Choosing a porcelain stonework for the inner or outdoor cladding, it is important to remember that according to its technical characteristics, this material is different from a well-known ceramic tile. Therefore, for its laying, special adhesive mixes are used, having a higher clutch strength with the base.

Choosing a porcelain stonework for the inner or outdoor cladding, it is important to remember that according to its technical characteristics, this material is different from a well-known ceramic tile. Therefore, for its laying, special adhesive mixes are used, having a higher clutch strength with the base.

|

|

|

|

Press and firing

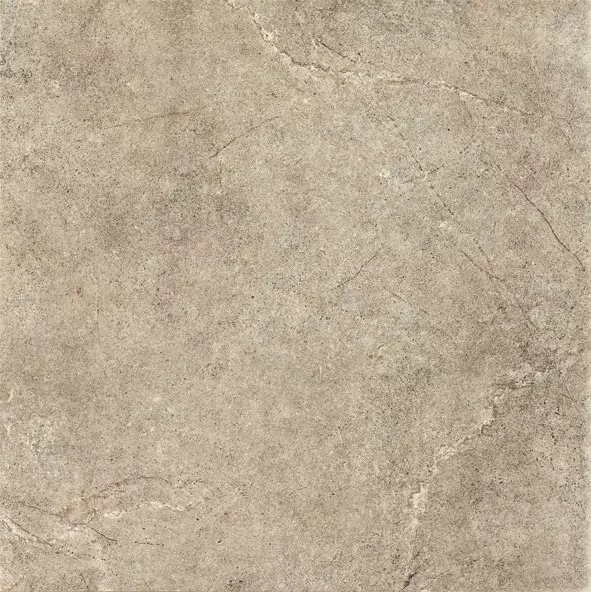

Porcelain stoneware, as well as ceramic tiles, manufactured from a mixture of crushed clay of different varieties and some other mineral components, but the recipes differ somewhat. In the production of porcelain stoneware, the dry mixture is placed in shape and pressed under very high pressure (50 MPa). Naturally, after such a processing, there are no microcracks, pores and emptiness, which are quite a lot in the "body" of ceramic tiles. The preparation of the porcelain is then burned at a temperature of 1200-1300 s, and all components are sintered, turning in almost monolith. The result is a very solid non-porous material with water absorption, close to zero (0.05-0.5%), is less than any natural stone. Undermined tiles This indicator is 3-20%.

|

|

|

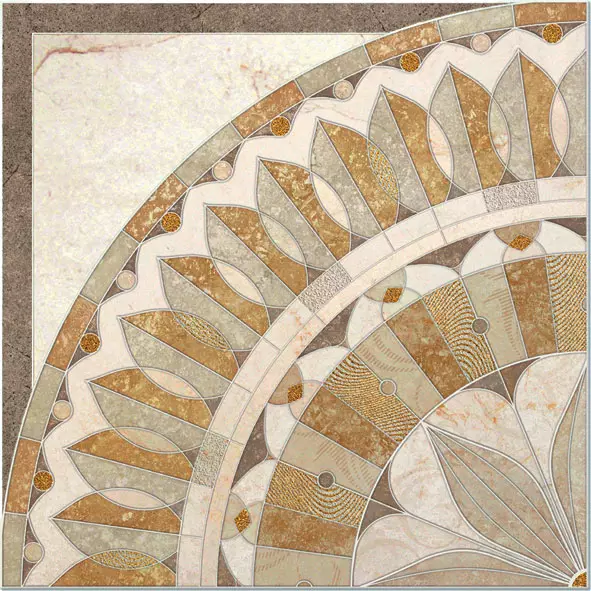

Retailed porcelain stonewares are labeled using seamless styling only indoors. There is no significant temperature drops that can cause strong stress in the floor design due to the temperature change of geometric sizes from delight tiles, especially large format (a).

SOHO porcelain stoneware (Peronda) is classic retreed tiles measuring 44x44cm (price 1m2- 2100rub.), Designed for seamless styling in rooms of any types (B, B). The background elements of the collection are complemented by decorative elements: contrasting borders 44x11cm, inserts (price - 490 rubles) and curbs with a geometric pattern (the price is 1200 rubles.), As well as panel 88x88cm (price 1 pc. - 3540 CM) and 44x8 cm.

|

|

Due to low water absorption, porcelain is highly resistant, or resistant to temperature drops. It is not by chance that such a facing are actively used not only in the interiors, but also on open terraces, balconies, basements and house facades, despite the very stern Russian climate. This cannot be said about Ceramic tiles: the vast majority of its collections are intended for interior, and only individual species can be laid on the street.

Opinion of a specialist

When clamping terraces, balconies, heated floors, chimneys, fireplace portals and other surfaces undergoing temperature drops, we recommend using elastic adhesive mixtures, such as "KNAUF-FLEX". In addition to the high adhesion strength with the base, they have a property to hold the tile in its linear deformations that occur during periodic heating and cooling. Neelastic adhesive compositions will gradually crack, and emptiness - fill in moisture, reducing the adhesion of the tile coating, so it will last long. Alastic is capable of partially change their geometry and return to its original position, while maintaining properties and ensuring reliable fastening of porcelain stoneware to various bases (including not absorbing water). It means that facing without problems will endure temperature changes and elevated dynamic loads both inside and outside the room.Irina Trifonova,

Product Manager for cement mixtures of Knauf

Porcelain stoneware is highly resistant to abrasive loads, which means that high wear resistance. By the way, it is not tested on the surface hardness not as ceramics, but as a natural stone, according to the mineralogical scale of the Moos (the hardness is determined by which of the ten standard minerals, the test material is scratched). Cerambularian hardness is 5-8 units. Depending on the type of surface. On this basis, the material is divided into unhappy and glazed. The most practical and durable (8 units) is a unghalled porcelain stoneware with a uniform structure throughout the thickness. Such tiles are resistant to the main abrasive - sand (it consists of a quarten grazing, the hardness of which on the MOOS scale is 7 units) and when wear does not change the appearance. Less hardness has polished and glazed porcelain stoneware. The first after firing is polished, getting a brilliance of varying degrees. Before burning the second, the glaze layer is applied to its surface.

Only strictly complying with the recommendations of the manufacturer for breeding adhesive mixtures for porcelain stoneware, the choice of tools and the laying method, you will receive a truly durable cladding.

Porcelain stoneware is extremely resistant to the effects of chemicals - organic solvents, strong acids and alkalis. Therefore, it is perfect for bathrooms, kitchens and garages. The most obvious minus of porcelain stoneware is its relative fragility in loose state. But this deficiency will not cause problems if you carefully handle the material during transportation and laying.

The dimensional row of porcelain tiles is quite wide: it starts with a shallow mosaic (2. 2cm) and ends with large-format elements (180. 120cm). The thickness of the tiles is 4-30 mm. Poppers - private persons use the greatest demand with a thickness of 4-14mm: this is quite enough to withstand household loads in residential premises. The thinnest porcelain stoneware is usually used for cladding walls, and thicker (from 8mm and more) - for the floor. Winteriers often use a retreed (i.e. edged) porcelain. Its edges are cut off with a diamond instrument, which provides accurate calibration. When laying such elements, the seams between them are practically not visible, so the impression of a homogeneous surface arises.

Opinion of a specialist

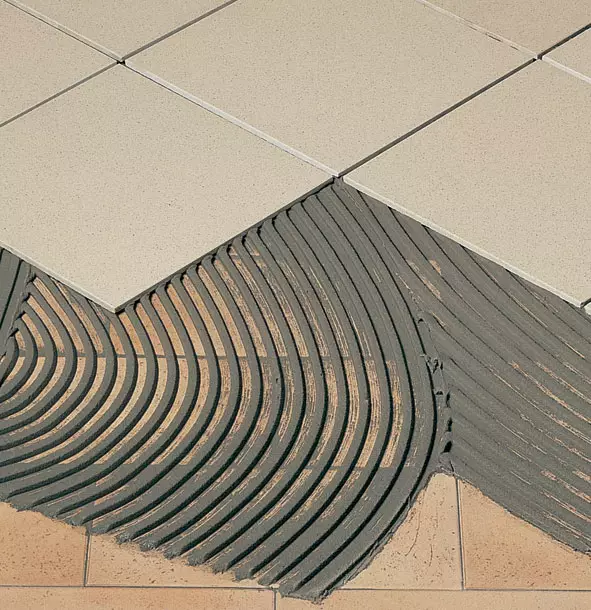

To get high-quality and durable cladding, it is very important to withstand the thickness of the adhesive layer recommended by the manufacturer. The tweechnic characteristics of each glue there is a table with these data. The optimal thickness of modern compositions, as a rule, does not exceed 5mm. If you apply a thicker glue layer, it will give a shrinkage, voids are formed under the tile, and as a result, various defects will appear. For example, from delta tiles will be more recessed with respect to the overall plane of the floor. The limits of the air sinuses can crack under the exposure to the point load. Through the case there will be a separation and detachment of tiles from the adhesive layer or tiles along with glue - from the base. There will be no such problems if applying glue with a toothed spatula. Due to the square tooths of the same size, the composition is distributed on the surface evenly, and the grooves have the desired thickness (2 times less than the height of the teeth).

Valery Gemadiev, Technical Director of Litokol.

So, we listed the basic properties of porcelain stoneware, thanks to which its popularity continues to grow steadily. It can be said that this material with outstanding technical characteristics, which has no restrictions on application. If it is placed in the same conditions as the usual ceramic tile, it will last a few times longer. However, in order to competently put a porcelain stoneware, you need to know some of its features.

Simple logic

All differences in the installation of porcelain stoneware and ceramic tiles are explained by different properties of these materials. For example, ceramic tiles with fairly large water absorption (up to 20%) are often placed on cement-sandy solution. It partially penetrates the pores of the back of the tile, and the facing is kept due to mechanical clutch. By the way, the old masters still preserved the habit of pumping tiles before laying. The fact is that the material with a plurality of open pores actively absorbs moisture, and due to this additional amount of water increases the "open time" of the mixture during which the position of the tiles can be corrected. When laying a "dry" tile on the simplest solution, it is no more than 10 minutes, and for the "wet" - the time interval becomes more than 2 times.

|

|

|

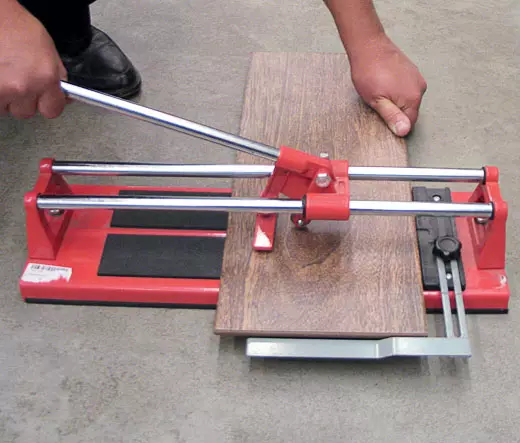

Glue for porcelain stoneware is distributed over the surface with a toothed spatula. Teeth must have a square shape, and their size is knocked out depending on the tiles format: up to 10 cm - 4mm, up to 15 cm - 6mm IT.P.

When working with modern tiled adhesives, such manipulations are hardly appropriate, as manufacturers are recommended to breed a dry mixture in a strictly defined amount of water. Additional moisture from the "wet" tiles will break this ratio, which will lead to a decrease in the adhesion strength with the base below the necessary and sufficient level - 0.3 MPa, and will also increase the drying time of the composition.

Opinion of a specialist

By buying an adhesive mixture for laying a porcelain stoneware on the floor, pay attention to the manufacturer specified by the manufacturer the clutch strength with the base that provides a specific composition. The harder tile, the greater the adhesion value should be. For example, for porcelain stoneware weighing 450 g / 100cm, we recommend choosing "Starplips T-11" adhesive (adhesion strength with a base of 0.6 MPa), 600 g / 100 cm- "MastPLIX T-12" (0.7 MPa), to 800 g / 100 cm - "Gerppiles T-14" (1 MPa). For large-format tiles, adhesives with high strength and adhesion characteristics should also be purchased. After all, as soon as a person comes to the edges of the tile, under which there is a partially absent glue layer, immediately formed "shoulder", working for a gap. Which is more unpromising plot, the more significant the force seeking to tear the tile from the base.

Vladimir All Sweat,

Technologist Engineer TD STROYMONTAZH MS

It has a very dense, non-porous and not absorbent moisture stoneware does not make any sense. (In the same way, it is unlikely that someone will come to the head to grind glass tiles and lay them on the cement-sandy mixture.) But such an appeal with porcelain stoneware, alas, not uncommon, and it is impossible to guarantee the durability of the facing in this way. Kkleev mixtures for porcelain stoneware are presented more serious requirements than to adhesives for ceramic tiles. These must be the compositions of the contact type, creating an adhesive film, which simultaneously performs the role of adhesive and the deforming layer during loads. It is necessary that the adhesion strength with the base of such adhesive solutions was at least 0.5 MPa for internal laying and at least 1 MPa - for the outer. The greater the weight and format of the tiles, the higher the adhesion should have glue. Such complex cases (when laying a large-format porcelain stoneware, external facing or installation of tiles for deforming bases) manufacturers recommend using adhesives in which the clutch strength with the surface is 1-1.5 MPa. Manufacturers receive such indicators by introducing special polymers into adhesives, which increases their cost. In the domestic market you can find a lot of adhesive mixes for laying a porcelain stoneware. They are released by the company "Glims-Production", "Knauf", "Saint-Goben Construction Products Rus" (trademark Weber-Vetonit), "TD STROYMONTAZH MS" (brand "Best"), Ivsil, Litokol, Unis (all - Russia), Index, Mapei (both - Italy), Henkel (Trademark Ceresit, Germany).

|

|

|

|

but. Glue mixes: for poorly absorbed water tiles - Fliesen Plus (25kg - 250 rub.), Elastic - Flex (25kg - 530 rub.)

b. Mixtures: for large-format plates - "Mast Plux T-12" (25kg - 275 rubles), for heavy slabs - "Gerppiles T-14" (25kg - 280 rubles)

in. Glue mixtures: Litof Loor K66 (25kg - 450rub.), Litof Lex K81 (25kg - 569 rub.), Litof Lex K80 (5kg - 160 rub.)

Glue mixtures: Weber.vetonit Easy Fix (25kg - 290 rub.), Weber.vetonit PROF I plus (25kg - 350 rub.)

Necessary and sufficient

The lifetime of the porcelain stovers depends not only by the revealed mixture, but also on how correctly the basis was prepared. It is necessary to align it, although non-professional brigades often neglect it and try to smooth out minor height differences with glue. However, it is roving the base with modern adhesive compositions - non-disabilities, since they are many times more expensive than ordinary leveling means.

|

|

|

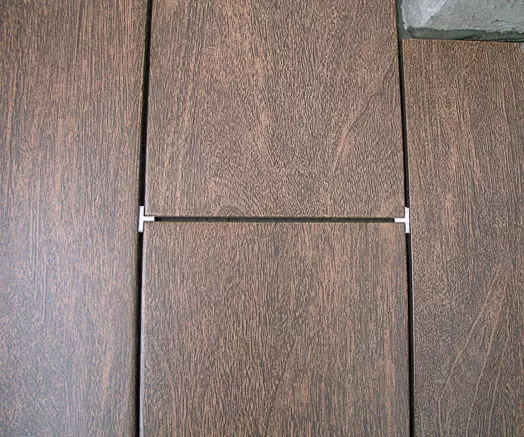

When laying a porcelain stoneware on the street between the tiles, it is necessary to leave 3-7mm gap to compensate for temperature deformations.

The basis must comply with the requirements of SNiP 3.04.01-87 and have sufficient carrying capacity. The surface under the lining should be as smooth as possible, with a 2mm tolerance at the length of the two-meter rail applied to this plane. The aligned surface must be deleted because the dust prevents adhesion of glue, like flour, which hostess sprinkle the table to ensure that the dough does not stick to it when mixing. Finally, the base should be primed up to moisture, necessary for normal adhesion, did not leave it too quickly.

For laying a porcelain stoneware on complex (deforming during operation) base - plasterboard, wood, fane, wood and cement-chipboard IT.D. - single-component elastic adhesives, having high adhesion strength with a surface (at least 1 MPa), for example, weber.vetonit.absolut ("Saint-Goben Construction Products Rus"), see 17 Ceresit (Henkel), "Best Maximplips T-16" ("TD STROYMONTAZH MS"), or two-component compositions on epoxy or polyurethane based. When connecting components (immediately before use), they enter the chemical reaction. Of the results of the result, its finished adhesive layer acquires special properties: let's say, more high than in conventional cement adhesives, elasticity, the ability to dissolve under the influence of water and adhere to any surfaces, including plastics, metal, concrete. It can be said that these are practically universal compositions. Their only drawback is a high price.

Opinion of a specialist

Porcelain stoneware has high abrasion resistance. Therefore, it is used on stairs, terraces and ramps. The greater the patency in the floor facing area, the stronger should be the adhesion of the tile glue with the base and porcelain stoneware. For example, for cladding floors on the open balcony, the apartment is enough adhesion, which provides the tiled glue Weber.vetonit Easy Fix - 0.6 MPa. When facing outdoor stairs, platforms and terraces, stronger fixation is required using Weber.vetonit PROF I plus glue - at least 1 MPa. When choosing a tile glue for exterior facing of facades, stairs, a patio in addition to high elasticity, it is necessary to take into account the frost resistance of the tile composition. Tile adhesives Weber.vetonit belong to the F75 brand in frost resistance and are successfully used in conditions of repeatedly freezing grounds.Evgenia Ivlya, Product Manager

"Saint-Goben Construction Products Rus"

Full contact

In the instructions of most leading manufacturers of adhesives, it is written: "With the correct selection of the consistency of the mortar mixture and the size of the spatula of the spatula, after the tile was pressed to the base, should cover at least 65% of the glued surface on the walls and 80% - on the floors." But this does not mean that it should be applied not to the entire surface, but only on certain sections. Placement of porcelain indoors on the walls on the walls, glue is applied to the base with a toothed spatula. He lies with smooth grooves. Then on the adhesive layer lay the tile and pressed it to the base. After that, the grooves are somewhat flattened, and glue takes 65-70% of the area. When laying a porcelain stoneware on the floor (here the appearance of emptiness under the lining is especially dangerous, as it is impossible to predict where the feet of the cabinet will be, or, for example, piano), as well as in external work, experts recommend a combined method, or a method of double spanning. The glue is applied to the base, and on the back side of the porcelain tile smooth or toothed spatula. In the last case, the tile is applied to the base, turning it into 90 so that adhesive grooves formed a "grid".

|

|

|

|

|

|

The installation of porcelain stoneware consists of the following steps: an adhesive mixture (a) is applied to the aligned base; Then the tile is applied to it, the back side of which is also covered with glue (b); Smooth seams between tiles are obtained using plastic crosses (B); If necessary, the elements are cut (g); Extremely lined floor tiles check with a building level (E); After drying the glue, the seams (E) are sutured.

The fulfillment of these recommendations is extremely important, since in the street, ceramic cladding is subjected to destructive impacts of moisture, temperature drops, the consequence of thermal expansion of the base and the facing itself. Possible deformations and stresses between tiles and the base must be poured by a layer of elastic and high-adhesive glue.

Inconcludes, we note that facing work is desirable to perform at air temperature of 10-30 s and relative humidity no more than 80%. These conditions are comfortable for curing adhesive compositions, and for a wizard, laying tiles.

The editors thanks the company "Ceramics", Estima, Knauf, Saint-Goben Construction Products Rus ", Litokol, as well as the Shopping Department of the Spanish Embassy in Moscow for help in preparing the material.