The use of traffic jam in the finishing of the house and the apartment is no longer surprised. But the use of it during the construction of a country house is rare case. Is the insulation-based insulation for Russian operating conditions?

The use of traffic jam in the finishing of the house and the apartment is no longer surprised. But the use of it during the construction of a country house is rare case. Is the insulation-based insulation for Russian operating conditions?

Recently, another type of such insulation appeared on the domestic market - a plug, more precisely, cork agglomerate. It is to him, as well as the construction of a country house with an area of 105m2, insulated by a cork agglomerate, our further narration will be devoted. Asodno, we will try to figure out how expensive it is the construction of a building using this eco-controller.

|

|

|

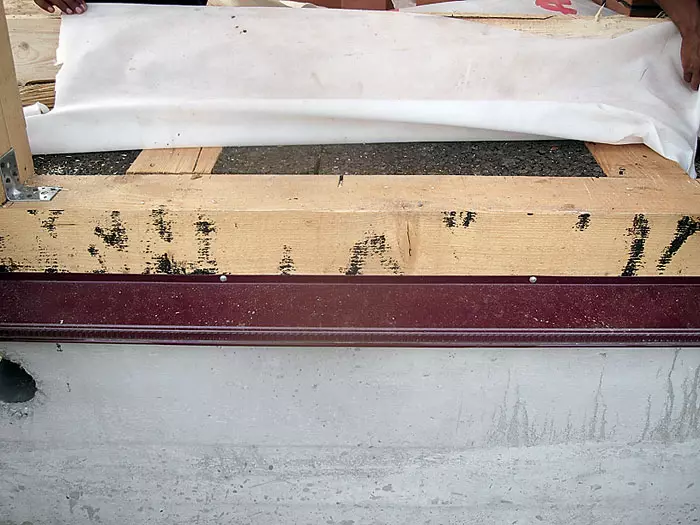

The foundation of the house is a small-breeding ribbon. For its device, testers with a depth of 80cm, they created a sandy pillow with a thickness of 20cm. Next, in the trenches, a wooden formwork was installed, the boards of which were covered with rubberoid (1) so that concrete did not stick to them. The proactory was laid out the reinforcement frame (2), and in those places where the tapes should be produced, the segments of asbated pipes. Then the ribbons themselves were cast from the M300 brand concrete (3).

Project creation

Interested in a new insulation, the future owners decided to use it in the construction of a long planned country house. Juda, the sketch of the house drew themselves, based on this, not only from the composition of their own family, but also from the number of periodically coming friends and relatives.

According to this sketch, experts manufactured a working draft building. It was taken into account the wishes of the owners regarding the materials for the manufacture of the frame and its plating, as well as the features of construction technology, determined by the use of cork agglomerate (the step of the frame of the frame was not 60cm, as usual, and 50 cm, which is equal to the width of the plin agglomerate plates). Why was this insulation chosen?

|

|

|

|

The strapping of the basement was made of a bar with a cross section of 150x150 mm. The lags were performed from a bar of 150x100 mm (4), joking them in length over the foundation ribbons (5). All wooden parts were processed by an antiseptic.

The power frame of future walls created from a bar of 150x150 mm (6). The rack's strapping was attached with nails and powerful steel perforated corners (7).

Natural Unicum

Cork - vegetable matter with an unusual structure. It is formed by many microfer cells (1cm3 cork contains 30-42 million cells), each of which is a 14-sided polyhedron with a closed internal space. Cell walls consist of several layers. The most thick of them is the average: it alternates the natural cork resin (suberin) and wax that gives the plug special elasticity. The inner cavity of the cells is filled with gas, very similar in composition on the air, but without CO2.

Such a structure makes a plug with an excellent heat insulator. It was used with the quality of it from time immemorial times - the plates of the genuine plug were covered with walls and ceilings, overlapping one layer on another, and the work was very laborious. Only after the invention of the cork agglomerate in 1892. It became possible to use the plug as a heat insulator widely.

|

|

|

To make it easier to build intergenerational overlap, completely completed the base overlap. Between his lags (8), plugs of traffic jams (9) were laid, protecting them from below the rubberoid, and on top - vapor insulation (10) and flooring board.

Agglomerates

There are two types of cork agglomerates: clean (usually referred to as black) and composite (as a rule, they are called white). Black agglomerates are used for thermal insulation, white - mostly as finishing materials. The black agglomerate consists of cork granules glued together with subperin without the use of other binders. It is obtained by treating cork granules in the autoclave with strict adjustment of temperature and pressure. At the same time, they first expand (extended), of which the cork resin performs, gluing the granules, and then at high temperatures, the vaporation of the volatile components of the plug occurs. By the way, black such agglomerators are called because the fibers of cork oak wood, which are always present in the corky crumb, during temperature processing "charred", and as a result, the final product becomes dark color. Its density is less than a natural cork. But it has a suitable form for construction - these are plates (plates) with a size of 1x0.5m and a thickness of 10/20/25 / 50mm.Characteristics of agglomerate

The density of the material obtained may be different: it is set depending on the purpose of the material and is regulated by the degree of compression of cork granules during the processing process. Thus, a black cork agglomerate with a density of less than 95kg / m3 is traditionally used to correct the acoustics of the room, the medium density material (95-130 kg / m3) is used for thermal insulation, and the product with a density of more than 130kg / m3 is mainly for the manufacture of gaskets (vibration shock absorbers). All three varieties of black agglomerate have wonderful quality: they are able to shrink under the action of the load and, if the magnitude of the latter did not exceed the permissible, after its disappearance, take an initial form without residual deformations.

|

|

|

|

When creating the frame of the second floor (11), the bars of the strapping were connected with racks in Poledev (12). They laid the lags of overlappings, to which the racks of the wall frame were attached. Corner racks reinforced with coloring.

A 150x50mm, created from the board, a 150x50mm, a rafting design was beaten by a 200x25mm cutting board crate, leaving the gaps of 100mm (13). On top of it lay a layer of vapor-permeable moisture insulation and pressed the second cladder from the board of 120x25mm, having it strictly over the gaps of the first crate. Thus, consisting of two layers of boards, a powerful roof flooring was created, on which metal tile (14) was laid.

Scope of application

The heat-insulating agglomerate has several applications. First - Outdoor insulation. The plates of the agglomerate are placed on the plastered (mainly in order to align) the wall. At the same time, the wall and one side of the cork agglomerate are labeled with a special composition, and then the plates are consistently glued to the wall (so that they are aslended to each other as close as possible, use a wooden hammer). After 24 hours directly on the cork agglomerate, the finishing coating is applied - plaster, and then the front paint.

Second sphere. Since the black cork agglomerate is a material with very low water absorption, and also is capable of withstanding significant compression without any damage, it is successfully used for the insulation of flat roofs, including those operated. In this case, the plates are simply glued to the base (the method of laying the material is similar to the already described), and then a protective coating is applied to them.

Third sphere - insulation of frame, roofing IT.P. Designs, as well as beam overlaps with a free laying method. Methods for mounting cork plates are almost similar to the techniques used when laying the plates of the mineral wool insulation.

In addition, the thermal insulation cork agglomerate may well be used as a soundproofer - laid in overlapping or interior partitions, it becomes a serious obstacle on the path of sound waves (the coefficient of sounding the rugway in the frequency range is over 2.1 kHz - 0.85, which makes it almost completely Isolate the room from loud sharp sounds, such as a cry, barking dogs, tv noise, stereo systems IT.D.). (For more information about the properties of the plug and the materials produced from it, see "IVD", 2007, No. 8 or website IVD. RU.)

Now, having understood with the properties of the plugs and the agglomerates made from it, we turn to the construction of the country house and its insulation with the help of these materials. The process is shown in detail in photos, and most of it is described in their accompanying signatures. Interest, only the necessary additional explanations are left.

|

|

|

The walls of the house outside were covered with a windproof membrane and laid a block house (15, 17). At the corners, the block House decided not to stir under 45, but to connect under direct UGR (16), which is less laborious. These joints will be covered with decorative trim

Foundation of the house

Since the owners, focusing on the local geological conditions and the existing construction experience, abandoned the basement device, the foundation of the house was decided to make small-breeded. It is immersed in the ground just 60cm and the same amount towers above its level. Later, on the perimeter of the foundation from concrete Magni M300, a warmed gentle was created, which allowed to push the soil freezing line from the foundation. To do this, before laying concrete, a layer of waterproofing layer was placed on a pre-arranged sand pillow, on it - the plates of the cork agglomerate, and on top of them - the reinforcement grid. The scene was made wide enough - 1m. It made it possible to move freely around the house even with a cargo. For similar technology, a concrete platform for two cars was created and insulated.

|

|

|

The strength of cork slabs made it possible to abandon the creation of the draft floor: the plates of the edges are based on the cranial bar attached to the lags (20, 21). From above they are covered by vapor barrier and floor board (22).

Power frame

The owners preferred to make a power frame of a house of a bar with a cross section of 150x150mm - such a design, they found more powerful and, therefore, more reliable. The stands in the design are located with such a calculation (the maximum step is 1.5 m) so that the windows can be installed between them, and install additional "struts" from the 150x50mm board, creating a "niche" with 50 cm width to lay the cork insulation.The lags of the base and inter-floor floors made from a bar with a cross section of 150x100mm, having them 50cm from each other (Recall: Plate width - 50cm). The result of the design of the design was obtained almost a two-time stock of the safety - with their help it would be easy to overlap the spans up to 5m, while the maximum width of real spans was only 3.85m. It is just rejoiced by the owner of the strength of the owners in the future, saying: "Go on the wooden floor, and it seems that under the legs of the monolithic plate."

Cork thermal insulation

Warming carcass

Brigadier Builders, who first insulated a traffic jam, said: "It is very simple to work with this material. Unless to cut it with a knife a little difficult, because it is stronger and harder than the usual insulation. But it is these characteristics that provide serious advantages, for example, when laying between rafters from the room side (It is necessary to do this because of the rains), in three layers (total thickness - 150mm) with overlap slabs in length so that it does not appear. Working with a conventional insulation looks like this.

Put the first layer, then one worker constantly supports the insulation from the bottom, and the second brings and lays the plates of the two subsequent layers. Further, in order to keep all three layers on the spot until the vapor barrier is fixed, and then the trim, it falls from the bottom between the rafters of the snake to pull the twine or temporarily navigate the rails. The current situation when laying a cork with everything one master copes with everything: puts the next plate in place and fixes two nails. "

It is worth adding a few words about the thickness of the cork agglomerate layer in the erected frame design. Holly overlap, walls and ceiling of the second floor it is laid with a layer of 150mm. The intergaling overlap and the inner partitions, its thickness was only 100mm. This is quite enough, since in this case the agglomerate is not so much insulation, how much is the soundproofer. The joints of the plates between themselves and with the framework of the frame were not additionally applied - the plates were simply tightly pressed to each other and to the elements of the structure.

|

|

|

|

At the base of the house in two layers, the cork coating isocork (23) was applied. The wooden trim of the outer walls was protected by a polyethylene film (24).

Between the frame racks and rafters from the inside of the house were laid in three layers of the slab of the cork agglomerate (25). They were covered with vapor barrier, and then - imitating the timing of a trim board (26).

Cork in finishing

To strengthen the effect of sound insulation created by the cork agglomerate laid in the overlap, the owners of the house decided to cover the floors with this material. Being the unevenness of the boarded flooring smoothed with the help of electrolabanka, then all the floors were covered with a waterproof plywood with a thickness of 8mm, attaching them to the floor boards with self-drawers (at the same time they watched the screws of the screws did not rise above the surface of plywood and were not recessed in it). Next, using a special composition on a water basis, pasted on the surface of puff pliers of floor cork coverage PK (Corkart, Portugal) thickness of 6mm (a layer of extruded plug is covered with a natural cork veneer, size - 600x300mm). To improve operational characteristics (wear resistance, strength to scratch, chemical impact of IT.P.) and facilitating the care cork tiles were covered in three layers with a special lacquer based water-based WS 2K SUPRA CORK (LOBA, Germany).

Used the plug and at the exterior finish of the house, more precisely, its base. To do this, they applied a sprayed cork decorative coating of ISocork ("Russian traffic jam", Russia). In composition, it is a mixture of cork granules, acrylic resin and vegetable fats. Produced in the form of a dry powder, packaged in plastic buckets (12kg / 22l). Before applying, it is enough to add the required amount of water and dye (it produces the same manufacturer) and mix thoroughly.

The material was applied by the method of air spraying at a pressure of 5 atm using a compressor and a gun for textured plaster. The first layer was done thin (it basically provides adhesion with the surface of concrete), the second is thicker (this is a decorative layer). As a result, the overall coating thickness was 2.5-3mm.

|

|

|

|

The inner finish of the house of Spartanski is simple: the walls were covered with light decorative moisture-proof composition. On the floor board, Phaneur 12mm thick was installed and the slabs of the SK cork cover (Corkart) were pasted onto it, the bay of their special varnish (27, 28). Heat the house brick oven (its front and rear facades come out in different rooms) and installed under the windows electrical convectors.

Thanks to the wide windows with wooden glued rams in the house very light (29). Pipes of the water supply (water is supplied from the well) and sewage (the drains are entered into the concrete septic tank) are laid in an open method (30).

Ecology and economics

Unlike Europe, where the desire to apply in construction exclusively environmentally friendly materials has become massive, and the number of already built eco-leaves is calculated by thousands, in our country, eco-controllers do not use high demand. The reason is simple - most developers believe that they will make construction much more expensive. But is it really a great reducing cost?

We asked for this question to answer the owner of the house, about which is told in the article. This is what he said: "If we compare prices for cork aglomarate (12 thousand rubles per 1m3) and mineral wool (1800-7000rub. For 1m3), the rise seems very significant. But it is necessary to take into account that the share of the insulation in the total exhibition value. The buildings are only 12-15%. In addition, the use of the plug made it possible to abandon the device of the draft floors (and this is 3-4m3 boards), made less time-consuming insulation of the house. I, of course, not an accountant, but I tried to calculate it, and it turned out, that the actual increase in the total cost of construction is about 8-10%. "

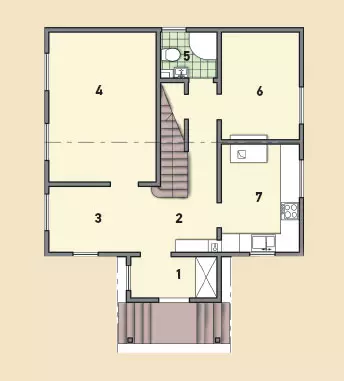

Explanation of the first floor

2. Corridor 11m2.

3. Tea 6,4m2

4. Living room 17m2

5. Bathroom 3,2m2

6. Bedroom 8.9M2

7. Kitchen 7.9M2

Explanation of the second floor

2. Bedroom + Cabinet 18,2m2

3. Wardrobe 6.1M2

4. Bathroom 3.2m2

5. Bedroom 8.2m2

6. Bedroom 9,3m2

As we see, the appreciation caused by the use of traffic jam instead of other popular insulation, turned out to be not a fabulous. An abolish or small is let everyone who wishes to build Ecodach, solves himself.

The editorial board thanks the company "Cork Center" for help in preparing the material.