It is well known that when finishing any surface, the end result largely depends on the quality of the base preparation. This is especially true of floors that should be not only smooth and beautiful, but also reliable, that is, to withstand significant mechanical loads

It is well known that when finishing any surface, the end result largely depends on the quality of the base preparation. This is especially true of floors that should be not only smooth and beautiful, but also reliable, that is, to withstand significant mechanical loads

When it comes to repairing an urban apartment, under the words "draft floor" usually imply a structure located between the bearing slab overlapping and the finish flooring. It is rare to do without this shareholder, first of all because the overlap is almost never perfectly smooth. Even if there are no noticeable drops between the plates, the simple level check, as a rule, detects "waves" and the biases that will lead to the defillas. In addition to the alignment layers of the "cake" of the draft floor may include hydro, sound, heat insulating and underlying. Are they always needed? How to reduce the cost of design and speed up its construction without loss of quality? What are the typical errors in the establishment of the flooring of the floor? We will try to answer these questions using the article, as a peculiar visual allowance, four real cases from construction practice.

|

|

|

|

Without special costs

It is possible how many things can argue that "cheap does not happen cheaply" and "the miser pays twice," however, most people still seek to minimize repair costs, and not at all of the congenital tackle, but for quite objective reasons. Here and the heroes of our first story - a young family with two children - I had to repair a two-room apartment in the house of the P-44T series, having a rather modest budget. Spouses immediately decided that they would use inexpensive, but most practical and durable materials. Accidentally, the wear-resistant laminate was planned to be installed on the floor in residential and corridors, and in the bathroom and the kitchen to lay seamless porcelain stonewares. The invited masters examined the existing screed taken during the construction of the house, and estimated its condition as satisfactory. In principle, the selected coatings could be laid directly on it if it were not for the level of the level (about 8mm), detected in the corridor, and a few more small "hills" and shallow "pits" in the rooms.

|

|

|

|

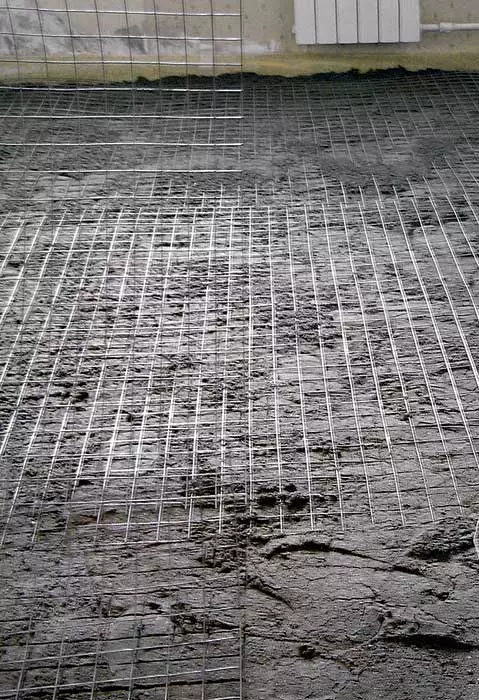

Device of water heat in the kitchen: on the slab overlap was laid out waterproofing from a polyethylene film, heat and soundproofing mats from synthetic fiber and reinforcing road grid (A); on top of them there were water pipes and another layer of the grid (B); The solution was poured, and when the screed dried, started laying the tiles (g). The design provides an additional decrease in shock noise by 25-30dB, and if there is an additional layer from basalt fiber (b) - by 36DB

|

|

|

|

Installation of a "floating" soundproofing floor: laid in two layers of matte from mineral fiber "SHUTYSTOP-C2", arranged along the walls "Bork" with a height of 150mm (D); On top of the mats put a layer of semi-dry sandcant with a thickness of 30mm (E); Reinforced the screed (g) and leveled it with a solution of sour cream-like consistency (layer thickness - 20mm) (s). The design guarantees an additional decrease in shock noise by 42DB and protects against penetration from the bottom of the air noise, although it is much worse due to the transmission of sound on the wall panels.

The builders offered to eliminate all defects in one apparatus, the self-leveling mixture is bottled on top. They called the rates (550 rubles. For 1m2) and immediately calculated the cost of work - 22 thousand rubles. The owner asked if it was impossible to make local repair of the screed. Workers rather reluctantly agreed to this, stating that the result would be far from the ideal. The protrusions were shotped by a perforator with a special nozzle. To close the deepening and eliminate the "threshold", used the level of "Wetonite 5000" ("Saint-Goben Construction Products Rus", Russia). The area for which he was applied was approximately 6m2. Work was worth only 5 thousand rubles. Of course, a horizontal surface was received in the corridor, but the slope, but so smoothly, that after laying the flooring, it became almost impaired (the workers warned that the laminate bar can "play" in this place, but this did not happen). However, absolutely without chagrin still did not cost. The porcelain booking floor was 4mm below the laminate due to the difference in the thickness of the coatings. The joke had to close the thorough. In addition, the insulation of shock noise in those zones, where porcelain stoneware was put on the floor, remained unsatisfactory.

Opinion of a specialist

Different flooring presented various requirements for the rough floor. Accompliant, the tile can sometimes be put directly on the ceramzite-concrete screed, despite the fact that the surface of the latter has a pronounced embossed texture. An experienced master is not difficult to eliminate small irregularities, changing the thickness of the adhesive layer. Linoleum is permissible to put directly on the sand-concrete screed, if its humidity does not exceed 9%. The laminate requires a cork or polyethylene substrate on top of a smooth screed. Wooden flooring - piece parquet, massive and parquet board - much more soils. For them, it is necessary to equip a reliable and fairly expensive base of lag and / or thick plywood.

Andrei Khrustalev, Director of Ay Di Stroina

Styling and drying problems

There is no news screed in new flat planning apartments. The owner of the housing seats her himself. At the same time, he is obliged to take care of neighbors from below, including the soundproofing layer in the design. Our second story is about how it is not necessary to fill the cement-sand tie.

|

|

|

|

|

|

The device of a ceramic concrete screed in the kitchen: The slab of the overlap was hydroizing the polymer-bitumen mastic, and in places of the stakes and their adjoining the compositions were not two, and in three layers (a); using the laser level, installed lighthouses from special steel profiles on the solution (B, B); When the solution was frozen, checked the horizontal with a conventional bubble level (g); put the main layer of ceramzitobetone (D); In several stages, lined with a liquid cement-sandy solution (E)

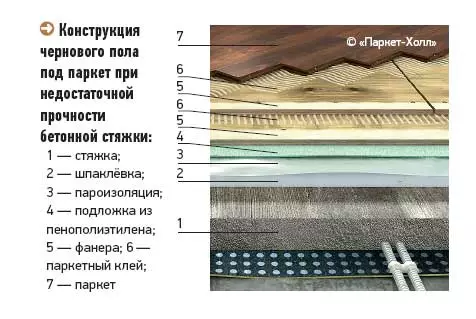

The owner of a spacious apartment in a new monolith-brick house wanted to use piece parquet as the main flooring. But instead of consulting immediately with specialists in this material, hurried to invite a brigade for the draft finish - alignment of floors and walls, standing under the wiring. After the end of these works, the construction was frozen almost a year, and then another company resumed it. When I reached the floor to the floor, the floor-party masters, conducting an examination of the grounds, only divorced by their hands. Checking using a sclerometer showed that the strength to compress the surface layer is less than 50 MPa; In some places, the concrete was covered with a grid of cracks, and in one of the corners, the screed raised over the slaughter of the overlap, and when it fell on it, a deaf blow was heard. There was no sound insulation under the tie.

|

|

|

|

Before the shrewing, you need to water the overlap. This applies not only to the "wet" zones, but also to the whole apartment. Waterproofing is necessary primarily to ensure that the water contained in the concrete in concrete does not penetrate the microcracks and the joints of the plates and did not appear on the ceiling in the neighbors living below. The same, the dry slab of the overlapping is able to "pull out" water from the lower layer from the stretch - as a result, the concrete will dry and not gain the necessary strength. The created hydraulic was useful in the future: in case of small, in time of liquidated leaks, it will not give water to penetrate the overlap.

Determine the main cause of defects was not difficult: the concrete was incorrectly dried. The base was not primed - due to this, the bottom layer; They did not cover on top and did not water the water - as a result, the upper layer was lost as a result. Uneven curing (on the edges it happened faster) led to the deformation of casting. The full dismantling of the existing screed was a very difficult task, so the builders offered to repair it. To fix all detected defects, it took a lot of time. It was necessary to pour new layers of the cement-polymer mixture, and in some places to drill holes and pour a liquid solution in voids. For repair of 1M2 draft floor, the owner had to pay about 450 rubles., That is, about half the cost of casting a new screed.

|

|

|

|

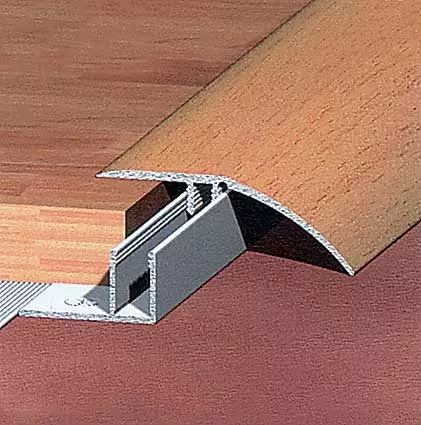

To create a smooth surface of coatings of different thicknesses, it is better to provide a pre-provision of the surfaces of the draft floor. If this is not done, the thresholds will have to be installed (a).

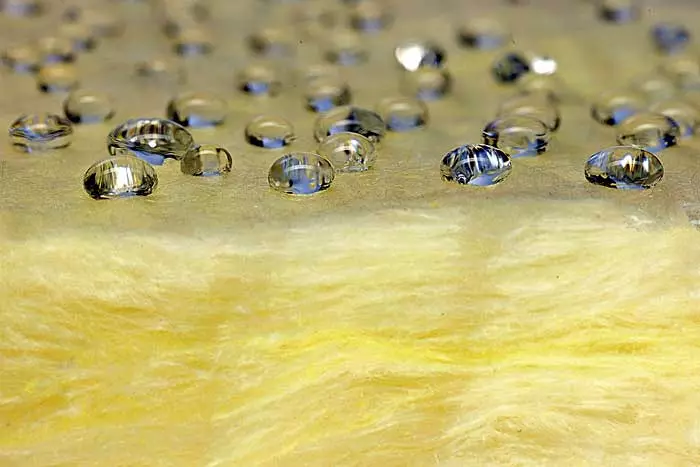

ISOVER mineral wool plates made using TEL technology have low water absorption and are suitable for insulation of the first floor overlap (b).

Opinion of a specialist

The soundproofing ability of the overlap characterizes the index of the reduced level of shock noise under this design (LNW) when working standard shock machines: the smaller the value of LNW, the better the stove isolates the shock sound. According to SNiP 23-03-2003 "Noise Protection", in residential buildings of category B (with comfortable conditions) this indicator should not exceed 58DB. Alas, in typical buildings, the bearing overlap rarely satisfies this requirement. However, it is enough to put under the screed layer of the damping material - mineral wool, polyethylene foam, porous rubber, technical cork, and the LNW value is significantly reduced. So, in the case of mineral wool slabs with a thickness of 30-40mm, this decrease can reach 38DB. When it comes to floors on the lags, the task of improving sound insulation is largely complicated. To solve it, you have to install lags for special vibrooporas.

Nikolai Eremin, head of the "Acoustics"

Companies "Saint-Goben Eau

Such different mixes

For the finishing alignment of the ceiling slab, as well as a sand-concrete or clay-concrete screed, solutions prepared from special mixtures based on cement and gypsum with polymer additives are used. They are divided into putty and bulk. The first is inducing with water to pasty consistency and apply a wide spatula; From the second, the liquid solution is made, which is able to spread over the surface itself. Those cases are focused on the beacons exhibited by level (most often laser). The selection of a particular surface leveling method often depends on the subjective factors, such as personal preferences of the masters of a particular repair company. As for objective circumstances, the bulk floors cost somewhat more expensive, more demanding on the quality of the work: the solution is hardening very quickly, to have time to evenly apply it and remove air bubbles, professional skills are required. It is believed that the bulk solutions are better suited for leveling significant areas. Another nuance is an abundance in the fake market and overdue mixtures for bulk floors (their storage time does not exceed 6 months, and sometimes it is only 3 months). The leveling layer of a poor-quality solution does not have the necessary compressive strength. In addition, afterwards it can partially be compressed from the concrete slab, even coated with contact primer. It threatens serious trouble, especially if an expensive finish coating is glued to the base, because then it is impossible to remove it without damaging.

|

|

|

|

Installation of draft floor based on mats from stone wool "Flor Batts" (Rockwool): on the stove put mats (A, B); There were two layers of plywood 12mm thick and glued a parquet board (B, d). Mates have considerable compressive strength (3.5 MPa), so the design easily withstands the weight of the furniture and load when walking, providing additional decrease in shock noise to 36 dB

Opinion of a specialist

Often, the mechanical impact on the base of the floor created by the coating of a piece parquet or a massive board exceeds the usual loads (walking, weight of furniture). Therefore, the elements of the base (screed, layer from plywood) should effectively resist the efforts to the separation and bend. This must be taken into account when designing a rough floor. Accidentally, the strength to compress the cement-sand screed should be at least 15 MPa, the strength to the tip of the upper layer of putty is at least 3.5 MPa, the thickness of the underlying layer of plywood, glued to the screed, is at least 3/4 of the coating thickness. In the creation of the shipments, the temperature and humidity regime in the room should also be taken into account, the availability of communications in the screed, deformation seams in the overlap and other nuances.

Vadim Smirnov, Technical Director of Parquet Hall

Oh, this belch!

Residents of many apartments located on the first floors are frown in winter. One of the reasons for this is the poor thermal insulation of the lower overlap separating the apartment from the basement, the temperature in which rarely exceeds 10 ° C. We will tell about the repair of a three-room apartment in the II-49 panel house. Its owners (CHAU of active working retirees) immediately stated with a construction company the need for floor insulation and agreed to sacrifice 70mm of the height of the room to mount the "warm" caustment. The company's experts advised to put tiles in the lobby and "wet" zones, placing mats with a heating cable under it, and in the rest of the rooms to equip the wooden floor on the lags with a layer from basalt wool (here it was planned to use a parquet board as a finish coating). The owners wanted the floor to be perfectly smooth, without protruding thresholds. To do this, it was necessary to accurately calculate the thickness of two different "pies" and take into account the irregularities of the foundation.

|

|

|

|

Installation of the flooring of the floor on adjustable lags: lags were located in 300mm increments, while using a special template (A); Pre-drump over the hole in the ceiling plate, attached to it dowel-nails of lags (b); put the bars horizontally, adjusting the height of plastic supporting sleeves, and screwed the sheets of waterproof plywood with a thickness of 15 mm (B); We started laying outdoor coverage (g)

First in the hallway and the kitchen cast a ceramzite-concrete screed with a thickness of 70mm. While she was kept, they began to install the services in the rest of the rooms (the panouse pallet did not touch the bathroom at all). The cement-polymeric waterproofing "GLIMS-WaterStop" (GLIMS, Russia) was applied on the cement-polymer waterproofing (GLIMS) to protect the insulation from the water vapor coming from the wet basement. Then installed lags made from glued bars with a cross section of 40x40mm, with a step of 300mm. They were attached to self-drawing every 500mm. For pre-alignment, a dice from waterproof plywood was used, and for accurate - galvanized steel plates. Between the lags, the mats from the stone wool Light Batts (Rockwool, International Concern) were laid and covered the entire design with a polyethylene film, which would prevent the flow of particles of material into the room. Above lay two layers of plywood grade PSF 12mm (bottom) and 9mm (upper), leaving gaps at the joints width 3-5mm (sheets without typing moisture and increase in size, abut each other and pripodnimut). The compensation gaps of 10mm width left around the perimeter of the residential rooms and at the junction of flooring. Forward, they were closed by plinths, in the second, the cork compensator was pasted into the slit. Mats with heating cable placed under the tile (in the glue layer). The cost of 1m2 of the draft floor of wooden lags and plywood was 1250 rubles, and 1m2 of the warm floor (including the price of electrical equipment) - 2700 rubles.

Opinion of a specialist

When the insulation of floors is required, we usually recommend using wooden lags, between which you can put any thermal insulation material: sheets of polystyrene foam, matte from mineral fiber, soft wood-fibrous plates, polyurethane foam spraying, ceramic filling. The advantage of clay and foams is that they are non-fragic: if water will fall into the design of the draft floor, it will not be delayed there, and freely go through the overlap. As a result, wooden structures will suffer less. As for a significant part of fibrous materials, the water is delayed for a long time in their pores, which leads to the appearance of mold and fungus, as well as a catastrophic deterioration of microclimate in the apartment. If the design of the draft floor includes a thermal insulating layer, we do not recommend waterproof the stove of the interlated overlap. Another version of the heat-insulating draft floor is the reinforced sand-concrete screed over the sheets of foam or technical cork with a thickness of at least 30mm.

Sergey Golovochko, Programmer's foreman

No alcohol law

In conclusion, we will tell about replacing the design of the draft floor in the house built in the 60s. Xx in. The first thing that struck the new owners of the apartment was the creaking of the Half when walking. Removing the old flooring, discovered the finned slab slab. On top of it lay lags, the space between them was filled with a mixture of sand, crumples and construction trash. Dies under lags, whether they moved from their places, whether they were rotted, and the bars themselves almost turned into a duch. It immediately became clear that it was necessary to change the entire system.

|

|

|

|

|

|

Montage of a dry screed on the "Knauf" technology: the plane spread the polyethylene film, the "side" was attached to the walls around the perimeter of the room from the damping material - polyethylene foam (A); poured a layer of small clamzit, carefully tumped it (b) and leveled (c); collected flooring from gypsum fiber pumps (d), causing a sealant (E) on the joints; For fastening plates to each other used conventional screws (E)

However, it's not easy to find a good and inexpensive alternative version of the screed. Lags "disappeared" by themselves: To create a reliable basis, they need to be firmly fixed to the overlap, and the thickness of the slab between the ribs was equal to only 95mm, and when drilling holes under the dowel, there was a risk of breaking through it. To load the old overlap of the concrete tie was just dangerous ... Vitoga stopped the choice on the dry team of the "OP 135" ("Knauf", Russia). It is a puzzle two-layer gypsum-fiber plates stacked over the underlying layer (clay sand). If the joints of the plates are sharpened, the surface will be suitable for sticking linoleum - it is such a flooring that chose the owners for the entire apartment (a new tile was laid on top of the old). With a thickness of 80mm, the mass of 1m2 dry screed is only about 30kg. The design perfectly isolates the shock noise - when it is used, LNW is reduced by 18-22DB (but RW increases slightly - only 2-4DB). The cost of 1m2 dry screed was 1050 rubles.

Bet on a tree

The editorial board thanks the company "Ay Di Stroy", "Parquet Hall", "Saint-Goben Construction Products Rus", "Old Man Hottabych", Knauf Insulation, Rockwool, Tarkett for help in preparing the material.