters was covered with a vapor-permeable membrane, which the counter tests were pressed against the rafyles.

10, 11. In order for the thermal insulation layer, it moves from the walls to the roof without breaking, the processes of insulation and the other were carried out simultaneously. When the walls are insulated to them, with the help of U-shaped metal elements, the frame-crate from the board with a cross section of 150x50mm (10) was attached, and then the insulation plates were laid between its racks with a thickness of 150mm, additionally attaching them to the walls of a plate dowel-nail (11).

The process of additional insulation of walls and roofing structures is shown in detail in the photos and schemes, so in large comments, in our opinion, does not need. Avtot process insulation floors We will look more detailed.

Heat float

The floor of the first floor was created after the base of the house was posted. At the aligned and the rambled ground from the inside of the house laid a layer of waterproofing, which started on the walls of the base and on its upper surface to separate the brick base from the first row of aerated concrete blocks. The hydraulic insulation was poured with a layer of clay with a thickness of about 200mm (at the same time its top level should coincide with the upper level of the first row of the conchion of the base). Further, the ceramzite was shed the so-called cement milk, then the concrete screed with a thickness of 100mm, reinforced by the road grid, was filled. It was laid on her stone wool slabs "Flor Batts" thickness of 150mm. From above, a reflective layer and a metal grid was used to which the pipes of water warm floor were attached, and then poured another concrete screed with a thickness of 80mm.

|

|

|

12-14. Across the rafter criticized the crate from the board with a cross section of 100x30mm, and at the same time they mounted the crate from the same boards on brick pipes, inside which the smoke channel of the fireplace and risers of exhaust ventilation are located (12). The crate was put on a guide carpet and metal tile (13). The insulation was covered with a vapor-permeable membrane on the walls, pressing her to holding the insulation by the lattice by the Raiki counterchettage (14).

|

|

15. On top of the waterproofing membrane, the lattice was mounted with a cross section of 100x50 mm, under which, for the creation of a ventilated gap, put the bars with a cross section of 30x30 mm.

16. The RockPanel Natural Panels were attached to the created crate of greenish-brown color, the same as the tone of the heaters from the stone wool. These panels are distinguished by the fact that after a certain time after installation, the color is changed, purchasing a red-brown tint.

Engineering equipment

The heating and hot water supply system is provided at the expense of the soil heat pump, ten wells were drilled on the site next to the house, each 35m depth (initially planned four wells to 70m, but in the process of drilling the first well when passing the 35th meter Superfered into the basalt reservoir, as a result, it was necessary to reduce the depth of wells twice and increase their number 2.5 times). The PND pipes connecting the pump in the house with wells are laid at a depth of more than 1.5 m, which is lower than the level of ground freezing. The thing is not traditional radiators, the heating is ensured due to the water heating floor (low-temperature heating system). Avot from the device of a centralized supply system of the supply and exhaust ventilation with heat recovery was decided to refuse - a natural ventilation system operates in the house when fresh air enters the living rooms through open windows or windows, but is removed from ventilation risers located in the kitchen and bathrooms. The authors of the idea "House for Life" decided to do this precisely on the basis of the results of the economic calculation carried out by them, which convincingly proved that the projected equipment for the organization of forced supply and exhaust ventilation with heat recovery costs quite expensive and the cost of its acquisition, installation and work pays for Due to the saved heat. The hosts of the house, if, of course, will want, in the future they can independently install on the windows of the device for organizing a permanent air flow, and the ventilation channels located in the kitchen and bathrooms can be equipped with constantly pumping the target air fans constantly. It will be possible to go and otherwise to embed in the walls of the residential premises of the house special ventilation devices equipped with heat recuperator.Warming of external walls

That in the end

It should be recognized that the use of energy-efficient solutions in the construction of the Natural Balance has led to an increase in the cost of its construction compared to a regular building by 22.2% (which, by the way, it fully complies with the difference in the cost of energy efficient and ordinary houses in the West) . However, it should be borne in mind that if the house, insulated in accordance with the standards current and heated today, consumes 175 kWh to 1m per year, then a total of 37.3 kWh of 1m is required to be built on the energy efficient home for calculations. The result of an annual savings due to the reduction only energy consumption for heating will be 22,125 rubles. per year, which will allow approximately 12 years to justify increased costs of building an energy efficient home.

|

|

|

17-19. All residential premises of the house are heated with the help of water warm floors, the polymer pipes of which are attached to the grid laid on top of the reflective layer covering the insulation slab (17). All these pipes converge to the comb, located in the "boiler room" near the installed thermal pump (18). There is also another comb, to which the PND pipes of the ground probes (19) are reduced.

In the whole story, it remains to add that the built-in home Natural Balance immediately acquired an ordinary family, which, having weighed everything and against, with pleasure I could change my home to the energy saving, the content of which is less costly for the family budget, confirming that construction is economically profitable, Available and can be in demand.

"Rockpanels" and design

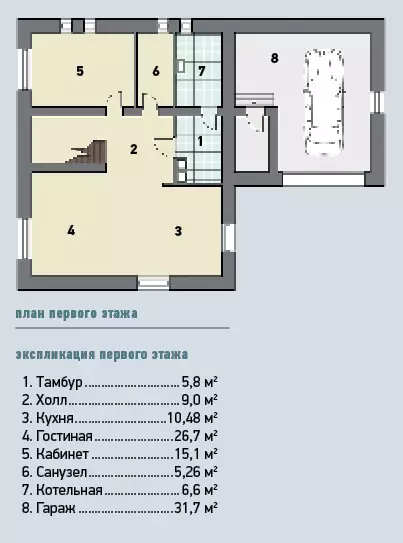

Explanation of the first floor

2. Hall 9.0m2

3. Kitchen 10,48m2

4. Living room 26.7m2

5. Cabinet 15.1m2

6. Bathroom 5.26m2

7. Boiler room 6,6m2

8. Garage 31,7m2

Explanation of the second floor

2. Bedroom 20,7m2

3. Wardrobe 2,7m2

4. Bathroom 7,6m2

5. Bedroom 16,6m2

6. Bedroom 19,1m2

The editors thanks Rockwool for help in preparing the material.