Metal tile is a very sensible choice for the roof of a country house. It is lightweight, durable and durable material. It is easy to install, has a democratic price. Due to the wide color palette and a large assortment of metal tile drawings, it becomes a real decoration of the house

A variety of types of textures and a rich color gamut metal tiles make it harmoniously enter it into the environment or pick up the color of other elements of the building. The roof will look very impressive in which several shades are combined.

"Metal Profile"

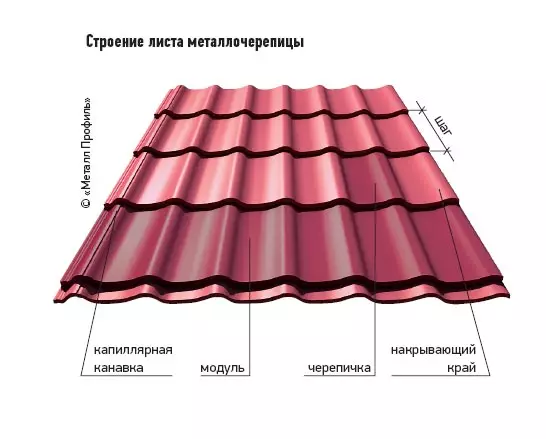

The form of ceramic groove tiles moved to metal tile. This material combines the aesthetic and functional advantages of traditional tiles with the durability of galvanized steel having a polymer coating (A, b)

Profile sheets have good stiffness and withstand snow load with a rather thin crate

Ruukki.

The drainage systems ensure the collection and removal of rainwater, protecting the walls and the foundation of the structure from premature destruction (A, B)

"Metal Profile"

The use of a special nozzle for a drill makes the installation of metal tile easier and fast (a). The aerosol repair enamel reliably protect the edges, eliminate scratches, scratch, chips that may appear during roofing work (b). The thickness of the dry film, which is formed after applying enamel - 20-25 microns

"Metal Profile"

When installing metal tile sheets lift to the roof one by one (a). It is advisable to do it on the roof mounted from the edge to the land of lagas. To ensure the unimpeded movement of air under the roof from the cornice to the skate, the ventilation outputs (b) are installed in the rafter spans. Distribute snow loads above the eaves and protect people and their property from the avalanche-shaped snow from the roof help the tubular snowstores (B). A branched staircase, which is often a continuation of the wall, rise to the roof and approach to the chimney and antenna (d) will be safe

Metal tile is a very sensible choice for the roof of a country house. It is lightweight, durable and durable material. It is easy to install, has a democratic price. Due to the wide color palette and a large assortment of metal tile drawings, it becomes a real decoration of the house

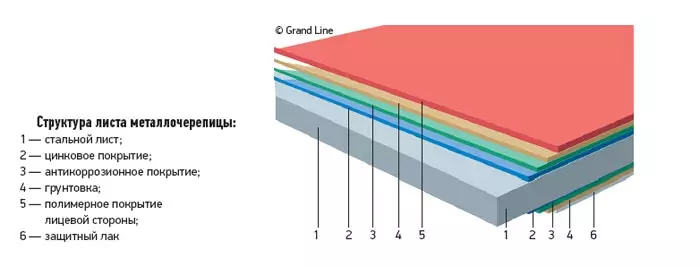

Steel barrier

Sheets of metal tiles are made of rolled steel 0.40-0.55mm thick. The producer of production is covered with zinc or zinc alloy with aluminum, passivated, apply a layer of soil, then a polymer coating on the front side, and on the back - protective varnish. (The quality of the material must correspond to GOST R 52146-2003 "Rental of a thin-rolled cold rolled and cold-rolled hot-diplotted with a polymer coating with continuous lines".) After that, the rental is passed through the profiling shafts of the machine, which form "waves" on them, and "rows" (steps) Get stamping method. As a result of a metal coated with a metal polymer really becomes like a roof relief from clay tiles.Now let's talk about what you should pay attention to when choosing a metal tile. One of the most important parameters is the thickness of the steel sheet. It is responsible for the carrying characteristics of roofing: strength, rigidity, and therefore, the ability to keep the form. The thinnest (0.4mm) profiled sheet appears as well as its thicker "counterparts", but in places of bending the thickness of steel may be less source due to the deformation, which will necessarily appear when installing and maintaining a roof. The probability of deformation or damage to metal tile from fine steel when moving on it is much higher than sheets with a greater basic thickness, moreover, the latter will last longer. However, the price at high indicators will also not be low.

Experts believe that the optimal thickness of the steel base is 0.5mm. To ensure the necessary strength, it should be the same all over the entire area of the sheet. However, steel hire produce different companies in different countries, and it differs significantly in quality - for example, galvanized. The larger the zinc on the 1m contains the protective layer of the steel sheet, the more it is racks to corrosion. According to European standards there are four grades of galvanizing. Clerv belongs to steel rolling, which contains 275 g / m zinc on each side, to the second - 200 g / m, to the third - 140 g / m, to the fourth - 100 g / m. Veverop, where climate is softer than in Russia, for residential buildings do not apply materials with the class of galvanizing below the first. After all, zinc performs the function of cathode protection: gradually destroying under the influence of moisture, it saves the steel base. The ordinary buyer is quite difficult to determine the quality of galvanized steel. Sometimes unscrupulous building brigades are used by this circumstance using poor-quality, but cheap products and calculating that a few years after the end of construction, a claim will simply be presented. The warranty of the quality of the roofing material can be the well-known name of the manufacturer and the long experience of its work on the roofing market. Such products, as a rule, is more expensive, but serious companies are unprofitable to produce low-quality products. They are aimed at long-term work and development, so we value with your reputation.

Opinion of a specialist

Due to the natural process of expansion and compression of the metal when the temperature drops, the metal tile is loosened. With a leaf length of less than a 4m linear expansion coefficient, you can neglected, but if it is over 4m, it will be more noticeable, especially on extreme self-draws. Therefore, we do not recommend using a registered metal tile more than 4m. If the length of the roof of the roof is 6 or 8m, it is better to close it, but a few sheets. The extreme leaf is mounted so that he performs 40mm from the cornice, and the space is left to the ventilation space. Sales Office Managers calculate the amount of material, select the optimal length of the sheets and offer the scheme of their laying. Of course, the reliability of the fastening of the roof depends on many factors: the quality of the screws, proper adjustment of the torque of the screwdriver, the quality of the crate (the tree should be dry, without signs of rotting). But Whatever the length of the sheets of metal tiles, after the installation, we advise you to check the screws and do it, if necessary, do it.

Valery Kolbejev,

Grand Line Technical Specialist

Polymer measure

In this section, we turn your attention to the polymer coatings of metal tile. The idea of applying them on steel galvanized sheets was not born by chance. They perform not only decorative, but also a protective function. The fact is that polymers are resistant to ultraviolet radiation and mechanical damage, and also have good corrosion resistance. All these properties will help to withstand climatic and mechanical effects on the roof. In our market, it is possible to meet metal tire with a coating from a conventional and upgraded polyester, polyurethane, polyvinyl chloride (plastisol).Polyester - The most common and budget of them. It has good corrosion resistance and exposure to UV rays, plastic, but is distinguished by medium resistance to mechanical damage. The layer thickness is usually 25-30 microns. The surface of the sheet looks smooth and even a little glossy. Some time ago, the opponents of the "gloss" could stop their choice on the matte polyester with a slightly rough and more durable outer layer than the ordinary polyester. But today it is practically not used. He came to replace the modernized polyester (35 microns), which has better characteristics in this group. Its pronounced matte texture looks very attractive.

Polyurethane coating (Thickness - 50 μm) has the most attractive characteristics for consumers. It easily transfers the effect of ultraviolet radiation, significant daily temperature differences, as well as stay in an aggressive environment of coastal areas with a high salt content in the air. Metal tile with such a coating has the longest warranty (15 years) and service life (40-50 years), but therefore it is more expensive by 20-50%.

Polyvinyl chloride coating (PVC) - It is also called plaseris - they apply a thicker layer (100-200 microns). It reliably protects the steel base from scratches and other mechanical impacts even with unqualified installation. Now, it is less resistant to the sunshine, under which heats up, becomes soft and deformed. Some manufacturers use modified plastisol, whose properties are significantly improved by various stabilizing additives. But if in the middle strip of metal tile, covered with polyvinyl chloride, will serve as faithful, then for areas with large solar activity is not the best choice. Other manufacturers use a PVC coating only in the manufacture of finishing and drainage elements, where protection against mechanical damage is most relevant, and the effect of the Sun is not as strong as on the roof plane. After all, the drains systems are often in the shadow of the facade of the building, and the area for which the sun's rays fall is small.

Wasing large manufacturers metal tile has materials with different polymer coatings. However, be vigilant: unfair companies can resort to various tricks to reduce the cost of final products. For example, manufacturers reduce the amount of zinc in a protective coating or reduce the thickness of the polymer layer, which naturally leads to a worsening of quality. Honeymage, detect this buyer is not able. Often, sellers give one coating for another or exaggerate the thickness of the layer. "Indicator" is a guarantee for a polymer coating or material given by the manufacturer, not a seller. Moreover, the guarantee should be not oral, but in writing - in the form of a special coupon, where all defects are listed to which it applies, its conditions, as well as the rules for transportation, unloading, storage and installation, not subject to violation. Note that the written guarantee is not common everywhere - it gives only major manufacturers.

Leading positions in the Russian market occupies Metal Accounts of Companies "Interpril", "Metal Profile", "Odintsovo Plant of Lung Designs", "Unicam", Grand Line (all - Russia), Pelti Ja Rauta, Poimukate, Ruukki, Weckman (all - Finland) , MERA SYSTEM (Sweden). The price of 1M varies in the range of 200-500 rubles.

Opinion of a specialist

Evgeny Lazukin, Head of Sales Department

Drain and roofing systems of the company "Metal Profile"

Warehouse or "special price"?

Sheets of metal tile of one or more sizes (the most common - 2200x1180mm) and colors offer many building markets and shops. These are the so-called storage sheets. The same trading organizations and numerous specialized companies provide such a service as the manufacture of material to order (the size of the sheets will be calculated for a specific roof project). Their length can be any in the range from 400 to 8000mm, and the width, as a rule, is 1180mm (operating width - 1100mm). The period of waiting is about 3 days, although at the height of the construction season, when enterprises work at the capacity limit, this period increases.What preferred: warehouse sheets or custom? It depends on many circumstances. For example, on the roofs of complex configurations, abundant fuss and protrusions, there will be a lot of waste when working with warehouse sheets, and the execution to order will minimize their number. If you press the deadlines, it is worth using the warehouse program, as the manufacture of custom sheets will take some time. Small duplex roofs are easier to cover with whole sheets, the length of which corresponds to the length of the skate.

If this parameter is more than 6m, difficulties may occur with the transportation and installation of the material, for example with a roof rise. In short, in each particular situation will have to look for a golden middle. A video mall with a choice should professional roofers who have experience with metal tile.

Mandatory condition for providing guarantees by the manufacturer - compliance with the rules for transportation, storage, loading and editing. In production, ready-made sheets are packaged before transportation in accordance with the norms. They are placed one on another, applying a special lubricant so that they do not stick out, they did not lose and scratch each other. Then they are placed in a special pallet from a wooden bar, close on top of the same, tighten with belts and transport. Packaging with metal tile must necessarily be attached to the body. It often happens that the car rows from the slide and loose cargo falls out of her body. It is notable to control the process of manual unloading on the object. The fact is that metal sheets should be transferred only in a vertical position. If you keep a sheet with a length of 6m for two edges, like a blanket, it will join and deform. At the package of packs with metal tile laid in the same place on the bars. If it is assumed that they will be stored more than 1 month, the sheets are unpacking and put on each other, be sure to lay the same wooden slats to provide ventilation.

Opinion of a specialist

Yuri Galashov,

Technical specialist Ruukki

Cold or heat?

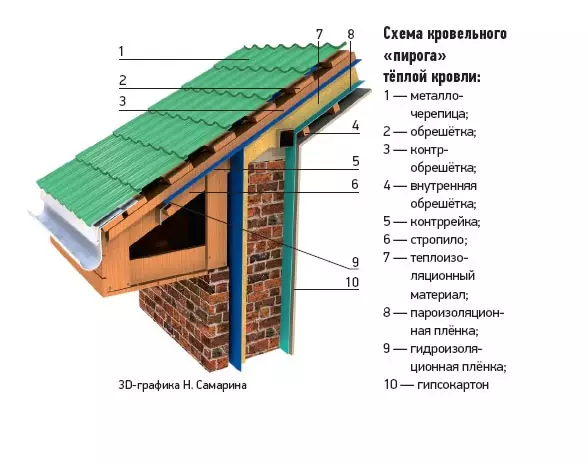

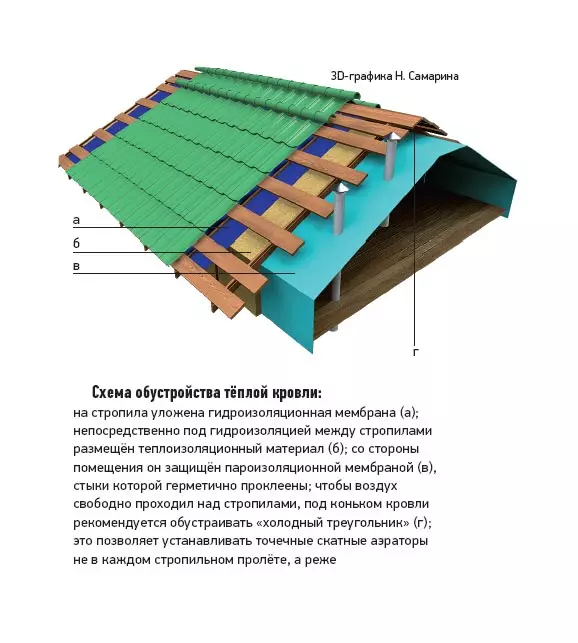

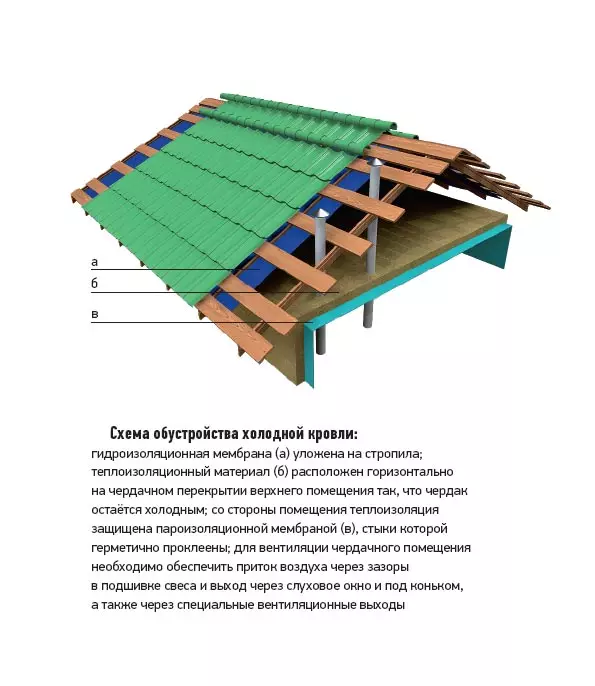

Metal tile is only part of the roofing system, which should be kept warm in the premises in the winter, and in the summer to prevent the heat from entering the roof in the house. This peculiar "pie" protects the insulating material from the penetration of the vapors that are generated during the human activity process, and also passes the insulation who has already surrendered into it and, which is important, takes to the street. At the same time, the daily temperature difference even in the summer leads to the formation of condensate on the inner surface of the sheets. Moisture or water drops can cause rotting wooden roof designs, and moisturized thermal insulation materials, as you know, lose their properties. Therefore, it is not so important which room is under the roof - a residential or cold attic; In any case, when it is installed, special attention needs to be given to the device of underpox ventilation and waterproofing.Waterproofing membranes, fired under metal tile (under the crate), will not allow moisture to penetrate further into the underpants space. Aparazolation, stacked under the layer of thermal insulation, protect it and the roof from vapors coming from residential premises. The Russian market offers many hydro and vapor insulation films of various manufacturers, including Jutafol (Juta, Czech Republic), Eurotop (International Concern Fakro) Idre.

Glitter or purity

Many believe that after the arrangement of the roofing "cake" and flooring on the roof can be forgotten at least for a while. The same guarantee of manufacturers on metal tile or polymer coating is 5-15 years old, and the service life of the roof is 20-50 years. IHS and it is necessary to take care of it - wash and clean. Of course, on pitched roofs, especially with a big bias, rainwater and debris are not delayed for a long time. However, those who hoped that the duties for the care will perform the usual rain, wrong. The smaller the slope, the greater the chances that the dirt, dust, flower pollen, the leaves and branches will become accumulated in the recesses on the surface of the metal tile, as well as in the places of the allen sheets (transverse and longitudinal). When moisturizing, bacteria multiplied here, fungus and mold appear. Therefore, experts advise at least once a year to clean the roof, roofing gutters and drains.

Do not fear neither thunder or zipper

Lightning conductor (threshing) protects the house from the effects of electricity resulting from a thunderstorm discharge, or reduces the effects of direct lightning. In addition to creating the main bulky of the building, the roof of the metal tile can be grounded a separate (additional) tire. This will help prevent the danger of damage to the structure and damage to the electric current of residents of the house, if the lightning accidentally falls into the gross rod, but in a metal roof. The simplest lightning system consists of lightningness, a current and earthing machine. Lightning message (steel or aluminum rod with a diameter of 12mm and 200-1500mm long) is installed at the highest roof point on wooden backups. The current (steel or aluminum single-core wire of 6mm thick) is welded to lightningness and descend on the claw under the tiles sheets. It is branched in several sheets so that the points of contact was larger and lightning went along the path of minimal resistance. Then the cocoquer lead along the wall of the house removed from the entrance, attaching the brackets, and welded with the earthing (iron beam with a length of 1.5 m or leaf with an area of 1m), located in the ground at a depth of 1.5 m. Once in 5 years it is desirable to check all the connections of the lightning conduction.

The editors thanks Grand Line, Metal Profile,

"Unicam", Ruukki for help in preparing the material.