When redeveloping an apartment often have to build partitions between rooms. These works are not considered complex, and many owners give them "on the spill" to masters from a random brigade. And then it is found that the design does not isolate the sound completely, does not withstand the loads and cracks. Let's try to find out how to avoid such trouble

When redeveloping an apartment often have to build partitions between rooms. These works are not considered complex, and many owners give them "on the spill" to masters from a random brigade. And then it is found that the design does not isolate the sound completely, does not withstand the loads and cracks. Let's try to find out how to avoid such trouble

Immediately make a reservation that in this article we will talk only about stationary insulating partitions. "Over the scenes" will remain decorative zoning and transformable designs, information about which the reader will be able to find in the "IVD", 2007, N 4 (105); 2010, N 6 (140). The input of redevelopment of partitions is erected from small-piece blocks and plates or plasterboard and dry-fiber sheets (GKL and GWL) prior to finishing works. At the same time, the base is the slab of overlap or a concrete screed of the floor, and in the houses with beam overlaps - a carrier beam or lag.

|

|

|

3. Even to a relatively thin (130-150mm) brick wall, you can fix heavy structures without any risk, for example mirrors. If the partition is made of foam blocks, use special dowels and chemical anchors. Securely attach something to the drywall design will be able only if you know where carrier profiles are located

|

|

4. Erecting radius walls is a difficult task. We have to lead a masonry at the lighthouses located close close to each other (they are set on the plumb), and then in several techniques to level the surface with cement or plaster plaster.

5. Partitioned foam block is an unusually convenient material in the work. But to fold the solid wall from it, you need to use special glue, follow the dressing of the seams and fix the partition to the supporting structures

Heads of golden middle

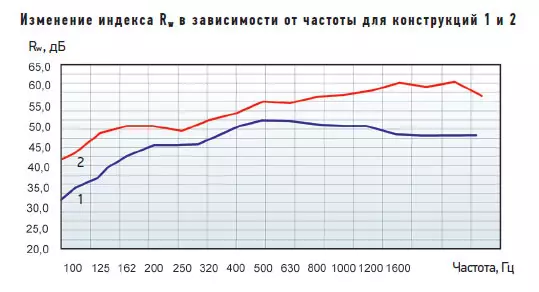

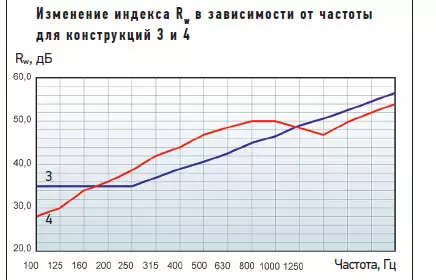

When erecting interroom partitions, you have to take into account the requirements that contradict each other. The sides, the design should be light and not too thick so that the load on the overlap does not increase, and the useful area has not decreased. In addition, you always want to finish repairs faster and, if possible, reduce the cost of materials and work. Solid side, if the partitions are too light and thin, increases the risk to face problems: the slamming door can cause a frightened concussion of the walls in the entire apartment, and trying to hang a picture, you suddenly burn the "window" to the neighboring room.The thickness of the partition is obliged to be no less than the width (mounting depth) of the interior door box (about 90mm), and its soundproofing ability - correspond to SNiP 23-03-2003 "Noise Protection". According to this document, in houses of category B (with comfortable conditions), partitions between the rooms of the apartment should provide a reduction in air noise by 41DB, and between the bathroom and room - for 47DB. However, some experts believe that the requirements of the Snip are too modest and better to navigate the value of 52-54DB - such an air noise isolation index (RW) has a brick wall plastered with a thickness of 280mm. Conflective sound insulation as one of the most controversial we will return more than once. Finally, according to SNiP 2.01.02-85 "Fireproof norms", internal non-permanent partitions should have the limit of fire resistance at least 15 minutes (in practice, this means that it is permissible to use non-combustible and labor-made materials).

Wip houses partitions are usually made of thin (about 100mm) monolithic reinforced concrete panels. The use of concrete casting during the repair of the apartment is associated with unjustified difficulties (the need to build formwork, the use of a mixer, concrete pump IT.D.). Therefore, partitions are erected from bricks, small-piece blocks - foam concrete (gas-silicate) and ceramzite concrete, puzzle plaster plates (PGP), as well as GLCs on a metal frame. What's better? There is no definite answer to this question. Materials of their advantages and disadvantages.

Without too much noise

On medium and high frequencies, sound insulation depends mainly on the mass of the barrier. In addition, fibrous materials are capable of extinguishing the household air noise, such as basalt wool mats. It is the harder to deal with a low-frequency noise that can "rally" practically any partition and make it re-emit sound in the next room. Here are most effective massive brick walls, as well as structures of alternating soft and solid layers, and the latter should not be rigidly connected with each other.

You need a lot of bricks ...

Vnashi days brick partitions have somewhat lost their popularity - the competition of other materials affects. WHATS They also have indisputable advantages: they are durable, capable of keeping fasteners well, and thanks to a significant mass (1m2 masonry in the Polkirpich weighs 240-260kg) is not bad, but also at low frequencies. In addition, compared with monolithic reinforced concrete, brickwork is less susceptible to resonant oscillations.

When erecting interior partitions, the masonry is usually conducted in a pollipich inlet (such a method provides good adhesion with a layer of plaster). Watching on both sides partition in Pollockich has an air noise insulation index of 45-47DB. A bitter wall with a thickness of 80-100mm (masonry on a edge with bilateral plastering) This indicator does not exceed 40 DB, and the strength is much lower. Therefore, with its help, you can separate only the utility rooms (storerooms, wardrobe IT.P.). But in this case, it is necessary to use frequent vertical and horizontal reinforcement from steel wire.

Hospitality, sometimes advantages can turn the disadvantages. Because of the large mass of brick partitions, they cannot be erected in old houses with dilapidated overlaps. Even in typical panel buildings after 10 years of service, the maximum permissible load on 1m2 overlap does not exceed 500kg (it is easy to calculate that the partition in the Polkirpich exhausts the entire margin of stove strength). Therefore, before starting redevelopment, try to get in the project organization accurate information about the supporting ability of the designs of your home. The use of slotted brick allows you to reduce the load on the slab almost 2 times, however, most experts are poorly responding about the soundproofing ability of thin walls from this material.

If you believe the manufacturers, somewhat more efficient in terms of sound insulation ceramic widged stones and blocks of 250x137x120 / 140 / 219mm. Syntom, thanks to the exact geometry, they are easier to lay them. Keep in mind that it is difficult to fix heavy items to the walls with voids. True, if in the estimated places of fastening to pour cement mortar into the cavity, the design will endure even heavy plug or cantilever bookshelves (in the same way reinforce the masonry from hollow ceramzite concrete blocks).

The disadvantages of brick partitions are also the complexity of their construction and high demands on the skill of masters. Sometimes it is badly plastered masonry. It is necessary to sneak GLC, and this unnecessarily increases the thickness of the partition and its cost. Prices for brick and masonry work vary widely. So, according to the estimates of Moscow foresters, 1 pose M brick partition 2,7m height cannot cost less than 4800 rub. The wall from the invoked blocks will cost somewhat more expensive, and from the ceramzite-concrete - cheaper by about 20%.

|

|

|

8. To improve the soundproofing properties of masonry from a slotted or holey brick, its internal cavities should be filled with a soft porous material. True, the labor intensity of the work will increase several times.

|

|

|

9. Soft wood fiber plates - good and inexpensive sound-absorbing material

Vaga format

An alternative to brick serve foam concrete and ceramzite concrete blocks, as well as the PGP. On any construction market you will find special partitioned foam concrete blocks 600x300x150 // 120/100 / 75mm, the specific mass of which is 12 times less than bricks. Blocks can be cut with hacksaw and lay on a conventional cement solution, although it is better to use special compositions, such as Weber. Bat ("Saint-Goben Construction Products Rus", Russia). But note that the wall will have to plaster on both sides. Vitoga it will be just 15-20% cheaper brick. Keep in mind that the maximum console (pulling fastener) load on foam cloth even when using powerful anchors does not exceed 20kg.Widespread use of full-scale and hollow PGP thick 80mm thick, stacked on alabaster or special glue, for example, "Gypsite" (Perfekta, Russia). Unicted their advantages: they are more durable than foam blocks, besides, with a neat laying, the partition should not be plastering. To align it and close the seams, you only need to apply two or three layers of putty. Due to this, the cost of the structure usually does not exceed 3 thousand rubles. For 1 p. m.

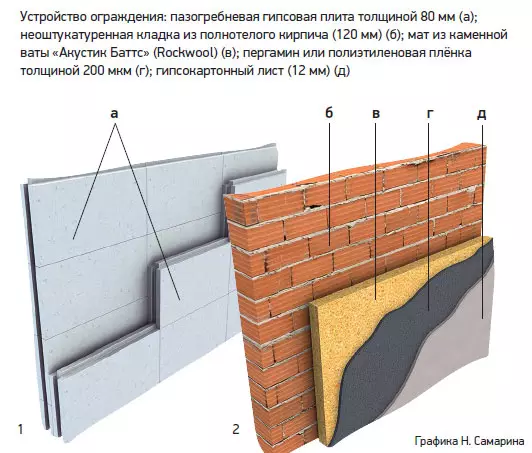

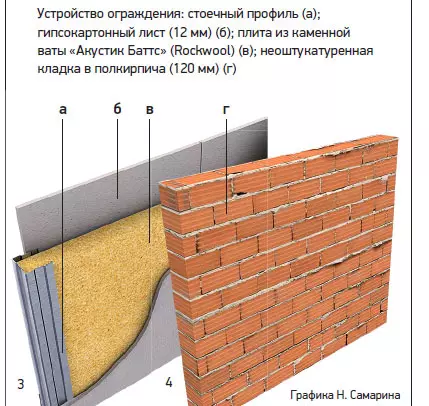

Upgrades from foam blocks and PGP The value of the RW index is 4-6DB is lower than that of the brick of the same thickness. In addition, the laying of the PGP is known for its ability to transfer structural noise into the premises. Therefore, if you separate the bedroom or the office, it is at least on the one hand (better from the intended source of noise) to apply mounted sound insulation. In essence, this is a common cover from GLC, however, its frame is mounted using special vibration-indulgent mounts, and the empty space is filled with a noise absorbing material, for example "Acoustic Batts" (Rockwool, Denmark), "ISOVER" ("Saint-Goben Construction Products Rus ") IDR. High sound insulation (RW at least 52DB) has a three-layer design of the PGP: it represents two independent walls from each other, between which the distance is 10-40mm (this clearance is filled with rolled damping materials or noise-absorbing mats).

Where does the door go?

Preparation for installation of sliding doors is best carried out at the construction stage. In this case, it is not difficult to create a wall with a niche in which the canvas will leave, and this will not require large additional costs and a significant increase in the thickness of the partition. Material for construction serve ordinary GLCs and metal profiles - of which two independent frames are collected at a distance of 40-50mm from each other (you can use the finished penalty - it is purchased together with the mechanism of the canvas movement). After assembling the frame, the guide rail and the canvas itself are installed, equipped with rollers. It follows to the design of the design by plasterboard only after 1-2 weeks - it is pre-trigger to "drive" the mechanism and adjust it if necessary, since further access to the adjusting screws will be difficult.

Memo developer

Partitions made of bricks and blocks should be erected not on the slab of the overlapping or tie of the floor, but on a low (40-80 mm) reinforced concrete base. Such a "base" allows you to more evenly distribute the load on the base, increases the self-supporting ability of the structure and reduces the risk of cracking in the masonry. Under the base is resting the Ruberoid band. This is primarily necessary for concrete without drying, giving moisture slab overlap. The rubberoid layer also serves as protection against structural noise. The best basis for partitioning from the PGP will be the technical cork band with a thickness of maximum 5mm. The tube or other vibration-fixing material is sometimes paved in the places of laying to the overhaul, but most builders consider this measure precaution of unnecessary.

|

|

|

12. In spacious premises, where few furniture often occurs the effect of echo. To create a comfortable acoustic medium, various techniques are used, in particular, light and thin semi-rods from GLCs on a single frame filled with mineral wool or other noise absorber are erected. Similar designs are able to send a sound wave in the desired side and reduce reverberation time

|

|

|

13-17. Installation of lightweight plasterboard partition filled with mats from stone wool "Acoustic Batts": collected a frame (13). At the same time, the pitch was chosen, based on the size of the noise absorbing mats. The finished frame was cut on one side of HCL (14), then the noise-absorbing material was laid between the profiles (15). Mates must be tight, without gaps enter the cells intended for them (16). The partition is almost ready (17) - it remains only to sharpen the joints of the sheets, perform the finish finish and install the door

Capital walls and plate of upper overlap The brick or block partition is fixed using the mortgage reinforcement pins or plate from sheet steel with a thickness of at least 2mm, close in laying seams. At the same time, the vertical fastening step should be no more than 500-600 mm, and horizontally 1200 mm. The openings are overlapped with large-format blocks, ready or cast on the site of reinforced concrete beams or metal rolling (corners, channels or laid in rods).

The gap between the upper chain of masonry and overlap is usually filled with mounting foam. However, this material has low sound absorption, so after the polymerization of the foam it is worth separating the seam to a depth of 20-30 mm on both sides and fill it with cement mortar.

Means from dampness

Partitions in the bathrooms and kitchens are better to construct from full-length red bricks or from special hydrophobized PGPs. However, other materials are allowed to be used (with the exception of non-fatty GLCs), including ceramzite concrete and foam concrete blocks. However, the latter will have to be protected using special plaster compositions and impregnations, such as Magnum ("Glims"), "Tiner K" (Sasi) (both - Russia), "Magma" (Stoltz), Flachendicht (KNAUF) (both - Germany), OSMOFL EX (INDEX, ITALY). In accordance with fashion trends Now, when erecting septal baths, glass blocks are used, combining them with other materials. Such a solution allows not only to decorate the interior, but also improve the insolation of the premises, while practically no affecting their sound insulation.Race

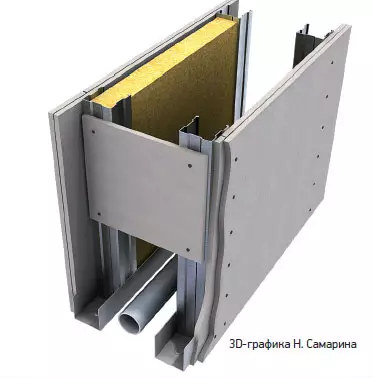

The plasterboard partition can be erected much faster than from foam blocks or gypsum plates, and it will be 2-4 times less. (We note that it is the structures from GLC optimal for houses with weak and dilapidated overlaps.) Building technology makes it possible to do without "wet" processes and at the same time easily ensure the correct geometry and the perfectly smooth surface of the wall. Another significant advantage of the Wall from GLC is that in its voids it is easy to place communication (in a brick or block masonry will have to do stages for this). The cost of a plasterboard partition is relatively low: even when using double frame and filling from mineral wool, it will cost no more than 4 thousand rubles. For 1 p. m.

|

|

|

18. The laying of glass blocks is usually conducted on cement mortar or tiled glue. If necessary, use white cement, in which the dye is added. The seams are filled with colored grout.

19. Manufacturers offer glass blocks of many colors. This material is aesthetic and safe.

20. The minimum thickness of the plasterboard partition on a double frame - 110mm. If it is necessary to pave inside the design of electrical cables, pipes or air ducts, the distance between the frames has to be increased

However, it is not easy to obtain satisfactory sound insulation indicators when erecting a plasterboard partition. Because of a small mass and high elasticity, it easily transmits sound in a wide frequency range. We will have to collect not alone, but two frames independent from each other (it is enough to leave a 10mm width of 10mm between them). Wheels where the frame profiles are adjacent to walls and overlaps, you need to install elastic gaskets (for example, from porous rubber or technical cork). Frame cells are filled with noise absorbing mats. With a thickness of 120-140mm, the RW index of the design of this type is approximately 47DB. If it is not a single side of the frame on each side of each side, and the two layers of HCL, there is a slot of the sheets by a rotary, the RW value will increase by 4-5DB.

Neat demolition

In no case can not be trusted demolition of old partitions by random brigades. Such "widespread profile masters" is armed with only a perforator, a small grinder and a sledgehammer, and most often the last thing goes exactly. Strong vibrations that occur with such a dismantling method are adversely reflected on all nearby building structures: weakens the adhesion of concrete with reinforcement, interpanel seams are diverged, communications may suffer. This will not happen if you contact a specialized firm using powerful disk saws - with their help, reinforced concrete panels are neatly cut into small fragments. True, rates such companies are now quite high - to 6 thousand rubles. for demolition 1 m partitions.

But if, for example, you are going to hang heavy shelves on a plasterboard partition, secure them not to the trim, but to a frame. Therefore, it is necessary to maintain the drawing with an indication of the location of the supporting profiles or at the construction stage, apply the corresponding markup on the wall and not to close it when finished. If the calculated console load exceeds 25kg, the framework will be required to amplify with additional jumpers, and possibly even replace the standard profiles with a metal of 2-3mm thick.